Professional Documents

Culture Documents

Inspection and Test Plan For Steel Structure

Uploaded by

eva maniceOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Inspection and Test Plan For Steel Structure

Uploaded by

eva maniceCopyright:

Available Formats

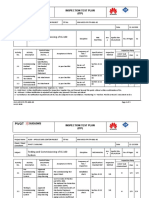

INSPECTION AND TEST PLAN FOR STEEL STRUCTURE

Project Name : Gardu Induk 150KV/275KV Wotu Legend : Prepared by Approved by Page : 2 of 3

Customer : PT. Kelinci Mas Unggul H : Hold Point PT. Anugerah Perkasa Konstruksi Plus PT. Kelinci Mas Unggul PLN Doc.No.: IX-36-QC-20-KMU-001

Project Code : APKP/IX.19/36 W : Witness Point Rev. No. Date

Owner : PT. PLN (Persero) SW : Spot Witness Point 0 21/09/2020

Description : Fabrication of Steel Structure R : Review

( Support, Tower, Beam Gantry ) M : Monitor

X : Responsibility

Description of Inspection Reference Aceptance Record Inspection Mode

No REMARKS

Activities Document Criteria VENDOR CONTRACTOR PLN

1.0 MATERIALS

1.1 Review of Mill,Test Certificate & Conformance to Code Client spec. Standart Mill Cert. X R R

1.2 Check visual,dimensional and thickness ASTM/JIS Standart Mill Cert. X R R

1.3 Mechanical test for material steel and bolt Client spec. Standart Test Report X W W

2.0 FABRICATION

2.1 Cutting

Check dimension,visual and identification Drawing Drawing Insp. Report X R R

2.2 Marking

Check mark of material ( hard stamp ) Drawing Drawing Insp. Report X R R

2.3 Drilling

Check location of hole centre & hole diameter Drawing Drawing Insp. Report X R R

2.4 Fit up

Check preparation of joint ( dimension, gap, Drawing Drawing Insp. Report X R R

squareness) of parts

2.5 Welding

Check of welding visual ( cleaning surface of welding, AWS D1.1 AWS D1.1 Insp. Report X SW SW

defect of visual welding & thickness of filled weld )

2.6 Finishing

Check dimension,visual and identification Drawing Drawing Insp. Report X R R

2.7 Trial Assembly

Check trial assembly for Post Tower and Beam in full Drawing Drawing Insp. Report X W W

body assembly horizontal position

Check trial assembly for HV Support in full body Drawing Drawing Insp. Report X W W

assembly vertical position

3.0 FINAL INSPECTION

Check dimension Drawing Drawing Insp. Report X W W

Check branch connection elevation & squareness

Check component completion

4.0 GALVANIZING

- 100 % visual check Client spec. ISO 1461 Insp. Report X SW SW

- thicknes of coating check ( random by elcometer ) ASTM A 123

5.0 FINAL CHECK ( After Galvaizing )

Visual check ( packing & protection )

Check material quantities & marks Pack List Pack List Insp. Report X M M

6.0 DOCUMENTATION

Preparing of reports Reporting X R R

You might also like

- Emergency Lighting Periodic Inspection - GreenDocument4 pagesEmergency Lighting Periodic Inspection - GreenjweremaNo ratings yet

- Daido Hydrodynamic BRG Material PDFDocument2 pagesDaido Hydrodynamic BRG Material PDFMachineryengNo ratings yet

- Iwp Cable Tray Installation Checklist: Appendix - 9Document3 pagesIwp Cable Tray Installation Checklist: Appendix - 9dennykvg0% (1)

- Ayala Triangle Gardens: Roughing Installation (Drop-Off Landscape Lightings)Document6 pagesAyala Triangle Gardens: Roughing Installation (Drop-Off Landscape Lightings)james alfarasNo ratings yet

- Fiber Optic Cable Splicing and Termination Test ReportDocument2 pagesFiber Optic Cable Splicing and Termination Test ReportBharathiNo ratings yet

- Site Test Report: 0 Doc No: RRVPNL - Doc-06 Rev.: ADocument8 pagesSite Test Report: 0 Doc No: RRVPNL - Doc-06 Rev.: AAkhileshkumar PandeyNo ratings yet

- Factory Acceptance Test Procedure For DCS - Part 6Document1 pageFactory Acceptance Test Procedure For DCS - Part 6kapsarcNo ratings yet

- Air Cooled Condensing Unit Checklist: Mr. Aden LiuDocument45 pagesAir Cooled Condensing Unit Checklist: Mr. Aden LiuADEN LIUNo ratings yet

- Distribution Panel Board Testing ChecklistDocument2 pagesDistribution Panel Board Testing ChecklistSumit SaurabhNo ratings yet

- EDO-PLN-QAC-GNR-INT-XXX-013-110-111-Rev-A.SAMPLE PROJECT QUALITY MANAGEMENT FOR STORAGE TANK PDFDocument31 pagesEDO-PLN-QAC-GNR-INT-XXX-013-110-111-Rev-A.SAMPLE PROJECT QUALITY MANAGEMENT FOR STORAGE TANK PDFErol DAĞNo ratings yet

- Itp Electrical SwitchgearDocument4 pagesItp Electrical SwitchgearpertmasterNo ratings yet

- ChecklistDocument8 pagesChecklistSrikar Reddy GummadiNo ratings yet

- Quality PlanDocument40 pagesQuality PlanSakthi Kasi RajanNo ratings yet

- Method Statement FOR Testing and Commissioning: Grounding SystemDocument3 pagesMethod Statement FOR Testing and Commissioning: Grounding SystemNon Etabas Gadnatam100% (1)

- Technical Proposal: BKT Wellhead PlatformDocument43 pagesTechnical Proposal: BKT Wellhead PlatformMaina MathengeNo ratings yet

- Factory Acceptance Test Procedure For DCS - Page 5Document2 pagesFactory Acceptance Test Procedure For DCS - Page 5kapsarcNo ratings yet

- Electrical Inspection and Test PlanDocument1 pageElectrical Inspection and Test PlanJames Pol JumarangNo ratings yet

- Seeion No. Session Title Date From To Chair Paper No. Presetation ID Paper Title SpeakerDocument4 pagesSeeion No. Session Title Date From To Chair Paper No. Presetation ID Paper Title SpeakerSERRA DANIŞ100% (1)

- ITP - Fiber Optic CableDocument2 pagesITP - Fiber Optic CableRamy AiadNo ratings yet

- Global Power Test Sdn. Bhd. Site Acceptance Test Report: Testing of 415V LV Switchgear PanelDocument10 pagesGlobal Power Test Sdn. Bhd. Site Acceptance Test Report: Testing of 415V LV Switchgear PanelTHULASI RAMNo ratings yet

- Attachment 12.5 - QA - QC Checklist - SMDBDocument6 pagesAttachment 12.5 - QA - QC Checklist - SMDBehteshamNo ratings yet

- Itr Ew 05a - EngDocument1 pageItr Ew 05a - Engwassim nasriNo ratings yet

- QM Plan ProcedureDocument13 pagesQM Plan ProcedureHans JonesNo ratings yet

- ChecklistDocument35 pagesChecklistShashi Kant Singh100% (1)

- Minor Electrical Installation Works - RedDocument2 pagesMinor Electrical Installation Works - RedSeby SebastianNo ratings yet

- MOS-Construction of OHTL From SS 8768 Layla PVDocument45 pagesMOS-Construction of OHTL From SS 8768 Layla PVEngr Muhammad Azam ThaheemNo ratings yet

- A Qac Pro 000 38951Document30 pagesA Qac Pro 000 38951Amin GNo ratings yet

- Dokgoro K1785 Method StatementDocument6 pagesDokgoro K1785 Method StatementJackie van SchalkwykNo ratings yet

- ELECT-TIC-1.4 (Backfilling and Concrete Tile Installation)Document2 pagesELECT-TIC-1.4 (Backfilling and Concrete Tile Installation)Muhammad Irfan100% (1)

- CHECKLIST For Installation of Electrical UPVC DuctsDocument1 pageCHECKLIST For Installation of Electrical UPVC DuctskevinNo ratings yet

- 16126Document13 pages16126uddinnadeemNo ratings yet

- Transformer Method StatementDocument13 pagesTransformer Method StatementHareesh R IyerNo ratings yet

- Earthing and Bonding Method StatementDocument4 pagesEarthing and Bonding Method StatementMusthafa Shaik100% (1)

- Record No.: Equip. No. Drawing Ref.: Sheet: Contractor: Contract No.: Substation NoDocument2 pagesRecord No.: Equip. No. Drawing Ref.: Sheet: Contractor: Contract No.: Substation NoDinesh Pitchaivel100% (1)

- Testing and Commissioning Procedure No 6 - Low Voltage Cubicle SwitchboardDocument23 pagesTesting and Commissioning Procedure No 6 - Low Voltage Cubicle SwitchboardknsbNo ratings yet

- 13 Fan Coil Unit: Location: - No.Document1 page13 Fan Coil Unit: Location: - No.JIJUNo ratings yet

- PSK Checklist New Elec E01 - 18 HT CablingDocument1 pagePSK Checklist New Elec E01 - 18 HT CablingBAHARUDIN BURAHNo ratings yet

- QCS 2010 Section 28 Part 2Document38 pagesQCS 2010 Section 28 Part 2Saif Abdulla0% (1)

- Anchr Bolt RefDocument9 pagesAnchr Bolt ReferleosNo ratings yet

- SS04 CH01 - 48V BDT Transducer SAT FormatDocument74 pagesSS04 CH01 - 48V BDT Transducer SAT FormatshameemindiaNo ratings yet

- Inspection and Tests Plan: OPGW 60mm, 24coresDocument3 pagesInspection and Tests Plan: OPGW 60mm, 24coresErika Rafani WibowoNo ratings yet

- DSB 95 6 Substation Installation RequirementsDocument40 pagesDSB 95 6 Substation Installation RequirementscesartovarNo ratings yet

- Roxas Substation Pert-CpmDocument1 pageRoxas Substation Pert-CpmJohn Paul AlbanezNo ratings yet

- ITP-Line Hardware - Sample Test PDFDocument3 pagesITP-Line Hardware - Sample Test PDFPrabhakar Sv100% (1)

- Epic For Upgradation of Ac Ups Units in Ngl3, Mesaieed: Result Checklist Description Remarks ItemDocument1 pageEpic For Upgradation of Ac Ups Units in Ngl3, Mesaieed: Result Checklist Description Remarks ItemmeeNo ratings yet

- IMS 448-EQCL - Transformer Installation Checklist Rev01Document1 pageIMS 448-EQCL - Transformer Installation Checklist Rev01zhangjieNo ratings yet

- Checklist For CablesDocument4 pagesChecklist For Cablesmilton1987No ratings yet

- ESPDocument23 pagesESPkarthikraja21No ratings yet

- Epic For Upgradation of Ac Ups Units in Ngl3, Mesaieed: Result Remarks Checklist Description ItemDocument1 pageEpic For Upgradation of Ac Ups Units in Ngl3, Mesaieed: Result Remarks Checklist Description ItemmeeNo ratings yet

- Testing and Commissioning of IG 100 System: Inspection Test Plan (ITP)Document3 pagesTesting and Commissioning of IG 100 System: Inspection Test Plan (ITP)Samboy DionisioNo ratings yet

- Project: Instrument Junction Box InstallationDocument2 pagesProject: Instrument Junction Box InstallationAhmad DagamsehNo ratings yet

- ITP For Testing and Commissioning of ACSDocument1 pageITP For Testing and Commissioning of ACSRommel Espinosa ParasNo ratings yet

- Itp Package UnitDocument2 pagesItp Package UnitWasim AhmedNo ratings yet

- ACI 207.1R-96 Mass ConcreteDocument42 pagesACI 207.1R-96 Mass ConcreteAc2140No ratings yet

- In Amenas Compression Project Fire Equipment FAT ProcedureDocument8 pagesIn Amenas Compression Project Fire Equipment FAT ProcedureDaoued HaouesNo ratings yet

- Commissioning Standard Test FormatsDocument2 pagesCommissioning Standard Test FormatstajudeenNo ratings yet

- Raychem Screened, Separable Connection System RSTI-68 800 A Up To 42 KVDocument4 pagesRaychem Screened, Separable Connection System RSTI-68 800 A Up To 42 KVgiovany_vq91No ratings yet

- Mar HM 18.06.22Document302 pagesMar HM 18.06.22özgen bölükNo ratings yet

- Inspection Testing Plan (ITP)Document1 pageInspection Testing Plan (ITP)Kdown 99100% (1)

- MDR C40 Pt. DmiDocument14 pagesMDR C40 Pt. DmiwidiNo ratings yet

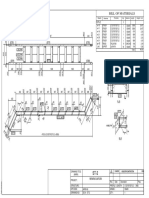

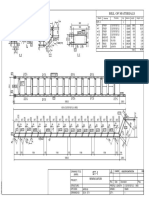

- A-39 - BRC - Rev 0Document1 pageA-39 - BRC - Rev 0eva maniceNo ratings yet

- Inspection and Test Plan: Start IncomingDocument1 pageInspection and Test Plan: Start Incomingeva maniceNo ratings yet

- ITP1Document1 pageITP1eva maniceNo ratings yet

- Factory Acceptance Test Procedure for Steel Structure HV Equipment SupportDocument1 pageFactory Acceptance Test Procedure for Steel Structure HV Equipment Supporteva maniceNo ratings yet

- FAT2Document1 pageFAT2eva maniceNo ratings yet

- A-12 - BRC - Rev 0Document1 pageA-12 - BRC - Rev 0eva maniceNo ratings yet

- A-42 - V.BRC - Rev 0Document1 pageA-42 - V.BRC - Rev 0eva maniceNo ratings yet

- A-41 - A-PLATE - Rev 0Document1 pageA-41 - A-PLATE - Rev 0eva maniceNo ratings yet

- A-40 - ASSY HOR - Rev 0Document1 pageA-40 - ASSY HOR - Rev 0eva maniceNo ratings yet

- TS-SP-1 - SPLITZENT - Rev 0Document1 pageTS-SP-1 - SPLITZENT - Rev 0eva maniceNo ratings yet

- A-11 - BRC - Rev 0Document1 pageA-11 - BRC - Rev 0eva maniceNo ratings yet

- A-13 - HOR - Rev 0Document1 pageA-13 - HOR - Rev 0eva maniceNo ratings yet

- A-9 - V.BRC - Rev 0Document1 pageA-9 - V.BRC - Rev 0eva maniceNo ratings yet

- A-10 - H.BRC - Rev 0Document1 pageA-10 - H.BRC - Rev 0eva maniceNo ratings yet

- TS-SL-1 - POST - Rev 0Document1 pageTS-SL-1 - POST - Rev 0eva maniceNo ratings yet

- TS-SL-2 - ASSY SOLAR CEL - Rev 0Document1 pageTS-SL-2 - ASSY SOLAR CEL - Rev 0eva maniceNo ratings yet

- TS-SL-1 - POST - Rev 0Document1 pageTS-SL-1 - POST - Rev 0eva maniceNo ratings yet

- BD-1 - ASSY BORDES - Rev 0Document1 pageBD-1 - ASSY BORDES - Rev 0eva maniceNo ratings yet

- ST-2 - ASSY STAIR - Rev 0Document1 pageST-2 - ASSY STAIR - Rev 0eva maniceNo ratings yet

- ST-2 - ASSY STAIR - Rev 0Document1 pageST-2 - ASSY STAIR - Rev 0eva maniceNo ratings yet

- ST-1 - ASSY STAIR - Rev 0Document1 pageST-1 - ASSY STAIR - Rev 0eva maniceNo ratings yet

- ST-2 - ASSY STAIR - Rev 0Document1 pageST-2 - ASSY STAIR - Rev 0eva maniceNo ratings yet

- BD-3 - ASSY BORDES - Rev 0Document1 pageBD-3 - ASSY BORDES - Rev 0eva maniceNo ratings yet

- HR-2 - ASSY HANDRAIL - Rev 0Document1 pageHR-2 - ASSY HANDRAIL - Rev 0eva maniceNo ratings yet

- Bill of Materials StructureDocument1 pageBill of Materials Structureeva maniceNo ratings yet

- Factory Inspection Test Record:: APAJ/VI.20/66Document1 pageFactory Inspection Test Record:: APAJ/VI.20/66eva maniceNo ratings yet

- HR-3 - ASSY HANDRAIL - Rev 0Document1 pageHR-3 - ASSY HANDRAIL - Rev 0eva maniceNo ratings yet

- Factory Inspection Test Record:: APAJ/VI.20/66Document1 pageFactory Inspection Test Record:: APAJ/VI.20/66eva maniceNo ratings yet

- Factory Inspection Test Record:: APAJ/VI.20/66Document1 pageFactory Inspection Test Record:: APAJ/VI.20/66eva maniceNo ratings yet

- Factory Inspection Record for Steel Structure ProjectDocument1 pageFactory Inspection Record for Steel Structure Projecteva maniceNo ratings yet

- EVOH Review of Barrier Properties For Packaging Shelf Stable FoodsDocument11 pagesEVOH Review of Barrier Properties For Packaging Shelf Stable FoodsAriane Victoria DantesNo ratings yet

- Concrete Formwork Loads and Pressure Calculations PDFDocument8 pagesConcrete Formwork Loads and Pressure Calculations PDFmohamed.s.elsayedNo ratings yet

- FM 200Document3 pagesFM 200raviNo ratings yet

- Wang 2007Document10 pagesWang 2007sri murti astutiNo ratings yet

- Product Range Watches and JewelleryDocument16 pagesProduct Range Watches and JewellerymlaorrcNo ratings yet

- Stabilization of Clay Soil Mixed With Wood AshDocument4 pagesStabilization of Clay Soil Mixed With Wood AshIvan Lee Lozano TorresNo ratings yet

- Dupont 6611Document3 pagesDupont 6611Joan GnanaoliNo ratings yet

- Examples 1Document5 pagesExamples 1Pornsawan Junto100% (1)

- ME597 Lecture5 13Document34 pagesME597 Lecture5 13bee1406763181No ratings yet

- Haryana Exporters Complete ListDocument8 pagesHaryana Exporters Complete ListShashank SrivastavaNo ratings yet

- 190 e Cr302 en Servomotors-For-steam-turbinesDocument10 pages190 e Cr302 en Servomotors-For-steam-turbinesscribdkhatnNo ratings yet

- ATS Power 325 Series Diesel EnginesDocument12 pagesATS Power 325 Series Diesel EnginesMTU650No ratings yet

- Mobilfluid 424Document8 pagesMobilfluid 424Islam FawzyNo ratings yet

- Adept Heterostruct TutorialDocument23 pagesAdept Heterostruct TutorialLavi TyagiNo ratings yet

- Catalog 79603ENG HOKE Relief Valves R6000 Series 01.03.14Document10 pagesCatalog 79603ENG HOKE Relief Valves R6000 Series 01.03.14Nilesh MistryNo ratings yet

- Derive W, S, e and G and Check IfDocument10 pagesDerive W, S, e and G and Check IfAdhitya YogaNo ratings yet

- 1 PDFDocument12 pages1 PDFBárbara Rani BorgesNo ratings yet

- Elektromontazas ShemaDocument68 pagesElektromontazas ShemaDorin100% (1)

- An Air Separation Plant Separates Atmospheric Air Into Its Primary ComponentsDocument4 pagesAn Air Separation Plant Separates Atmospheric Air Into Its Primary ComponentsAbhinav AjmaniNo ratings yet

- Mechanical Seals JohnCraneDocument6 pagesMechanical Seals JohnCranevalikka100% (3)

- DPT145 Multiparameter Transmitter For SF6 Gas: Online Reliability Risk-Free, Greener Solution The Fruit of ExperienceDocument2 pagesDPT145 Multiparameter Transmitter For SF6 Gas: Online Reliability Risk-Free, Greener Solution The Fruit of ExperienceRenzo Romero ArenasNo ratings yet

- 7B Microstructure of Iron Carbon AlloysDocument14 pages7B Microstructure of Iron Carbon AlloysAhmed AliNo ratings yet

- Surface PlateDocument5 pagesSurface Platetevqwe1No ratings yet

- Process Plan Layout and Piping Design - Roger Hunt PDFDocument445 pagesProcess Plan Layout and Piping Design - Roger Hunt PDFFernando Caffroni100% (3)

- AsmeDocument11 pagesAsmeManoj BallaNo ratings yet

- Equivalent Weight Class XI DPPDocument3 pagesEquivalent Weight Class XI DPPAshwin Jambhulkar0% (1)

- Hard WindingDocument7 pagesHard WindingSarker Choton100% (1)

- The Motor Guide- basic technical information about low voltage standard motorsDocument135 pagesThe Motor Guide- basic technical information about low voltage standard motorsmatchoo87No ratings yet

- GL Vi-9-2 e PDFDocument20 pagesGL Vi-9-2 e PDFValli RajuNo ratings yet