Professional Documents

Culture Documents

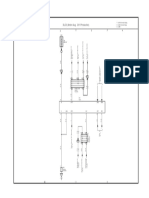

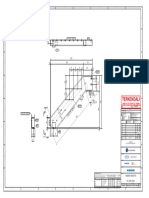

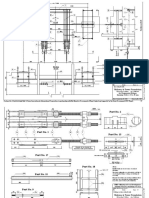

Welding Detail of Part I - L Vertical Legs Welding Detail of Part I - 2 Diagonal Bracing

Uploaded by

Ranjit Kumar ShahOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Welding Detail of Part I - L Vertical Legs Welding Detail of Part I - 2 Diagonal Bracing

Uploaded by

Ranjit Kumar ShahCopyright:

Available Formats

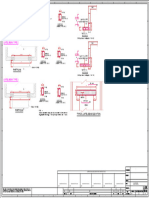

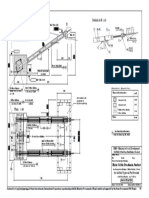

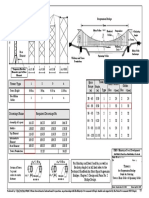

WELDING DETAIL OF PART I - l WELDING DETAIL OF PART I - 2

Vertical Legs Diagonal Bracing FRONT ELEVATION

I-3

ELEVATION SIDE ELEVATION ELEVATION SIDE ELEVATION

I-4

Rod φ 16 mm “C” Main Joint

I-lc

2270

I-2a Plate

240

30

I-2b Tube 240

35

“B” Part

I-1

Rod φ 12 mm

I-lb

Part No. I-2

Angle 65/65/6

I-la

Main Joint

30 240 30 25 350 25 I-5 I-6 I-7 I-4

300 400

PLAN

DETAIL at “A” DETAIL at “C” Standart Section I-3

10

Angle 65/65/6

I-la Rod φ 12 mm I-4

I-lc

Lacing. Plate 283 / 100 / 10

I-2a

Rod φ 12 mm 6

I-lc

6

6

Rod φ 12 mm 6

I-lb 50 50

“A” 300 1100 1100 300

300

Angle 65/65/6 4 66 NOTES :

I-la

1) To obtain uniformity, use of templates and jigs

MAIN JOINT Rod φ 12 mm is mandatory for holing bending and welding

I-lb

Rod φ 12 mm Lacing. of assembly.

I-lb Tube φ 76.1/3.65

I-2b

l = 2621 HMG / Ministry of Local Development

Angle 65/65/6 DETAIL at “B” DoLIDAR / Short SpanTrail Bridge Standard

I-la

4 Bridge Name: Budhi Khola 1

Bolt + Nut + washer No: Span: 52

I-5 I-6 I-7 Steel Drawing:

Plate 290/296/6

119 φ 76.1 12 33 10 331

I-3 Intermediate Element

100 φ 76.1

Rod φ 12 mm

for Tower No. 1, 2 or 3

I-lc

Assembly & Welding Details

Plate 290/58/6

I-5

Date : September 30, 2002 Drawing No. 109N

Produced by Nepal Swiss Association for International Cooperation, in partnership with His Majesty’s Government of Nepal, funded and supported by the Swiss Government (SDC Nepal). 27

You might also like

- 2003 Tacoma-ECUN2WDDocument8 pages2003 Tacoma-ECUN2WDMiguel ruizNo ratings yet

- ABS-J-089-03-DRG-002 - Detail Fabrication Drawing Instrument Air Receiver - 39 Cu.m-paRT DRAWINGDocument1 pageABS-J-089-03-DRG-002 - Detail Fabrication Drawing Instrument Air Receiver - 39 Cu.m-paRT DRAWINGPrabu KumarNo ratings yet

- Cruise Control (1VD-FTV W/o DPF) (Before Jan. 2013 Production), ECT and A/T Indicator (1VD-FTV W/o DPF) (Before Jan. 2013 Production), Engine Control (1VD-FTV W/o DPF) (Before Jan. 2013 Production)Document28 pagesCruise Control (1VD-FTV W/o DPF) (Before Jan. 2013 Production), ECT and A/T Indicator (1VD-FTV W/o DPF) (Before Jan. 2013 Production), Engine Control (1VD-FTV W/o DPF) (Before Jan. 2013 Production)Yannick de WalqueNo ratings yet

- SRP-Waste Management Plan-G225IEX-SRP-R-PLN-003Document10 pagesSRP-Waste Management Plan-G225IEX-SRP-R-PLN-003Ows AnishNo ratings yet

- Extrusion For ClassDocument49 pagesExtrusion For ClassNABIL HUSSAINNo ratings yet

- The Rough Guide to Beijing (Travel Guide eBook)From EverandThe Rough Guide to Beijing (Travel Guide eBook)Rating: 2 out of 5 stars2/5 (1)

- Stainless Steel Flat ProductsDocument15 pagesStainless Steel Flat Productsstrip1No ratings yet

- 25.Checklist-Metal Doors, Windows & VentilatorsDocument2 pages25.Checklist-Metal Doors, Windows & Ventilatorsajit karandikar50% (2)

- ABS-J-089-03-DRG-002 - Detail Fabrication Drawing Instrument Air Receiver - 39 Cu.m-paRT DRAWINGDocument1 pageABS-J-089-03-DRG-002 - Detail Fabrication Drawing Instrument Air Receiver - 39 Cu.m-paRT DRAWINGPrabu KumarNo ratings yet

- Revise - Final Inception Report - PK-14 - 076-77Document59 pagesRevise - Final Inception Report - PK-14 - 076-77Ranjit Kumar ShahNo ratings yet

- MANUAL-CG302-轿顶插件板 3相220 PDFDocument32 pagesMANUAL-CG302-轿顶插件板 3相220 PDFAsdrubal Fredy Gutierrez100% (1)

- Electrodes Consumables PDFDocument2 pagesElectrodes Consumables PDFravi00098No ratings yet

- List of Companies Sap NewDocument30 pagesList of Companies Sap NewDasi Rakesh KumarNo ratings yet

- Pvivate Limited Companies Database SampleDocument10 pagesPvivate Limited Companies Database SampleBinduPrakashBhattNo ratings yet

- Cochrane Gulf ClearVu Brochure 2022Document22 pagesCochrane Gulf ClearVu Brochure 2022hani hannaNo ratings yet

- Welding Detail of Part I - L Vertical Legs Welding Detail of Part I - 2 Diagonal BracingDocument1 pageWelding Detail of Part I - L Vertical Legs Welding Detail of Part I - 2 Diagonal BracingkonelegeseNo ratings yet

- Ax 063Document1 pageAx 063Al Fakhamah LiftsNo ratings yet

- Train-1 Process Flow DiagramDocument1 pageTrain-1 Process Flow DiagramHtoo Htoo KyawNo ratings yet

- I I I I: CrocompilterDocument2 pagesI I I I: CrocompilterJustan MendezNo ratings yet

- Regal Beloit America, Inc.: Rev Date/ © Date Revision by Request Number Drawing Revision Drawn by Date Approved byDocument1 pageRegal Beloit America, Inc.: Rev Date/ © Date Revision by Request Number Drawing Revision Drawn by Date Approved byDANIEL'S SERVICIOS INTEGRALES EN SOLDADURANo ratings yet

- DZX-1051 ADocument2 pagesDZX-1051 AZain UddinNo ratings yet

- 7 PDFDocument1 page7 PDFaritw541214No ratings yet

- Smps Half Bridge 2153 Irfp460 Smps Plain SchematicDocument1 pageSmps Half Bridge 2153 Irfp460 Smps Plain SchematicValmir MorschheiserNo ratings yet

- Shimano EV-FD-C101-E, C102 Altus Top Swing Front DerailleurDocument1 pageShimano EV-FD-C101-E, C102 Altus Top Swing Front DerailleurxjcaiNo ratings yet

- All in One PDFDocument85 pagesAll in One PDFklasio artNo ratings yet

- Battery Changeover PanelDocument3 pagesBattery Changeover PanelJulio TolentinoNo ratings yet

- Detail 4-Lintel 4Document1 pageDetail 4-Lintel 4Manoj JaiswalNo ratings yet

- 11-2756-b Elevator Boot Assy 28SIDocument1 page11-2756-b Elevator Boot Assy 28SIBoanerges BritoNo ratings yet

- Take Off Sketch 20230316Document8 pagesTake Off Sketch 20230316Emmanuel OtienoNo ratings yet

- Chapter/Section Number Title Number Number: HT-206A/B-SERIES-IDocument6 pagesChapter/Section Number Title Number Number: HT-206A/B-SERIES-Iedward alba torresNo ratings yet

- Handrail Typical Elevation - Span U-Grider - Straight Alignment Handrail Typical Cross Section Cross Section I - IDocument1 pageHandrail Typical Elevation - Span U-Grider - Straight Alignment Handrail Typical Cross Section Cross Section I - ITrươngPhiNo ratings yet

- Ma5 TT01-ST05-1C259-4: Grid Location TT01-ST05-1C259-4 B-A/2-1/E Assembly Top Level: EL. +14.800Document1 pageMa5 TT01-ST05-1C259-4: Grid Location TT01-ST05-1C259-4 B-A/2-1/E Assembly Top Level: EL. +14.800Gandara SugandhiNo ratings yet

- Lampiran 2: LIST BLIND: 1. 30" Inlet Flange 19C-3 - Isolation Authority: Signature: Date: / / TimeDocument3 pagesLampiran 2: LIST BLIND: 1. 30" Inlet Flange 19C-3 - Isolation Authority: Signature: Date: / / TimeRaihanadityaNo ratings yet

- Signal - HazardDocument1 pageSignal - Hazardtuan anh nguyễnNo ratings yet

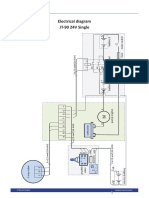

- Electrical Diagram JT-90 24V SingleDocument5 pagesElectrical Diagram JT-90 24V SingleCatherine RiquelmeNo ratings yet

- 27 Hilux (Cont. Next Page) : Engine Control (1GD-FTV)Document8 pages27 Hilux (Cont. Next Page) : Engine Control (1GD-FTV)autocomtrucksNo ratings yet

- 27 Hilux (Cont. Next Page) : Engine Control (1GD-FTV)Document8 pages27 Hilux (Cont. Next Page) : Engine Control (1GD-FTV)autocomtrucksNo ratings yet

- 27 Hilux (Cont. Next Page) : Engine Control (1GD-FTV)Document8 pages27 Hilux (Cont. Next Page) : Engine Control (1GD-FTV)autocomtrucksNo ratings yet

- 27 Hilux (Cont. Next Page) : Engine Control (1GD-FTV)Document8 pages27 Hilux (Cont. Next Page) : Engine Control (1GD-FTV)autocomtrucksNo ratings yet

- 27 Hilux (Cont. Next Page) : Engine Control (1GD-FTV)Document8 pages27 Hilux (Cont. Next Page) : Engine Control (1GD-FTV)autocomtrucksNo ratings yet

- 27 Hilux (Cont. Next Page) : Engine Control (1GD-FTV)Document8 pages27 Hilux (Cont. Next Page) : Engine Control (1GD-FTV)autocomtrucksNo ratings yet

- 4217 CSD S 1a 1413 Ra Enlarged Plans & Sections Pers. Lift 1Document1 page4217 CSD S 1a 1413 Ra Enlarged Plans & Sections Pers. Lift 1Adi PriyapurnatamaNo ratings yet

- Top Plan of 2P X 15 Mms Table: Solar PV Project SolapurDocument1 pageTop Plan of 2P X 15 Mms Table: Solar PV Project Solapurisan.structural TjsvgalavanNo ratings yet

- Front Elevation Side Elevation General Arrangement: SaddleDocument1 pageFront Elevation Side Elevation General Arrangement: SaddleRanjit Kumar ShahNo ratings yet

- JB00 B PPDC 020 0001 5Document1 pageJB00 B PPDC 020 0001 5tariq100% (1)

- 230V MSB - STBD.: Alarm SystemDocument2 pages230V MSB - STBD.: Alarm SystemhamzehNo ratings yet

- Top View / Half SectionDocument1 pageTop View / Half SectionMD shawonNo ratings yet

- PZ12426b GADocument1 pagePZ12426b GAwesquiNo ratings yet

- Shimano BR-M422Document1 pageShimano BR-M422soyjoaquinNo ratings yet

- Final Sheet-Model - PDF 1Document1 pageFinal Sheet-Model - PDF 1Prateek SharmaNo ratings yet

- Forester 19my Pubno - G8240be Version - 008Document5 pagesForester 19my Pubno - G8240be Version - 008s.navarro.skcNo ratings yet

- RV - Ref-Model A5Document1 pageRV - Ref-Model A5daniel vicenteNo ratings yet

- Wa0002 PDFDocument1 pageWa0002 PDFAnjo MolinaNo ratings yet

- InstalatieDocument1 pageInstalatiemik3linoNo ratings yet

- Opus 1110 (37997)Document18 pagesOpus 1110 (37997)arie goudNo ratings yet

- UntitledDocument5 pagesUntitledDimce BusinoskiNo ratings yet

- Air Handler Selection Data - Model GAM5B0B36 (10-24-19)Document4 pagesAir Handler Selection Data - Model GAM5B0B36 (10-24-19)Trever TomesNo ratings yet

- LC 09Document1 pageLC 09Ramadan GhanmNo ratings yet

- Em0240up - Overall Electrical DiagramDocument3 pagesEm0240up - Overall Electrical Diagramimmune2u2No ratings yet

- FinalDocument1 pageFinalVinh Lê KhảiNo ratings yet

- Signal Mast Beaver 1200 With Awning: Ihc Holland Beaver Dredgers B.VDocument1 pageSignal Mast Beaver 1200 With Awning: Ihc Holland Beaver Dredgers B.VMD shawonNo ratings yet

- Drawing1 A3Document1 pageDrawing1 A3Dimas WiryaNo ratings yet

- Semiconductor KIA393P/S/F/FK: Technical DataDocument4 pagesSemiconductor KIA393P/S/F/FK: Technical DataAdam SchwemleinNo ratings yet

- Comparador Dual Usado en Plasma LG KIA393P - S - F - PDFDocument5 pagesComparador Dual Usado en Plasma LG KIA393P - S - F - PDFAntonio ChavezNo ratings yet

- Comparador Dual Usado en Plasma LG KIA393P - S - F - PDFDocument5 pagesComparador Dual Usado en Plasma LG KIA393P - S - F - PDFAntonio ChavezNo ratings yet

- Semiconductor KIA393P/S/F/FK: Technical DataDocument4 pagesSemiconductor KIA393P/S/F/FK: Technical DataAdam SchwemleinNo ratings yet

- Tủ điện 2Document1 pageTủ điện 2Nhật LêNo ratings yet

- Engine CoolantDocument1 pageEngine CoolantMarcos DiazNo ratings yet

- Syllabi Master of TechnologyDocument63 pagesSyllabi Master of TechnologyRanjit Kumar ShahNo ratings yet

- Morpho-Hydraulic Parameters and Existing Stability Condition of Nakhu River, Southern Kathmandu, Central NepalDocument22 pagesMorpho-Hydraulic Parameters and Existing Stability Condition of Nakhu River, Southern Kathmandu, Central NepalRanjit Kumar ShahNo ratings yet

- EOI Detailed Bridge Maintenance Survey and Design of The Existing Motorable Bridges On SRNDocument12 pagesEOI Detailed Bridge Maintenance Survey and Design of The Existing Motorable Bridges On SRNRanjit Kumar ShahNo ratings yet

- Jhilke Khola Hydrology Aug 1 2021 20mx1Document15 pagesJhilke Khola Hydrology Aug 1 2021 20mx1Ranjit Kumar ShahNo ratings yet

- Intermediate-Lanes Traffic, Simply Supported Span, 3 Web, Cast-in-SituDocument8 pagesIntermediate-Lanes Traffic, Simply Supported Span, 3 Web, Cast-in-SituRanjit Kumar ShahNo ratings yet

- 2.pokhariya Estimation FinalDocument152 pages2.pokhariya Estimation FinalRanjit Kumar ShahNo ratings yet

- Section at A-A, 1:50 Detail at B 1:15: Main Cable Deadman AnchorDocument1 pageSection at A-A, 1:50 Detail at B 1:15: Main Cable Deadman AnchorRanjit Kumar ShahNo ratings yet

- Final Field ReportDocument37 pagesFinal Field ReportRanjit Kumar ShahNo ratings yet

- 48 NconDocument1 page48 NconRanjit Kumar ShahNo ratings yet

- Section A-A, 1:40: Part No Section (MM) Quantity (Nos) Working Drawing Weight KG/PC Total KGDocument1 pageSection A-A, 1:40: Part No Section (MM) Quantity (Nos) Working Drawing Weight KG/PC Total KGRanjit Kumar ShahNo ratings yet

- Section at A-A, 1:50: Part No Section (MM) Quantity (Nos) Working Drawing WeightDocument1 pageSection at A-A, 1:50: Part No Section (MM) Quantity (Nos) Working Drawing WeightRanjit Kumar ShahNo ratings yet

- Section at A-A, 1:50 Detail at B 1:15: Main Cable Deadman AnchorDocument1 pageSection at A-A, 1:50 Detail at B 1:15: Main Cable Deadman AnchorRanjit Kumar ShahNo ratings yet

- Plan View: (M) Type of Construction BDocument1 pagePlan View: (M) Type of Construction BRanjit Kumar ShahNo ratings yet

- Assembly Detail Welding Details: Part No. 1Document1 pageAssembly Detail Welding Details: Part No. 1Ranjit Kumar ShahNo ratings yet

- φ 311, cut thread M 35 and fit tightly with part no 1d before galvanizationDocument1 pageφ 311, cut thread M 35 and fit tightly with part no 1d before galvanizationRanjit Kumar ShahNo ratings yet

- Tower Type 1 2 3 4: Suspension BridgeDocument1 pageTower Type 1 2 3 4: Suspension BridgeRanjit Kumar ShahNo ratings yet

- Welding Detail of Part B-1 (A-J) : Front Elevation Side Elevation View - XDocument1 pageWelding Detail of Part B-1 (A-J) : Front Elevation Side Elevation View - XRanjit Kumar ShahNo ratings yet

- φ 311, cut thread M 35 and fit tightly with part no 1d before galvanizationDocument2 pagesφ 311, cut thread M 35 and fit tightly with part no 1d before galvanizationRanjit Kumar ShahNo ratings yet

- HMG / Ministry of Local Development: Bridge Name: No: Bank: SpanDocument2 pagesHMG / Ministry of Local Development: Bridge Name: No: Bank: SpanRanjit Kumar ShahNo ratings yet

- Evidence For Chemical Change LabDocument2 pagesEvidence For Chemical Change LabPhilly Cheung100% (1)

- Vol 2 - Metal Curtain Walls - VS-TOC - V2 - 3-11-11Document1 pageVol 2 - Metal Curtain Walls - VS-TOC - V2 - 3-11-11philipNo ratings yet

- ASTM F423-95Document5 pagesASTM F423-95Tamara Silvana CárcamoNo ratings yet

- Chemical Effect of Current - 8thDocument14 pagesChemical Effect of Current - 8thVijay KumarNo ratings yet

- Facial Mirror With Plywood BackingDocument65 pagesFacial Mirror With Plywood BackingVinod Mohan100% (1)

- Fluorescent Liquid Penetrant Examination Using The Solvent-Removable ProcessDocument6 pagesFluorescent Liquid Penetrant Examination Using The Solvent-Removable ProcessJHONNATAN ORJUELA CORTESNo ratings yet

- Division 05-Metal - 050513, 050523, 055000Document62 pagesDivision 05-Metal - 050513, 050523, 055000rmltechnicalservicesNo ratings yet

- GN - ART - T.Torries - 1995 - Comparative Costs of Nickel Sulphides and LateritesDocument9 pagesGN - ART - T.Torries - 1995 - Comparative Costs of Nickel Sulphides and LateritesEduardo CandelaNo ratings yet

- Section 04200 Masonry UnitDocument14 pagesSection 04200 Masonry UnitMØhãmmed ØwięsNo ratings yet

- COBALT Sugar Catalog 2021 WEBDocument32 pagesCOBALT Sugar Catalog 2021 WEBEdz ApolinarioNo ratings yet

- Manufacturing Engineering Assignment Thapar UniversityDocument5 pagesManufacturing Engineering Assignment Thapar UniversitySaurav Kumar0% (1)

- Housekeeping Schedule: Schedule For The Month ofDocument12 pagesHousekeeping Schedule: Schedule For The Month ofLemuel Escubio PerezNo ratings yet

- Stress Strain Curve - SS - Gayathri.mDocument50 pagesStress Strain Curve - SS - Gayathri.mGayathri kalkiNo ratings yet

- 2023-02-28 MAR-080 IMC Pipes & Fittings (Smartube) ANAKO Philippines Corporation Rev. ADocument24 pages2023-02-28 MAR-080 IMC Pipes & Fittings (Smartube) ANAKO Philippines Corporation Rev. AjaymarNo ratings yet

- Hallowell Full Line Catalog 2019Document140 pagesHallowell Full Line Catalog 2019fariboy123No ratings yet

- Astm F880MDocument5 pagesAstm F880MJUAN DAVID GOMEZ PATIÑONo ratings yet

- AGARD (Advisory Group For Aeroospace Research and Development) - Corrosion Handbook - Vol 1Document209 pagesAGARD (Advisory Group For Aeroospace Research and Development) - Corrosion Handbook - Vol 1KatNo ratings yet

- MetE 206 - Exp 3 - Revised ViewSlides PDFDocument30 pagesMetE 206 - Exp 3 - Revised ViewSlides PDFUfuk CevtekinNo ratings yet

- FPJ 320 Series: Explosion Proof Cum Weatherproof Junction BoxesDocument2 pagesFPJ 320 Series: Explosion Proof Cum Weatherproof Junction BoxestejassidhpuraNo ratings yet

- Stud Ends Din 2353 With BSPP ThreadDocument9 pagesStud Ends Din 2353 With BSPP ThreadAysmentolNo ratings yet

- Bell Gossett Series 80 - Year 2000 CatalogDocument8 pagesBell Gossett Series 80 - Year 2000 CatalogAnonymous 7xHNgoKE6eNo ratings yet

- EP FE ME SPC 011 01 E - Specification - Piping - Classes - ASME - B31.3Document451 pagesEP FE ME SPC 011 01 E - Specification - Piping - Classes - ASME - B31.3Lumy NastaseNo ratings yet