Professional Documents

Culture Documents

Scaffold Risk Assissment

Uploaded by

Saleem AkhtarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Scaffold Risk Assissment

Uploaded by

Saleem AkhtarCopyright:

Available Formats

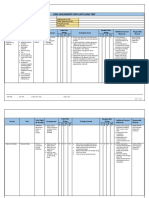

Scaffolding -Risk Assessment

Legal

Task Step H Hazard details Consequence Details P S Risk Current Control Measures Req. P S Risk Additional control

SI No Code Rank Y/N Rank measures

-Barricade the loading/off-loading area to

ensure that no unauthorized persons are

There inside the area.

-All unwanted materials must be moved to

The dumping area of material store yard.

Only required material to be stored at the

site, which must be arranged and secured

properly. Concerned engineer or the general

Forman is responsible to remove unwanted

materials from the site.

-Following measures to be ensured as a safety

factor.

1 Loading and M1 Caught in Fatality 4 5 20 -Mobile crane to be used to load or unload all Y 2 5 10

unloading of between and Heavy weights.

scaffold M3 struck by the

-Forklift operator will be possession of a valid

materials loose load

3rd party trained certificate to operate the

Forklift.

-only a trained and competent riggers to be

used if necessary.

-The forklift and lifting tackle will have a valid

load test certificates.

-The crane and lifting tackle will be inspected

daily to ensure that the equipment is not

damaged.

-personal protective equipment such as safety

helmet, safety shoes and hand gloves to be

worn while handling material.

-During transportation, all objects to be

properly secured.

-Personnel must be cleared from the area

while unloading.

-Use PPE (Hand Gloves) when handling sharp

edge materials.

-Access shall be properly maintained for use of

trucks and emergency vehicles.

-Proper height/ stack ratio shall be maintained, .i.e.

3 x shortest base.

Scaffolding -Risk Assessment

Legal

Task Step H Hazard details Consequence Details P S Risk Current Control Measures Req. P S Risk Additional control

SI No Code Rank Y/N Rank measures

-Scaffolding erection area will be barricaded with solid

barricading and proper signage will be erected, .i.e.

overhead works in progress and scaffold erection works

in progress.

-spotters will be placed to prevent unauthorized entry

into the erection area as an additional precautionary

measure.

-Scaffold material which will be passed to persons above

and below will be done one by one and not throw n to

each other.

-All scaffold materials will be checked by an authorized

person prior to the material being used for erection.

-All scaffold boards will be inspected before brought on to 1 5 5

Erection of Fall from height. site. Damaged or cracked boards will be discarded.

2 J7 Fatality 5 5 25 -All scaffold erection personnel as well be in possession of

Hanging (scaffolding

scaffold operatives) a valid 3rd party trained certificate.

-All scaffold will comply with BSEN 12811-1

-After erection is complete the scaffold will be inspected

by a competent inspector and tagged green if found safe

for use.

-All scaffolds will be re inspected every 7 days by a

competent inspector.

-Fall arrest equipment to be checked prior to each period

of use by the user.

-All equipment found to be damaged as per the inspection

guidelines, must be removed immediately from service

destroyed. Replaced with new issue and recorded.

-Fall arrest equipment to be attached to load bearing

structures in the correct manner.

Double lanyard to be used on Fall Arrest Equipment

Scaffolding -Risk Assessment

Legal

Task Step H Hazard details Consequence Details P S Risk Current Control Measures Req. P S Risk Additional control

SI No Code Rank Y/N Rank measures

Installation Scaffold Collapse - Ties to be placed as per design requirements and 1 5 5

Of suitable Resulting in

3 ties and J7 injuries to Fatality 3 5 15 at regular intervals.

bracings scaffolders.scaffold Design drawing will be utilized for the inspection.

users and other in

the vicinity.

-Automate or mechanise the handling where possible.

-Use handling aids such as pump trucks, forklift,trolly or

Barrows where possible.

-Use the least cluttered route for moving material

through the work area.

-Modify the task, load or environment where possible and

Musculoskeletal ensure individual capabilities are matched to the activity.

4 Manual E3 Injuries to Back, 3 3 9 -Follow the manual handing guidelines on technique. 2 5 10

Injury’s, and work Tendons, Ligament and

Handling Related upper limb -Before lifting, check the weight, plan the route of the

Muscles. carry, and establish a firm, comfortable grip.

Disorder (WRULD).

The Lift, bend the knees and use the leg muscles to lift,

keep back upright, keep the load close to the body, avoid

twisting, over reaching, jerking.

Sitting down, use the same principles as when lifting

maintain good balance, set the load down and adjust the

position using body weight.

-Check lifting Equipment’s.

Installation Failure of lifting -Ensure PPE is worn.

of Electrical Equipment. -Ensure power supply cables are routed in a safe manner.

5 Equipment’s Trailing . Power Fatality -prevent unauthorized personnel entering the risk area.

1 5 5

supply/cables

-All personnel will wear appropriate PPE, .i.e. hard hat,

Gloves, dust masks, overalls, safety boots/shoes,

Cleaning of Strains and sprains, reflective vests.

6 Ergonomics -All material will be taken away and separated as waste

1 3 3

area Back injuries when

Lifting heavy equipment and /or reusable material.

-Wests will be disposed of as required, hazardous and /or

general.

Scaffolding -Risk Assessment

Contact Hanging Access Scaffolding

Task Description Erection of Hanging Access Scaffolding

RISK SCORE CALCULATOR

Use The Risk Score Calculator to Determine The Level Of Risk Of Each Hazard

What would the ?What is the LIKELIHOOD of an occurrence Hierarchy of Controls

SEVERITY

?of an assurance be Severity Almost Very Likely Unlikely Very Unlikely Can the hazard be eliminated or removed from the

Rating Certain Likely ?work place

CATASTROPHIC 5 High High High Med Med Can the product or process be substituted for a less

Multiple facilities/environmental release with ?hazardous alternative

determinable effect requiring external emergency

services

Major 4 High High High Med Low Can the hazard be engineered away with guards or

Major illness or injury, disability/environmental ?barriers

release

Moderate 3 High High Med Med Low Can administrative controls be adopted i.e.

Serious but non-permanent injury or ill health work .procedure, job rotation etc

days lost on site release requiring environmental

emergency plan to be activated

Minor 2 Med Med Med Low Low Can Personal Protective Equipment and Clothing be

Medical alternation needed ?worn to safeguard against hazard

No work restrictions/ Local on safe environmental

release treated locally

Negligible 1 Med Low Low Low Low RISK RATING (Likelihood x Severity)

Minor cuts or sickness/Nuisance release with no LOW RISK (No further action required) 1-4

advance impact MEDIUM RISK (Procedure to be available ) 5-10

Likelihood Rating 5 4 3 2 1 HIGH RISK (Full time Supervision present) 11-25

You might also like

- Boiler InstallationDocument2 pagesBoiler InstallationRod Kenneth LubongNo ratings yet

- Jsa For Air Flushin Amp Mech Cleaning of Pipes PDF FreeDocument17 pagesJsa For Air Flushin Amp Mech Cleaning of Pipes PDF FreeAbdullah FazilNo ratings yet

- Erection of Tanks JSADocument4 pagesErection of Tanks JSASalah Abd EldayemNo ratings yet

- FO-JSA-08 - Lifting, Lowering, Laying and Backfilling of 6'' PipelineDocument4 pagesFO-JSA-08 - Lifting, Lowering, Laying and Backfilling of 6'' PipelineRidha Bennasr100% (1)

- JSA-Road Crossing of 6'' PipelineDocument6 pagesJSA-Road Crossing of 6'' PipelineRidha BennasrNo ratings yet

- Fabrication Work Shop RADocument4 pagesFabrication Work Shop RASalah Abd Eldayem67% (3)

- Site Safety Supervisor - Lifting OperationDocument10 pagesSite Safety Supervisor - Lifting Operationflex xibleNo ratings yet

- RISK ASSESSMENT FOR ALUMINUM & GLAZING INSTALLATIONDocument1 pageRISK ASSESSMENT FOR ALUMINUM & GLAZING INSTALLATIONAjith Pillerkatill Antony100% (1)

- Steel Erection JSADocument5 pagesSteel Erection JSASalah Abd Eldayem100% (1)

- JSA - Winstar Pipeline CrossingDocument6 pagesJSA - Winstar Pipeline CrossingRidha BennasrNo ratings yet

- CraneOperations PDFDocument2 pagesCraneOperations PDFIrshad AkhterNo ratings yet

- Jsa For Installation of Fence Amp Area Grading PRDocument11 pagesJsa For Installation of Fence Amp Area Grading PRvik neshNo ratings yet

- Working at Height Risk AssessmentDocument9 pagesWorking at Height Risk AssessmentBasky0% (1)

- Crane AssemblyDocument3 pagesCrane AssemblyM Waqas HabibNo ratings yet

- Working at Height Risk AssessmentDocument9 pagesWorking at Height Risk AssessmentNebosh Diploma Assignment83% (6)

- Hazard Identification and Risk Assessment Worksheet.: Zubair New Degassing Station Project Caravan LiftingDocument2 pagesHazard Identification and Risk Assessment Worksheet.: Zubair New Degassing Station Project Caravan LiftingNaveed AhmedNo ratings yet

- JOB SAFETY ANALYSIS FOR SCAFFOLD ERECTIONDocument3 pagesJOB SAFETY ANALYSIS FOR SCAFFOLD ERECTIONJixtha SaintNo ratings yet

- RISK ASSESSMENTDocument4 pagesRISK ASSESSMENTAnh VàngNo ratings yet

- Risk Assessment For Balustrade Glass InstallationDocument3 pagesRisk Assessment For Balustrade Glass InstallationNicos PapadopoulosNo ratings yet

- Job Safety Analysis (Jsa) : ScaffoldingDocument1 pageJob Safety Analysis (Jsa) : Scaffoldingsk sajidNo ratings yet

- Pile Load Test Pile No2Document4 pagesPile Load Test Pile No2Sanjeet SinghNo ratings yet

- RA Shoring System & Diving - HSR Project-1Document20 pagesRA Shoring System & Diving - HSR Project-1Mohamed Hasafy100% (1)

- Attachments 3 - Risk Assessment For Structure Work of FoudationDocument4 pagesAttachments 3 - Risk Assessment For Structure Work of FoudationAnh VàngNo ratings yet

- Risk Assessment Ubderground Electric Power SupplyDocument4 pagesRisk Assessment Ubderground Electric Power SupplySameer Abdul RaufNo ratings yet

- JSA For HOT JobDocument1 pageJSA For HOT JobEquipment MaterialsNo ratings yet

- RA Erection of Pre-Engineered Steel Buildings (Structural Steel)Document8 pagesRA Erection of Pre-Engineered Steel Buildings (Structural Steel)kumar100% (1)

- JHA For Pipe Work-01.09Document3 pagesJHA For Pipe Work-01.09Anonymous Xb3zHio100% (1)

- Lifting Operation BNQDocument2 pagesLifting Operation BNQsathiamurti100% (1)

- JHA Tower Crane ErectionDocument4 pagesJHA Tower Crane Erectionmark jayson yabesNo ratings yet

- Risk Assessment For Plate Load TestDocument4 pagesRisk Assessment For Plate Load TestShah Jan100% (7)

- RA Shoring System & Diving - HSR Project-1Document23 pagesRA Shoring System & Diving - HSR Project-1Mohamed Hasafy100% (1)

- Job Safety Analysis for Lifting MS SheetsDocument2 pagesJob Safety Analysis for Lifting MS SheetsM Waqas HabibNo ratings yet

- Risk Assessment and Method Statement Hollowcore Plank Installation With CraneDocument17 pagesRisk Assessment and Method Statement Hollowcore Plank Installation With CraneA123Y123No ratings yet

- Revised Job Safety AnalysisDocument11 pagesRevised Job Safety AnalysisTigor GurningNo ratings yet

- Doku - Pub Risk-AssessmentDocument10 pagesDoku - Pub Risk-AssessmentUlviyye ElesgerovaNo ratings yet

- JSA Erection StructureDocument11 pagesJSA Erection StructureJAYESH JOSHINo ratings yet

- Job Safety AnalysisDocument3 pagesJob Safety AnalysisMuhammad KaleemNo ratings yet

- Pile Load Test Pile No2Document3 pagesPile Load Test Pile No2M Waqas HabibNo ratings yet

- Risk Assessment For Electrical Equipment InstalationDocument15 pagesRisk Assessment For Electrical Equipment Instalationmanikandan100% (2)

- Risk Assessment and Method Statement Beam and Block Installation From LorryDocument16 pagesRisk Assessment and Method Statement Beam and Block Installation From LorryAbdulkerim A.AbdiNo ratings yet

- Activity Wise Possible Controls Sheet For JSADocument4 pagesActivity Wise Possible Controls Sheet For JSAahmar javedNo ratings yet

- Risk Assessment of Erecting Steel StructuresDocument10 pagesRisk Assessment of Erecting Steel StructuresTubagus DikaNo ratings yet

- HIRA For Utility TrenchingDocument7 pagesHIRA For Utility TrenchingNilamSanjeev Kumar SinghNo ratings yet

- Protective Equipment (P.P.E) : Gashubin Eng Pte LTDDocument11 pagesProtective Equipment (P.P.E) : Gashubin Eng Pte LTDMd ShahinNo ratings yet

- JOB SAFETY ANALYSIS Nahar HomeDocument11 pagesJOB SAFETY ANALYSIS Nahar Homesiddhu mendheNo ratings yet

- Appendix BDocument14 pagesAppendix Bmohsin.meizaNo ratings yet

- NO. Activities Description of Risks Expected Consequences Probability Severity Mitigation Action Person Responsible 1Document5 pagesNO. Activities Description of Risks Expected Consequences Probability Severity Mitigation Action Person Responsible 1Iris LucasNo ratings yet

- Dump Truck Engine1Document3 pagesDump Truck Engine1M Waqas HabibNo ratings yet

- RA-Alumino-Thermic WeldingDocument10 pagesRA-Alumino-Thermic WeldingAli Usman Ali100% (1)

- Protective Equipment (P.P.E) : Gashubin Eng Pte LTDDocument10 pagesProtective Equipment (P.P.E) : Gashubin Eng Pte LTDMd ShahinNo ratings yet

- JSA Work at Hight - Rev-6Document2 pagesJSA Work at Hight - Rev-6Mahamudul HasanNo ratings yet

- Attachment 7505Document11 pagesAttachment 7505Charles DoriaNo ratings yet

- Jsa for Drilling WellDocument5 pagesJsa for Drilling WellAnna JisabaNo ratings yet

- Generic Risk Assessment - RA01: General Work at Height Page 1 of 3Document3 pagesGeneric Risk Assessment - RA01: General Work at Height Page 1 of 3RamNo ratings yet

- JSA For Materia/equipment Loading Unloading & Shifting Work JsaDocument3 pagesJSA For Materia/equipment Loading Unloading & Shifting Work JsaAKBAR ALINo ratings yet

- SWP 02 - Use of Mobile ScaffoldDocument4 pagesSWP 02 - Use of Mobile ScaffoldGerald Wong NttNo ratings yet

- 8015 0151 CK01 00 000 HS RP 06219Document7 pages8015 0151 CK01 00 000 HS RP 06219Saleem AkhtarNo ratings yet

- Weekly HSE Report for Gas Turbine ConstructionDocument12 pagesWeekly HSE Report for Gas Turbine ConstructionSaleem AkhtarNo ratings yet

- 8015 0151 CK01 00 000 HS RP 06202 - 00Document9 pages8015 0151 CK01 00 000 HS RP 06202 - 00Saleem AkhtarNo ratings yet

- 8015 0151 CK01 00 000 HS RP 06226Document9 pages8015 0151 CK01 00 000 HS RP 06226Saleem AkhtarNo ratings yet

- Cover PageDocument1 pageCover PageSaleem AkhtarNo ratings yet

- Risk Assessment For InsulationDocument9 pagesRisk Assessment For InsulationSaleem Akhtar71% (7)

- Scaffolding Safety Audit ReportDocument3 pagesScaffolding Safety Audit ReportSaleem AkhtarNo ratings yet

- Calik Hse Observation Form 1386Document3 pagesCalik Hse Observation Form 1386Saleem AkhtarNo ratings yet

- Adil Salman CVDocument1 pageAdil Salman CVSaleem AkhtarNo ratings yet

- Samsung Scaffold Risk Assesment 2Document7 pagesSamsung Scaffold Risk Assesment 2Saleem AkhtarNo ratings yet

- Insulation Method for Zubair Oil Field PipingDocument14 pagesInsulation Method for Zubair Oil Field PipingSaleem AkhtarNo ratings yet

- Co-Operation Agreement: ST NDDocument1 pageCo-Operation Agreement: ST NDSaleem AkhtarNo ratings yet

- SCH 2Document4 pagesSCH 2Saleem AkhtarNo ratings yet

- Scaffolding Access and Egress Gap IssueDocument3 pagesScaffolding Access and Egress Gap IssueSaleem AkhtarNo ratings yet

- Risk Assessment Guidance: Hazard Severity Likelihood of OccurrenceDocument10 pagesRisk Assessment Guidance: Hazard Severity Likelihood of OccurrenceSaleem AkhtarNo ratings yet

- Scaffolding Inspection RegisterDocument2 pagesScaffolding Inspection RegisterSaleem AkhtarNo ratings yet

- To Remove & Reinstall Heat Insulation Cover 350Document7 pagesTo Remove & Reinstall Heat Insulation Cover 350Saleem AkhtarNo ratings yet

- Hygiene and Sanitation Inspection Checklist and RecordDocument6 pagesHygiene and Sanitation Inspection Checklist and RecordSaleem Akhtar100% (1)

- Calik Energy Hse Observation Form 716Document3 pagesCalik Energy Hse Observation Form 716Saleem AkhtarNo ratings yet

- CSEP Log Blank FormDocument2 pagesCSEP Log Blank FormSaleem AkhtarNo ratings yet

- Type 4Document105 pagesType 4Saleem AkhtarNo ratings yet

- Scaffolding Risk Assessment: Rev SECL Job NoDocument5 pagesScaffolding Risk Assessment: Rev SECL Job NoSaleem AkhtarNo ratings yet

- Plan of Temporary Facilities Work. No Activity Name Start Finish DurationDocument1 pagePlan of Temporary Facilities Work. No Activity Name Start Finish DurationSaleem AkhtarNo ratings yet

- Confined Space Checklist Location / Area: Company Name: Date: Requirements Yes No N/ADocument1 pageConfined Space Checklist Location / Area: Company Name: Date: Requirements Yes No N/ASaleem AkhtarNo ratings yet

- Soban Wajid: Urriculum ItaeDocument3 pagesSoban Wajid: Urriculum ItaeSaleem AkhtarNo ratings yet

- ح.م.م ةماعلا تلاواقملل تيركنوك Warning Notification: Concrete General Contracting LlcDocument2 pagesح.م.م ةماعلا تلاواقملل تيركنوك Warning Notification: Concrete General Contracting LlcSaleem AkhtarNo ratings yet

- Faizan CV AdDocument1 pageFaizan CV AdSaleem AkhtarNo ratings yet

- ITT - Compliance DeclarationDocument5 pagesITT - Compliance DeclarationSaleem AkhtarNo ratings yet

- Dr. Concrete General Contracting LLC price schedules for Basra Refinery projectsDocument2 pagesDr. Concrete General Contracting LLC price schedules for Basra Refinery projectsSaleem AkhtarNo ratings yet

- 6-Transformer Installation PDFDocument3 pages6-Transformer Installation PDFAhmed ZaiNo ratings yet

- 988H M&O ManualDocument170 pages988H M&O Manualr1p2100% (4)

- Msds Ammonium Bifluoride PDFDocument5 pagesMsds Ammonium Bifluoride PDFDesiyantri Siti PinundiNo ratings yet

- _Technician 5G Active Networks InstallationDocument26 pages_Technician 5G Active Networks InstallationNagarajanNo ratings yet

- PPE Audit Checklist and FEEDBACKDocument4 pagesPPE Audit Checklist and FEEDBACKprojit basuNo ratings yet

- Introduction To Excavation Safety IOSH - Nebosh IGC: Federal Institute of TechnologyDocument6 pagesIntroduction To Excavation Safety IOSH - Nebosh IGC: Federal Institute of TechnologyaminNo ratings yet

- Fcaw NC IiDocument60 pagesFcaw NC IiDick Mijares UndagNo ratings yet

- Parafin - Msds - ECO 15 PLDocument8 pagesParafin - Msds - ECO 15 PLmehmetNo ratings yet

- Legal Register - Federal Law No. 32Document7 pagesLegal Register - Federal Law No. 32Priyanka JNo ratings yet

- Transport Emergency Response Plan TemplateDocument9 pagesTransport Emergency Response Plan TemplateGlenda SibongaNo ratings yet

- TM25 Technical Manual - 82450 - AADocument36 pagesTM25 Technical Manual - 82450 - AAreviansyahfadhil100% (2)

- MSFJ020D - Denso - CPT 1000 Innerwrap and CPT 1000 OuterwrapDocument7 pagesMSFJ020D - Denso - CPT 1000 Innerwrap and CPT 1000 OuterwrapMakamu Max Las MokgaoganyiNo ratings yet

- Cleaning and Vacuum Test of Refrigerant PipesDocument8 pagesCleaning and Vacuum Test of Refrigerant PipesachusanachuNo ratings yet

- Safety EquipmentDocument6 pagesSafety Equipmentkhalid hosnyNo ratings yet

- IGC1 - Element 6 Principles of Control (1st Ed) v.1.0Document87 pagesIGC1 - Element 6 Principles of Control (1st Ed) v.1.0Umair Ahmed Abbasi100% (2)

- Confined Space Entry Plan V06-D-0001Document3 pagesConfined Space Entry Plan V06-D-0001REHAN IQBAL100% (1)

- Tallow Amine - MSDS PDFDocument4 pagesTallow Amine - MSDS PDFshreeket3953No ratings yet

- SAFE PPE AND HAZARDS PROCEDUREDocument7 pagesSAFE PPE AND HAZARDS PROCEDUREMd Shahin100% (1)

- Wenaas CatalogueDocument29 pagesWenaas CatalogueAnonymous 1dCz409sNo ratings yet

- Risk Assessment Method Statement Storage Tank PDFDocument6 pagesRisk Assessment Method Statement Storage Tank PDFNiyi Folayan100% (1)

- Asphalt Emulsions Material Safety Data SheetDocument9 pagesAsphalt Emulsions Material Safety Data SheetTorero02No ratings yet

- Learn Infection Control PrecautionsDocument4 pagesLearn Infection Control PrecautionsTashaNo ratings yet

- CU2547Document3 pagesCU2547Diana BicazanNo ratings yet

- Plumbing BookDocument24 pagesPlumbing BookbendeniNo ratings yet

- Brake Fluid MSDSDocument8 pagesBrake Fluid MSDSMichelleNo ratings yet

- Carbon Disulphide MSDSDocument7 pagesCarbon Disulphide MSDSPRNo ratings yet

- RA Overhead CraneDocument5 pagesRA Overhead CraneRandy Adisyah100% (2)

- MSDS Hempalin Enamel 52140Document13 pagesMSDS Hempalin Enamel 52140safety bnmNo ratings yet

- Asbestos Surveying - Mdhs100Document44 pagesAsbestos Surveying - Mdhs100Adam EdwardsNo ratings yet

- Atlas Copco Qas28Document68 pagesAtlas Copco Qas28jose luisNo ratings yet