Professional Documents

Culture Documents

Far Eastern University: Feuture Inc

Uploaded by

Jan GeleraOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Far Eastern University: Feuture Inc

Uploaded by

Jan GeleraCopyright:

Available Formats

FAR EASTERN UNIVERSITY

FEUture Inc.

Operations Management

MBA 703

FEU-Manila

Submitted by:

GROUP # 1

Reporting Group Reacting Group

LIM, SHIELLA

GELERA, JANUARY

TARUN, PATRICIA

MASTER OF BUSINESS ADMINISTRATION 1 | Page

FAR EASTERN UNIVERSITY

I. Case Background

FEUture Inc. decides to expand its product line by producing new plug-in 256

MB backup systems for Dell laptop computers. The goal for this new product is to

become cost leader and also to develop a new expertise in plug-ins. Management

aims to produce 1000 units every standard forty-hour workweek.

Engineers, production managers, and assembly line workers studied plug-in

system production and developed 25 different steps with respective task times

which are based on times of doing identical current tasks. It is given that time

estimates may be off by as much as 10 percent and that demand may change over

time. The following table shows the order and duration of each identified task:

Task Task Predecess

Time ors

A 1.00 None

B 0.40 A

C 0.45 A

D 1.10 A

E 0.36 A

F 0.05 None

G 1.32 B,C

H 0.49 C,D

I 0.54 E

J 1.54 E

K 0.35 F

L 2.10 G

M 0.30 H,I

N 1.82 I

O 0.89 J

P 1.20 L,M,N

Q 1.30 N,O

R 0.62 O

S 1.30 K

T 1.20 P,Q,R,S

MASTER OF BUSINESS ADMINISTRATION 2 | Page

FAR EASTERN UNIVERSITY

U 1.80 S

V 0.30 T

W 0.87 U

X 1.20 U

Y 1.90 V,W,X

II. Statement of the Problem

This study aims to answer the question:

What is the optimal design product layout for FEUture Inc.’s new product the

plug-in system?

III. Assumptions

The assumptions of this study are the following:

● FEUture Inc. has conducted a study that concludes beneficiary to the

company to expand its product line rather than just fix current financial

problems

● One worker is assigned per station

IV. Areas of Consideration

a. Human Resource and Development

● Employee current expertise is on hard disk systems

b. Operations

● The company has been manufacturing peripherals for

microcomputers for the past decade

● Time estimates may be off by as much as 10 percent

● Demand will change over time

● The company intends to become cost leader for plug-in systems

● The company intends to convert its hard disk expertise to plug-in

expertise

● Management targets to produce 1,000 units per week

MASTER OF BUSINESS ADMINISTRATION 3 | Page

FAR EASTERN UNIVERSITY

● Current operations use a standard forty-hour week, and the

operations vice-president insists that this be maintained for the new

product

c. Finance

● There has been a recent slump in sales with the current products

● The company intends to become cost leader for plug-in systems

● Management decided to target only 1,000 units per week

d. Marketing

● The company intends to become cost leader for plug-in systems

● It is projected that 60,000 units per years is a reasonable sales goal

e. IT / R & D Business Development etc.

● The company intends to convert its hard disk expertise to plug-in

expertise

MASTER OF BUSINESS ADMINISTRATION 4 | Page

FAR EASTERN UNIVERSITY

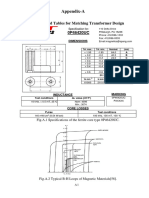

V. Framework

Precedence Diagram

MASTER OF BUSINESS ADMINISTRATION 5 | Page

FAR EASTERN UNIVERSITY

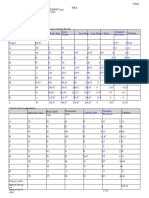

Line Balancing

Task Task time (in No. of Positional

mins) following weights

tasks

A 1 18 0

E 0.36 11 0.00

C 0.45 8 9.26

F 0.05 8 8.97

K 0.35 7 8.92

I 0.54 7 8.56

S 1.3 6 8.57

B 0.4 6 8.42

J 1.54 6 7.75

D 1.1 6 6.49

G 1.32 5 8.02

N 1.82 5 7.72

O 0.89 5 6.21

H 0.49 5 5.39

L 2.1 4 6.70

M 0.3 4 4.90

U 1.8 3 5.77

Q 1.3 3 4.70

P 1.2 3 4.60

R 0.62 3 4.02

T 1.2 2 0.00

X 1.2 1 3.10

W 0.87 1 2.77

V 0.3 1 2.20

Y 1.9 0 0.00

Total 24.4

MASTER OF BUSINESS ADMINISTRATION 6 | Page

FAR EASTERN UNIVERSITY

Computations:

a. Cycle time

CT = OT/D

= 40/1000

= 0.04 hours or 2.4 mins

b. Minimum number of Workstations

N = ∑t /CT

= 24.4/2.4

= 10.167 ≈ 11 workstations

Workstation Task Assigning

Using both the rules of most following tasks and positional weights, two

variations of workstation assignments can be generated. The only difference is the

workstation assignment of task V where in the first setup it is in station 10 and in

the second in the 11th station.

Assignment A

Station Time Remaining Assign Task Revised Time Remaining Idle Time

1 2.40 A 1.40

1.40 E 1.04

1.04 C 0.59

0.59 F 0.54

0.54 I 0.00 0.00

2 2.40 K 2.05

2.05 J 0.51

0.51 B 0.11

0.11 - - 0.11

3 2.40 S 1.10

1.10 D 0.00 0.00

4 2.40 G 1.08

MASTER OF BUSINESS ADMINISTRATION 7 | Page

FAR EASTERN UNIVERSITY

1.08 O 0.19

0.19 - - 0.19

5 2.40 N 0.58

0.58 H 0.09

0.49 - - 0.09

6 2.40 L 0.30

0.30 M 0.00 0.00

7 2.40 U 0.60

0.60 - - 0.60

8 2.40 Q 1.10

1.10 R 0.48

0.48 - - 0.48

9 2.40 P 1.20

1.20 T 0.00 0.00

10 2.40 X 1.20

1.20 W 0.33

0.33 V 0.03

0.03 - - 0.03

11 2.40 Y 0.50

0.50 - - 0.50

TOTAL IDLE 2

Assignment B

Station Time Remaining Assign Task Revised Time Remaining Idle Time

1 2.4 A 1.4

1.4 E 1.04

1.04 F 0.99

0.99 C 0.54

0.54 I 0 0

2 2.4 K 2.05

2.05 B 1.65

1.65 J 0.11

0.11 - - 0.11

3 2.4 D 1.3

1.3 S 0 0

4 2.4 G 1.08

MASTER OF BUSINESS ADMINISTRATION 8 | Page

FAR EASTERN UNIVERSITY

1.08 O 0.19

0.19 - - 0.19

5 2.4 N 0.58

0.58 H 0.09

0.09 - - 0.09

6 2.4 L 0.3

0.3 M 0 0

7 2.4 U 0.6

0.6 - - 0.6

8 24 Q 1.1

1.1 R 0.48

0.48 - - 0.48

9 2.4 P 1.2

1.2 T 0 0

10 2.4 X 1.2

1.2 W 0.33

0.33 - - 0.33

11 2.4 V 2.1

2.1 Y 0.2

0.2 - - 0.2

TOTAL IDLE TIME 2

The total idle time for both task groupings is the same with 2 minutes idle

time. Subsequently, the balance delay or percent idle time is also equal.

Computation is shown below.

Balance delay = Total idle time/ (N)(CT)

= 2 / (11*2.4)

= 0.076 or 7.6%

With this, the efficiency of both setups is:

Efficiency = 1 – 0.076

= 0.924 or 92.4%

The following graphs show plotting of consumed times per workstation

MASTER OF BUSINESS ADMINISTRATION 9 | Page

FAR EASTERN UNIVERSITY

for the 2 assignments:

Assignment 1

3

2.5

1.5

0.5

0

1 2 3 4 5 6 7 8 9 10 11

Assignment 2

3

2.5

1.5

0.5

0

1 2 3 4 5 6 7 8 9 10 11

MASTER OF BUSINESS ADMINISTRATION 10 | Page

FAR EASTERN UNIVERSITY

Smoothing Efficiency

Smoothing efficiency was also computed to compare the 2 groupings. The

lower the smoothing efficiency value using idle time, the better the line balancing.

Smoothing efficiency is computed as:

Smoothing Efficiency = √ ¿ ¿

Assignment 1 Assignment 2

Station Idle Time IT^2 Station Idle Time IT^2

1 0.00 0.00 1 0.00 0.00

2 0.11 0.01 2 0.11 0.01

3 0.00 0.00 3 0.00 0.00

4 0.19 0.04 4 0.19 0.04

5 0.09 0.01 5 0.09 0.01

6 0.00 0.00 6 0.00 0.00

7 0.60 0.36 7 0.60 0.36

8 0.48 0.23 8 0.48 0.23

9 0.00 0.00 9 0.00 0.00

10 0.03 0.00 10 0.33 0.11

11 0.50 0.25 11 0.20 0.04

Sum 0.90 Sum 0.80

Smoothin 0.95 Smoothing 0.89

g Efficiency

Efficiency

VI. Alternative Courses of Action (at least 4)

Advantages:

Disadvantages:

MASTER OF BUSINESS ADMINISTRATION 11 | Page

FAR EASTERN UNIVERSITY

VII. Action Plans

Activity Responsible Person/s, or Timeline

Department/s, Team/s, etc

VIII.Recommendation

MASTER OF BUSINESS ADMINISTRATION 12 | Page

FAR EASTERN UNIVERSITY

IX. Conclusion

MASTER OF BUSINESS ADMINISTRATION 13 | Page

You might also like

- Jose Rizal Heavy BombersDocument12 pagesJose Rizal Heavy BombersKYN KIETH PAMA100% (3)

- 2 - (Ebook Trading) Williams, Larry - The Secret of Selecting Stocks For Immediate and Substantial GainsDocument131 pages2 - (Ebook Trading) Williams, Larry - The Secret of Selecting Stocks For Immediate and Substantial GainsviperunuNo ratings yet

- Service Provider Bond FormDocument2 pagesService Provider Bond FormlawrencelazerrickNo ratings yet

- IE MatrixDocument1 pageIE MatrixJan GeleraNo ratings yet

- Competitive Profiel MetrixDocument4 pagesCompetitive Profiel MetrixJan GeleraNo ratings yet

- Marketing ManagementDocument174 pagesMarketing ManagementTanmay ShuklaNo ratings yet

- Project: Cadangan Klinik Kesihatan 4 Dengan Kuarters, Pengkalan Hulu, Hulu Perak, Perak (Ibs Sepenuhnya)Document5 pagesProject: Cadangan Klinik Kesihatan 4 Dengan Kuarters, Pengkalan Hulu, Hulu Perak, Perak (Ibs Sepenuhnya)faiz salimNo ratings yet

- Coffee Shop Preferences Among Engineering Students in Roxas City Insight To Customer Buying BehaviorDocument25 pagesCoffee Shop Preferences Among Engineering Students in Roxas City Insight To Customer Buying BehaviorJethro Mathew AstrosNo ratings yet

- Project Managment Assignment 2Document11 pagesProject Managment Assignment 2Darragh RossNo ratings yet

- Discrete Cosine Transform: Algorithms, Advantages, ApplicationsFrom EverandDiscrete Cosine Transform: Algorithms, Advantages, ApplicationsNo ratings yet

- Impact of JetDocument8 pagesImpact of JetbandarNo ratings yet

- Contingency Theory of LeadershipDocument37 pagesContingency Theory of LeadershipJan Gelera100% (1)

- 2009 - Prof Eng - WWTP Design ExcelDocument9 pages2009 - Prof Eng - WWTP Design ExcelLinh PhamNo ratings yet

- Final Exam 1st Semester 2018Document6 pagesFinal Exam 1st Semester 2018SHEREE BLAKENo ratings yet

- Mckinsey China Consumer Report 2021Document158 pagesMckinsey China Consumer Report 2021brianNo ratings yet

- Case #5: Feuture, Inc.: Far Eastern UniversityDocument9 pagesCase #5: Feuture, Inc.: Far Eastern UniversityEly CasugaNo ratings yet

- Case: Feuture, Inc.: Far Eastern UniversityDocument11 pagesCase: Feuture, Inc.: Far Eastern UniversityAmro Ahmed RazigNo ratings yet

- MBRF10200CT SangdestmicroelectronicsDocument7 pagesMBRF10200CT SangdestmicroelectronicsАлексей ГомоновNo ratings yet

- Line Balancing ExampleDocument1 pageLine Balancing ExampleKathryn SantosNo ratings yet

- Murb1060Ct Ultrafast Plastic Rectifier: Sangdest Microelectronics Green ProductsDocument5 pagesMurb1060Ct Ultrafast Plastic Rectifier: Sangdest Microelectronics Green ProductsJOHN BRICCO A. MATACSILNo ratings yet

- Libro 1Document2 pagesLibro 1Brando Kevin Palomino MorenoNo ratings yet

- MGT 3110: Exam 3 Study Guide Discussion QuestionsDocument13 pagesMGT 3110: Exam 3 Study Guide Discussion QuestionsSihle GwazelaNo ratings yet

- Assignment 2 OMDocument2 pagesAssignment 2 OMKirti SainiNo ratings yet

- QBA (Class Test) Autumn 2020Document1 pageQBA (Class Test) Autumn 2020Nusrat IslamNo ratings yet

- Exercises 4 ProgramDocument5 pagesExercises 4 ProgramScribdTranslationsNo ratings yet

- INdu ASDocument7 pagesINdu ASbelaynehNo ratings yet

- Caseres VentiDocument3 pagesCaseres VentiVan Eldridge Kyle CaseresNo ratings yet

- Mbr1060Ctl Schottky Rectifier: Sangdest Microelectronics Green ProductsDocument6 pagesMbr1060Ctl Schottky Rectifier: Sangdest Microelectronics Green ProductsManos MagicasNo ratings yet

- Smartchem Gopalpur - Report - ILPLT - TP-2 - DT 07.11.2022 SubmissionDocument11 pagesSmartchem Gopalpur - Report - ILPLT - TP-2 - DT 07.11.2022 Submissionram.deshpandeNo ratings yet

- SorptionDocument19 pagesSorptionROMELIE GABALLO ALBIANo ratings yet

- Exercises On ELECTRICAL MACHINESDocument29 pagesExercises On ELECTRICAL MACHINESDavide100% (1)

- Evaco 2 FDocument5 pagesEvaco 2 Fsahil gohadNo ratings yet

- PM Assignment TwoDocument15 pagesPM Assignment TwoGonzalo MoyaNo ratings yet

- Sweta Bharti Pgma2053 OmDocument9 pagesSweta Bharti Pgma2053 OmRiddhi GuptaNo ratings yet

- Hariff Power Services - MidTerm Case OSCM - Farabi Muhammad Mahdy - 29120254Document7 pagesHariff Power Services - MidTerm Case OSCM - Farabi Muhammad Mahdy - 29120254rizqighaniNo ratings yet

- Yarmouk University Civil Engineering Department Fluid Mechanics and Hydraulic Laboratory CE 354Document10 pagesYarmouk University Civil Engineering Department Fluid Mechanics and Hydraulic Laboratory CE 354Mohammed MigdadyNo ratings yet

- Chapter 1 - IntroductionDocument31 pagesChapter 1 - IntroductionBùi Quang MinhNo ratings yet

- Model 9123: RevereDocument2 pagesModel 9123: RevereJuan Carlos BallinariNo ratings yet

- Thermofluids Lab 1-Force Due To Jet AbeebDocument16 pagesThermofluids Lab 1-Force Due To Jet AbeebFajobi AbeebNo ratings yet

- MBR10150CT/MBRB10150CT/MBR10150CT-1 Schottky Rectifier: Sangdest MicroelectronicsDocument6 pagesMBR10150CT/MBRB10150CT/MBR10150CT-1 Schottky Rectifier: Sangdest MicroelectronicsJOHN BRICCO A. MATACSILNo ratings yet

- Two Stage Evaporator: InputsDocument5 pagesTwo Stage Evaporator: InputsHina JagnikNo ratings yet

- Lab 4 SpecunknownDocument4 pagesLab 4 Specunknownapi-436054247No ratings yet

- 5535 Chapter 19Document56 pages5535 Chapter 19ChunTing LinNo ratings yet

- Spaulding Lighting Burlington II Floodlight Spec Sheet 4-86Document2 pagesSpaulding Lighting Burlington II Floodlight Spec Sheet 4-86Alan MastersNo ratings yet

- Exercises On Process Layout & Product LayoutDocument4 pagesExercises On Process Layout & Product Layoutjanhabi.s25No ratings yet

- DCD1 Tutorial 1 SolutionsDocument5 pagesDCD1 Tutorial 1 SolutionsChristopher RileyNo ratings yet

- IVDocument2 pagesIV12TĐ15 Bạch Long VĩNo ratings yet

- Balance of Lines Using Incremental Utilization HeuristicsDocument2 pagesBalance of Lines Using Incremental Utilization HeuristicsRaymundo VargasNo ratings yet

- Chap8 EEDDocument38 pagesChap8 EEDKhanh NguyenNo ratings yet

- Final Exam Prep OpsDocument9 pagesFinal Exam Prep OpsadarshNo ratings yet

- Experiment 7Document9 pagesExperiment 7MahmoudSehweilNo ratings yet

- Om 3Document1 pageOm 3VaibhavrvNo ratings yet

- Module/submodel: Project Management (PERT/CPM) Problem Title: (Untitled) Method: Triple Time Estimate Network Type: Immediate Predecessor ListDocument2 pagesModule/submodel: Project Management (PERT/CPM) Problem Title: (Untitled) Method: Triple Time Estimate Network Type: Immediate Predecessor Listsriram kumarNo ratings yet

- Aggregate Planning FinalDocument12 pagesAggregate Planning FinalDewashish RaiNo ratings yet

- Part Number 2875 - 2820, Tapered Roller Bearings - TS (Tapered Single) ImperialDocument5 pagesPart Number 2875 - 2820, Tapered Roller Bearings - TS (Tapered Single) ImperialGỗ MộcNo ratings yet

- MBR10100 MBRB10100 N0751 Rev.Document5 pagesMBR10100 MBRB10100 N0751 Rev.Gabriel RochaNo ratings yet

- Developing The "Right" Modularization Decisions For Mining Modules in ChinaDocument28 pagesDeveloping The "Right" Modularization Decisions For Mining Modules in ChinaKhaled GameaNo ratings yet

- Appendix ADocument3 pagesAppendix ANaeemo IraqiNo ratings yet

- Different Approaches For The Determination of Degradation Rates in PEMFC Durability TestsDocument23 pagesDifferent Approaches For The Determination of Degradation Rates in PEMFC Durability TestsAndreas FriedrichNo ratings yet

- KBU4,6,8/RS6 SERIES: Single-Phase Silicon Bridge Reverse Voltage - Forward CurrentDocument3 pagesKBU4,6,8/RS6 SERIES: Single-Phase Silicon Bridge Reverse Voltage - Forward CurrentНиколайNo ratings yet

- Desgin The Sewers in The Selected Street Below:: ExampleDocument6 pagesDesgin The Sewers in The Selected Street Below:: Exampleashraf refaatNo ratings yet

- JMI Submersible Pumps: Performance CurveDocument3 pagesJMI Submersible Pumps: Performance CurveBasabRajNo ratings yet

- Question: From The Following Data, Perform A Sensitivity Ana..Document5 pagesQuestion: From The Following Data, Perform A Sensitivity Ana..Muhammad WaqasNo ratings yet

- BBSDocument3 pagesBBSTheTaju RgNo ratings yet

- Mbrf2080Ctl Schottky Rectifier: ApplicationsDocument5 pagesMbrf2080Ctl Schottky Rectifier: Applicationsmalucos123No ratings yet

- PERT Complete ExersicesDocument18 pagesPERT Complete ExersicesUmair MansoorNo ratings yet

- Data Hidrogeo DebitDocument6 pagesData Hidrogeo DebitMahwarti Novelli PurbaNo ratings yet

- 19bme1186 FM Ex 8Document5 pages19bme1186 FM Ex 8Koushik Ch 19BME1186No ratings yet

- Determination of Major Loss Through A Single Pipe FlowDocument5 pagesDetermination of Major Loss Through A Single Pipe FlowKoushik Ch 19BME1186No ratings yet

- Pengujian SumurDocument16 pagesPengujian Sumurmuhammad taufikNo ratings yet

- Shawn VijDocument2 pagesShawn VijJan GeleraNo ratings yet

- Strategy EvaluationDocument6 pagesStrategy EvaluationJan Gelera100% (1)

- Jonathan HaidtDocument2 pagesJonathan HaidtJan GeleraNo ratings yet

- IFE MatrixDocument3 pagesIFE MatrixJan Gelera0% (1)

- Internal Strategy Position External Strategy Position X Axis 3.2 Y Axis 0.8Document1 pageInternal Strategy Position External Strategy Position X Axis 3.2 Y Axis 0.8Jan GeleraNo ratings yet

- BCG Matrix Relative Market ShareDocument2 pagesBCG Matrix Relative Market ShareJan Gelera100% (1)

- Explain How To Conduct An External Strategic-Management AuditDocument7 pagesExplain How To Conduct An External Strategic-Management AuditJan GeleraNo ratings yet

- Jan Assignment 6Document3 pagesJan Assignment 6Jan GeleraNo ratings yet

- Measurement in ResearchDocument36 pagesMeasurement in ResearchJan GeleraNo ratings yet

- N J Pandya Accounting Outsourcing Services PresentationDocument3 pagesN J Pandya Accounting Outsourcing Services PresentationNiks pandyaNo ratings yet

- Impairment of ReceivablesDocument15 pagesImpairment of ReceivablesNicole Daphne FigueroaNo ratings yet

- As A Preliminary To Requesting Budget Estimates of SalesDocument4 pagesAs A Preliminary To Requesting Budget Estimates of SalesChiodos OliverNo ratings yet

- Lesson 1 - Business Organization - Graphic Organizer - DukeDocument31 pagesLesson 1 - Business Organization - Graphic Organizer - DukeRowena ManuelNo ratings yet

- Mergers and AcquisitionsDocument123 pagesMergers and AcquisitionsAshi RohraNo ratings yet

- Dal455 - Ia FFM FWBDocument3 pagesDal455 - Ia FFM FWBnaumanazam32No ratings yet

- Improving Cash and Working Capital ManagementDocument4 pagesImproving Cash and Working Capital Managementlehandri losperNo ratings yet

- Heavy Lift 25 Ton Rod Hook Operators Manual: ContentDocument6 pagesHeavy Lift 25 Ton Rod Hook Operators Manual: ContentMateo PorrasNo ratings yet

- 4.1 E Varun Beverages LTDDocument22 pages4.1 E Varun Beverages LTDChanchal MadankarNo ratings yet

- Thesis On Youth EntrepreneurshipDocument7 pagesThesis On Youth Entrepreneurshipbrookecurtiscolumbia100% (2)

- SEIKO INTERNAL SALES FOR SEIKO Manufacturing (Singapore) Pte. LTDDocument1 pageSEIKO INTERNAL SALES FOR SEIKO Manufacturing (Singapore) Pte. LTDFaezah RosliNo ratings yet

- Issue Analysis Group 2Document16 pagesIssue Analysis Group 2anamargaridajoaquim66No ratings yet

- ts16949 2002 ChecklistDocument44 pagests16949 2002 Checklistcover filterNo ratings yet

- CH 15 TaxationDocument10 pagesCH 15 Taxationparam ambaliaNo ratings yet

- IUBAT-International University of Business Agriculture and TechnologyDocument7 pagesIUBAT-International University of Business Agriculture and Technologytaniya rahmanNo ratings yet

- 41 Verified Email ListDocument2 pages41 Verified Email ListprodipNo ratings yet

- Transaction History - IB Payroll3269 - 592023195937Document4 pagesTransaction History - IB Payroll3269 - 592023195937Satria NugrahaNo ratings yet

- FRM 5 Market Risk Related RisksDocument38 pagesFRM 5 Market Risk Related RisksLoraNo ratings yet

- ERP IntroDocument27 pagesERP IntroSraVanKuMarThadakamallaNo ratings yet

- Practice Final Test.Document7 pagesPractice Final Test.SVGNo ratings yet

- Institutions, Institutional Change, and Economic PerformanceDocument6 pagesInstitutions, Institutional Change, and Economic PerformancePaula MartinezNo ratings yet

- Working Capital Management: Answers To End-Of-Chapter QuestionsDocument27 pagesWorking Capital Management: Answers To End-Of-Chapter QuestionsMiftahul FirdausNo ratings yet

- Huc Acc201-Revision Questions May Intake, 2022Document29 pagesHuc Acc201-Revision Questions May Intake, 2022Sritel Boutique HotelNo ratings yet