Professional Documents

Culture Documents

Proceess .File

Uploaded by

kiran raghukiranOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Proceess .File

Uploaded by

kiran raghukiranCopyright:

Available Formats

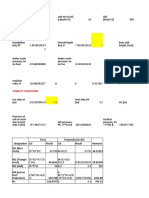

SEWERAGE TREATMENT PLANT 100 KLD FOR

Project : Sewage Treatment Plant for

PROCESS DESIGN CALCULATION

MLD Cu.m/Hr. Cu.m/Sec.

Design Average Flow MLD 0.100 4.167 0.001

Peak Flow Factor (As per CPHEEO Manual) 3.00

Peak Flow MLD 0.300 12.500 0.003

Raw & Treated Effluent + Sewage characteristics

Parameters Unit Inlet Outlet

pH 5.5 - 9.0 5.5 - 9.0 As Per Guide Lines

BOD mg/l 250.00 ≤ 10 As Per CPHEEO Manual

TSS mg/l 375.00 ≤ 20 As Per CPHEEO Manual

COD mg/l 450.00 50 As Per CPHEEO Manual

Total Nitrogen mg/l 50.00 ≤ 10 As Per CPHEEO Manual

Ammonical Nitrogen (NH3-N ) mg/l 32.50 As Per CPHEEO Manual

Nitrate Nitrogen (NO3-N) mg/l 5.00 As Per CPHEEO Manual

Total Phosphorus mg/l 7.10 ≤1 As Per CPHEEO Manual

Oil & Grease mg/l 45.00 Nil As Per CPHEEO Manual

Total Coliform Organism MPN/100ml ≤ 10 As Per CPHEEO Manual

Fecal Coliform Organism MPN/100ml <100 /100 ml As Per CPHEEO Manual

UNIT SIZING - COLLECTION SYSTEM

BAR SCREEN CHAMBER Manual

No of Units 1.00 No.

Design Flow 0.300 MLD

Design Flow/Unit 0.300 MLD

12.500 Cu.m/Hr.

0.003 Cu.m/Sec

Clear Opening of Screen 12.00 mm

Width of Screen Flat 6.00 mm

Design Velocity through Screen 0.90 m/sec.

Area Required for Flow 0.004 Sq.m

Effective Area required 0.0058 Sq.m

Width 0.600 m

Depth Required 0.010 m

Depth Provided 0.500 m

Approach Velocity 0.01 m/sec.

Velocity of flow through screen 0.02 m/sec.

Head loss through clean screen 0.000 m

Drop in Screen Chamber Floor 0.000 m

Applying Bernoulis Equation between U/S & D/s of Screen

Z1 + d1 + V1 2 / 2g = Z2 + d2 + V2 2/2g + Hl

Solving by Trial & Error

d2 = 0.181 m

v2 = 0.032 m/sec

When Screen is 50% Clogged

Applying Bernoulis Equation between U/S & D/s of Screen

Z1 + d1 + V1 2 / 2g = Z2 + d2 + V2 2/2g + Hl

Solving by Trial & Error

d1 = 0.141 m

v1 = 0.041 m/sec

Velocity through 50% Clogged Screen 0.123

Approach Velocity at 50% Clogged Condition 0.041

Head Loss through 50% clogged screen = 0.0729*(V1^2-V2^2) 0.001 m

Head Loss in the System at 50% Clogging -0.040 m

Say 0.100 m

Head Buildup on U/S Side at 50% Clogging -0.359 m

Say 0.120 m

Depth Required 0.141 m

Depth Provided 0.200 m

Angle of Inclination of Screen 60.0 Deg

Length Required 1.00 m

Length Provided 2.00 m

FGL of Coarse Screen Chamber area m

Top Level of Coarse Screen Chamber m

Invert Level of Incoming Sewer m

Free fall in receiving chamber 0.15 m

MWL of Screen Channel m

Free Board 0.00 m

Total Depth 0.20 m

Size of Barscreen 2.00 x 0.90 x0.20

PROCESS DESIGN SHEETS 1 of 10

OIL & GREASE TRAP

No of Units 1.00 No.

Design Flow 0.30 MLD

Design Flow/Unit 0.30 MLD

Retention Time 5.00 Min

Volume Required 1.04 Cu.m

Depth Provided 0.50 m

Area Required 2.08 Sq.m

Length to Width Ratio 2.00

Width of O & G Trap 1.02 m

Say 0.90 m

Length of O & G Trap 2.31 m

Say 3.23 m

Free Board 0.30 m

Total Depth 0.80 m

Provide Oil & Grease Trap Size 4.30x2.20x1.00 m

EQUALISATION TANK

No of Units 1.0 No.

Total Flow 0.10 MLD

Design Flow/Unit 0.10 MLD

Retention Time 6.00 Hrs. (MAXIMUM 8 HOURS )

Volume Required 25.88 Cu.m

Depth Provided 2.50 m

Area 10.35

Length of Chamber 5.00 m

Width required 2.07 m

Width Provided 3.00 m

Free Board 0.50 m

Total Depth 3.00 m

Air Requirment Calculation for Mixing (Based on Volume of Tank)

Volume of Equ Tank 37.5 Cu.m

Air Requirment for Mixing 12.50 Cu.m/1000 Cu.m/min ( As Per Blowers Vender )

Capacity of Blower Required for Mixing 28.1 Cu.m/Hr.

Say 30.00 Cu.m/Hr.

Flow per Diffuser (Coarse Bubble Tubular Diffuser) 7.00 m3/Hr. (As per venders chart )

No. of Diffusers required per Tank 4.29 Nos.

Say 13.00 Nos.

Type of Pump Ver Submersible

No. of Working Pumps 3.00 Nos.

No. of Standby Pumps 1.00 Nos.

Total number of pumps 4.00 Nos.

Capacity of Each Raw Sewage Pump 1.44 Cu.m/Hr.

Say 13.00 Cu.m/Hr.

H1(Depth of Tank ) 5.70

H2 ( Horizontal Distance) 0.00

H3 ( Anoxiec tank ) 4.60

H4 ( Residual head ) 2.00

H5 (Frictional losses) 1.23

Head (H) 13.53 m

PROCESS DESIGN SHEETS 2 of 10

MOVING BED BIO REACTOR (MBBR) TANK

No of Units 1.00 No.

Design Flow 0.104 MLD

Design Flow/Unit 0.104 MLD

(The First Tank 2/3 of the

Design BOD Removal 160.00 mg/l BOD)

MLSS 4000.00

F/M 0.16

Aeration Tank Volume Required 25.88 Cu.m

Depth of Tank 2.50 m

Area Required (For One Tank) 10.35 Sq.m

Length of Each Tank 3.00 m

(Width 6.00 m We have

Width of Each Tank 3.45 m Provided )

Width Provided 4.00 m

Surface Area Provided (For Each Tank) 12.00 Sq.m

Free Board 0.40 m

Total Depth 2.90 m

Media Volume For Tank -1 5.520 m3

PROCESS DESIGN SHEETS 3 of 10

Volume of Tank Including Media Filling 35.52 Cu.m

Retention Time 8.24 Hrs.

Tank Size (9.50 x 6.0x4.50)+49.680

Hence Retention of Time 306.18

71.00 Hrs.

Second Tank (The Second Tank 1/3 of

Design BOD Removal 80.00 mg/l the BOD)

MLSS 4000.00

F/M 0.16

Aeration Tank Volume Required 12.94 Cu.m

Depth of Tank 2.50 m

Area Required (For One Tank) 5.18 Sq.m

Length of Each Tank 2.50 m

(Width 6.00 m We have

Width of Each Tank 2.07 m Provided )

Width Provided 4.00 m

Surface Area Provided (For Each Tank) 10.00 Sq.m

Free Board 0.50 m

Total Depth 3.00 m

Volume of Tank Including Media 27.76 Cu.m

Retention Time 6.44 Hrs.

Volume of Tank Including Media requiered (Actual ) 15.70 Cu.m

Hence we have Provided 27.76 Cu.m

BOD Removed in Each Aeration Tank-1 16.56 Kg/Day

BOD Removed in Each Aeration Tank-2 8.28 Kg/Day

BOD Loading Rate Tank-1 0.466 Kg BOD/m3.d

BOD Loading Rate Tank-2 0.298 Kg BOD/m3.d

Total BOD Loading rates 0.764

Recommended BOD Loading Rate for MBBR (As per Metcalf &

Eddy Page No. 955, CPHEEO Manual Page No.5 -208) 1.0 to 1.4 Kg BOD/m3.d

Organic Loading Rate for MBBR Media 0.75 Kgs of BOD/100 m2 of media /day (From Venders Chart)

Surface area of media required for tank-1 2208 Sq.m

Surface area of media required for tank-2 1104 Sq.m

Unit Surface area of media 400.00 Sq.m/Cu.m of Media

Volume of Media Required tank-1 5.520 m3

Volume of Media Required tank-2 2.760 m3

% of media Volume 26.581 %

Sludge Production from BOD Removal 0.30 Kg/ Kg of BOD As per CPHEEO

Quantity of Sludge per Day for BOD Removal on Dry Weight Basis 4.968 Kg/Day

Quantity of Sludge per Day for BOD Removal on Dry Weight Basis 2.484 Kg/Day

Total Quantity of Sludge on Dry Weight Basis 7.452 Kg/Day

Sludge Age 83.33 Days

OXYGEN CALCULATIONS :

Volume of Sewage treated 100.00 m3/day

Theoretical Kg O2 required per Kg BOD as per Sewage Manual 1.20 Kg/Kg BOD

Inlet BOD5 250 mg/l

Outlet BOD5 10.00 mg/l

BOD5 removed 240 mg/l

Kg of BOD removed in a day 24.00 Kg/day

Kg O2 reqd. for BOD load 28.8 Kg/day

Inlet Total Kjeldhal Nitrogen 32.5 mg/l

Outlet Ammoniacal Nitrogen 0.00 mg/l

Nitrogen assimilated in during BOD removal (@ 5% of Inlet BOD) 12 mg/l

Outlet Nitrate Nitrogen 5.00 mg/l

NH3-N removed in a day 20.5 mg/l

Kg O2 required per Kg of NH3-N 4.60 Kg/ Kg of NH3-N

Kg of NH3-N removed in a day 2.05 Kg/day

Kg O2 reqd. for NH3-N removal 9.43 Kg/day

Kg O2 released per Kg of Nitrate-Nitrogen during denitrification 2.86 -

Kg of Nitrate-Nitrogen generated 1.54 Kg/day

Assuming 75% of Nitrification

Kg of Nitrate Nitrogen in the treated sewage 0.50 Kg/day

Quantity of Nitrate Nitrogen that is denitrified 1.04 Kg/day

Kg O2 released during denitrification 2.97 Kg/day

Total Kg O2 required/day 35.26 Kg/day

AIR REQUIREMENT CALCULATIONS:

Total actual Kg O2 required per day (AOR) 35.26 Kg/day

PROCESS DESIGN SHEETS 4 of 10

T = Field Temperature 40 °C 18

H = Altitude of site 536.00 m

Properties of Air

g 9.81 m/ s2

M = Mole of Air 28.97 kg / kg-Mole

R =Universal Gas Constant 8314.00 kg.m2/s2.kg.mole.k

Pa = Atmospheric Pressure 101.325 KN/m2

Oxygen by Weight in air 23.180 %

Ot = % Oxygen Concentration leaving tank 19.00 18 to 20

C = Oxygen Concentration in Tank 2.00

α = Oxygen Transfer Correction Factor 0.65 -

As per Metcalf & Eddy - Page No. 711 - Example 8.2

β = Salinity Surface Tension Correction Factor 0.95 -

F = Fouling Factor 0.9 -

Aeration Depth 2.60 m

Relative Pressure (Pb/Pa)

exp (- g M (Zb - Za) / RT) 0.9432 0.9390

For 20 Deg C

DO Concentration (As per Table D 1 of App D, Metcalf & Eddy) 6.410 9.450 9.080

Specific Weight (As per Table C 1 of App C, Metcalf & Eddy) 9.730 9.793 9.789

Oxygen Concentration at specified temp & altitude (C STH) 6.046 8.874

Atmospheric Pressure at Specified Elevation & Temp in m 9.822 9.716

C' S T H

(C STH) (1/2) (((Patm,h + Pw, eff depth)/Patm,h) +(Ot / 21)) 6.5580 9.6384

Oxygen required under Standard Conditions (SOTR)

= AOTR ÷ [((βC'STH – C) ÷ CS20) x 1.024(T – 20) x α x F] 80.52 Kg/day 80.20

Hence, SOR 80.52 Kg/day 80.20

No. of Basins 1 Nos. 1

Standard O2 required at Field Conditions per Basin 80.52 Kg/day/Basin 80.20

Top Water Level (TWL) in Basin 2.50 m 2.50

Bottom Water Level (BWL) in Basins 0.00 m 0.00

Liquid level in Basin 2.50 m 2.50

Height at which Diffusers are kept 0.30 m 0.30

Effective Aeration Depth 2.20 m 2.20

OTE for Diffusers per m depth of submergence 6.00 %

SOTE for the above Effective Aeration Depth 13.200 % 13.20

Fraction of O2 in Air 23.18 % 23.18

Specific Gravity of Air at field Condition

ra = (PM/RT)*(Pb/Pa) 1.063 1.139

Air required at Field Conditions per Basin 2474.65 Nm3/day/ Basin 2301.72

Hours of Aeration per Basin per day 24.00 hr/day/Basin 24

Air required per hour per Basin = M / N 103.11 Nm3/hr/ Basin 95.90

No. of Operating Air Blowers per Basin 1.00 Nos. 1

Capacity of Air Blowers required = O / P 103.11 Nm3/hr 95.90

Safety Factor in Blower Capacity 5.00 % 5

Capacity of Air Blowers with Safety Factor = Q x (1 + R) 108.27 Nm3/hr 100.70

Capacity of Air Blowers provided 110.00 Nm3/hr 110.00

Air Requirment Calculation for Mixing (Based on Surface Area of Tank)

Area of One Reactor Tank 10.4 Sq.m

Air Requirment for Mixing 2.25 Cu.m/Hr./Sq.m

Capacity of Blower Required for Mixing (For One Tank) (On Area Ba 23.3 Cu.m/Hr.

Air Requirment Calculation for Mixing (Based on Volume of Tank)

Volume of One Reactor Tank 35.5 Cu.m

Air Requirment for Mixing 12.50 Cu.m/1000 Cu.m/min

Capacity of Blower Required for Mixing (For One Tank) (On Volume 26.6 Cu.m

Capacity of Blower Required For Each Tank 110 Nm3/Hr.

No of Working Blowers for two Tanks 1.00 Nos.

Capacity of each Blower Required 110 Nm3/Hr.

Say 110.00 Cum/Hr

Head for Blower 3.50 MWC

Number of Working Blowers 1.00 Nos.

Number of Standby Blowers 1.00 Nos.

Total number of Blowers 2.00 Nos.

Type of Blower Twin Lobe

Flow per Diffuser (Fine Bubble Tubular Diffuser) 9.00 m3/Hr.

PROCESS DESIGN SHEETS 5 of 10

No. of Diffusers required per Tank 12.22 Nos.

Say 13.00 Nos.

PROCESS DESIGN SHEETS 6 of 10

TUBE SETTLER

No of Units 1.00 No.

Design Flow 0.104 MLD

Design Flow/Unit 0.104 MLD

Surface Loading Rate 18 Cu.m/Day/Sq.m

Surface Area required 5.75 Sq.m

Retention Time 2.50 Hrs.

Volume Required 10.78 Cu.m

Depth Required 0.30 m

Depth Provided 2.50 m

Free Board 0.60 m

Total Depth 3.10 m

Velocity of flow in launder 0.60 m/sec.

Area of Launder Required 0.001 Sq.m

Width of Launder 0.30 m

Liquid Depth in Launder 0.00 m

Wall Tk of launder 0.10 m

Volume Provided 154.80 Cu.m

INTERNAL RECRICULATION (NITRIFIED LIQUOR)

Recirculation 25 %

Volume of Recirculation per Day 25 Cu.m/Day

Capacity of Pump Required 1.04 Cu.m/Hr.

No. of Working Pumps 1.00 Nos.

No of Pumps provided (1W+1S) 2.00 Nos.

Type of Pump Submersible

Capacity of Each Pump Required 1.04 Cu.m/Hr.

SLUDGE RECRICULATION

Sludge Recirculation 25 %

Volume of Recirculation per Day 25 Cu.m/Day

Volume of Sludge per Day 0.94 Cu.m/Day

Capacity of Pump Required 1.08 Cu.m/Hr.

No. of Working Pumps 1.00 Nos.

No of Pumps provided (1W+1S) 2.00 Nos.

Type of Pump Centrifugal

Capacity of Each Pump Required 1.08 Cu.m/Hr.

H-1(Tube settler ) 4.90 m

H-2 (Horizontal distance) 0.00 m ( Top of Flatform )

H-3 ( Frictional loss ) 2.00 m

Total Head 6.90 m

FILTER FEED SUMP

No of Units 1.00 No.

Design Inlet 0.10 MLD

Retention Time 3.00 Hr.

Volume Required 12.75 Cu.m

Depth Provided 2.50 m

Length of Chamber 1.50 m

Width required 3.40 m

Width Provided 4.00 m

Free Board 0.50 m

Total Depth 3.00 m

Filter Feed Pump

From Tube settlrer to Filter Feed 0.10 MLD

Filter Feed Tank Retention Time 3.00 Hours

Volume of tank 12.75

Capacity of Pump Required 4.25 Cu.m/Hr.

No. of Working Pumps 2.00 Nos.

No of Pumps provided (2W+1S) 3.00 Nos.

Type of Pump Centrifugal

Capacity of Each Pump Required 2.13 Cu.m/Hr.

20.00 Cu.m/Hr.

H1(Filter Feed tank ) 4.90 m

H2 ( Horizontal Distance ) 0.00 m (Top of Platform )

H3 ( Sand Filter requiered Pressure ) 10.00 m

H4 ( Friction Losses ) 5.00 m

H (Total Head ) 19.90 m

PROCESS DESIGN SHEETS 7 of 10

PRESSURE SAND FILTER

No of Units 1.00 No.

Total Flow 0.10 MLD

Design Flow/Unit 0.102 MLD

Hours of Operation 23.00 Hrs

Flow Rate 4.43 Cu.m/Hr.

Filtration Rate 15.00 Cu.m/Hr./Sq.m

Area of Filter Required 0.30 Sq.m

No of Units 1.00 Nos.

Area of Each Filter Required 0.30 Sq.m

Dia of Filter Required 0.61 m

Say 0.60 m

ACTIVATED CARBON FILTER

No of Units 1.00 No.

Total Flow 0.10 MLD

Design Flow/Unit 0.10 MLD

Hours of Operation 23.00 Hrs

Flow Rate 4.43 Cu.m/Hr.

Filtration Rate 15.00 Cu.m/Hr./Sq.m

Area of Filter Required 0.30 Sq.m

No of Units 1.00 Nos.

Area of Each Filter Required 0.30 Sq.m

Dia of Filter Required 0.61 m

Say 0.60 m

TREATED WATER SUMP

No of Units 1.00 No.

Design Flow 0.10 MLD

Design Flow/Unit 0.10 MLD

Retention Time 8.00 Hrs.

Volume Required 33.33 Cu.m

Depth Provided 2.50 m

Length of Chamber 3.50 m

Width required 3.81 m

Width Provided 7.00 m

Free Board 0.30 m

Total Depth 2.80 m

TREATED WATER PUMP

From Carbon Filter to Treated water tank 0.10 MLD

Volume of treated water tank 331.20

Capacity of Pump Required 110.40 Cu.m/Hr.

No. of Working Pumps 2.00 Nos.

No of Pumps provided (1W+1S) 1.00 Nos.

Type of Pump Centrifugal

Peak Pumping Hours 5.00 Hours

22.08

Capacity of Each Pump Required 22.08 Cu.m/Hr.

22.00 Cu.m/Hr.

H1(Treated water tank ) 2.80 m

H2 ( Horizontal Distance ) 0.00 m (Top of Platform )

H4 ( Friction Losses ) 3.00 m

H5 ( Out side ) 10.00 m

H (Total Head ) 15.80 m

SLUDGE TREATMENT

SLUDGE QUANTITY FROM TUBE SETTLER

Sludge Production from BOD Removal 0.30 Kg/ Kg of BOD As per CPHEEO

Quantity of Sludge per Day for BOD Removal on Dry Weight Basis 7.50 Kg/Day

Total Quantity of Sludge on Dry Weight Basis 7.50 Kg/Day

Sludge Concentration 0.80 %

Volume of Sludge per Day 0.94 Cu.m/Day

SLUDGE DEWATERING

Volume of Sludge 0.25 Cu.m

Total dry sludge per day 7.5 kg/day

Dewatered sludge solids concentration 20 %

Total dewatered wet sludge per day 37.5 kg/day

Total volume of dewatered wet sludge per day 37.5 Lit/day 900

Size of Filter Plate 310 x 310

Volume of Each Chamber 10.00 Lit

No. of chambers required 3.75 Nos.

No. of chambers provided 4.00 Nos.

No. of batches per day 4.00 No.

Hours of operation per day 16.0 Hrs

Material of Construction

Feed Head MS fabricated and machined

Fixed End MS fabricated and machined

Moving Plate MS fabricated and machined

PROCESS DESIGN SHEETS 8 of 10

Rollers & Hand wheel PP Machined

Plate PP -virgin

Tie Bar MS Fabricated and Machined

Cocks PP cocks

Distance piece MS Fabricated and Machined

Type of delivery Open Discharge

Closing device Hydraulic Power pack

Structure MS Fabricated

Size & Capacity 410mm x 410mm (24”)

Cake / Plate Thickness 32 mm / 60 mm

Feed inlet nozzle Dia 2.5” Feed Pipe

Filtration Area 7.8 m2 approx

Design feed pressure 7 Bar

Hours per batch approx 3-4 Hrs

PE Dosing System

PE Dosing Rate 2.00 Kg/Ton of Dry Solids

PE Required per day 0.02 Kg.

Solution Strength 0.1 %

Volume of PE Prep tank 15.00 Lit

0.015 Cu.m

Providing a dosing tank for 12 Hrs.

Vol of tank required 7.50 Ltrs

Say 20.00 Ltrs

Capacity of Dosing Pump 0.94 Ltrs/Hr.

No of Dosing Pumps 1.00 Nos.

Capacity of each Dosing Pump 0.94 Ltrs/Hr.

Say 1.00 Ltrs/Hr.

PROCESS DESIGN SHEETS 9 of 10

SODIUM HYPO CHLORITE DOSING SYSTEM

Chlorine Dosage 5.00 PPM

Design flow 0.10 MLD

Chlorine Required per Day 0.50 Kgs.

0.021 Kgs./Hr.

Solution Strength as procured in % 5.00

Available strength at point of use in % 4.00

Volume of solution needed liters / Hr. 0.52 Lit/Hr.

12.50 Lit.Day

Providing a dosing tank for 24.00 Hrs.

Vol of tank required 12.50 Ltrs

Say 20.00 Ltrs

Capacity of Dosing Pump 0.52 Ltrs/Hr.

No of Dosing Pumps 1 Nos.

Capacity of each Dosing Pump 0.52

Say 1.00 Ltrs/Hr.

FERRIC CHLORIDE Dosing System

Phosporous to be removed 5.1 mg/l

Total phosporous to be removed per day 0.51 Kg.

FeCl Dosing Rate 2.30 kg/kg of P

FeCl Required per day 1.17 Kg.

Solution Strength 10 %

Volume of FeCl Prep tank 11.73 Lit

0.01173 Cu.m

Dosing Tank Volume required per hour 0.49 Ltrs.

Providing a dosing tank for 24 Hrs.

Vol of tank required 11.73 Ltrs

Say 20.00 Ltrs

Capacity of Dosing Pump 0.49 Ltrs/Hr.

Say 1.00 Ltrs/Hr.

PROCESS DESIGN SHEETS 10 of 10

You might also like

- Process Design CalcDocument9 pagesProcess Design Calckiran raghukiranNo ratings yet

- Design Flow Rates and Water Quality Parameters for Wastewater Treatment SystemDocument17 pagesDesign Flow Rates and Water Quality Parameters for Wastewater Treatment SystemMohamed ArafatNo ratings yet

- 6000 M3/D STP Process Design & Unit SizingDocument8 pages6000 M3/D STP Process Design & Unit SizingMinakshi SinghNo ratings yet

- Extended AerationDocument5 pagesExtended Aerationgautam guptaNo ratings yet

- Clarifier Sizing SpreadsheetDocument1 pageClarifier Sizing Spreadsheetarvin4dNo ratings yet

- Softener CalculationDocument5 pagesSoftener CalculationAri WijayaNo ratings yet

- Effluent Treatment Plant Tech Report for LAIL Sugar MillDocument28 pagesEffluent Treatment Plant Tech Report for LAIL Sugar MillGarad MadhukarNo ratings yet

- WW ExcelDocument5 pagesWW Excelpartha6789No ratings yet

- De NitrificationDocument3 pagesDe Nitrificationkiran raghukiranNo ratings yet

- 5m3d MBR Package Sewage Treatment PlantDocument13 pages5m3d MBR Package Sewage Treatment PlantDevNo ratings yet

- 105.a.0 - RO-DM Plant Chain Sizing CalcDocument7 pages105.a.0 - RO-DM Plant Chain Sizing Calcmkchy12No ratings yet

- Aeration Tank Blower Calcns Package - US UnitsDocument19 pagesAeration Tank Blower Calcns Package - US UnitsAqua tech chemicals officesNo ratings yet

- Tech City-STP 100 KLD Price Comparison (03092016)Document10 pagesTech City-STP 100 KLD Price Comparison (03092016)Preston VargheseNo ratings yet

- MM Aqua Technologies LTD.: TubedekDocument47 pagesMM Aqua Technologies LTD.: TubedekSourabh Manuja100% (1)

- UASB-Process Design For Various Types of WastewatersDocument21 pagesUASB-Process Design For Various Types of WastewatersapitbhuNo ratings yet

- 40 KLD MBR QuoteDocument15 pages40 KLD MBR QuoteV Narasimha RajuNo ratings yet

- Hydro-Flo Technologies, Inc.: Chemical Name Acid - Typical Project Name XX-XXXXDocument4 pagesHydro-Flo Technologies, Inc.: Chemical Name Acid - Typical Project Name XX-XXXXPutra TatorNo ratings yet

- Workbook Contents: Find More Excel Spreadsheets For Engineering atDocument34 pagesWorkbook Contents: Find More Excel Spreadsheets For Engineering atGabrielito Pachacama100% (1)

- Prefabricated Effluent Treatment Plant ProposalDocument18 pagesPrefabricated Effluent Treatment Plant Proposalt m murshedNo ratings yet

- Membrane Treatment Processes Offer Versatility and Physical Barrier for Contaminant RemovalDocument8 pagesMembrane Treatment Processes Offer Versatility and Physical Barrier for Contaminant RemovalbazediNo ratings yet

- Budgetary Offer: Sms Envocare Limited For Muzafarpur CetpDocument41 pagesBudgetary Offer: Sms Envocare Limited For Muzafarpur Cetpsreekanth reddyNo ratings yet

- List of SymbolsDocument11 pagesList of SymbolsKaarthic EmayNo ratings yet

- Design of Carbon Filters: InputsDocument5 pagesDesign of Carbon Filters: InputsarcelitasNo ratings yet

- Enviraj MBBR CalculatorDocument3 pagesEnviraj MBBR Calculatorankur100% (2)

- UF Process DesignDocument58 pagesUF Process DesignAsad RazaNo ratings yet

- Sewer Pump Calculation ReportDocument4 pagesSewer Pump Calculation Reportarguteconsultants0% (1)

- Design of STP for HapurDocument5 pagesDesign of STP for HapurKalyca Nazhifa SalwaNo ratings yet

- Filter SizingDocument2 pagesFilter SizingRoland LumpasNo ratings yet

- ETP Design CalculationDocument6 pagesETP Design Calculationmanuel.hernandez100% (2)

- Techno-Commercial Offer For 150 KLD STP, Based Upon MBBR.Document9 pagesTechno-Commercial Offer For 150 KLD STP, Based Upon MBBR.Anshika RaiNo ratings yet

- Side Stream FiltrationDocument8 pagesSide Stream FiltrationAhmed WagihNo ratings yet

- Chemical Pump Dosing CalcsDocument4 pagesChemical Pump Dosing CalcsAnonymous BJ9omONo ratings yet

- 02 - Biological WWTP III - Membrane BioreactorDocument26 pages02 - Biological WWTP III - Membrane BioreactorAhmed100% (1)

- Clarifier DesignDocument5 pagesClarifier DesignSwaminathan ThayumanavanNo ratings yet

- CE 432 Wastewater treatment plant design optimizationDocument19 pagesCE 432 Wastewater treatment plant design optimizationjnmanivannanNo ratings yet

- Bill of Quantities Sewage Treatment PlanDocument11 pagesBill of Quantities Sewage Treatment PlanMiguel ChanNo ratings yet

- STP Design (With Aeration Tank)Document16 pagesSTP Design (With Aeration Tank)Sagar Patel.No ratings yet

- 02.12.21 90m3hr Euroclean-DHV MaithonDocument16 pages02.12.21 90m3hr Euroclean-DHV MaithonSagnik DasNo ratings yet

- SBR DesignDocument10 pagesSBR DesignQuốc TuyênNo ratings yet

- 20 KLD STP Upgreation PROPOSAL-GMCPLDocument7 pages20 KLD STP Upgreation PROPOSAL-GMCPLTech Monger100% (1)

- MBR DesignDocument5 pagesMBR DesignDavid LambertNo ratings yet

- 150 KLD AhlayaDocument17 pages150 KLD Ahlayaalok_rajpoot786100% (1)

- Design of An Extended Aeration Treatment Plant P.EDocument47 pagesDesign of An Extended Aeration Treatment Plant P.ENoureddine Merah100% (1)

- 1 Designing A Reverse Osmosis Plant For Desalination of Agricultural Drainage WaterDocument14 pages1 Designing A Reverse Osmosis Plant For Desalination of Agricultural Drainage Waterabdo magdyNo ratings yet

- MBR Process Design Calculations - US UnitsDocument35 pagesMBR Process Design Calculations - US Unitsshruti sinha100% (1)

- Design Economic Sewage Treatment PlantDocument17 pagesDesign Economic Sewage Treatment PlantDavid LambertNo ratings yet

- Dual Media FilterDocument4 pagesDual Media FilterPandiaraj MkNo ratings yet

- PH Control Using CO2Document38 pagesPH Control Using CO2Bob SmithNo ratings yet

- 45 KLD STP PROPOSAL VRANDAVAN GREENS PDFDocument9 pages45 KLD STP PROPOSAL VRANDAVAN GREENS PDFTech MongerNo ratings yet

- 20 KLD STP Proposal Abha Shree Hotel at BetulDocument10 pages20 KLD STP Proposal Abha Shree Hotel at BetulTech MongerNo ratings yet

- CHAP6 Anaerobic UASB AFDocument18 pagesCHAP6 Anaerobic UASB AFravinder_mittalNo ratings yet

- MBR Membrane Offer for 30 MLD STPDocument8 pagesMBR Membrane Offer for 30 MLD STPakshay salviNo ratings yet

- Multiorganics 50 KLDDocument24 pagesMultiorganics 50 KLDArjun KrishnakumarNo ratings yet

- Summary Report: RO System Flow DiagramDocument3 pagesSummary Report: RO System Flow Diagramjugal ranaNo ratings yet

- Design Spread Sheet For W&WWDocument18 pagesDesign Spread Sheet For W&WWsuinsas75% (8)

- Pochampally Process Design SheetsDocument2 pagesPochampally Process Design Sheetskiran raghukiranNo ratings yet

- 500 KLD Sewage Treatment Plant DesignDocument5 pages500 KLD Sewage Treatment Plant Designkiran raghukiran100% (1)

- Design of Sewage Treatment Plants for Hapur CityDocument110 pagesDesign of Sewage Treatment Plants for Hapur CityyoyoNo ratings yet

- Steel & Con 22-09-14Document24 pagesSteel & Con 22-09-14kiran raghukiranNo ratings yet

- SlabsDocument11 pagesSlabskiran raghukiranNo ratings yet

- Water Tank CLPMDocument3 pagesWater Tank CLPMkiran raghukiranNo ratings yet

- Water Tank DesignDocument3 pagesWater Tank Designkiran raghukiranNo ratings yet

- Water Tank CLPMDocument3 pagesWater Tank CLPMkiran raghukiranNo ratings yet

- TrussDocument1 pageTrusskiran raghukiranNo ratings yet

- Design Constants: Load On SlabDocument5 pagesDesign Constants: Load On Slabkiran raghukiranNo ratings yet

- Design Constants: Load On SlabDocument5 pagesDesign Constants: Load On Slabkiran raghukiranNo ratings yet

- Design Constants: Load On SlabDocument5 pagesDesign Constants: Load On Slabkiran raghukiranNo ratings yet

- Steel & Con 22-09-14Document24 pagesSteel & Con 22-09-14kiran raghukiranNo ratings yet

- Water Tank CLPMDocument3 pagesWater Tank CLPMkiran raghukiranNo ratings yet

- TrussDocument1 pageTrusskiran raghukiranNo ratings yet

- Design Constants: Load On SlabDocument5 pagesDesign Constants: Load On Slabkiran raghukiranNo ratings yet

- SlabsDocument11 pagesSlabskiran raghukiranNo ratings yet

- PileprDocument13 pagesPileprkiran raghukiranNo ratings yet

- TrussDocument1 pageTrusskiran raghukiranNo ratings yet

- Water Tank DesignDocument3 pagesWater Tank Designkiran raghukiranNo ratings yet

- SlabsDocument11 pagesSlabskiran raghukiranNo ratings yet

- PURLINDocument1 pagePURLINkiran raghukiranNo ratings yet

- 100 Bedded Hospital at Jadcherla: Load CalculationsDocument3 pages100 Bedded Hospital at Jadcherla: Load Calculationskiran raghukiranNo ratings yet

- Steel & Con 22-09-14Document24 pagesSteel & Con 22-09-14kiran raghukiranNo ratings yet

- SBC foundation design parameters and calculationsDocument21 pagesSBC foundation design parameters and calculationskiran raghukiranNo ratings yet

- Design of Combined Footing Cf5: 5742 C1 C2 620 C.G 3000 0.75 X 0.75 0.6 X 0.6 2250 2242 1250Document5 pagesDesign of Combined Footing Cf5: 5742 C1 C2 620 C.G 3000 0.75 X 0.75 0.6 X 0.6 2250 2242 1250kiran raghukiranNo ratings yet

- RCC ELSR structural design calculationsDocument41 pagesRCC ELSR structural design calculationskiran raghukiranNo ratings yet

- Design of Drain Wall Stability CheckDocument3 pagesDesign of Drain Wall Stability Checkkiran raghukiranNo ratings yet

- Combined Footing Pcf1 Node L/C Fy MX MZ Node Fy MX MZDocument3 pagesCombined Footing Pcf1 Node L/C Fy MX MZ Node Fy MX MZkiran raghukiranNo ratings yet

- PileprDocument13 pagesPileprkiran raghukiranNo ratings yet

- STP Design SheetsDocument86 pagesSTP Design Sheetskiran raghukiran100% (1)

- Beam Design With Deflection CheckDocument7 pagesBeam Design With Deflection Checkkiran raghukiranNo ratings yet

- De NitrificationDocument3 pagesDe Nitrificationkiran raghukiranNo ratings yet

- For Bakery Dough CoolingDocument1 pageFor Bakery Dough CoolingEnver YiğitNo ratings yet

- Welding AWS B1.11Document16 pagesWelding AWS B1.11Sathishkumar. K67% (3)

- Tutorial Felting A 3 D Rose Part 1, English VersionDocument7 pagesTutorial Felting A 3 D Rose Part 1, English VersionJanine Bronneberg100% (6)

- ACE ACADEMY ESE - 2020 (Prelims) - Offline Test Series 01 SolutionDocument13 pagesACE ACADEMY ESE - 2020 (Prelims) - Offline Test Series 01 SolutionAbhilasha CIVILNo ratings yet

- Chemrite - 520Document2 pagesChemrite - 520ICPL-RWPNo ratings yet

- Sambeiro Close Revised Plumbing Bill 2Document7 pagesSambeiro Close Revised Plumbing Bill 2Dapo AlimiNo ratings yet

- Separation of Cations by Paper ChromatographyDocument4 pagesSeparation of Cations by Paper Chromatographyapi-281104735100% (1)

- Strength of Materials Lecture NotesDocument272 pagesStrength of Materials Lecture NotesVignesh Vicky67% (3)

- Lithonia Outdoor KK Series Area Post Top Brochure 1-89Document10 pagesLithonia Outdoor KK Series Area Post Top Brochure 1-89Alan MastersNo ratings yet

- PRSDocument6 pagesPRSavikbandyopadhyayNo ratings yet

- Bomb SamplerDocument2 pagesBomb SamplerSaravana Vijayan RNo ratings yet

- Diagramatic Plumbing Layout PDFDocument1 pageDiagramatic Plumbing Layout PDFdkdesign consultantNo ratings yet

- Microorganisms in Diesel and in Biodiesel FuelDocument5 pagesMicroorganisms in Diesel and in Biodiesel FueladrimelisNo ratings yet

- High Voltage Design For Airborne Equip.Document217 pagesHigh Voltage Design For Airborne Equip.charlesc5746100% (1)

- JT Checklist FormattingDocument7 pagesJT Checklist FormattingMOHAMAD ISKANDAR BIN SHAMSUDIN MKK172024No ratings yet

- Green ChemistryDocument8 pagesGreen Chemistryyeni100% (1)

- Pultrusion WW 06 2012 Rev3 Us FinalDocument8 pagesPultrusion WW 06 2012 Rev3 Us FinalPradeep MahalikNo ratings yet

- 8.3.2 General Spec For Civil&BDocument205 pages8.3.2 General Spec For Civil&BsurangaNo ratings yet

- Basic Concept of Quantity SurveyingDocument13 pagesBasic Concept of Quantity SurveyingRohitNo ratings yet

- Notes Chapter 3 Class 10 (Metallurgy)Document2 pagesNotes Chapter 3 Class 10 (Metallurgy)Yashmit SanwariaNo ratings yet

- KCC Datasheet A-F7950 (Eng)Document2 pagesKCC Datasheet A-F7950 (Eng)Trịnh Minh Khoa0% (1)

- Vibrating MachineDocument12 pagesVibrating MachineponcoNo ratings yet

- Single Stage Rotary: World Class Efficiency ReliabilityDocument5 pagesSingle Stage Rotary: World Class Efficiency ReliabilitySethuraman Kumarappan (KPCL)No ratings yet

- Mfl67454308 Spirit XP Esl v2Document43 pagesMfl67454308 Spirit XP Esl v2Kai Siang TayNo ratings yet

- Camco Subsurface Chemical Injection SystemsDocument24 pagesCamco Subsurface Chemical Injection SystemsBruceNo ratings yet

- Installation Aspects of MAN B&W Main and Auxiliary EnginesDocument18 pagesInstallation Aspects of MAN B&W Main and Auxiliary EnginesJuurniex100% (4)

- Learning Programme BM and Deflected ShapeDocument73 pagesLearning Programme BM and Deflected ShapeSodiq GbiteNo ratings yet

- Design Basis: M/S Space Combine Kind Attn: Mr. Arun VishwakarmaDocument6 pagesDesign Basis: M/S Space Combine Kind Attn: Mr. Arun Vishwakarmabyajaytyagi2266No ratings yet

- Sondex - A World of Heat Exchangers-2015-EN-SP-LRDocument6 pagesSondex - A World of Heat Exchangers-2015-EN-SP-LRpablo bustamanteNo ratings yet

- Catalogue enDocument38 pagesCatalogue enAndré Luiz Tombini100% (1)