Professional Documents

Culture Documents

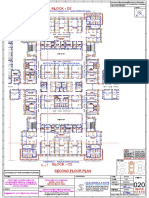

Design Sheets - 500 KLD Extended Aeration

Uploaded by

kiran raghukiranOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design Sheets - 500 KLD Extended Aeration

Uploaded by

kiran raghukiranCopyright:

Available Formats

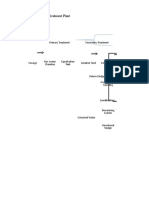

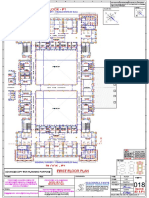

SEWERAGE TREATMENT PLANT 500 KLD FOR THIMMAIGUDA AT HYDERABAD

Project : Sewage Treatment Plant for 500 KLD

Client : GHMC

Contractor:

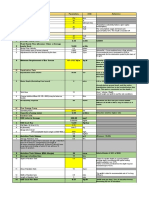

PROCESS DESIGN CALCULATION

MLD Cu.m/Hr.

Design Average Flow MLD 0.500 20.833

Peak Flow Factor (As per CPHEEO Manual) 3.00

Peak Flow MLD 1.500 62.500

Raw & Treated Effluent + Sewage characteristics

Parameters Unit Inlet Outlet

pH 5.5 - 9.0 5.5 - 9.0

BOD mg/l 250.00 ≤ 10

TSS mg/l 375.00 ≤ 20

COD mg/l 450.00 50

Total Nitrogen mg/l 50.00 ≤ 10

Ammonical Nitrogen (NH3-N ) mg/l 32.50

Nitrate Nitrogen (NO3-N) mg/l 5.00

Total Phosphorus mg/l 7.10 ≤1

Oil & Grease mg/l 45.00 Nil

Total Coliform Organism MPN/100ml ≤ 10

Fecal Coliform Organism MPN/100ml <100 /100 ml

UNIT SIZING - COLLECTION SYSTEM

BAR SCREEN CHAMBER Manual

No of Units 1.00 No.

Design Flow 1.500 MLD

Design Flow/Unit 1.500 MLD

62.500 Cu.m/Hr.

0.017 Cu.m/Sec

Clear Opening of Screen 12.00 mm

Width of Screen Flat 6.00 mm

Design Velocity through Screen 0.90 m/sec.

Area Required for Flow 0.019 Sq.m

Effective Area required 0.0289 Sq.m

Width 0.400 m

Depth Required 0.072 m

Depth Provided 0.500 m

Approach Velocity 0.09 m/sec.

Velocity of flow through screen 0.13 m/sec.

Head loss through clean screen 0.001 m

Drop in Screen Chamber Floor 0.000 m

Applying Bernoulis Equation between U/S & D/s of Screen

Z1 + d1 + V1 2 / 2g = Z2 + d2 + V2 2/2g + Hl

Solving by Trial & Error

d2 = 0.181 m

v2 = 0.240 m/sec

When Screen is 50% Clogged

Applying Bernoulis Equation between U/S & D/s of Screen

Z1 + d1 + V1 2 / 2g = Z2 + d2 + V2 2/2g + Hl

Solving by Trial & Error

d1 = 0.141 m

v1 = 0.308 m/sec

Velocity through 50% Clogged Screen 0.924

Approach Velocity at 50% Clogged Condition 0.308

Head Loss through 50% clogged screen = 0.0729*(V1^2-V2^2) 0.055 m

Head Loss in the System at 50% Clogging -0.040 m

Say 0.100 m

Head Buildup on U/S Side at 50% Clogging -0.359 m

Say 0.120 m

Depth Required 0.141 m

Depth Provided 0.400 m

Angle of Inclination of Screen 60.0 Deg

Length Required 1.00 m

Length Provided 2.00 m

FGL of Coarse Screen Chamber area m

Top Level of Coarse Screen Chamber m

Invert Level of Incoming Sewer m

Free fall in receiving chamber 0.15 m

MWL of Screen Channel m

Free Board 0.00 m

Total Depth 0.40 m

Size of Barscreen 1.50 x 0.40x0.40

RAW SEWAGE SUMP

PROCESS DESIGN SHEETS 1 of 5

No of Units 1.00 No.

Inlet Sewage Flow 0.500 MLD

Filtrate Return Flow @ 1.5% 0.0000 MLD

PSF& ACF Back Wash Flow @ 2% 0.0000 MLD

Retention Time for Sewage 15.00 Min

Retention Time for Filtrate 16.00 Hrs.

Retention Time for PSF Back Wash 1.00 Wash

Volume Required for Sewage 5.21 Cu.m

Volume Required for Filtrate 0.00 Cu.m

Volume Required for PSF Backwash 0.00 Cu.m

Total Volume Required 5.21 Cu.m

Liquid Depth of Sump 1.00 m

Size of Sump required 2.28 m

Size of Sump Provided 3.00 m 19.2

Type of Pump Ver Submersible

No. of Working Pumps 3.00 Nos.

No. of Standby Pumps 1.00 Nos.

Total number of pumps 4.00 Nos.

Capacity of Each Raw Sewage Pump 20.83 Cu.m/Hr.

Say 21.00 Cu.m/Hr.

PROCESS DESIGN SHEETS 2 of 5

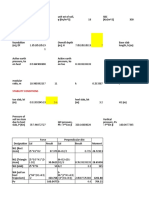

AERATION TANK

No of Units 1.00 No.

Design Flow 0.800 MLD

500.00 KLD

Design Flow/Unit 0.500 MLD

Flow 25.00 cum/hr

Design BOD Removal 250.00 mg/l

BOD Load 125.00 kg/day

MLSS 3500.00

F/M 0.16

Bio mass 781.25 kg/day

Hence we have increased 1500.00

Design MLSS 3500.00 mg/l

3.50 kg/cum

Aeration tank volume 428.57

Depth of Tank 3.50 m

Area Required 122.45 Sq.m

Length of Each Tank 10.00 m

Width of Each Tank 12.24 m

Width Provided 13.00 m

Surface Area Provided 130.00 Sq.m

Free Board 0.50 m

Total Depth 4.00 m

Aeration tank volume 455.00 Cum

Retention Time 21.84 Hours

OXYGEN CALCULATIONS :

Volume of Sewage treated 500.00 m3/day

Theoretical Kg O2 required per Kg BOD as per Sewage Manual 1.20 Kg/Kg BOD

Inlet BOD5 250 mg/l

Outlet BOD5 10.00 mg/l

BOD5 removed 240 mg/l

Kg of BOD removed in a day 120.00 Kg/day

Kg O2 reqd. for BOD load 144 Kg/day

Inlet Total Kjeldhal Nitrogen 32.5 mg/l

Outlet Ammoniacal Nitrogen 0.00 mg/l

Nitrogen assimilated in during BOD removal (@ 5% of Inlet BOD) 12 mg/l

Outlet Nitrate Nitrogen 5.00 mg/l

NH3-N removed in a day 20.5 mg/l

Kg O2 required per Kg of NH3-N 4.60 Kg/ Kg of NH3-N

Kg of NH3-N removed in a day 10.25 Kg/day

Kg O2 reqd. for NH3-N removal 47.15 Kg/day

Kg O2 released per Kg of Nitrate-Nitrogen during denitrification 2.86 -

Kg of Nitrate-Nitrogen generated 7.69 Kg/day

Assuming 75% of Nitrification

Kg of Nitrate Nitrogen in the treated sewage 2.50 Kg/day

Quantity of Nitrate Nitrogen that is denitrified 5.19 Kg/day

Kg O2 released during denitrification 14.84 Kg/day

Total Kg O2 required/day 176.31 Kg/day

AIR REQUIREMENT CALCULATIONS:

Total actual Kg O2 required per day (AOR) 176.31 Kg/day

T = Field Temperature 40 °C 18

H = Altitude of site 542.00 m

Properties of Air

g 9.81 m/ s2

M = Mole of Air 28.97 kg / kg-Mole

R =Universal Gas Constant 8314.00 kg.m2/s2.kg.mole.k

Pa = Atmospheric Pressure 101.325 KN/m2

Oxygen by Weight in air 23.180 %

Ot = % Oxygen Concentration leaving tank 19.00

C = Oxygen Concentration in Tank 2.00

α = Oxygen Transfer Correction Factor 0.65 -

As per Metcalf & Eddy - Page No. 711 - Example 8.2

β = Salinity Surface Tension Correction Factor 0.95 -

F = Fouling Factor 0.9 -

Aeration Depth 3.70 m

Relative Pressure (Pb/Pa)

exp (- g M (Zb - Za) / RT) 0.9426 0.9344

DO Concentration (As per Table D 1 of App D, Metcalf & Eddy) 6.410 9.450

Specific Weight (As per Table C 1 of App C, Metcalf & Eddy) 9.730 9.793

PROCESS DESIGN SHEETS 3 of 5

Oxygen Concentration at specified temp & altitude (C STH) 6.042 8.830

Atmospheric Pressure at Specified Elevation & Temp in m 9.815 9.669

C' S T H

(C STH) (1/2) (((Patm,h + Pw, eff depth)/Patm,h) +(Ot / 21)) 6.8928 10.0994

Oxygen required under Standard Conditions (SOTR)

= AOTR ÷ [((βC'STH – C) ÷ CS20) x 1.024(T – 20) x α x F] 389.70 Kg/day 393.25

Hence, SOR 389.70 Kg/day 393.25

No. of Basins 1 Nos. 1

Standard O2 required at Field Conditions per Basin 389.70 Kg/day/Basin 393.25

Top Water Level (TWL) in Basin 3.50 m 3.50

Bottom Water Level (BWL) in Basins 0.00 m 0.00

Liquid level in Basin 3.50 m 3.50

Height at which Diffusers are kept 0.30 m 0.30

Effective Aeration Depth 3.20 m 3.20

OTE for Diffusers per m depth of submergence 6.00 %

SOTE for the above Effective Aeration Depth 19.200 % 19.20

Fraction of O2 in Air 23.18 % 23.18

Specific Gravity of Air at field Condition

ra = (PM/RT)*(Pb/Pa) 1.063 1.208

Air required at Field Conditions per Basin 8239.56 Nm3/day/ Basin 7315.69

Hours of Aeration per Basin per day 24.00 hr/day/Basin 24

Air required per hour per Basin = M / N 343.32 Nm3/hr/ Basin 304.82

No. of Operating Air Blowers per Basin 1.00 Nos. 1

Capacity of Air Blowers required = O / P 343.32 Nm3/hr 304.82

Safety Factor in Blower Capacity 5.00 % 5

Capacity of Air Blowers with Safety Factor = Q x (1 + R) 360.48 Nm3/hr 320.06

Capacity of Air Blowers provided 370.00 Nm3/hr 330.00

Air Requirment Calculation for Mixing (Based on Surface Area of Tank)

Area of One Reactor Tank 122.4 Sq.m

Air Requirment for Mixing 2.25 Cu.m/Hr./Sq.m

Capacity of Blower Required for Mixing (For One Tank) (On Area Ba 275.5 Cu.m/Hr.

Air Requirment Calculation for Mixing (Based on Volume of Tank)

Volume of One Reactor Tank 130.0 Cu.m

Air Requirment for Mixing 12.50 Cu.m/1000 Cu.m/min

Capacity of Blower Required for Mixing (For One Tank) (On Volume 97.5 Cu.m

Capacity of Blower Required For Each Tank 370 Nm3/Hr.

No of Working Blowers for two Tanks 1.00 Nos.

Capacity of each Blower Required 370 Nm3/Hr.

Say 370.00 Cum/Hr

Head for Blower 4.50 MWC

Number of Working Blowers 1.00 Nos.

Number of Standby Blowers 1.00 Nos.

Total number of Blowers 2.00 Nos.

Type of Blower Twin Lobe

Flow per Diffuser (Fine Bubble Tubular Diffuser) 12.50 m3/Hr.

No. of Diffusers required per Tank 29.60 Nos.

Say 30.00 Nos.

PROCESS DESIGN SHEETS 4 of 5

SECONDARY CLARIFIER

No of Units 1.00 No.

Design Flow 0.500 MLD

Design Flow/Unit 0.500 MLD

500.000 KLD

SOR 60 (40-64 ) As per Metclaff & Eddy

Solids conic in settled sludge 0.80-0.90

Surface area of the tank 8.33

Retention Time 3.00 Hrs.

Volume Required 62.50 Cu.m

Depth Provided 3.00 m

Diametre Required for Secondary Settling Tank 3.26 m

Diameter Provided for Secondary Clarifier 4.00 m

Free Board 0.50 m

Total Depth 3.50 m

Velocity of flow in launder 0.60 m/sec.

Area of Launder Required 0.005 Sq.m

Width of Launder 0.30 m

Liquid Depth in Launder 0.02 m

Wall Tk of launder 0.10 m

Weir length in Clarifier 10.23 RM

Weir loading rate 48.89

Volume of Tank 150.72 Cum

Hydraulic Detention time 7.23 Hours

Hence ok for Retention time 3.00-6.00 Hours

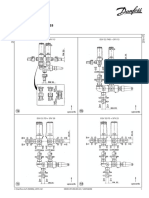

INTERNAL RECRICULATION (NITRIFIED LIQUOR)

Recirculation 100 %

Volume of Recirculation per Day 500 Cu.m/Day

Capacity of Pump Required 20.83 Cu.m/Hr.

No. of Working Pumps 1.00 Nos.

No of Pumps provided (1W+1S) 2.00 Nos.

Type of Pump Submersible

Capacity of Each Pump Required 20.83 Cu.m/Hr.

Sludge Drying Beds

Bed surface area required for digested primary sludge 80-120 kg dry solids /m2 /yr

Sludge drying time 2-4 weeks

Size of bed 6-30 m length

3-8 width

Specific sludge solids loading rate 50-210 kg /m2 -yr

Dry solids produced 280000 g/day

280 kg/day

area of bed needed 1022 (assumed 100 kg /m2 /year

Check for area of drying bed per capita 0.146 m2 / capita

Area of one bed 30x8 m wide beds

Number of beds 4.26

Say 5.00 Nos

SODIUM HYPO CHLORITE DOSING SYSTEM

Chlorine Dosage 6.00 PPM

Design flow 0.50 MLD

Chlorine Required per Day 3.00 Kgs.

0.125 Kgs./Hr.

Solution Strength as procured in % 5.00

Available strength at point of use in % 4.00

Volume of solution needed liters / Hr. 3.13 Lit/Hr.

75.00 Lit.Day

Providing a dosing tank for 24.00 Hrs.

Vol of tank required 75.00 Ltrs

Say 100.00 Ltrs

Capacity of Dosing Pump 3.13 Ltrs/Hr.

No of Dosing Pumps 1 Nos.

Capacity of each Dosing Pump 3.13

Say 4.00 Ltrs/Hr.

PROCESS DESIGN SHEETS 5 of 5

You might also like

- ASP - Process Design CalculationDocument21 pagesASP - Process Design Calculationvishu100% (1)

- Sps and Wetwell NTLDocument3 pagesSps and Wetwell NTLProject ManagerStructuresNo ratings yet

- Extended AerationDocument5 pagesExtended Aerationgautam guptaNo ratings yet

- Bep Rev.c-New 20 MLD WTP, NathavaliDocument380 pagesBep Rev.c-New 20 MLD WTP, NathavaliAnonymous 7l8AIyq2No ratings yet

- Design 2 MLDDocument9 pagesDesign 2 MLDANIL KUMAR H CNo ratings yet

- Design Calculation - STPDocument23 pagesDesign Calculation - STPForam ParekhNo ratings yet

- Free Design Calculations For STP and ETP by Richa Environmental Services PVT LTD PDFDocument6 pagesFree Design Calculations For STP and ETP by Richa Environmental Services PVT LTD PDFmuradali01No ratings yet

- Intake Design: DataDocument4 pagesIntake Design: DataGokulNo ratings yet

- STP CalculationDocument17 pagesSTP CalculationHimanshu Phuloria0% (1)

- Cpheeo Manual Filter Bed and Sed. TankDocument9 pagesCpheeo Manual Filter Bed and Sed. TankChauhan UjjvalNo ratings yet

- Etp - 30 KLDDocument18 pagesEtp - 30 KLDsubramanyam kumarNo ratings yet

- Filter DesignDocument4 pagesFilter Designhassan11783100% (1)

- Hyd - Cal. WTP BaggiDocument27 pagesHyd - Cal. WTP BaggiChief Engineer PMUNo ratings yet

- 35 MLD WTP EstimateDocument78 pages35 MLD WTP EstimateaneeshmeloottuNo ratings yet

- Techno Commercial Offer For 5 KLD Packaged Effluent Treatment PlantDocument11 pagesTechno Commercial Offer For 5 KLD Packaged Effluent Treatment PlantDogo ArgentinoNo ratings yet

- Conventional STP 400 KLDDocument15 pagesConventional STP 400 KLDK&K ConsultantsNo ratings yet

- 4b., 5. & 6. PDC, HDC & LCUDocument16 pages4b., 5. & 6. PDC, HDC & LCUepe civil1No ratings yet

- Design Calculation of 61kld STPDocument4 pagesDesign Calculation of 61kld STPAminur Rahman100% (2)

- STP Design (With Aeration Tank)Document16 pagesSTP Design (With Aeration Tank)Sagar Patel.No ratings yet

- 3.1 Final Process Design of 6 MLD - Stp.sbr.Document8 pages3.1 Final Process Design of 6 MLD - Stp.sbr.Minakshi SinghNo ratings yet

- Design Basis: M/S Space Combine Kind Attn: Mr. Arun VishwakarmaDocument6 pagesDesign Basis: M/S Space Combine Kind Attn: Mr. Arun Vishwakarmabyajaytyagi2266No ratings yet

- STP Design Report - IndiqubeDocument20 pagesSTP Design Report - IndiqubeRajkishore NayakNo ratings yet

- Symrpl 15 KLD STPDocument15 pagesSymrpl 15 KLD STPDnyaneshwar Dattatraya Phadatare100% (3)

- Design of Carbon Filters: InputsDocument5 pagesDesign of Carbon Filters: InputsarcelitasNo ratings yet

- Design Basis Report - STP 90 KLDDocument11 pagesDesign Basis Report - STP 90 KLDvishu talapeNo ratings yet

- Design of Slow Sand Filter KinfraDocument2 pagesDesign of Slow Sand Filter KinframajeedctNo ratings yet

- Nitrogen RemovalDocument96 pagesNitrogen RemovalnusageniNo ratings yet

- STP MBR 50KLDDocument13 pagesSTP MBR 50KLDDhanraj Bn100% (1)

- 45 KLD STP PROPOSAL VRANDAVAN GREENS PDFDocument9 pages45 KLD STP PROPOSAL VRANDAVAN GREENS PDFTech MongerNo ratings yet

- 250-Lph-Ro SpecificationDocument7 pages250-Lph-Ro Specificationsubhananda routNo ratings yet

- 120KLD ETP - DharmikbhaiDocument7 pages120KLD ETP - DharmikbhaiM. D. RAMCHANDANINo ratings yet

- Dual Media FilterDocument4 pagesDual Media FilterPandiaraj Mk100% (1)

- Annex 30 Tool - Design - Waste Stabilization PondsDocument8 pagesAnnex 30 Tool - Design - Waste Stabilization Pondsmurkeking100% (1)

- Blower Calculation STP WWTPDocument3 pagesBlower Calculation STP WWTPrizky hardiNo ratings yet

- Hydraulic Design of Sewage Treatment PlantDocument9 pagesHydraulic Design of Sewage Treatment PlantSCR_010101No ratings yet

- STP Design 50KLDDocument3 pagesSTP Design 50KLDmurugaraj92% (13)

- 1) STP 500 LTR (Lal Pathlabs)Document16 pages1) STP 500 LTR (Lal Pathlabs)raj enterprise100% (1)

- STP DesignDocument47 pagesSTP DesignkoppinenipraneethNo ratings yet

- WTP Report - 1.5MLD PDFDocument97 pagesWTP Report - 1.5MLD PDFDesign TeamNo ratings yet

- Design .Areator - & - Flash - Mixer PDFDocument16 pagesDesign .Areator - & - Flash - Mixer PDFGomatesh PatilNo ratings yet

- Bill of Quantities Sewage Treatment PlanDocument11 pagesBill of Quantities Sewage Treatment PlanMiguel ChanNo ratings yet

- Design Sheet STPDocument17 pagesDesign Sheet STPBhagyashree Rath0% (1)

- STP SizingDocument4 pagesSTP SizingAlexandrine Roxanne Agcaoili100% (1)

- Design of Each Process of ETPDocument9 pagesDesign of Each Process of ETPFaisal Sr. ExecutiveNo ratings yet

- ETP DesignDocument49 pagesETP DesignMayank Mani100% (1)

- Design STP 2019Document16 pagesDesign STP 2019Abhiraj AbhirajNo ratings yet

- Interim Report 150 MLDDocument112 pagesInterim Report 150 MLDMaqsood Ibn Shaikhul ArfeenNo ratings yet

- Bill of Quantities: Project: Sewage Treatment Plant (0.90 MLD) Location: Pochampally Consultant: Mep ConsultantDocument7 pagesBill of Quantities: Project: Sewage Treatment Plant (0.90 MLD) Location: Pochampally Consultant: Mep Consultantsubramanyam kumarNo ratings yet

- Annexure 16 - Tool For Design of Tube SettlerDocument1 pageAnnexure 16 - Tool For Design of Tube SettlerWikaz FiansyahNo ratings yet

- Design Inputs QTY Unit: CalculationDocument7 pagesDesign Inputs QTY Unit: CalculationHemant Kale100% (1)

- 1000 LPH Ro PlantDocument5 pages1000 LPH Ro PlantKamatchi NathanNo ratings yet

- Process Design Calculation3 - NDDocument14 pagesProcess Design Calculation3 - NDabhishek5810No ratings yet

- WTP CalculationsDocument10 pagesWTP CalculationsAngshuman Roy ChoudhuryNo ratings yet

- 20 KLD STP Proposal Abha Shree Hotel at BetulDocument10 pages20 KLD STP Proposal Abha Shree Hotel at BetulTech MongerNo ratings yet

- Compact Waste Water Treatment MBR /MBBR TechnologyDocument6 pagesCompact Waste Water Treatment MBR /MBBR TechnologyVishal NakraniNo ratings yet

- Process Design CalcDocument9 pagesProcess Design Calckiran raghukiranNo ratings yet

- Proceess .FileDocument10 pagesProceess .Filekiran raghukiranNo ratings yet

- Pochampally Process Design SheetsDocument2 pagesPochampally Process Design Sheetskiran raghukiranNo ratings yet

- Water Tank DesignDocument3 pagesWater Tank Designkiran raghukiranNo ratings yet

- Water Tank CLPMDocument3 pagesWater Tank CLPMkiran raghukiranNo ratings yet

- 6) Raft & Stair CaseDocument41 pages6) Raft & Stair Casekiran raghukiranNo ratings yet

- Retaining WallsDocument21 pagesRetaining Wallskiran raghukiranNo ratings yet

- Design of Combined Footing Cf5: 5742 C1 C2 620 C.G 3000 0.75 X 0.75 0.6 X 0.6 2250 2242 1250Document5 pagesDesign of Combined Footing Cf5: 5742 C1 C2 620 C.G 3000 0.75 X 0.75 0.6 X 0.6 2250 2242 1250kiran raghukiranNo ratings yet

- SlabsDocument11 pagesSlabskiran raghukiranNo ratings yet

- Design Constants: Load On SlabDocument5 pagesDesign Constants: Load On Slabkiran raghukiranNo ratings yet

- 100 Bedded Hospital at Jadcherla: Load CalculationsDocument3 pages100 Bedded Hospital at Jadcherla: Load Calculationskiran raghukiranNo ratings yet

- Combined Footing Pcf1 Node L/C Fy MX MZ Node Fy MX MZDocument3 pagesCombined Footing Pcf1 Node L/C Fy MX MZ Node Fy MX MZkiran raghukiranNo ratings yet

- Design of Drain Wall: Mr-Mot-M Due To Earth On Toe Mnet/ (V-WT of Earth On Toe)Document3 pagesDesign of Drain Wall: Mr-Mot-M Due To Earth On Toe Mnet/ (V-WT of Earth On Toe)kiran raghukiranNo ratings yet

- De NitrificationDocument3 pagesDe Nitrificationkiran raghukiranNo ratings yet

- Beam Design With Deflection CheckDocument7 pagesBeam Design With Deflection Checkkiran raghukiranNo ratings yet

- Beam Design With Deflection CheckDocument7 pagesBeam Design With Deflection Checkkiran raghukiranNo ratings yet

- STP Design SheetsDocument86 pagesSTP Design Sheetskiran raghukiran100% (1)

- Report and DesignDocument53 pagesReport and Designkiran raghukiranNo ratings yet

- STP Design Sheets D PochampallyDocument121 pagesSTP Design Sheets D Pochampallykiran raghukiranNo ratings yet

- Aeration Tank DesignedDocument6 pagesAeration Tank Designedkiran raghukiranNo ratings yet

- Box Culvert Limit StateDocument37 pagesBox Culvert Limit Statekiran raghukiranNo ratings yet

- General Surgery - Female Ward (30 Beds) : NorthDocument1 pageGeneral Surgery - Female Ward (30 Beds) : Northkiran raghukiranNo ratings yet

- Structural Design of Single Cell Box Culvert Vijayanagaram: Input DataDocument6 pagesStructural Design of Single Cell Box Culvert Vijayanagaram: Input Datakiran raghukiranNo ratings yet

- General Medicine - Male Ward (30 Beds) : Duct DuctDocument1 pageGeneral Medicine - Male Ward (30 Beds) : Duct Ductkiran raghukiranNo ratings yet

- General Surgery & Ent - Male Ward (30 Beds) : Duct DuctDocument1 pageGeneral Surgery & Ent - Male Ward (30 Beds) : Duct Ductkiran raghukiranNo ratings yet

- General Medicine - Female Ward (30 Beds) : Duct DuctDocument1 pageGeneral Medicine - Female Ward (30 Beds) : Duct Ductkiran raghukiranNo ratings yet

- General Surgery - Male Ward (30 Beds) : Duct DuctDocument1 pageGeneral Surgery - Male Ward (30 Beds) : Duct Ductkiran raghukiranNo ratings yet

- General Medicine & Opthalmology - Male Ward (30 Beds)Document1 pageGeneral Medicine & Opthalmology - Male Ward (30 Beds)kiran raghukiranNo ratings yet

- 1 Project Description: Hospital - DBRDocument19 pages1 Project Description: Hospital - DBRkiran raghukiranNo ratings yet

- Kiln Emergency YSDocument50 pagesKiln Emergency YSMUhammad Ishfaq Shakoor100% (1)

- 2015 04-2 PDFDocument41 pages2015 04-2 PDFPTIL ProcessNo ratings yet

- Introduction To Molecular Spectros PDFDocument333 pagesIntroduction To Molecular Spectros PDFmekoki86% (7)

- Painting System 20000E02Document142 pagesPainting System 20000E02prabha221No ratings yet

- Refrigerant Recovery and Recharge of A Room Air ConditionerDocument7 pagesRefrigerant Recovery and Recharge of A Room Air ConditionerPahan WijayabandaraNo ratings yet

- Lab #1paper ChromatographyDocument2 pagesLab #1paper ChromatographyKenysha jNo ratings yet

- Me 209 Thermodynamics: Introduction To Thermodynamics: System, Surroundings, BoundariesDocument9 pagesMe 209 Thermodynamics: Introduction To Thermodynamics: System, Surroundings, BoundariesPrayas JainNo ratings yet

- 8b Dados TecnicosDocument2 pages8b Dados TecnicosWeyvson SilvaNo ratings yet

- Diagnostic of Kashmir SapphiresDocument14 pagesDiagnostic of Kashmir SapphiresNaveed NaseerNo ratings yet

- ERDAnewsvol 32no 32015Document12 pagesERDAnewsvol 32no 32015sasenthil241464No ratings yet

- Machine Learning-Based Inverse Design For Single-Phase High Entropy AlloysDocument13 pagesMachine Learning-Based Inverse Design For Single-Phase High Entropy Alloysbaikw KewuNo ratings yet

- Exp 4 Osborne Reynolds DemonstrationDocument9 pagesExp 4 Osborne Reynolds DemonstrationJivashiniBalasupurManiamNo ratings yet

- SCITEC11Document82 pagesSCITEC11RamkatNo ratings yet

- 1st Periodic Test - Science 7Document4 pages1st Periodic Test - Science 7laarni malata100% (1)

- Design Against CreepDocument112 pagesDesign Against CreepRishabh TripathiNo ratings yet

- NitricAcid PDFDocument2 pagesNitricAcid PDFmladen lakicNo ratings yet

- q3 cGBPariantDocument4 pagesq3 cGBPariantGhasem BashiriNo ratings yet

- Diffusion TestDocument14 pagesDiffusion TestVinoth KumarNo ratings yet

- Specification For Non Toxicity Requirements For Paints and CoatingsDocument5 pagesSpecification For Non Toxicity Requirements For Paints and CoatingsVJ QatarNo ratings yet

- Proposal Defiance Gelatin ExtractionDocument26 pagesProposal Defiance Gelatin ExtractionSiti Amirah100% (2)

- Understanding ESCRDocument9 pagesUnderstanding ESCRimru2No ratings yet

- PC Chapter 26Document58 pagesPC Chapter 26ultimuNo ratings yet

- Adobe Scan 10 Oct 2020 PDFDocument1 pageAdobe Scan 10 Oct 2020 PDFShyam Sundar JanaNo ratings yet

- Henkel - Composites Materials EngineeringDocument27 pagesHenkel - Composites Materials EngineeringsantiagoNo ratings yet

- B-10 Barrier Cream - Industrial Chemical TechnologiesDocument2 pagesB-10 Barrier Cream - Industrial Chemical TechnologiesBiju_PottayilNo ratings yet

- Nmat Reviewer Gen and Ana ChemDocument22 pagesNmat Reviewer Gen and Ana Chemforfuture reviewersNo ratings yet

- 446 Questions With Answers in MINERALOGY Science TopicDocument1 page446 Questions With Answers in MINERALOGY Science TopicTri johan saputraNo ratings yet

- Appendix XVI B. Microbiological Examination of Non-Sterile Products - British PharmacopoeiaDocument30 pagesAppendix XVI B. Microbiological Examination of Non-Sterile Products - British PharmacopoeiaGeotamNo ratings yet

- Powder Metallurgy & Mining: Electrochemical Chelation of Heavy Metals by 2-BenzimidazoleDocument5 pagesPowder Metallurgy & Mining: Electrochemical Chelation of Heavy Metals by 2-Benzimidazolecharaf lNo ratings yet

- SPM Chemistry Form 5 Chap 2Document19 pagesSPM Chemistry Form 5 Chap 2KhimSimNo ratings yet