Professional Documents

Culture Documents

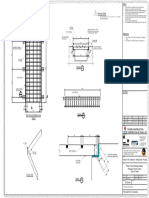

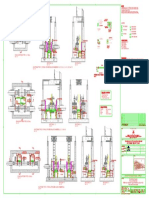

SHEET No 03 CENTER FLANGE WITH ARCH ASSY-GA

SHEET No 03 CENTER FLANGE WITH ARCH ASSY-GA

Uploaded by

Karikalan JayCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SHEET No 03 CENTER FLANGE WITH ARCH ASSY-GA

SHEET No 03 CENTER FLANGE WITH ARCH ASSY-GA

Uploaded by

Karikalan JayCopyright:

Available Formats

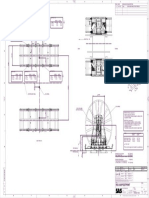

4 3 2 1 SHEET No : 03

Notes.

1. All profile cutting shall be done according this drawing dimensions.

2. All welding is full round, Full penetration and continuous welding.

3. All welding is to be done by qualified Welder.shall be certified for 6G.

Certificate shall be provided before commeNcement of works.

4. All welding are subjected to MPI.

5. Weding standard shall be AWS D1.1 / ASME Sec IX.

D 6. Flange to Flange Joints are Double Groove Butt Joint as per AWS Figure 3.4 D

7. Electrodes AWS 5.5 Class E7018 is reccommended for S355 material as per

AWS D1.1.

8. Root Opening shall be minimum 3.0mm Root Face is min 3.0mm

9. All weld surfaces shall be free from moist, grease and shall be cleaned prior to weld.

10. Post / Pre weld heat treatment is not required for this structure.

11. Weld process shall be SMAW as per AWS D1.1.

12. All welding on the top surface be ground to flat for flange plates.

13. Mill Certificate for materials shall be kept in record.

5500

PLEASE SEE

3896 SHEET 7

1931 1931

C C

R2750

790

R1238

R2750

R2750

1963

1931

5500

3896

B B

1963

R1238 PLEASE SEE

SHEET 7

790

Edition Description Drawn by Checked by Approved by

A1 REEL FLANGE FABRICATION - STAGE : 5 31.08.20 Jaya Peter Raymond

A A

NEXT OPERATION: DWG# UTS XX/XXX/XX/XXX

UNLESS OTHERWISE SPECIFIED Sheet: UTS HOSE REEL DIA 5.5m x

UNDERWATER TECHNOLOGY SERVICES (S) PTE LTD TOLERANCES:

WHOLE NUMBERS ± 0.5 3 WIDTH 5.9m x CORE 2.5m

35 Pioneer Road, Unit J7, Singapore 628503 ONE DECIMAL PLACE ± 0.1

Qty: REEL FLANGE FABRICATION -

Tel : +65 68618006 Fax : +65 68632865 TWO DECIMAL PLACE ± 0.05 Paper

Size: A4 1 CENTER FLANGE WITH ARCH GA

Email : enquiries@underwatertechnologyservices.com BREAK ALL SHARP EDGES

JOB #: DWG #: Edition:

THIS DOCUMENT IS CONFIDENTIAL AND REMAINS THE PROPERTY OF UTS.

IT MAY NOT BE USED IN ANY MANNER WITHOUT THE PRIOR WRITTEN CONSENT OF UTS.

DO NOT SCALE DRAWING UTS - XXX UTS/XXX/XX/XXX A1

4 3 2 1

You might also like

- SHEET No 10 FLANGE GUSSETS AND REINFORCEMENTS DETAILDocument1 pageSHEET No 10 FLANGE GUSSETS AND REINFORCEMENTS DETAILKarikalan JayNo ratings yet

- SP40-Steel Portal FrameDocument82 pagesSP40-Steel Portal FrameTarun saiNo ratings yet

- RC DetailingDocument82 pagesRC DetailingkishoreNo ratings yet

- الخطأ والصواب في تسليح العناصر الانشائيهDocument47 pagesالخطأ والصواب في تسليح العناصر الانشائيهBen ÂmarNo ratings yet

- Reinforcing Detailing of R.C.C MembersDocument47 pagesReinforcing Detailing of R.C.C Membersmanumeet100% (2)

- R1 Cheruthony Truss 4 - 4Document1 pageR1 Cheruthony Truss 4 - 4Anujith K BabuNo ratings yet

- Reinforcing Detailing of R.C.C Members - K.kaviTHADocument47 pagesReinforcing Detailing of R.C.C Members - K.kaviTHAGurupriyaNo ratings yet

- الخطأ والصواب في تسليح العناصر الانشائيهDocument47 pagesالخطأ والصواب في تسليح العناصر الانشائيهSwift WardNo ratings yet

- A.00 Cable Ixxat-Delphi 1MDocument1 pageA.00 Cable Ixxat-Delphi 1Mpedrofigueiredo.eiNo ratings yet

- Reinforcing Detailing of R.C.C MembersDocument47 pagesReinforcing Detailing of R.C.C MembersAmey ShettiNo ratings yet

- Reinforcement DetailingDocument47 pagesReinforcement DetailingMuhammad Saqib Abrar94% (16)

- Reinforcement DetailingDocument47 pagesReinforcement DetailingLimar SetstraNo ratings yet

- 1585848242cve DRGDocument42 pages1585848242cve DRGmarco miguelNo ratings yet

- RTD-201 203Document2 pagesRTD-201 203amekhzoumiNo ratings yet

- Reinforcement DetailingDocument47 pagesReinforcement DetailingSun Rise100% (1)

- DownloadDocument47 pagesDownloadGajanVashishth100% (1)

- D1836 Series (Nas1836)Document1 pageD1836 Series (Nas1836)blackhawkNo ratings yet

- PT5C 08 PHC T12 004 D2Document1 pagePT5C 08 PHC T12 004 D2ma.shaheNo ratings yet

- How To Weld 254 SMODocument12 pagesHow To Weld 254 SMOsateesh chand100% (7)

- Om03-H1019dv3010001-Hatch Cover-1-3Document91 pagesOm03-H1019dv3010001-Hatch Cover-1-3K MNo ratings yet

- UM - MVG - SO60976 - Modificaton BucketDocument4 pagesUM - MVG - SO60976 - Modificaton Bucket1989vasu.pNo ratings yet

- Notes: General Steel Fabrication Notes: Carbon Steel Fabrication Notes: Stainless Steel FabricationDocument6 pagesNotes: General Steel Fabrication Notes: Carbon Steel Fabrication Notes: Stainless Steel FabricationAquiles MartinezNo ratings yet

- BEP Marine TS1 Ultrasonic Sender User Manual enDocument12 pagesBEP Marine TS1 Ultrasonic Sender User Manual enfranciscoNo ratings yet

- Spool With Certificate: Document Control GCCDocument1 pageSpool With Certificate: Document Control GCCProorocu MikyNo ratings yet

- Mark Piece Information: For Weld Details, See Sheet: 3Document5 pagesMark Piece Information: For Weld Details, See Sheet: 3Proorocu MikyNo ratings yet

- 2500 DrumDocument2 pages2500 DrumPM PandianNo ratings yet

- ASNA2536-collars CortaduraDocument6 pagesASNA2536-collars CortaduraCurro Espadafor Fernandez AmigoNo ratings yet

- TSeries CouplingDocument6 pagesTSeries Couplingcarlos sotoNo ratings yet

- Surface Mounted TriacsDocument15 pagesSurface Mounted TriacsElinton PassiniNo ratings yet

- 1280a4-8430-Ds-0001 Rev F1Document6 pages1280a4-8430-Ds-0001 Rev F1Stephen LowNo ratings yet

- Creepresistant Hightemperature FCAW ENGDocument12 pagesCreepresistant Hightemperature FCAW ENGRuben Dario Mamani ArellanoNo ratings yet

- Manufacturing Wiring Harnesses Amp Cables PDFDocument8 pagesManufacturing Wiring Harnesses Amp Cables PDFarun.nagarkarNo ratings yet

- Catalog Shear ConnectorDocument16 pagesCatalog Shear ConnectordedeNo ratings yet

- S-TSK TLKDocument6 pagesS-TSK TLKEdgarNo ratings yet

- Camisa Deslizable Modelo L para H2SDocument5 pagesCamisa Deslizable Modelo L para H2SCO BDNo ratings yet

- Conectores Multiconductores Serie TCDocument2 pagesConectores Multiconductores Serie TCING_MBMNo ratings yet

- 701 Cable Gland Type: Industrial General PurposeDocument1 page701 Cable Gland Type: Industrial General Purposewe202No ratings yet

- Format No.:DEPL/ENGG/F-07: Rev No/Date: 00 / 18-Aug-2021Document3 pagesFormat No.:DEPL/ENGG/F-07: Rev No/Date: 00 / 18-Aug-2021Dinesh MNo ratings yet

- FHS Valve Chamber Platform SE CTJ CVAL D 986NLXX 67765Document1 pageFHS Valve Chamber Platform SE CTJ CVAL D 986NLXX 67765varadarajNo ratings yet

- Rigid Metal Conduit (RMC) - Steel Elbows: S T E E L C O N D U I TDocument1 pageRigid Metal Conduit (RMC) - Steel Elbows: S T E E L C O N D U I TAntonio EstevezNo ratings yet

- STPE600 - Dadi A ProiezioneDocument17 pagesSTPE600 - Dadi A ProiezioneLucaNo ratings yet

- Leapton 480W Ntype BifacialDocument2 pagesLeapton 480W Ntype Bifacialpatrick.labalette23No ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Anglo–American Microelectronics Data 1968–69: Manufacturers A–PFrom EverandAnglo–American Microelectronics Data 1968–69: Manufacturers A–PNo ratings yet

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Profile of the Worldwide Semiconductor Industry - Market Prospects to 1997: Market Prospects to 1997From EverandProfile of the Worldwide Semiconductor Industry - Market Prospects to 1997: Market Prospects to 1997No ratings yet

- Modelling a Tiger I s.Pz.Abt.507, East Prussia, November 1944: In I/35 scaleFrom EverandModelling a Tiger I s.Pz.Abt.507, East Prussia, November 1944: In I/35 scaleNo ratings yet

- High-Temperature Brazing in Controlled Atmospheres: The Pergamon Materials Engineering Practice SeriesFrom EverandHigh-Temperature Brazing in Controlled Atmospheres: The Pergamon Materials Engineering Practice SeriesNo ratings yet

- Mechanics of Optimal Structural Design: Minimum Weight StructuresFrom EverandMechanics of Optimal Structural Design: Minimum Weight StructuresNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- An Introduction to Timber Engineering: Pergamon Series of Monographs on Furniture and TimberFrom EverandAn Introduction to Timber Engineering: Pergamon Series of Monographs on Furniture and TimberRating: 5 out of 5 stars5/5 (1)

- The Art of Lead Burning: A practical treatisening the apparatus and processesFrom EverandThe Art of Lead Burning: A practical treatisening the apparatus and processesNo ratings yet

- Buk Crane-Lattice Boom Corrosion Verification by Calculation-13-4-2023Document2 pagesBuk Crane-Lattice Boom Corrosion Verification by Calculation-13-4-2023Karikalan JayNo ratings yet

- Ex4 deDocument9 pagesEx4 deKarikalan JayNo ratings yet

- Sea Fastening Beams For HLS-25-4-23 (5 45)Document11 pagesSea Fastening Beams For HLS-25-4-23 (5 45)Karikalan JayNo ratings yet

- FA2B Winch SpecificationsDocument3 pagesFA2B Winch SpecificationsKarikalan JayNo ratings yet

- HH07 - (CR170) 10Tx16M (R) HOSE HANDLING CRANEDocument318 pagesHH07 - (CR170) 10Tx16M (R) HOSE HANDLING CRANEKarikalan JayNo ratings yet

- HH09 - Provision Crane (CR172)Document30 pagesHH09 - Provision Crane (CR172)Karikalan JayNo ratings yet

- HH06 - (CR171) 13Tx18M (R) HOSE HANDLING CRANEDocument158 pagesHH06 - (CR171) 13Tx18M (R) HOSE HANDLING CRANEKarikalan JayNo ratings yet

- Illage & Gantry With Spooler - Ga For Manufacturing-Rev A2-.Document1 pageIllage & Gantry With Spooler - Ga For Manufacturing-Rev A2-.Karikalan JayNo ratings yet

- 5.detail A, B, C & H, Mounting Plates 15 & 17-Rev A2Document1 page5.detail A, B, C & H, Mounting Plates 15 & 17-Rev A2Karikalan JayNo ratings yet

- PNL Jib Crane GA & PicturesDocument5 pagesPNL Jib Crane GA & PicturesKarikalan JayNo ratings yet

- Illage - Smaller Skid Assembly For MFGDocument1 pageIllage - Smaller Skid Assembly For MFGKarikalan JayNo ratings yet

- 00031361-A WCU T1 Wiring DiagramDocument8 pages00031361-A WCU T1 Wiring DiagramKarikalan JayNo ratings yet

- 00027634-B RCC Wiring DiagramDocument50 pages00027634-B RCC Wiring DiagramKarikalan JayNo ratings yet

- SHEET No 10 FLANGE GUSSETS AND REINFORCEMENTS DETAILDocument1 pageSHEET No 10 FLANGE GUSSETS AND REINFORCEMENTS DETAILKarikalan JayNo ratings yet

- Tuition Grant Option Form PDFDocument1 pageTuition Grant Option Form PDFKarikalan JayNo ratings yet

- Illage - Full Skid Assembly For Mfg-Rev A2Document1 pageIllage - Full Skid Assembly For Mfg-Rev A2Karikalan JayNo ratings yet

- SHEET No 01 REEL FULL ASSLY GA DWGDocument1 pageSHEET No 01 REEL FULL ASSLY GA DWGKarikalan JayNo ratings yet

- 00027626-C General 1T+1RDocument7 pages00027626-C General 1T+1RKarikalan JayNo ratings yet

- 00027639-B DCPR1 Wiring DiagramDocument67 pages00027639-B DCPR1 Wiring DiagramKarikalan JayNo ratings yet

- 00027646-C JB Wiring DiagramDocument37 pages00027646-C JB Wiring DiagramKarikalan JayNo ratings yet

- 00027647-C Cable ListDocument12 pages00027647-C Cable ListKarikalan JayNo ratings yet

- 00027636-B DCT1 Wiring DiagramDocument77 pages00027636-B DCT1 Wiring DiagramKarikalan JayNo ratings yet

- R3540-2002-A Drive AssemblyDocument1 pageR3540-2002-A Drive AssemblyKarikalan JayNo ratings yet

- Drive Unit TENH EH 10003, 225, 50/60Hz 400/440V: Qty. Description Specification Material Size DT Doc IdDocument1 pageDrive Unit TENH EH 10003, 225, 50/60Hz 400/440V: Qty. Description Specification Material Size DT Doc IdKarikalan JayNo ratings yet

- 00027627-C Cable Block DiagramDocument41 pages00027627-C Cable Block DiagramKarikalan JayNo ratings yet

- R3572-4002-B HPU Column Reel DriveDocument1 pageR3572-4002-B HPU Column Reel DriveKarikalan JayNo ratings yet

- Rds 350T Footprint: 1 1 RDS 350t DWG R3500-1003 /qty. Description Material Size RemarkDocument1 pageRds 350T Footprint: 1 1 RDS 350t DWG R3500-1003 /qty. Description Material Size RemarkKarikalan JayNo ratings yet

- 00027628-B Network DiagramDocument7 pages00027628-B Network DiagramKarikalan JayNo ratings yet

- R3540-3009-B Hub AssemblyDocument1 pageR3540-3009-B Hub AssemblyKarikalan JayNo ratings yet

- Insider Secrets of Bellows RepairDocument1 pageInsider Secrets of Bellows RepairAhmad NilNo ratings yet

- This Is How Guns Are Made in A Factory From ScratchDocument27 pagesThis Is How Guns Are Made in A Factory From ScratchSurafelNo ratings yet

- Pickling Passivation ProcedureDocument5 pagesPickling Passivation ProcedureKoya Thangal100% (1)

- A WPS Is A Document That Describes How Welding Is To Be Carried Out in ProductionDocument3 pagesA WPS Is A Document That Describes How Welding Is To Be Carried Out in Productionukavathekar100% (1)

- Monte Carlo Simulation of Grain GrowthDocument11 pagesMonte Carlo Simulation of Grain GrowthSachinrajKvNo ratings yet

- Saudi Aramco Inspection Checklist: Buttering And/or Weld Build-Up - Pipelines SAIC-W-2047 31-Dec-14 WeldDocument2 pagesSaudi Aramco Inspection Checklist: Buttering And/or Weld Build-Up - Pipelines SAIC-W-2047 31-Dec-14 WeldpravinNo ratings yet

- QW-424 Asme Ix 2023Document1 pageQW-424 Asme Ix 2023CARLOS OLIVEROSNo ratings yet

- Welding Electrode ChartDocument2 pagesWelding Electrode ChartZaheed Manoo50% (2)

- Datasheet Sandvik 3r65 For Medical Applications en v2020!12!10 06 - 47 Version 1Document6 pagesDatasheet Sandvik 3r65 For Medical Applications en v2020!12!10 06 - 47 Version 1Mohammed Saleem Syed KhaderNo ratings yet

- Pe 020000Document302 pagesPe 020000Andronicoll Mayuga NovalNo ratings yet

- Optimization of Resistance Spot Welding Parameters On Joining Electrogalvanized Steel Using The Taguchi MethodDocument10 pagesOptimization of Resistance Spot Welding Parameters On Joining Electrogalvanized Steel Using The Taguchi MethodM. SukarmanNo ratings yet

- High Purity Chemicals - Processing Equipment EssentialsDocument8 pagesHigh Purity Chemicals - Processing Equipment EssentialsBramJanssen76No ratings yet

- Astm A381Document7 pagesAstm A381hadeNo ratings yet

- DVS Technical Codes On Plastics Joining TechnologiesDocument11 pagesDVS Technical Codes On Plastics Joining Technologiesmarlon gutierrezNo ratings yet

- Ok 78.16Document1 pageOk 78.16Mario IntikNo ratings yet

- Attachment 8 - STN 00 Z20 V SP 0002 - A01 - ENDocument18 pagesAttachment 8 - STN 00 Z20 V SP 0002 - A01 - ENrameshqcNo ratings yet

- Standards Approvals & Certificates: TL Tuv CWB Abs Hakc Classnk Rina DB Ce BV DNV-GL LR Tse GostDocument3 pagesStandards Approvals & Certificates: TL Tuv CWB Abs Hakc Classnk Rina DB Ce BV DNV-GL LR Tse GostKhaled GamalNo ratings yet

- Operating & Maintenance Manual Rotary Kiln Burner: Customer: XXXX Facility: XXXX UC Commission No.: XX/XXXXDocument18 pagesOperating & Maintenance Manual Rotary Kiln Burner: Customer: XXXX Facility: XXXX UC Commission No.: XX/XXXXzain140No ratings yet

- Transair Catalog 2017Document120 pagesTransair Catalog 2017Lalo BandaNo ratings yet

- 1 Free Trial: STAAD - Pro Structural Engineers 2 Handbook of Titration 3 Download This To PDF Start DownloadDocument9 pages1 Free Trial: STAAD - Pro Structural Engineers 2 Handbook of Titration 3 Download This To PDF Start DownloadAbsec PandaNo ratings yet

- 4 - A S SahneyDocument26 pages4 - A S SahneyMahendra RathoreNo ratings yet

- Hydraulic Turbine and Associated EquipmentDocument47 pagesHydraulic Turbine and Associated Equipmentpavankumar0010% (1)

- Weldability of Structural Steel PDFDocument48 pagesWeldability of Structural Steel PDFsurawutwijarnNo ratings yet

- Mc1091 Recrushed SlagDocument4 pagesMc1091 Recrushed Slagtoxicity23No ratings yet

- Fabrication of Intelligent Braking SystemDocument6 pagesFabrication of Intelligent Braking SystemVishal LabdeNo ratings yet

- Lab Report 2..weldingDocument7 pagesLab Report 2..weldingUsman Saeed Kiani100% (1)

- Friction Stir Welding ReportDocument16 pagesFriction Stir Welding ReportjishnuNo ratings yet

- South 24 ParganasDocument26 pagesSouth 24 ParganasDFBDHHNo ratings yet

- IACS Rec47rev8Document67 pagesIACS Rec47rev8ciekawskiNo ratings yet

- Technical Spacification For Electrical WorkDocument147 pagesTechnical Spacification For Electrical WorkKhawaja Kashif QadeerNo ratings yet