Professional Documents

Culture Documents

JSA For HOT Job

Uploaded by

Equipment MaterialsOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

JSA For HOT Job

Uploaded by

Equipment MaterialsCopyright:

Available Formats

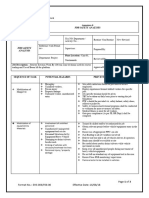

JOB SAFETY ANALYSIS (JSA)

Rehabilitation works around Old Ammonia Storage Tank (AT-911) against Inspection Report# 8219. Job scope include:

Activity: 1. Replacement of Staircase Tower Column Structure / Top and bottom shell segments of drum, Top plate, cable conduits, cable supports & instrument supports

2. Partial replacement of Tank Top platform piping supports & structure (1)

Urea Date of JSA: Area/ Ammonia Storage/AT-911

Unit: 24-09-2020 Eqpt Tag:

Ops: Shoaib Masood, Kashif Sher, Danyal Ahuja

Eqpt: Prince Wamiq Rasheed, Jamil Ahmed

JSA Team: Special PPE`s: Safety harness, Ammonia Gas Mask, Leather Gloves, Face Shield, Welding Helmet

Elect: Aamer Ejaz

Safety: Shahzad Ahmed

POTENTIAL PROBABILITY CONTROL MEASURES Responsible

Step # Basic Job Steps HAZARD *(H, M, L) WHO IS AT RISK Unit

(Recommended Safe Practices)

-No permit of direct welding with tank will be issued

-Ensure availability of fire extinguisher at job location OPS

Fire - Explosivity to be checked after every two hours at the location of hot job

Cutting / Grinding / (Due to presence of Personnel &

1 welding combustible material M Property

& gases) -Adequate blanketing with fire proof cloth to be done at the location of hot job

EQPT

-Welding Earth to installed nearest to the job location

- Training session to be arranged for hot Job safety / emergency evacuation plan

for all personnel involved in the job Safety

-Checklist to be installed on the scaffolding before start of structure replacement

job

Falling of personnel - All persons to use safety harness in healthy condition hooked at all times to avoid

from height L Personnel falling from height. EQPT

- Persons with height phobia should not be involved in job

- All tools to be tied with lan yard to aviod its falling

-Toe boards to be used on all platforms where material is placed to avoid fall of

material

- Area under which rigging / shifting / scaffolding is being performed will be

barricaded. Person not involved in the job to use alternate route.

Falling of material / Personnel

tool from height M & Property - All tools to be shifted at height in tool boxes/bags EQPT

- Crane / rigging tools to be used for shifting of material at height should be load

tested.

- Donot perform working on multi platforms at the same location

2 Work at height -Contractor to ensure availibility of trained safety incharge during entire working

shifts

-Ensure availability of Ammonia Mask for use in case of emergency situation. EQPT

-Safety unit to arrange training session on wearing Ammonia masks SAFETY

-Contractor to ensure that all workers have attended safety orientation on

Ammonia Release M Personnel Ammonia masks and know how to properly wear Ammonia masks.

-Daily safety talk on work at height and Ammonia Emergency response plan will be

conducted. EQPT

-Ensure provision of two access platforms on opposite sides of the tank for

emergency escape.

Use of cellphones L Personnel - Contractor to ensure that personnel working in area will not carry cell Phones EQPT

Presence of - All relevant securities to be by passed during the duration of wok permit and

securities / switches L Personnel taken back after complettion of Job (list attached). OPS

-Ensure maximum presence of safety personnel in area to take observations, if any,

General L Personnel and ensure immediate corrective actions. SAFETY

*Legends: H = High, M = Medium, L = Low

1- This JSA does not cover replacement of tank top platform which requires direct / indirect welding with tank roof / shell.

2- All FFBL IMS Work Procedures apply in addition to the above mentioned recommended safe practices.

General 3- Ensure safety orientation of all contractor work force prior to allowing him to perform work in area.

Notes:

4- Ensure proper housekeeping of the area after job execution.

5- Properly barricade the area at ground level and ensure that working platforms are provided for jobs on multiple levels for proper isolation.

Route Initiated By Reviewed By Approved By

Name

Design Area Engineer UM- Urea UM-Equipment UM - Safety Department Manager

Sign

You might also like

- Working at Height Risk AssessmentDocument9 pagesWorking at Height Risk AssessmentNebosh Diploma Assignment83% (6)

- JSA For Bore Hole DrillingDocument4 pagesJSA For Bore Hole DrillingWit world77% (13)

- JHA 15-Work at Height Using ScaffoldingDocument3 pagesJHA 15-Work at Height Using ScaffoldingWte SB100% (7)

- Jsa-For Loading Arm InstallationDocument10 pagesJsa-For Loading Arm InstallationKamal DeshapriyaNo ratings yet

- Risk Assessment For Resin Injection Via HoseDocument1 pageRisk Assessment For Resin Injection Via HoseKrishna KishoreNo ratings yet

- JOB SAFETY ANALYSIS FOR SCAFFOLD ERECTIONDocument3 pagesJOB SAFETY ANALYSIS FOR SCAFFOLD ERECTIONJixtha SaintNo ratings yet

- JSA-Road Crossing of 6'' PipelineDocument6 pagesJSA-Road Crossing of 6'' PipelineRidha BennasrNo ratings yet

- PJHA Form - Compi (Ash Bin) Piling of CHBDocument3 pagesPJHA Form - Compi (Ash Bin) Piling of CHBPaul TamayoNo ratings yet

- F5B-BMJV-0001-AHA-HSE 00 AHA For Precast Storm Drain and Subdrain Uty.Document13 pagesF5B-BMJV-0001-AHA-HSE 00 AHA For Precast Storm Drain and Subdrain Uty.Taiwo Oshin100% (1)

- Role Play Script BHS INGGRISDocument6 pagesRole Play Script BHS INGGRISardiyantiNo ratings yet

- JSA For Scaffolding Erection Removal Around AT-911Document1 pageJSA For Scaffolding Erection Removal Around AT-911Equipment Materials100% (1)

- Working at Height Risk AssessmentDocument9 pagesWorking at Height Risk AssessmentBasky0% (1)

- JSA Work at Hight - Rev-6Document2 pagesJSA Work at Hight - Rev-6Mahamudul HasanNo ratings yet

- JOB SAFETY ANALYSIS Nahar HomeDocument11 pagesJOB SAFETY ANALYSIS Nahar Homesiddhu mendheNo ratings yet

- JSA Scaffolding - DRY WALLDocument3 pagesJSA Scaffolding - DRY WALLseppyfNo ratings yet

- CraneOperations PDFDocument2 pagesCraneOperations PDFIrshad AkhterNo ratings yet

- Safe Plan of Action Ramsu EnterpriseDocument5 pagesSafe Plan of Action Ramsu EnterpriseSanjeev Kumar100% (1)

- Crane AssemblyDocument3 pagesCrane AssemblyM Waqas HabibNo ratings yet

- Gritting, Railling and Stair Case Erection Work JsaDocument5 pagesGritting, Railling and Stair Case Erection Work JsaAKBAR ALINo ratings yet

- 06 Steel Structure Erection PESB 01 PDFDocument5 pages06 Steel Structure Erection PESB 01 PDFShureendran Muniandy RajanNo ratings yet

- Job safety analysis for ambient air monitoringDocument2 pagesJob safety analysis for ambient air monitoringPrakash PavuralaNo ratings yet

- Scaffold Risk AssissmentDocument4 pagesScaffold Risk AssissmentSaleem AkhtarNo ratings yet

- FPS 008 - WeldingREV1Document3 pagesFPS 008 - WeldingREV1grantNo ratings yet

- Jsa Dekade KineDocument21 pagesJsa Dekade Kineramaiksan038No ratings yet

- Structural Fabrication _ Erection JSA HSE ProfessionalsDocument1 pageStructural Fabrication _ Erection JSA HSE Professionalsm.rehanhseNo ratings yet

- SWP - The AtelierDocument10 pagesSWP - The AtelierMd ShahinNo ratings yet

- Pedestal Shuttering JSA HSE ProfessionalsDocument2 pagesPedestal Shuttering JSA HSE ProfessionalsViron BaxhiaNo ratings yet

- Sunmow Jha 001Document3 pagesSunmow Jha 001Douglas DellyNo ratings yet

- Final Steam Blowing PermitF03Document4 pagesFinal Steam Blowing PermitF03Mostafa AbdullahNo ratings yet

- Roofing Sheeting Cladding Works JSA HSE ProfessionalsDocument1 pageRoofing Sheeting Cladding Works JSA HSE ProfessionalsSamadov 13No ratings yet

- PT-03 JSA Dismantling of Slip Form (22-05-09)Document10 pagesPT-03 JSA Dismantling of Slip Form (22-05-09)M Waqas HabibNo ratings yet

- Job Hazard Analysis (ASSEMBLY)Document4 pagesJob Hazard Analysis (ASSEMBLY)Syafiq NorizanNo ratings yet

- Scaffolding JSADocument10 pagesScaffolding JSASubbu AbuNo ratings yet

- FO-JSA-08 - Lifting, Lowering, Laying and Backfilling of 6'' PipelineDocument4 pagesFO-JSA-08 - Lifting, Lowering, Laying and Backfilling of 6'' PipelineRidha Bennasr100% (1)

- F5B-BMJV-0001-AHA-HSE 00 AHA For Foul Sewer - Manhole ConstructionDocument11 pagesF5B-BMJV-0001-AHA-HSE 00 AHA For Foul Sewer - Manhole ConstructionTaiwo OshinNo ratings yet

- Job Safety Analysis (Jsa) : ScaffoldingDocument1 pageJob Safety Analysis (Jsa) : Scaffoldingsk sajidNo ratings yet

- Protective Equipment (P.P.E) : Gashubin Eng Pte LTDDocument10 pagesProtective Equipment (P.P.E) : Gashubin Eng Pte LTDMd ShahinNo ratings yet

- 2.risk Assessment of Working at HeightDocument7 pages2.risk Assessment of Working at HeightRisal Sinu50% (2)

- JHA LiftingDocument4 pagesJHA Liftingsyamimi balkhisNo ratings yet

- Job Safety Analysis for Rohan Builders Construction ProjectsDocument9 pagesJob Safety Analysis for Rohan Builders Construction Projectsradeep100% (1)

- Surface Preparation SafetyDocument11 pagesSurface Preparation SafetyShahid RazaNo ratings yet

- JSA TubingDocument9 pagesJSA TubingSubbu AbuNo ratings yet

- Surface Preparation SWMSDocument11 pagesSurface Preparation SWMSAmit SinghNo ratings yet

- Erection of Tanks JSADocument4 pagesErection of Tanks JSASalah Abd EldayemNo ratings yet

- JOB SAFETY ANALYSIS WORKSHEETDocument2 pagesJOB SAFETY ANALYSIS WORKSHEETCherry BetonioNo ratings yet

- Steel Erection JSADocument5 pagesSteel Erection JSASalah Abd Eldayem100% (1)

- Welding Safety ProceduresDocument3 pagesWelding Safety ProceduresAdilMunirNo ratings yet

- Civil Works Construction Laydown AreaDocument4 pagesCivil Works Construction Laydown AreaMohammed MinhajNo ratings yet

- Job Safety Analysis: Manually Lover Post Erection (300kg)Document2 pagesJob Safety Analysis: Manually Lover Post Erection (300kg)Mahamudul HasanNo ratings yet

- JSP For Electrical and HV TestingDocument4 pagesJSP For Electrical and HV TestingmohammedNo ratings yet

- Welspun Enterprises Limited Project: Am2 Group Risk AssessmentDocument4 pagesWelspun Enterprises Limited Project: Am2 Group Risk AssessmentDwijendra ChanumoluNo ratings yet

- Equipment/reactor Erection Work JsaDocument3 pagesEquipment/reactor Erection Work JsaAKBAR ALINo ratings yet

- Job Safety Analysis: Health Safety and Environment DepartmentDocument3 pagesJob Safety Analysis: Health Safety and Environment DepartmentseppyfNo ratings yet

- Use of 110v Tools B 05Document1 pageUse of 110v Tools B 05cardyNo ratings yet

- Job Hazard AnalysisDocument11 pagesJob Hazard AnalysisJP LorenteNo ratings yet

- Pile Load Test Pile No2Document4 pagesPile Load Test Pile No2Sanjeet SinghNo ratings yet

- JSA For SURGE VESSEL WorkDocument6 pagesJSA For SURGE VESSEL Workathul subashNo ratings yet

- Skilling For LivelihoodDocument19 pagesSkilling For LivelihoodPawanKumarNo ratings yet

- Potential of various fatty feeds to reduce methane release from rumen fermentation in vitroDocument14 pagesPotential of various fatty feeds to reduce methane release from rumen fermentation in vitroGabriela Casarotto DanielNo ratings yet

- The World Bank: IBRD & IDA: Working For A World Free of PovertyDocument25 pagesThe World Bank: IBRD & IDA: Working For A World Free of PovertyManish GuptaNo ratings yet

- Health Promoting Behaviour Among Secondary School Children With Respect To GenderDocument5 pagesHealth Promoting Behaviour Among Secondary School Children With Respect To GenderAnonymous CwJeBCAXpNo ratings yet

- 1st Quarter Exam Pe and Health 11Document4 pages1st Quarter Exam Pe and Health 11Irish John GulmaticoNo ratings yet

- Teenage Pregnancy Refers To The Adolescent Girls, Usually With in The AgesDocument6 pagesTeenage Pregnancy Refers To The Adolescent Girls, Usually With in The Agesmarina abanNo ratings yet

- Mbele ReferenceDocument1 pageMbele Referenceapi-313447959No ratings yet

- ORGB 5th Edition Nelson Solutions Manual 1Document44 pagesORGB 5th Edition Nelson Solutions Manual 1shirley100% (52)

- HRPDocument10 pagesHRPSurbhi BidviNo ratings yet

- Reducing AgeismDocument2 pagesReducing AgeismAntónio LealNo ratings yet

- Re-Opening Plan For The 2020-2021 School YearDocument18 pagesRe-Opening Plan For The 2020-2021 School YearNews 8 WROCNo ratings yet

- Modals of Suggestion HomeworkDocument2 pagesModals of Suggestion HomeworkmateoNo ratings yet

- JR NeuroanestesiDocument11 pagesJR Neuroanestesiliashuban29No ratings yet

- Conduct Disorder and Somatic Health in ChildrenDocument3 pagesConduct Disorder and Somatic Health in ChildrenJeric C. ManaliliNo ratings yet

- Journal - Pone.0227695 EndometriosisDocument13 pagesJournal - Pone.0227695 EndometriosisRominaNo ratings yet

- RA-032739 - MASTER PLUMBER - Lucena - 2-2023Document7 pagesRA-032739 - MASTER PLUMBER - Lucena - 2-2023Bon Opeña GorobaoNo ratings yet

- How To Sleep BetterDocument9 pagesHow To Sleep BetterMariaNo ratings yet

- Basic Safety GuideDocument214 pagesBasic Safety Guide180190105084rabadiyahenilNo ratings yet

- (Lecture 2) Skin TestDocument31 pages(Lecture 2) Skin TestShubham KadiwalaNo ratings yet

- Instability of The Distal Radioulnar JointDocument12 pagesInstability of The Distal Radioulnar JointOryza SatriaNo ratings yet

- Action Insulin Name Effective Considerations Onset Peak DurationDocument2 pagesAction Insulin Name Effective Considerations Onset Peak DurationDr. Ricardo R.V. de BritoNo ratings yet

- Exercise 5 Characteristics of Soil ColloidsDocument4 pagesExercise 5 Characteristics of Soil ColloidslexiclesmcgeeNo ratings yet

- Occlusal Plane Template TechniqueDocument39 pagesOcclusal Plane Template TechniqueREWA KAWADENo ratings yet

- Healthlittoolkit2 Tool2aDocument7 pagesHealthlittoolkit2 Tool2aRenzz Irven PlotadoNo ratings yet

- Akeela House Intake Packet RDocument11 pagesAkeela House Intake Packet RDamonNo ratings yet

- Fate of Manganese Associated With The Inhalation of Welding Fumes: Potential Neurological EffectsDocument7 pagesFate of Manganese Associated With The Inhalation of Welding Fumes: Potential Neurological EffectsAndrea Carolina Salas LalindeNo ratings yet

- House Democratic Caucus Task Force On Aging and Families LTR To Biden Harris Transition - Geriatrician To COVID Advisory BoardDocument2 pagesHouse Democratic Caucus Task Force On Aging and Families LTR To Biden Harris Transition - Geriatrician To COVID Advisory BoardPeter SullivanNo ratings yet

- D&D 5eDocument4 pagesD&D 5eranaculaeNo ratings yet

- G7M-1055-05 - On-Line Visual Inspection Procedures and ChecklistDocument1 pageG7M-1055-05 - On-Line Visual Inspection Procedures and ChecklistMohammad Qureshi100% (1)