Professional Documents

Culture Documents

Choosing An HVAC System 223

Uploaded by

Rohit Shrestha0 ratings0% found this document useful (0 votes)

11 views2 pagesOriginal Title

1 (138).pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

11 views2 pagesChoosing An HVAC System 223

Uploaded by

Rohit ShresthaCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

Choosing an HVAC System 223

TYPES OF HVAC SYSTEMS

The basic types of HVAC systems used in commercial build-

ings are all-air, air and water, all-water, and unitary. Water sys-

tems are also called hydronic systems. Hydronic is the term used

for heating and cooling with liquids.

All-air systems provide heated or cooled air to the condi-

tioned space through a ductwork system. The basic types of all-

air duct systems are: single-zone, multizone, dual or double duct,

terminal reheat, constant air volume, variable air volume (VAV),

and combination systems. In the typical system, cooling and heat-

ing is accomplished by the mixed air (a combination of the return

and outside air) passing over a refrigerant coil (cooling) or a heat

exchanger (heating).

The basic air-water system (also called air-hydronic) is a cen-

tral system similar to the all-air system with chilled water coils

instead of refrigerant coils for cooling (with an air-cooled con-

denser) and hot water coils for heating. A variation of this system

is the water-air (hydronic-air) system with refrigerant coils for

cooling and a water-cooled condenser.

All-water (all-hydronic) systems accomplish space cooling

by circulating chilled water from a central refrigeration system

through cooling coils in air handling units (also called terminal

units or fan-coil units). The units are located in the building’s

conditioned spaces. Heating is accomplished by circulating hot

water through the same (cooling/heating) coil or through a sepa-

rate heating coil. When one coil is used for cooling only, heating

only, or heating and cooling at various times, a two-pipe water

distribution system is used. When two coils are used, one for

heating and one for cooling, a four-pipe water distribution system

is used. Heating may also be accomplished using electricity or

steam. Straight water heating systems will commonly use convec-

tors, baseboard radiation, fin-tube radiation, standard fan-coil

units, and unit heaters.

224 HVAC Fundamentals

UNITARY SYSTEMS

A unitary system is an air-conditioning unit that provides all

or part of the air-conditioning functions. The components, fan(s),

filter(s), controls, and the cooling apparatus (refrigerant coil, re-

frigerant piping, compressor, and condenser) are all factory-as-

sembled into an integrated package. Components are matched

and assembled at the factory to achieve specific performance

objectives in accordance with industry-established increments of

capacity (such as cfm of air per ton of refrigeration). These perfor-

mance objectives are set by trade associations that have devel-

oped standards by which manufacturers may test and rate their

equipment. These performance parameters and standards allow

for the manufacture of quality-controlled, factory-tested systems.

Types of unitary systems include window-mounted air condition-

ers and heat pumps, through-the-wall air conditioners and heat

pumps, packaged terminal air conditioners and heat pumps,

packaged units, and rooftop units.

Unitary systems are used in a wide range of applications and

may or may not be used with central systems. Cooling capacity

can range from fractional tonnage for window-type units to 100

tons of refrigeration or more for package units. A unitary system

that uses the refrigeration system as the primary heating source is

a heat pump. Commercial grade unitary systems are called pack-

age units. Some package units also have heating apparatus (e.g.,

natural gas heat exchanger, electric elements, steam or hot water

coils) and humidifiers. A package unit designed to be placed on

the roof is called a rooftop unit.

PACKAGE UNITS

Package units are used in almost all types of building appli-

cations, especially in applications where performance require-

ments are less demanding, and relatively low initial cost and

simplified installation are important. Applications include hotels,

You might also like

- Mep Hvac 2Document170 pagesMep Hvac 2Muhammad MusaNo ratings yet

- Introduction ..FoundryDocument160 pagesIntroduction ..FoundryDhananjay ShimpiNo ratings yet

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialFrom EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNo ratings yet

- HVAC & Water SystemDocument153 pagesHVAC & Water SystemSujan Bose100% (1)

- King Quad 700 Tips 101 Ver 1.2Document36 pagesKing Quad 700 Tips 101 Ver 1.2Andy House100% (1)

- Air Handling Unit BasicsDocument27 pagesAir Handling Unit Basicsobaidur_rehman_3No ratings yet

- Audi TT TweaksDocument82 pagesAudi TT TweaksMM100% (6)

- Heating Ventilation and Air ConditioningDocument14 pagesHeating Ventilation and Air ConditioningMiahsaheb Rafeeq100% (1)

- Heating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsFrom EverandHeating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsNo ratings yet

- Mebs6006 1112 10-Airside SystemDocument40 pagesMebs6006 1112 10-Airside Systemsimoncarter313No ratings yet

- Course Content: Fundamentals of HVAC ControlsDocument39 pagesCourse Content: Fundamentals of HVAC ControlsMuhammad AfzalNo ratings yet

- Yale PM D807 Erc - Erp - Atf 524150863 11 2005Document348 pagesYale PM D807 Erc - Erp - Atf 524150863 11 2005Eriflona100% (1)

- Instruction Manual Enardo Series 950 Pressure Vacuum Relief Valve Series 7 Flame Arrestor en Us 166422Document16 pagesInstruction Manual Enardo Series 950 Pressure Vacuum Relief Valve Series 7 Flame Arrestor en Us 166422comercial mox asesoria100% (2)

- Building Assignment - Ii: ServicesDocument53 pagesBuilding Assignment - Ii: ServicesVivek SinghNo ratings yet

- Water Cycle Stages & Plumbing Systems MCQ PracticeDocument101 pagesWater Cycle Stages & Plumbing Systems MCQ Practicegeraint phaeton100% (1)

- Piping and Instrumentation Diagram (Pnid)Document19 pagesPiping and Instrumentation Diagram (Pnid)ridzuanzabah0% (1)

- Seminar On AC System PDFDocument33 pagesSeminar On AC System PDFJagadish SahuNo ratings yet

- محاضرات انشاءات معدنية د.سعد الدين مصطفيDocument111 pagesمحاضرات انشاءات معدنية د.سعد الدين مصطفيEmad Elhussieny98% (58)

- Air conditioning systems explainedDocument33 pagesAir conditioning systems explainedJagadish SahuNo ratings yet

- Advantage-Disadvantage VRFDocument13 pagesAdvantage-Disadvantage VRFRatnasariPurnadewi100% (3)

- Hvac System & Test For Hvac QualificationDocument9 pagesHvac System & Test For Hvac Qualificationlaap85100% (1)

- Hvac (H V & A C) : Eating Entilation IR OnditioningDocument50 pagesHvac (H V & A C) : Eating Entilation IR OnditioningTushal100No ratings yet

- List Harga Spatrpart Mobil PDFDocument120 pagesList Harga Spatrpart Mobil PDFAni kk100% (1)

- Learn About Central Air Conditioning Systems in Under 2 MinutesDocument39 pagesLearn About Central Air Conditioning Systems in Under 2 Minutesmonica singh100% (1)

- HVAC and Lighting Control PresentationDocument52 pagesHVAC and Lighting Control PresentationEDUARD VI DANDANo ratings yet

- HVACDocument72 pagesHVACvarshneyrk@rediffmail.comNo ratings yet

- HVAC Equipment Guide for Heating and Cooling SystemsDocument16 pagesHVAC Equipment Guide for Heating and Cooling SystemsRahul Prajapati100% (1)

- HVAC Group Presentation: History, Components, and ApplicationsDocument36 pagesHVAC Group Presentation: History, Components, and Applicationsaishwarya903100% (2)

- Hvac 160820181216Document33 pagesHvac 160820181216mani aroraNo ratings yet

- Unit-Iv-Air Water SystemDocument6 pagesUnit-Iv-Air Water SystemManjeet CinghNo ratings yet

- AIRCONDITIONINGDocument13 pagesAIRCONDITIONINGrini0026No ratings yet

- Architectural Science (HVAC) Lecture 6 & 7Document32 pagesArchitectural Science (HVAC) Lecture 6 & 7ezakbelachewNo ratings yet

- Fan Coil Units (FCUs) and Air Handling Units (AHUs) Explained <40Document10 pagesFan Coil Units (FCUs) and Air Handling Units (AHUs) Explained <40bandhuarushiNo ratings yet

- Project Report of HvacDocument56 pagesProject Report of HvacPrince Syed83% (59)

- Solver Setting in AnsysDocument44 pagesSolver Setting in AnsysApurvNo ratings yet

- HVAC Systems Analysis and DesignDocument67 pagesHVAC Systems Analysis and DesignSidd SalNo ratings yet

- SIMEONDocument7 pagesSIMEONVincent Martinez100% (1)

- Types of HVAC SystemsDocument6 pagesTypes of HVAC Systemsm2110100% (1)

- Clark Equipment Company Parts ManualDocument238 pagesClark Equipment Company Parts ManualIrineu100% (2)

- TOPIC 1: Air-Conditioning Systems: Subtopic: Types of HVAC SystemsDocument32 pagesTOPIC 1: Air-Conditioning Systems: Subtopic: Types of HVAC SystemsMuhammad Fadhil Hilmi NasutionNo ratings yet

- Types of Hvac SystemsDocument16 pagesTypes of Hvac SystemsVinita KumariNo ratings yet

- Integration of HVAC SystemsDocument8 pagesIntegration of HVAC SystemsRiya Bansal0% (1)

- All Air Systems Air Conditioning: Can Be Used in Both Comfort As Well As Industrial ApplicationsDocument6 pagesAll Air Systems Air Conditioning: Can Be Used in Both Comfort As Well As Industrial ApplicationsManjeet CinghNo ratings yet

- Chapter 2Document12 pagesChapter 2Mohammad Muawya Nouri HijaziNo ratings yet

- Air Conditioning System ClassificationsDocument10 pagesAir Conditioning System ClassificationsPhạm Tấn PhátNo ratings yet

- Air Conditioning SystemsDocument3 pagesAir Conditioning SystemsArman Ul NasarNo ratings yet

- ERV Energy Recovery Ventilation GuideDocument3 pagesERV Energy Recovery Ventilation GuidePrabhat KumarNo ratings yet

- Okay 2Document17 pagesOkay 2Muhammad BilalNo ratings yet

- Albarkat Pharmaceutical Industries. Standard Operating ProcedureDocument16 pagesAlbarkat Pharmaceutical Industries. Standard Operating ProcedureFAYAZ HUSSAINNo ratings yet

- Ac-Design IssuesDocument31 pagesAc-Design IssuesSaran T SNo ratings yet

- Heating, Ventilation, and Air ConditioningDocument17 pagesHeating, Ventilation, and Air ConditioningJC DoloritoNo ratings yet

- Week 6maint MGMT BIE2016 MechanicalDocument90 pagesWeek 6maint MGMT BIE2016 MechanicalaimanfznnnNo ratings yet

- Air ConditioningDocument22 pagesAir ConditioningEmmanuel BuhwaNo ratings yet

- Hvac Def of TermsDocument3 pagesHvac Def of Terms88ncd4y4r7No ratings yet

- CIBSE Building Services Glossary Article Produced For RICS Construction Journal v2 +LPDocument5 pagesCIBSE Building Services Glossary Article Produced For RICS Construction Journal v2 +LPRandolph Chan100% (1)

- HVAC ApplicationsDocument20 pagesHVAC ApplicationsSrashmiNo ratings yet

- Terminology 285Document2 pagesTerminology 285rohitNo ratings yet

- AHU Guide to Air Handling Unit OperationsDocument15 pagesAHU Guide to Air Handling Unit OperationsParthJainNo ratings yet

- Me 451 - 1Document35 pagesMe 451 - 1Edrees AldreesNo ratings yet

- HVAC-40Document3 pagesHVAC-40Johnny BarretoNo ratings yet

- ME 512A Aircon Systems Guide (39Document73 pagesME 512A Aircon Systems Guide (39Arsenio OvillaNo ratings yet

- How VAV Systems Work to Condition BuildingsDocument3 pagesHow VAV Systems Work to Condition Buildingsparikhchirag88No ratings yet

- Cooling Towers Improve HVAC EfficiencyDocument18 pagesCooling Towers Improve HVAC EfficiencyHarjo Wiyono100% (1)

- Seminar On AC SystemDocument33 pagesSeminar On AC SystemHassan Elattar0% (1)

- Literature AdDocument7 pagesLiterature AdSINDU ANUMALANo ratings yet

- Residences: Systems Equipment Sizing Single-Family Residences Multifamily Residences Manufactured HomesDocument7 pagesResidences: Systems Equipment Sizing Single-Family Residences Multifamily Residences Manufactured Homesattrib2No ratings yet

- Lecture # 11: Dr. Muzaffar AliDocument40 pagesLecture # 11: Dr. Muzaffar AliNadeem AbbasNo ratings yet

- Control and condition air with an air handler unitDocument10 pagesControl and condition air with an air handler unitSreekanth MadakaNo ratings yet

- Sustainable and Energy-Efficient Heating Cooling System For HospitalDocument23 pagesSustainable and Energy-Efficient Heating Cooling System For HospitalRISHAB KABDI JAINNo ratings yet

- Temperature and Humidity Independent Control (THIC) of Air-conditioning SystemFrom EverandTemperature and Humidity Independent Control (THIC) of Air-conditioning SystemNo ratings yet

- Mechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesFrom EverandMechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesNo ratings yet

- Figure 4-7. Cooling Tower. TR Is Tower Range (95 F - 85 F), CR Is Condenser Rise (85 Fto95 F)Document2 pagesFigure 4-7. Cooling Tower. TR Is Tower Range (95 F - 85 F), CR Is Condenser Rise (85 Fto95 F)Rohit ShresthaNo ratings yet

- Compressors: Chapter FiveDocument2 pagesCompressors: Chapter FiveRohit ShresthaNo ratings yet

- Air Conditioning Systems 51Document2 pagesAir Conditioning Systems 51rohitNo ratings yet

- 1 PDFDocument2 pages1 PDFRohit ShresthaNo ratings yet

- Air Conditioning Condenser GuideDocument2 pagesAir Conditioning Condenser GuideRohit ShresthaNo ratings yet

- 1 PDFDocument2 pages1 PDFRohit ShresthaNo ratings yet

- Air Conditioning Systems 69: Heat Pump (Air-Air)Document2 pagesAir Conditioning Systems 69: Heat Pump (Air-Air)Rohit ShresthaNo ratings yet

- Air Conditioning Systems 57Document2 pagesAir Conditioning Systems 57rohitNo ratings yet

- Heating and Ventilating Systems 43: MAT (%OA ×Document2 pagesHeating and Ventilating Systems 43: MAT (%OA ×rohitNo ratings yet

- Air Conditioning Systems 55Document2 pagesAir Conditioning Systems 55rohitNo ratings yet

- Heating and Ventilating Systems 37: Figure 3-6. Combustion Chamber and Fire Tubes. Two-Pass BoilerDocument2 pagesHeating and Ventilating Systems 37: Figure 3-6. Combustion Chamber and Fire Tubes. Two-Pass BoilerrohitNo ratings yet

- Air Conditioning Systems 59: Figure 4-3. Water-to-Water AC SystemDocument2 pagesAir Conditioning Systems 59: Figure 4-3. Water-to-Water AC SystemrohitNo ratings yet

- Air Conditioning Systems 63: Evaporators (Heat Picked Up From The Conditioned Space)Document2 pagesAir Conditioning Systems 63: Evaporators (Heat Picked Up From The Conditioned Space)rohitNo ratings yet

- Figure 4-.2 Air Conditioning System ExampleDocument2 pagesFigure 4-.2 Air Conditioning System ExamplerohitNo ratings yet

- 1 PDFDocument2 pages1 PDFrohitNo ratings yet

- 1 PDFDocument2 pages1 PDFRohit ShresthaNo ratings yet

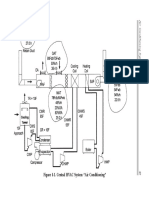

- Figure 4-1. Central HVAC System "Air Conditioning"Document2 pagesFigure 4-1. Central HVAC System "Air Conditioning"rohitNo ratings yet

- Heating and Ventilating Systems 41: Figure 3-8. Oil BurnerDocument2 pagesHeating and Ventilating Systems 41: Figure 3-8. Oil BurnerrohitNo ratings yet

- Heating and Ventilating Systems 25Document2 pagesHeating and Ventilating Systems 25rohitNo ratings yet

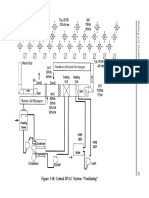

- Figure 3-10. Central HVAC System "Ventilating"Document2 pagesFigure 3-10. Central HVAC System "Ventilating"rohitNo ratings yet

- Figure 3-3. Btu Change in One Pound of Ice To Water To Steam To Superheated SteamDocument2 pagesFigure 3-3. Btu Change in One Pound of Ice To Water To Steam To Superheated SteamrohitNo ratings yet

- Heating and Ventilating Systems 33Document2 pagesHeating and Ventilating Systems 33rohitNo ratings yet

- Heating and Ventilating Systems 35Document2 pagesHeating and Ventilating Systems 35rohitNo ratings yet

- Heat Flow 15Document2 pagesHeat Flow 15rohitNo ratings yet

- Air Volume: HVAC Systems 11Document2 pagesAir Volume: HVAC Systems 11rohitNo ratings yet

- Heating and Ventilating Systems 27Document2 pagesHeating and Ventilating Systems 27rohitNo ratings yet

- Heating and Ventilating Systems 29: Figure 3-2. Steam BoilerDocument2 pagesHeating and Ventilating Systems 29: Figure 3-2. Steam BoilerrohitNo ratings yet

- Heat Flow 17: ConductionDocument2 pagesHeat Flow 17: ConductionrohitNo ratings yet

- HVAC Systems 13: VentilatingDocument2 pagesHVAC Systems 13: VentilatingrohitNo ratings yet

- Latent HeatDocument2 pagesLatent HeatrohitNo ratings yet

- 16 PSM0217-1 Pressure Switch ManualDocument2 pages16 PSM0217-1 Pressure Switch ManualJulioCesarNo ratings yet

- BS Databook 2013Document53 pagesBS Databook 2013loggynety159No ratings yet

- Chul Park Viscous Shock Layer Calculation of Stagnation-Region Heating Environment Viscous Shock Layer Calculation of Stagnation-Region Heating EnvironmentDocument7 pagesChul Park Viscous Shock Layer Calculation of Stagnation-Region Heating Environment Viscous Shock Layer Calculation of Stagnation-Region Heating EnvironmentlazharNo ratings yet

- A170 Abs 3 0Document3 pagesA170 Abs 3 0Gabriel UngureanuNo ratings yet

- RCA For Hotwell Level Transmitter Faulty.Document6 pagesRCA For Hotwell Level Transmitter Faulty.Nisar AhmedNo ratings yet

- Asonic Ghy 72 IngDocument2 pagesAsonic Ghy 72 IngseegnaNo ratings yet

- Study of Asphalt Binder Fatigue With A NDocument23 pagesStudy of Asphalt Binder Fatigue With A NMD. NASIF HOSSAIN IMONNo ratings yet

- Automatic Transmission F4A41, F4A42, F4A51: Revised PWEE9514-F Jun. 2000 Mitsubishi Motors CorporationDocument118 pagesAutomatic Transmission F4A41, F4A42, F4A51: Revised PWEE9514-F Jun. 2000 Mitsubishi Motors CorporationLuis Eduardo Prada PeñalozaNo ratings yet

- LABORATORY PRACTICAL V SYNCHRONOUS GENERATORDocument5 pagesLABORATORY PRACTICAL V SYNCHRONOUS GENERATORNuwan BandaraNo ratings yet

- Convert Singletrain Separator to OLGA 6Document23 pagesConvert Singletrain Separator to OLGA 6Umar KidaNo ratings yet

- HVOF Processed CoCrFeMnNiDocument11 pagesHVOF Processed CoCrFeMnNiRafael RiveraNo ratings yet

- 30 Supersonic AerodynamicsDocument31 pages30 Supersonic AerodynamicsjepegoNo ratings yet

- Asme3d1 nb-5000Document12 pagesAsme3d1 nb-5000KHALED OSMANNo ratings yet

- P310Document2 pagesP310CoreconNo ratings yet

- DD81-02158B-01 Install DW80R2031UDocument72 pagesDD81-02158B-01 Install DW80R2031Usam jonesNo ratings yet

- Engine Sensors and SystemsDocument14 pagesEngine Sensors and Systemsalex generalNo ratings yet

- Enimex - BVFL - GB PDFDocument6 pagesEnimex - BVFL - GB PDFAlienshowNo ratings yet

- 1.design For Shear For Prestressed ConcreteDocument34 pages1.design For Shear For Prestressed ConcretealexNo ratings yet

- Hybrid Rocket TechnologyDocument12 pagesHybrid Rocket TechnologyRitesh DubeyNo ratings yet