Professional Documents

Culture Documents

LT Panel MCC Revalidation Report - (Ril J3 Project) : S.No Check Points Observation Remarks

Uploaded by

Sanjay Kumar Kanaujia0 ratings0% found this document useful (0 votes)

27 views48 pagesOriginal Title

188416

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

27 views48 pagesLT Panel MCC Revalidation Report - (Ril J3 Project) : S.No Check Points Observation Remarks

Uploaded by

Sanjay Kumar KanaujiaCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 48

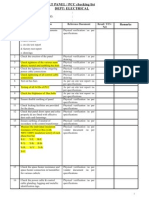

LT PANEL MCC REVALIDATION REPORT - (RIL J3 PROJECT)

Plant: Board No:

Substation: Tag No:

No of vertical Section: Date:

S.No Check Points Observation Remarks

Horizontal Busbar Chamber

1 Cleaning of HBB zone

2 shipping Section Fishplate joint tightness

3 Condition of busbar support Insulators

4 Check for presence of joint shrouds

5 Ensure no foreign material inside chamber like Hardwares, Spanners & etc

6 Gasket condition of top HBB cover

7 Ensure HBB top cover tightned by all screw

8 Ensure HBB chamber sealed it properly & no gap at frame

Vertical Busbar Chamber

9 HBB to VBB joint tightness

10 Condition of dropper support Insulators

11 Fixed contacts on VBB tightness

12 Check for presence of dropper shrouds

13 Gasket condition of compartment door

14 Verification of availability of Dropper bottom shrouds

15 Ensure no foreign material inside chamber like Hardwares, Spanners & etc

Aux Busbar Chamber

16 shipping Section Aux bus joint tightness

17 Every vertical feeders aux.bus taping cable tighness.

18 Ensure no foreign material inside chamber like Hardwares, Spanners & etc

Cable Chamber & Module Cubicle

19 Check for Safety shutter movement is free

20 Check for telescopic rail & racking screw

21 Greasing of racking screw & telescopic rail

22 Movement of contacts assembly is satisfactory for 250/500A Contacts

23 Check for Secondary isolating contacts (SIC)

24 Check all joint tightness in modules.

25 Module I/C & O/G contacts status & tightness

26 Module components status

27 Ensure all fuses are healthy (Fuse continuity)

28 Module alignment in cubicle

29 Ensure Door pushers, Module Pusher & Puller for above 600mm module

30 Check alignment of handle for all switches

31 Verification of MTB wiring for MCCs

Check for all cable alley door, top & bottom cover(100MM) door hardwares have

32

been engaged.

33 Check for Module door camlock are healthy

34 Ensure all unused holes are blocked.

Others

To Check & correct Y phase cable routing (as per scheme) in modules 15 to

35

22KW,30Kw, 37kW & 45kW

36 To check & make uniformity in MCOMP Communication port D+ & D- termination

37 To check & ensure 19mm clearance between HBB & Endcover

To check & ensure insulataed barrier (Polycarbonate Sheet) mounted in endcover

38

between HBB & Endcover

39 Rectification of manufcaturing defects like door alignment & panel coupling.

Supply of short supplied items, Installation of damaged & short supplied items (on

40

availability at site). (supply of damaged items not in our scope).

41 No of tools utilized for revalidation. Before revalidation: After revalidation:

42 Megger value after revalidation of Board

R-E : Y-E: B-E: N-E:

R-N: Y-N: B-N:

R-Y : Y-B: B-R:

Remarks:

Serviced By: Verified by RIL Engineer

Date:

You might also like

- Factory Acceptance Test Checklist for Low Voltage Electrical BoardsDocument5 pagesFactory Acceptance Test Checklist for Low Voltage Electrical BoardsBalamurugan Arumugam100% (2)

- 2014 NEC Codebook PDFDocument51 pages2014 NEC Codebook PDFargari1957% (7)

- Transistor Switching and Sequential CircuitsFrom EverandTransistor Switching and Sequential CircuitsRating: 5 out of 5 stars5/5 (1)

- Piping Reinstatement: Inspection Test Report Form NoDocument2 pagesPiping Reinstatement: Inspection Test Report Form NoFrancisco75% (4)

- PD CLC TS 50539 12 2013 Low Voltage Surge Protective Devices Surge Protective Devices For Specific Application Including D.C.Document38 pagesPD CLC TS 50539 12 2013 Low Voltage Surge Protective Devices Surge Protective Devices For Specific Application Including D.C.Chang Lee100% (1)

- Checklist of Panels - 00047 NewDocument6 pagesChecklist of Panels - 00047 NewKarthick NatrajanNo ratings yet

- Power System Analysis SlidesDocument34 pagesPower System Analysis SlidesSamundar Khan100% (2)

- Commissioning LT SwitchgearDocument13 pagesCommissioning LT Switchgearvikivarma147100% (1)

- Gas Insulated Switchgear (Gis)Document17 pagesGas Insulated Switchgear (Gis)Syed AbbasNo ratings yet

- SEC-EOA Site Test ReportDocument9 pagesSEC-EOA Site Test ReportmaheshknmNo ratings yet

- Function Checks Is Not Applicable For This Panel: Switchgear Functional TestDocument3 pagesFunction Checks Is Not Applicable For This Panel: Switchgear Functional Testeswaran005No ratings yet

- LT PANEL / PCC Checking List Dept: Electrical: Equipment Tag No: Incoming PCC Feeder No.: DateDocument3 pagesLT PANEL / PCC Checking List Dept: Electrical: Equipment Tag No: Incoming PCC Feeder No.: DateVelmurugan Chakkravarthy100% (4)

- Ohl TestDocument5 pagesOhl TestAnonymous ExWAN2xjFJNo ratings yet

- Maintenance Schedule Kiln Shut Down AUG 19Document17 pagesMaintenance Schedule Kiln Shut Down AUG 19swarupkumarnayakNo ratings yet

- Precommissioning Test FormatDocument72 pagesPrecommissioning Test Formatashutosh2009100% (3)

- Field Quality Plan for Agency ManufacturesDocument3 pagesField Quality Plan for Agency ManufacturesSourav RanaNo ratings yet

- 1A - 11kV HT PanelDocument10 pages1A - 11kV HT PanelPraveen KumarNo ratings yet

- Switch Gear Commissioning ChecklistDocument27 pagesSwitch Gear Commissioning ChecklistRAM SHANMUGAMNo ratings yet

- GIS Testing and Commissioning Checklist - SEC - CSDDocument4 pagesGIS Testing and Commissioning Checklist - SEC - CSDabdul basit100% (1)

- In-Process Inspection Checklist: SL Check Points Observations Checked I Fabricated Cubicle / in House FabricationDocument3 pagesIn-Process Inspection Checklist: SL Check Points Observations Checked I Fabricated Cubicle / in House FabricationViswa Bhuvan0% (1)

- Workpack TEMANA ShutdownDocument23 pagesWorkpack TEMANA ShutdownYusmin Mat Jusoh100% (2)

- CL-NG-6460-002-029 Checklist For Metal Clad Switchgear Rev00Document4 pagesCL-NG-6460-002-029 Checklist For Metal Clad Switchgear Rev00WajahatNo ratings yet

- 18002-Int-Fqe-Cl-Pw-001-0 - Checklist-Commissioning of Power Transformer PDFDocument1 page18002-Int-Fqe-Cl-Pw-001-0 - Checklist-Commissioning of Power Transformer PDFVenkataramanan S67% (3)

- National Grid: Checklist For Commissioning of Oil-Immersed Power TransformerDocument8 pagesNational Grid: Checklist For Commissioning of Oil-Immersed Power TransformerSanthosh Kumar VinayagamNo ratings yet

- Sec Calc Fault Locator For Red Rel 670Document3 pagesSec Calc Fault Locator For Red Rel 670ZokiNo ratings yet

- 11KV Og FDR-2Document2 pages11KV Og FDR-2Sathi Reddy ThondapuNo ratings yet

- 08.precommissioning Checklist GeneralDocument19 pages08.precommissioning Checklist GeneralAnujGarg100% (1)

- ABB Substation Condition Monitoring ScheduleDocument16 pagesABB Substation Condition Monitoring ScheduleRey Arthur100% (1)

- 3va Molded Case Circuit Breakers With Ul Certification en PDFDocument172 pages3va Molded Case Circuit Breakers With Ul Certification en PDFSanjay Kumar KanaujiaNo ratings yet

- RET670 Matrix Calculation With The Measured Current PDFDocument4 pagesRET670 Matrix Calculation With The Measured Current PDFSanjay Kumar KanaujiaNo ratings yet

- RET670 Matrix Calculation With The Measured Current PDFDocument4 pagesRET670 Matrix Calculation With The Measured Current PDFSanjay Kumar KanaujiaNo ratings yet

- PM Text As Per Bcel-002Document4 pagesPM Text As Per Bcel-002Jay Rameshbhai ParikhNo ratings yet

- CL-NG-6460-002-018 Checklist For Oil-Immersed Transformer Rev02Document8 pagesCL-NG-6460-002-018 Checklist For Oil-Immersed Transformer Rev02WajahatNo ratings yet

- Sace - AbbDocument332 pagesSace - AbbPop-Coman SimionNo ratings yet

- 14-Weekly Tower Crane Check ListDocument2 pages14-Weekly Tower Crane Check ListJigarNo ratings yet

- GAC-12-VX-RMH-LAH-001 - Attachments - 1 To 7Document17 pagesGAC-12-VX-RMH-LAH-001 - Attachments - 1 To 7Dipayan DasNo ratings yet

- BBP CBF - Function TestDocument21 pagesBBP CBF - Function TestAmr ElkadyNo ratings yet

- MDB Commissioning ChecklistDocument3 pagesMDB Commissioning ChecklistifranNo ratings yet

- A/b/c/d/e/f - PassDocument6 pagesA/b/c/d/e/f - PassVikrant DeshmukhNo ratings yet

- KV-27XBR51 KV-27XBR55Document81 pagesKV-27XBR51 KV-27XBR55David RoldanNo ratings yet

- Zenith Guy Wire NDTDocument35 pagesZenith Guy Wire NDTMohamed Elnagdy0% (1)

- Half-Yearly Maintenance of Auxiliary TransformerDocument3 pagesHalf-Yearly Maintenance of Auxiliary TransformerKrishna Mohan KolliparaNo ratings yet

- Indra: Cabinet NameDocument1 pageIndra: Cabinet NameBoualem AisNo ratings yet

- NullDocument20 pagesNullMichael OkwuwaNo ratings yet

- TDC - YER.1.00000 Updated (TDS-3)Document4 pagesTDC - YER.1.00000 Updated (TDS-3)Mohamed AnwarNo ratings yet

- 15.4 Prerequisites: 15.4.1 Typical List of Apparatus/InstrumentsDocument9 pages15.4 Prerequisites: 15.4.1 Typical List of Apparatus/InstrumentsIqbalilah RamdaniNo ratings yet

- Eot Ibl Crane Yearly ChecksheetDocument3 pagesEot Ibl Crane Yearly ChecksheetAmit ThakurNo ratings yet

- Electrical Plant ChecklistDocument5 pagesElectrical Plant ChecklistAjish Rajan TNo ratings yet

- JX Nippon Oil & Gas Exploration Inspection Test Record (Itr) - BDocument3 pagesJX Nippon Oil & Gas Exploration Inspection Test Record (Itr) - BAmyNo ratings yet

- CL-NG-6460-002-023 Checklist For CT Rev01Document5 pagesCL-NG-6460-002-023 Checklist For CT Rev01sachin francisNo ratings yet

- Metro Cash & Carry 800A LT Panel Test ReportDocument3 pagesMetro Cash & Carry 800A LT Panel Test ReportAROCKIA STEPHAN SESUMANINo ratings yet

- Paper B-E-3-2 With AnswersDocument6 pagesPaper B-E-3-2 With AnswersvidyasagNo ratings yet

- Motor Checks & MaintenceDocument5 pagesMotor Checks & Maintenceravi chandra mavuriNo ratings yet

- 4 Test AllDocument50 pages4 Test AllSukhee ByambaaNo ratings yet

- Upgradation & OverhaulingDocument20 pagesUpgradation & Overhaulingshailendra jaiswalNo ratings yet

- Reactor - For SwitchayrdDocument10 pagesReactor - For SwitchayrdSindhuKumarNo ratings yet

- Technical Specification for LT AC Distribution BoardDocument41 pagesTechnical Specification for LT AC Distribution BoardPrashant TrivediNo ratings yet

- VLSI 2 Project ReportDocument36 pagesVLSI 2 Project ReportTabassum RezaNo ratings yet

- NullDocument9 pagesNullMichael OkwuwaNo ratings yet

- GAC-12-VX-RMH-LAH-008 - Attachments - 1 To 7Document14 pagesGAC-12-VX-RMH-LAH-008 - Attachments - 1 To 7Dipayan DasNo ratings yet

- Attachment A PV Site Commissioning ChecklistDocument4 pagesAttachment A PV Site Commissioning ChecklistJames K. BitokNo ratings yet

- Igranic Powervac HHV12 S&S 12KVDocument32 pagesIgranic Powervac HHV12 S&S 12KVKevin Lee100% (1)

- Eaf Shutdown Job StatusDocument2 pagesEaf Shutdown Job StatusSHUVANKAR DASNo ratings yet

- 3300 - 440v Transformer Maintenance ProcedureDocument4 pages3300 - 440v Transformer Maintenance ProcedureGunadevan ChandrasekaranNo ratings yet

- Device Installation Status and Room DetailsDocument20 pagesDevice Installation Status and Room DetailsRajesh RaghunathanNo ratings yet

- Certificate From Chartered Accountant About Investment in Plant & Machinery Annexure 'III' (On C.A. Letter Head)Document1 pageCertificate From Chartered Accountant About Investment in Plant & Machinery Annexure 'III' (On C.A. Letter Head)Sanjay Kumar KanaujiaNo ratings yet

- Getting Started PDFDocument14 pagesGetting Started PDFCeliz MedinaNo ratings yet

- IndusInd Bank Iconia Visa Card Benefit GuideDocument12 pagesIndusInd Bank Iconia Visa Card Benefit GuideSanjay Kumar KanaujiaNo ratings yet

- Siprotec: Communication Module DNP 3.0 Bus Mapping / Point ListsDocument36 pagesSiprotec: Communication Module DNP 3.0 Bus Mapping / Point ListsChomsaniNo ratings yet

- User's Manual: Isolated, RS232 / RS485 To USB Converter. Model SC11UDocument5 pagesUser's Manual: Isolated, RS232 / RS485 To USB Converter. Model SC11USanjay Kumar KanaujiaNo ratings yet

- Siprotec: Communication Module DNP 3.0 Bus Mapping / Point ListsDocument36 pagesSiprotec: Communication Module DNP 3.0 Bus Mapping / Point ListsChomsaniNo ratings yet

- VFD-M Series AC Motor Drive ManualDocument173 pagesVFD-M Series AC Motor Drive ManualoarionIIINo ratings yet

- Test Certificate of Og Feeders Client Tested On Plant Tested by SWBD FeederDocument3 pagesTest Certificate of Og Feeders Client Tested On Plant Tested by SWBD FeederSanjay Kumar KanaujiaNo ratings yet

- Premier 300: Accurate & Interoperable Comms With Advance Event Detection For LV, MV & HV MeteringDocument2 pagesPremier 300: Accurate & Interoperable Comms With Advance Event Detection For LV, MV & HV MeteringVeera ChaitanyaNo ratings yet

- Test Certificate of Ac High Voltage of Bus-Bar: Test Done by Checked & Accepted by Reviewed byDocument1 pageTest Certificate of Ac High Voltage of Bus-Bar: Test Done by Checked & Accepted by Reviewed bySanjay Kumar KanaujiaNo ratings yet

- Erection, Testing and Commissioning Engineers: QuotationDocument1 pageErection, Testing and Commissioning Engineers: QuotationSanjay Kumar KanaujiaNo ratings yet

- Bus Bar CRM ValueDocument1 pageBus Bar CRM ValueSanjay Kumar KanaujiaNo ratings yet

- User's Manual: Isolated, RS232 / RS485 To USB Converter. Model SC11UDocument5 pagesUser's Manual: Isolated, RS232 / RS485 To USB Converter. Model SC11USanjay Kumar KanaujiaNo ratings yet

- Dok TD MRM3 2eDocument70 pagesDok TD MRM3 2eSanjay Kumar KanaujiaNo ratings yet

- Test Done by Checked & Accepted by Reviewed By: Sign. Date NameDocument2 pagesTest Done by Checked & Accepted by Reviewed By: Sign. Date NameSanjay Kumar KanaujiaNo ratings yet

- Auxiliary RelayDocument1 pageAuxiliary RelaySanjay Kumar KanaujiaNo ratings yet

- Micro Ohm MeterDocument14 pagesMicro Ohm MeterSanjay Kumar KanaujiaNo ratings yet

- Test Certificate of HT Switchgear PanelDocument2 pagesTest Certificate of HT Switchgear PanelSanjay Kumar KanaujiaNo ratings yet

- Test Certificate of NGR Client: Tested On Plant: Tested by Location: 1.0 Insulation Resistance: Resistor - Earth 2.0 Resistance in Ohms 3.0 RemarksDocument1 pageTest Certificate of NGR Client: Tested On Plant: Tested by Location: 1.0 Insulation Resistance: Resistor - Earth 2.0 Resistance in Ohms 3.0 RemarksSanjay Kumar KanaujiaNo ratings yet

- Multi-Functional Primary Test System For Substation Commissioning and MaintenanceDocument44 pagesMulti-Functional Primary Test System For Substation Commissioning and MaintenanceAbdul HadiNo ratings yet

- Control Bus IR TestDocument1 pageControl Bus IR TestSanjay Kumar KanaujiaNo ratings yet

- Sel User GuideDocument33 pagesSel User GuideSanjay Kumar KanaujiaNo ratings yet

- NI 40 Relay FlierDocument2 pagesNI 40 Relay FlierSanjay Kumar KanaujiaNo ratings yet

- XBEE Based Transformer Protection and Oil TestingDocument3 pagesXBEE Based Transformer Protection and Oil TestingijsretNo ratings yet

- Yagi Uda Antenna EquationDocument9 pagesYagi Uda Antenna EquationAshner Novilla100% (1)

- HEATING ELEMENT (With or Without Fuse) : Service Bulletin Washing 2520-2530Document1 pageHEATING ELEMENT (With or Without Fuse) : Service Bulletin Washing 2520-2530Torozan RomicaNo ratings yet

- A Silicon Sample Maintained at T 300K Is Characterized by The Energy Band-Diagram BelowDocument5 pagesA Silicon Sample Maintained at T 300K Is Characterized by The Energy Band-Diagram BelowsweetupriyaNo ratings yet

- Checklist of HT Motor MaintenancexlsxDocument2 pagesChecklist of HT Motor Maintenancexlsxersanjeeb_456No ratings yet

- Marine FlexenDocument67 pagesMarine FlexenpayaljeevaNo ratings yet

- MSS20046 E25Document4 pagesMSS20046 E25Pușcă MartinNo ratings yet

- Pages From ENG CAT 2009Document4 pagesPages From ENG CAT 2009Waleed Mohammed FekryNo ratings yet

- Abb DriveDocument3 pagesAbb DriveShatrughna SamalNo ratings yet

- GE Zoneline Air Conditioner Owner's Manual and Installation InstructionsDocument28 pagesGE Zoneline Air Conditioner Owner's Manual and Installation InstructionsDavidMarcusNo ratings yet

- 7.1 Grounding: ResourcesDocument7 pages7.1 Grounding: ResourcesTrần Quang TuyênNo ratings yet

- Service Manual: 65.12-6 977 768/65.12-6 977 767/ 65.12-6 977 766 (NPF I-Bus CDC)Document31 pagesService Manual: 65.12-6 977 768/65.12-6 977 767/ 65.12-6 977 766 (NPF I-Bus CDC)Matt MichiganNo ratings yet

- Gate Driver For N-Channel Mosfet: Experiment 6Document34 pagesGate Driver For N-Channel Mosfet: Experiment 6Noona MigleiNo ratings yet

- Block Diagram: Bridge RectifierDocument6 pagesBlock Diagram: Bridge Rectifierskull hertzNo ratings yet

- High-Frequency Model of Power Transformer IEEEDocument10 pagesHigh-Frequency Model of Power Transformer IEEEdankorankoNo ratings yet

- TLW - Part A Questions & AnswersDocument14 pagesTLW - Part A Questions & AnswerspushpaNo ratings yet

- 231Document53 pages231Rahul AlhanNo ratings yet

- Exhibitor’s ListDocument4 pagesExhibitor’s ListAhmad HassanainNo ratings yet

- PLCCDocument15 pagesPLCCSanjeev KumarNo ratings yet

- Eee150 Chapter 3 (Electrical Safety) PDFDocument52 pagesEee150 Chapter 3 (Electrical Safety) PDFMUHAMMAD LUKMAN ARSHADNo ratings yet

- FPGA Implementation On SVPWM MLIDocument5 pagesFPGA Implementation On SVPWM MLISheetal VermaNo ratings yet

- Control AC motor speed via smartphoneDocument45 pagesControl AC motor speed via smartphoneDebashishParidaNo ratings yet

- Samsung Cw29z306vbxxecDocument135 pagesSamsung Cw29z306vbxxecf17439100% (3)

- SK 3239.118 Toptherm Fan-And-Filter UnitsDocument5 pagesSK 3239.118 Toptherm Fan-And-Filter UnitsLOI HONo ratings yet

- Unit-7 (BJT & Its Biasing) 1llDocument86 pagesUnit-7 (BJT & Its Biasing) 1llAnurag SinghalNo ratings yet

- Analyze small signal parameters of CC amplifierDocument5 pagesAnalyze small signal parameters of CC amplifierAafaqIqbalNo ratings yet

- © Siemens 2019: 09/2019 Catalog D12Document238 pages© Siemens 2019: 09/2019 Catalog D12Go andWatchNo ratings yet