Professional Documents

Culture Documents

Cartoon Car PDF

Uploaded by

Shridhar ZambareOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cartoon Car PDF

Uploaded by

Shridhar ZambareCopyright:

Available Formats

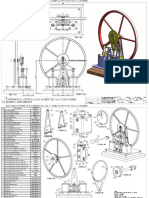

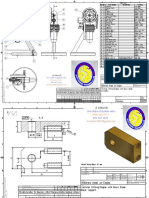

104 4.

09

95.5 3.76

137.4 5.41

QTY. PART NUMBER

1 STM-CAR-19-BURNER LAMP WICKING SCREENING

QTY. PART NUMBER 2 STM-CAR-20-BURNER GUIDE BLOCK

1 STM-CAR-01-CAR BODY 1 STM-CAR-21-CYLINDER

1 STM-CAR-02-CRANK HOUSING 1 STM-CAR-22-CYLINDER PIVOT SHAFT

2 STM-CAR-03-CRANK-AXLE SHAFT BEARING 1 STM-CAR-23-CYLINDER PIVOT SHAFT SPRING

1 STM-CAR-04-BULKHEAD 1 STM-CAR-24-CYLINDER REAR COVER

1 STM-CAR-05-FIREWALL 1 STM-CAR-25-PISTION AND CON ROD

1 STM-CAR-06-BOILER 1 STM-CAR-26-CRANK SHAFT-REAR AXLE

1 STM-CAR-07A-WATER FILLER NUT 4 STM-CAR-27-WHEEL HUB AND TIRE

1 STM-CAR-07B-WATER FILLER SCREW CAP 1 STM-CAR-28-FRONT WHEEL AXLE

1 STM-CAR-08-STEAM DOME 1 STM-CAR-29-STEERING ROD

1 STM-CAR-09-SAFETY VALVE BODY 2 STM-CAR-30-HEAD LIGHT

1 STM-CAR-10-SAFETY VALVE ADJSUTING NUT 2 STM-CAR-31-REAR LIGHT

1 STM-CAR-11-SAFETY VALVE STEM 1 STM-CAR-32-DRIVER

1 STM-CAR-12-SAFETY VALVE WASHER 1 STM-CAR-33-FLOOR

1 STM-CAR-13-SAFETY VALVE CORK DISK 3 STM-CAR-M2.5 NUT

1 STM-CAR-14-SAFETY VALVE SPRING 1 STM-CAR-M2.5x5 PAN HEAD SCREW

1 STM-CAR-15-CYLINDER MOUNTING BLOCK 2 STM-CAR-M2.5x10 PAN HEAD SCREW

1 STM-CAR-16-CYLINDER PORT BRACKET 1 STM-CAR-M2x5-WOOD SCREW

1 STM-CAR-17-BURNER TRAY 1 STM-CAR-M3 NUT

1 STM-CAR-18-BURNER LAMP WICKING 2 STM-CAR-M3 WASHER

NOTES:

TITLE DRAWING CONTENTS PROJECT No 09A-17-00 MODEL SCALE: 1:1

JDWDS

PROJECTION

A MIDGET STEAM CAR USING A DOUBLE GENERAL ARRANGEMENT, JDW DRAUGHTING SERVICES DATE

JULY-2015

DWG SCALE: 1:1 @A3 OR AS SHOWN

J.A.M. DE WAAL PAPAKURA NZ

Copyright ©

ACTING OSCILLATING ENGINE ISOMETRIC VIEWS AND B.O.M.

J.A.M. DE WAAL. 12 BRIGHTWELL STREET PAPAKURA 2110.

NEW ZEALAND. PHONE: OO64 09 2988815. MOB: 0211791000

E-MAIL: dewaal@xtra.co.nz. SHEET: 01 OF 03 A3 No: STM-CAR-01

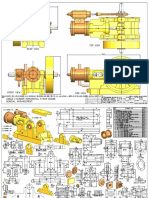

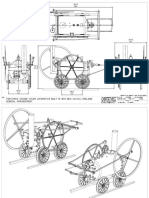

183 02 46

BRS

01 BRS

17

BRS

0.5

2

8.5

11

R57 76 R16 R51

88

2.5

3.5 ALL 05mm PLATE

FOLD UP

5

MAKE SEPARATELY 5

FOLD UP

13 16

2.5

R

4

SOLDER ALL BRZ

16

32

FOLD LINES 0.5

2.5 SCALE 2:1

44.5 0.5 03 A 6 7 7 7 6 MS or S/S

8.5

17

6 4

2.5

R5

BRS

7

R1

32

4 6 3 20

6 60

2.5

6

0.5mm THICK PLATE

2

3

19 3 6 3

69.5

5mm THICK SPS

30°

11

FOLD UP 127 2.3 3.5

A

4.5

4 2.5 2.5 22

88

7 3 3 2 6 23

MS

R5 BRS 73 26

37.5

3

M3

M3

5.5

4 4

WICK MATERIAL SECTION A-A 13 1 9 7 COILS

13 or LAMP WICKING

0.5 5

30° BRS

09

9.5

30° MESH SCREEN

6

76 25 31.5 WOOD

7

FLAT PATTERN SCALE 2:1 24

5.5

7

0.5mm THICK SCALE 1:1.5 BRS 19

64 1

10 72.5

26 18 72.5

BRS

15

M2 NUT 33

SCALE 2:1

5

4 1.5 4PL 3

3.4 23 23

26

26

1.6

0.3

56

1.2

1.2

1.6

31.5

3

R2

R2 1.6

4°

0.5mm THICK 36.5

4.5mm THICK

1.6

12

76

11.5

2.5 2.5 14

04

3

0.5mm THICK SCALE 1:1.5 15.5 FOLD LINE

0.5 76 13.5 3 13 3 R10

11 1mm THICK .5

BRS M2 SOLDER 40 21 3

6.5

22

SCALE 2:1 2.4

39

1.5

0.2

35

11.5

9.5

9.5

4

3

4

SOLDER SYN TUBE 3x2

4

2

ALU SOLDER

9.5

1.5

6.5 13 20 13 CU 4

12

0.5

1

SCALE 2:1 DETAIL-A

19

BRS 06 CORK or 1.5 3x1.5DEEP 1.5

05 1

10.8

59 GASKET 27

5.8 5.8

4

R10 .3 MATERIAL

4

.3 R10 BRS

4

2

R13

R1

25.5

R2

13

SOLDER ALL AROUND SCALE 2:1 16.5 16.5

12

7

59 BRZ 16

4.7 2 30 DETAIL-A

BRS

SOLDER 26 MS MS 14

15 1.5mm 3.1 ALU

12

BRS

8

THICK 13 0.7mm THICK PLATE

10 71.7 2.5 31 2

3.9

BRS ALU

26

3

BRS 5

R2.

5

11 60.3 7.5 26.8

9.5

07 14

11

2.5

1

16

8

7

GASKET

3.4

R57.5

8

M5 NUT SPS SOLDER 3

6.5

SYN SEAL R60 15.5

BRS 5 COILS

8

5 08 88.5

SCALE 2:1

NOTES:

TITLE DRAWING CONTENTS PROJECT No 09A-17-00 MODEL SCALE: 1:1

JDWDS

PROJECTION

A MIDGET STEAM CAR USING A DOUBLE PARTS AND ASSEMBLIES JDW DRAUGHTING SERVICES DATE

JULY-2015

DWG SCALE: 1:1 @A3 OR AS SHOWN

J.A.M. DE WAAL PAPAKURA NZ

Copyright ©

ACTING OSCILLATING ENGINE

J.A.M. DE WAAL. 12 BRIGHTWELL STREET PAPAKURA 2110.

NEW ZEALAND. PHONE: OO64 09 2988815. MOB: 0211791000

E-MAIL: dewaal@xtra.co.nz. SHEET: 02 OF 03 A3 No: STM-CAR-02

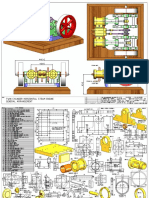

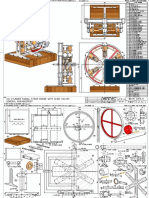

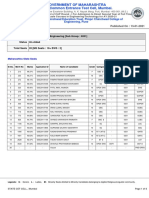

3.5 3 5 3 SOLDER 3 S 25 NOTES:

1 0. ALL THE DRAWINGS ARE IN METRIC MEASUREMENTS

2.5

1. ALL ENGINEERING PRACTICES SHALL BE APPLIED WITH REGARDS TO HOLE AND SHAFT TOLERANCES.

SOLDER 61.7

5.3

2. WHERE SCREWS OR BOLTS ARE USED THE CLEARANCE HOLES SHALL BE APPROXIMATELY 5% TO 8% LARGER

2.5

9

0.5 52 R2.5 52 THAN THE MATCHING TAPPED HOLE.

R1. 3. PREFERABLY ALL TAPPED HOLES AND MATCHING SCREWS AND/OR BOLTS TO BE METRIC FINE (MF)

5.5

BRS BRS 5 4. MATERIALS SPECIFIED ON THE DRAWINGS ARE INDICATIVE ONLY. THE BUILDER CAN MAKE HIS/HER OWN

BRS MS MATERIAL CHOICE.

29 WOOD 5. INQUIRE AT THE APROPRIATE AUTHOROTIES WHETHER OR NOT THIS BOILER REQUIRES A PRESSURE TEST

MS

5

CERTIFICATE.

2 6. ALL CONNECTIONS/JOINTS WHICH HAVE STEAM PRESSURE APPLIED TO IT SHALL BE SILVER/HARD SOLDERED.

08 07B 27 (IF STEAM PRESSURE IS LESS THAN 1.5BAR (22PSI) SOFT SOLDER CAN BE USED BUT NOT PREFERED)

SA-103 66.5 27 7. COMPRESSION SPRINGS ARE DRAWN IN COMPRESSED STATE (CP), UNCOMPRESSED STATE IS APPROX 40% TO

32 07A

60% LONGER THEN COMPRESSED STATE.

06 26 8. WHERE PREFERED SCREW OR RIVETED CONNECTIONS CAN BE OMITTED AND PARTS CAN BE BONDED TOGETHER

BY USING EITHER HIGH STRENGHT GLUE, POXY RESIN, OR SOLDER.

9. PARTS WHICH ARE DIRECTLY EXPOSED TO STEAM AND/OR WATER SHOULD BE CONSTRUCTED USING NON-

01 FERROUS OR NON CORROSIVE MATERIAL SUCH AS BRASS, BRONZE, GUNMETAL, STAINLESS STEEL, COPPER OR

LOCTITE OR GLUE MONEL.

10. THE ORDER IN WHICH THE PARTS/COMPONENTS ARE MANUFACTURED AND THE MODEL IS ASSEMBLED IS

SOLDER

SA-107 ENTIRELY LEFT TO THE BUILDER/MODELMAKER.

11. ERRORS AND/OR OMISSIONS MAY OCCUR IN THE DRAWINGS, DO NOT HESITATE TO CONTACT ME SO THAT THE

23.5

SA-102 27

76

27 ERRORS/OMISSSIONS CAN BE RECTIFIED.

MATERIAL ABBREVIATIONS: OTHER ABBREVIATIONS

SWIVEL ALU = ALUMINIUM PF = PRESS FIT

28 BRS = BRASS PCD = PITCH CIRCLE DIAMETER

BRZ = BRONZE OR GUNMETAL (BRZ/GM) RM = REAM

SA-102 CI = CAST IRON HEX = HEXACON, 6SIDED

AXLE FREE RUNNING IN SWIVEL CU = COPPER CP = COMPRESSED

03

20 16

05 04 02 SA-108 GRA = GRAPHITE

MS = MILD STEEL/BRIGHT MILD STEEL

KNL = KNURLED

SA-xxxx = SUB ASSEMBLY-xxx

15 S/S = SILVER STEEL OR STAINLESS STEEL

SA-101 SPS = SPRING STEEL

SYN = SYNTHETIC MATERIAL SUCH AS VETON, NYLON, TEFLON OR RUBBER

IN GENERAL SYNTHETIC MATERIALS SOULD BE ABLE TO WITHSTAND

10 THE HEAT AND PRESSURE(S) APPLIED TO THEM.

12

13

13

44 SA-105

09

SA-101

SA-104

11

14 19

27.5

18

29

17

SA-103

40

24 SA-105 SA-104

21

03 03

12

0.5 0.5

LOCTITE 22 23

SOLDER

SA-106

25

SA-106 SA-107

SA-108

SA-110

NOTES:

TITLE DRAWING CONTENTS PROJECT No 09A-17-00 MODEL SCALE: 1:1

JDWDS

PROJECTION

A MIDGET STEAM CAR USING A DOUBLE PARTS AND ASSEMBLIES JDW DRAUGHTING SERVICES DATE

JULY-2015

DWG SCALE: 1:1 @A3 OR AS SHOWN

J.A.M. DE WAAL PAPAKURA NZ

Copyright ©

ACTING OSCILLATING ENGINE

J.A.M. DE WAAL. 12 BRIGHTWELL STREET PAPAKURA 2110.

NEW ZEALAND. PHONE: OO64 09 2988815. MOB: 0211791000

E-MAIL: dewaal@xtra.co.nz. SHEET: 03 OF 03 A3 No: STM-CAR-03

You might also like

- 3 Speed Automatic Transmission Parts Catalog for 1997-99 Jeep Cherokee (XJDocument28 pages3 Speed Automatic Transmission Parts Catalog for 1997-99 Jeep Cherokee (XJjperez_450881No ratings yet

- Diagrama Electrico Mini - CooperDocument155 pagesDiagrama Electrico Mini - CooperMarvin Sagastume83% (6)

- SAM Unit Front FunctionDocument4 pagesSAM Unit Front FunctionJohn Eduard Sierra VelandiaNo ratings yet

- Single cylinder steam engine slide valveDocument6 pagesSingle cylinder steam engine slide valveDanilo AlvarezNo ratings yet

- 4 Cylindres Oscillant en Ligne PDFDocument3 pages4 Cylindres Oscillant en Ligne PDFJose Guadalupe AntonioNo ratings yet

- Muncaster 11 A3 Sheet 04Document1 pageMuncaster 11 A3 Sheet 04Juan PastorNo ratings yet

- Exp Vert See Saw 09 04 09Document5 pagesExp Vert See Saw 09 04 09radi adityaNo ratings yet

- Bicylindre en V PDFDocument5 pagesBicylindre en V PDFOrlando Rojas PintoNo ratings yet

- Ose 2 Vertical Ose Beginner 2 Svoste 00 OkDocument1 pageOse 2 Vertical Ose Beginner 2 Svoste 00 OkAnonymous MMLzZjbyNo ratings yet

- A Simple Small Metalworking ShaperDocument7 pagesA Simple Small Metalworking ShaperĐặng Ngọc Hùng100% (2)

- Solidworks MockUp DrawingDocument7 pagesSolidworks MockUp DrawingPANDU RADITYANo ratings yet

- C-Clamp: Scale: Sheet OF Title: Tolerances Unless Otherwise Specified: Drawn By: Developed At: RevDocument7 pagesC-Clamp: Scale: Sheet OF Title: Tolerances Unless Otherwise Specified: Drawn By: Developed At: RevC Cube Cad Centre - ErodeNo ratings yet

- CombineddrawingsDocument20 pagesCombineddrawingsapi-429073519No ratings yet

- c0 Vertical Steam Engine Assembly-MergedDocument3 pagesc0 Vertical Steam Engine Assembly-Mergedapi-555150734No ratings yet

- TF 000102Document8 pagesTF 000102api-299556237No ratings yet

- Single cylinder steam engine general arrangementDocument4 pagesSingle cylinder steam engine general arrangementJorge Luis Villegas ValdiviaNo ratings yet

- 1chseaw JDW CompletDocument4 pages1chseaw JDW CompletJesús Los ArcosNo ratings yet

- 2030-0 Narrow Gauge Electric Loco of The Mix Nitz-St. Erhard Local Railway Scale 1:5.6 Track Gauge 180Mm (7") General Arrangement & PartslistDocument5 pages2030-0 Narrow Gauge Electric Loco of The Mix Nitz-St. Erhard Local Railway Scale 1:5.6 Track Gauge 180Mm (7") General Arrangement & Partslisting aprNo ratings yet

- Solidworks Student Edition. For Academic Use Only.: Team Fantastic FourDocument55 pagesSolidworks Student Edition. For Academic Use Only.: Team Fantastic FourAldrick NapayNo ratings yet

- Flame Eating EngineDocument4 pagesFlame Eating EngineAxel DominiqueNo ratings yet

- Wren Minibike PlansDocument1 pageWren Minibike PlansANDRES MARCELO GORDON GARCESNo ratings yet

- Small Horizontal Steam Engine DrawingDocument6 pagesSmall Horizontal Steam Engine Drawingnferreira_245024No ratings yet

- Ose 12 Twin Ose Boxer OkDocument2 pagesOse 12 Twin Ose Boxer OkOrlando Rojas PintoNo ratings yet

- 2 Cyl Vert Steam Engine With Reverser J.p.duval-5Document4 pages2 Cyl Vert Steam Engine With Reverser J.p.duval-5duy2854No ratings yet

- MAQUINADocument2 pagesMAQUINAEnrique PinazoNo ratings yet

- v6 Engine Complete Assembly-ExplodedDocument1 pagev6 Engine Complete Assembly-Explodedmarouane najaheNo ratings yet

- A Gas Fired Steam Locomotive of The Dush RailwaysDocument15 pagesA Gas Fired Steam Locomotive of The Dush Railwaysing aprNo ratings yet

- Drawing PackageDocument150 pagesDrawing PackageRafael Paixao100% (1)

- 54 Vertical Twin Cylinder Steam Engine PDFDocument5 pages54 Vertical Twin Cylinder Steam Engine PDFAlex NaranjoNo ratings yet

- DOCUMENT Centrifugal pump assembly parts listDocument18 pagesDOCUMENT Centrifugal pump assembly parts listhelver Quenaya RoqueNo ratings yet

- Maudslay Marine Type Vertical Steam EngineDocument3 pagesMaudslay Marine Type Vertical Steam EngineAxel DominiqueNo ratings yet

- General Arrangement and Sections Locomotive Boiler For T3 "Badenia" For 5inch (127mm) GAUGEDocument4 pagesGeneral Arrangement and Sections Locomotive Boiler For T3 "Badenia" For 5inch (127mm) GAUGEAracely Cárdenas100% (1)

- DVSSE-01 Twin Cylinder Horizontal Steam Engine General ArrangementDocument4 pagesDVSSE-01 Twin Cylinder Horizontal Steam Engine General ArrangementJuan GabrielNo ratings yet

- A0056220020-Audi A6 Current Flow Wiring Diagram - Basic Equipment From Model Year 2003Document642 pagesA0056220020-Audi A6 Current Flow Wiring Diagram - Basic Equipment From Model Year 2003Thomas HallwrightNo ratings yet

- Single Cylinder Oscillating Steam EngineDocument1 pageSingle Cylinder Oscillating Steam EngineNiruban Santiagu Fernando100% (1)

- A Simple Small Metalworking ShaperDocument7 pagesA Simple Small Metalworking ShaperAxel DominiqueNo ratings yet

- Experimental twin cylinder steam engineDocument6 pagesExperimental twin cylinder steam engineGiuliana Acosta acostaNo ratings yet

- Tandem Scotch Yoke Steam EngineDocument4 pagesTandem Scotch Yoke Steam EngineAmar HairlahovicNo ratings yet

- 6 CylinderDocument5 pages6 CylinderCường TrọngNo ratings yet

- Pneumatic 6 Cylinder 1Document24 pagesPneumatic 6 Cylinder 1Cristian Ortiz67% (3)

- Chopper - Item No.11Document44 pagesChopper - Item No.11edmealemNo ratings yet

- 2000 Nissan Sentra GXE LIBRO (DIGRAMAS ELECTRICOS) PDFDocument64 pages2000 Nissan Sentra GXE LIBRO (DIGRAMAS ELECTRICOS) PDFjhon jairo Briceño GuatavaNo ratings yet

- Glass Crusher CompleteDocument16 pagesGlass Crusher CompleteKhalil Al MahdiNo ratings yet

- Proyecto Electiva PDFDocument7 pagesProyecto Electiva PDFAlf AdNo ratings yet

- General Arrangement, Isometric 2X1 Cyl. Horizontal Steam Engines With View, Notes Rope Driven Generator (Rope Drive)Document5 pagesGeneral Arrangement, Isometric 2X1 Cyl. Horizontal Steam Engines With View, Notes Rope Driven Generator (Rope Drive)adil jabaroNo ratings yet

- Data Sheet - Main Pump Jack Tools Zx350 - AllDocument9 pagesData Sheet - Main Pump Jack Tools Zx350 - AllSetyo HadyNo ratings yet

- Bản Vẽ Lắp Động Cơ DọcDocument32 pagesBản Vẽ Lắp Động Cơ DọcCủa Tôi Thần TuợngNo ratings yet

- BP9763 A3 Sheet 03Document1 pageBP9763 A3 Sheet 03Miguel MotaNo ratings yet

- Vertical steam engine slide valve assemblyDocument7 pagesVertical steam engine slide valve assemblyMonglafru MogNo ratings yet

- Trevithick Steam Locomotive 1805Document6 pagesTrevithick Steam Locomotive 1805АленаNo ratings yet

- Ose 1 Vertical Ose Beginner 1 Ok PDFDocument1 pageOse 1 Vertical Ose Beginner 1 Ok PDFAnonymous MMLzZjbyNo ratings yet

- Top View: Rtefer To Modelbouwer Magazine (S) October and November 1987 For DescriptionDocument4 pagesTop View: Rtefer To Modelbouwer Magazine (S) October and November 1987 For DescriptionLe TruongNo ratings yet

- (Hoccokhi - VN) Bai Tap Lap Rap Solidworks 2dongco NgangDocument4 pages(Hoccokhi - VN) Bai Tap Lap Rap Solidworks 2dongco NgangChien Dang VanNo ratings yet

- Maquina 34 PDFDocument3 pagesMaquina 34 PDFEstefannyNo ratings yet

- Balancier Gerry Dykstra 09 05 02 PDFDocument9 pagesBalancier Gerry Dykstra 09 05 02 PDFLal Krrish MikeNo ratings yet

- Round 2 CombinedDocument18 pagesRound 2 Combinedapi-362416767No ratings yet

- Centrifugal Pump Engineering DrawinsDocument16 pagesCentrifugal Pump Engineering DrawinsLeandro LimaNo ratings yet

- Programacion de Llaves y Controles 2014 PDFDocument84 pagesProgramacion de Llaves y Controles 2014 PDFJulNo ratings yet

- General Arrangement, Isometric Engine Called "Trunch Trojan" (Imperial) View, Bill of Materials 1-Cylinder Double Sided Beam SteamDocument4 pagesGeneral Arrangement, Isometric Engine Called "Trunch Trojan" (Imperial) View, Bill of Materials 1-Cylinder Double Sided Beam SteamOscar OsornoNo ratings yet

- Dokumen - Tips 1801 457 2019-04-14 2 Compound 1 42 Slide Valve Guide Bracket 1 Compound 2 01 CrankshaftDocument9 pagesDokumen - Tips 1801 457 2019-04-14 2 Compound 1 42 Slide Valve Guide Bracket 1 Compound 2 01 Crankshaftpercy obandoNo ratings yet

- Challenger Tractor MT700 Parts ManualDocument1,243 pagesChallenger Tractor MT700 Parts ManualkamilNo ratings yet

- BGRHHDocument3 pagesBGRHHShubham KalbhutNo ratings yet

- 4-Cylinder Oscillating Steam Engine Called "Simple" G.A., Isometric View, Bom, Notes, Parts and AssembliesDocument2 pages4-Cylinder Oscillating Steam Engine Called "Simple" G.A., Isometric View, Bom, Notes, Parts and AssembliesOrlando Rojas PintoNo ratings yet

- General Arrangement, Isometric 2X1 Cyl. Horizontal Steam Engines With View, Notes Rope Driven Generator (Rope Drive)Document5 pagesGeneral Arrangement, Isometric 2X1 Cyl. Horizontal Steam Engines With View, Notes Rope Driven Generator (Rope Drive)adil jabaroNo ratings yet

- General Arrangement A Simple Small Metalworking Shaper: JdwdsDocument7 pagesGeneral Arrangement A Simple Small Metalworking Shaper: JdwdsOscar Osorno100% (1)

- Carlos Manuel Estupiñan Cardenas - Luis Duin Armando MartinezDocument7 pagesCarlos Manuel Estupiñan Cardenas - Luis Duin Armando Martinezjhon freddy triana vargasNo ratings yet

- General Arrangement A Simple Small Metalworking Shaper: JdwdsDocument7 pagesGeneral Arrangement A Simple Small Metalworking Shaper: JdwdsPemesinan SMK Migas CepuNo ratings yet

- 6175 - Pimpri Chinchwad Education Trust, Pimpri Chinchwad College of Engineering, PuneDocument8 pages6175 - Pimpri Chinchwad Education Trust, Pimpri Chinchwad College of Engineering, PuneRushikesh KaleNo ratings yet

- Government of Maharashtra provisional allotment list for engineering admissionDocument8 pagesGovernment of Maharashtra provisional allotment list for engineering admissionShridhar ZambareNo ratings yet

- General Job Interview QuestionsDocument9 pagesGeneral Job Interview QuestionsfeketerigoNo ratings yet

- EXPERIMENTAL ANALYSIS OF SUBMERSIBLE PUMP PERFORMANCEDocument4 pagesEXPERIMENTAL ANALYSIS OF SUBMERSIBLE PUMP PERFORMANCEShridhar ZambareNo ratings yet

- HPCL ResumeDocument2 pagesHPCL Resumeshabaz3591No ratings yet

- Cap Project 1Document1 pageCap Project 1Shridhar ZambareNo ratings yet

- JDW Draughting Services Drawing Property and Contact DetailsDocument1 pageJDW Draughting Services Drawing Property and Contact DetailsShridhar ZambareNo ratings yet

- Water network design methodologyDocument2 pagesWater network design methodologyShridhar ZambareNo ratings yet

- SSC JE 2013 Answer KeyDocument1 pageSSC JE 2013 Answer KeyShridhar ZambareNo ratings yet

- Shridhar's ResumeDocument2 pagesShridhar's ResumeShridhar ZambareNo ratings yet

- Control de Invetario EXISTENCIASDocument9 pagesControl de Invetario EXISTENCIASgénesis puentesNo ratings yet

- Getgenuine Price GuideDocument2 pagesGetgenuine Price GuidejayNo ratings yet

- Alfa Romeo GiuliaDocument5 pagesAlfa Romeo GiuliakapetuszoNo ratings yet

- BOLETINDocument15 pagesBOLETINCarlos PeraltaNo ratings yet

- Suspension StoryDocument4 pagesSuspension StoryRandallCaulderNo ratings yet

- Eicher 11.14Document26 pagesEicher 11.14sanjuchn671100% (1)

- Isuzu D-Max Standard Crew Cabin Pickup 2Wd SR 2.5L MT / Iml 7035 DieselDocument5 pagesIsuzu D-Max Standard Crew Cabin Pickup 2Wd SR 2.5L MT / Iml 7035 DieselLESLEE PIOSNo ratings yet

- On Target (2019 - Vol. 1) Diagnostic FordDocument6 pagesOn Target (2019 - Vol. 1) Diagnostic FordcherokewagNo ratings yet

- Eng BBT 01-02-07 PDFDocument176 pagesEng BBT 01-02-07 PDFMadalin MugurelNo ratings yet

- Maruti Swift Engine Oil Change CircularDocument1 pageMaruti Swift Engine Oil Change Circularachilles7No ratings yet

- Kata LogDocument804 pagesKata LogAlex BancilaNo ratings yet

- KYOSHO Inferno Neo ST Race Spec ManualDocument32 pagesKYOSHO Inferno Neo ST Race Spec ManualMandu Ceriano100% (1)

- Bajaj GarageList (Updated 09.08.2012)Document336 pagesBajaj GarageList (Updated 09.08.2012)hide1234567890% (1)

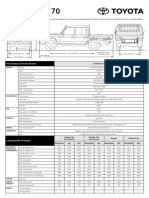

- LC70 - Spec SheetDocument2 pagesLC70 - Spec SheetRaka ajaNo ratings yet

- Ngk-Iridium Spark PlugsDocument1 pageNgk-Iridium Spark PlugsPradeep Kumar SwarnkarNo ratings yet

- DNY-Jan22 - 40%Document20 pagesDNY-Jan22 - 40%R NovNo ratings yet

- Changan 2014 Cx20 1.4L AMT Sunroof SpecsDocument6 pagesChangan 2014 Cx20 1.4L AMT Sunroof Specsrstec pyNo ratings yet

- Civic Dimension D17aDocument3 pagesCivic Dimension D17aYoshi VtecNo ratings yet

- Bosch Alternator Products ListDocument12 pagesBosch Alternator Products ListCTN2010No ratings yet

- Steals & Deals Central Edition 10-29-20Document12 pagesSteals & Deals Central Edition 10-29-20Roger WaynickNo ratings yet

- Final Research ProjectDocument84 pagesFinal Research ProjectPrathmesh ShuklaNo ratings yet

- BMW 318i 1985Document17 pagesBMW 318i 1985Piotr JaworskiNo ratings yet

- Harley-Davidson: Police Lighting & Warning ProductsDocument8 pagesHarley-Davidson: Police Lighting & Warning ProductsWira DarmawanNo ratings yet