Professional Documents

Culture Documents

Hydro Test Certificate Template (Soft Copy)

Uploaded by

zineddine sofieneOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hydro Test Certificate Template (Soft Copy)

Uploaded by

zineddine sofieneCopyright:

Available Formats

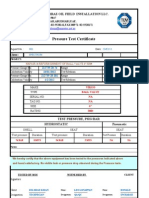

ACE PACKAGING CO. (PHILS.), INC.

#73 ROAD 7 GSIS HILLS TALIPAPA NOVALICHES, CALOOCAN CITY 1116 PHILIPPINES

Tel Nos. +632 9832780; +632 9847045. Factory No. +632 4328091 Fax No. +632 9832945

Email: apci@acepackaging.com.ph or info@acepackaging.com.ph

Website: http://www.acepackaging.com.ph

HYDROSTATIC TEST CERTIFICATE

1. CLIENT 2. TANK NAME 3. TANK NO./ SERIAL/ 4. CAPACITY 5. TANK WORKING PRESSURE

MODEL NO.

AXELUM SS MIXING TANK WITH MIXING TANK #1 3000 LITERS

AGITATOR

6. REFERENCES (TEST PRESSURE DRAWINGS, REFERENCE MANUALS OR OTHER APPLICABLE REFERENCES)

A. Tank Fabrication drawing B. ASME B31.3 sec. 345 “Hydrostatic Test” C. N/A

7. REQUIRED TEST AND INSPECTION – SPECIFY TEST REQUIREMENTS [i.e. TYPE OF TEST, TEST FLUID, SPECIAL VALVE POSITIONS, DURATION, ACCEPTANCE

CRITERIA, JOINTS TO BE TESTED (IF ENTIRE COMPONENT/SYSTEM IS TESTED, SO STATE)].

Hydrostatic testing of SS MIXING TANK WITH AGITATOR for leaks and weld integrity at specified test pressure.

Test pressure should be maintained for at least 12 hrs. Allowable pressure deviation shall be no more than 5 psi.

8. DIAGRAM OF TEST AREA INCLUDING GAGS AND BLANKS INSTALLED, VALVE POSITIONS, AND TEST GAGES/INSTR USED (DOCUMENT BELOW).

1. Hydro test pump (manual)

2. Pressure gauge

3. Isolation valves

9. GAUGE DATA RANGE (PSIG) SERIAL # CALIBRATED (Y/N)

PRIMARY 0-200

SECONDARY N/A N/A N/A

10. REQUIRED TEST PRESSURE 11. ACTUAL TEST PRESSURE (PSIG)

(PSIG) AND TEST DURATION:

START TEST PRESSURE __70 psig TIME/DATE: _1400H 12/26/2019

END TEST PRESSURE __70 psig TIME/DATE: _1400H 12/26/2019

12. TEST RESULTS (CHECK ONE):

SATISFACTORY UNSATISFACTORY

13. REMARKS:

14. CERTIFICATION

PERFORMED BY INSPECTED BY WITNESSED BY

APCI REPRESENTATIVE APCI PLANT MANAGER CLIENT REPRESENTATIVE

SIGNATURE OVER PRINTED NAME SIGNATURE OVER PRINTED NAME SIGNATURE OVER PRINTED NAME

DATE DATE DATE

Document Control N. 140618-001 Revision APCI-001 Dec 2011

You might also like

- ABB - 4 Biggest MistakesDocument7 pagesABB - 4 Biggest MistakesAnargha BhattacharyaNo ratings yet

- 5 - Tank Itp - Inspection & Test Plan For TanksDocument9 pages5 - Tank Itp - Inspection & Test Plan For Tanksmandi100% (1)

- QAP ValvesDocument15 pagesQAP ValvesAnonymous ciKyr0t100% (1)

- Sample For Painting ReportDocument1 pageSample For Painting ReportSơn Nguyễn TháiNo ratings yet

- Safety Instruction SheetDocument32 pagesSafety Instruction SheetAdamuNo ratings yet

- Inspection Release NoteDocument1 pageInspection Release NoteKarthik S67% (3)

- Asme B31.3Document69 pagesAsme B31.39440864459100% (4)

- ASME SB-444 (2013) - В-444-06 (R11) - eng.Document4 pagesASME SB-444 (2013) - В-444-06 (R11) - eng.TetianaNo ratings yet

- NCR Format NewDocument2 pagesNCR Format Newzahid1078100% (1)

- Storage Tank Hydrostatic Test Quality Control and Inspection Report Form PDFDocument1 pageStorage Tank Hydrostatic Test Quality Control and Inspection Report Form PDFมินคุง เอโอซีNo ratings yet

- Hydrostatic Test ReportDocument1 pageHydrostatic Test ReportMuhammadShabbirNo ratings yet

- Pressure Test Report - SampleDocument1 pagePressure Test Report - SamplemomoitachiNo ratings yet

- LPG Unloading Safety ChecklistDocument2 pagesLPG Unloading Safety ChecklistSamsul Huda Arpon67% (3)

- As 1271 Safety Valves & GuagesDocument50 pagesAs 1271 Safety Valves & Guagespvdang100% (4)

- Piping Fabrication Installation QCP On SiteDocument1 pagePiping Fabrication Installation QCP On SiteTarun PatelNo ratings yet

- Punch Points For Piping EngineersDocument8 pagesPunch Points For Piping EngineersVignesh MohanNo ratings yet

- Sample WorkpackDocument9 pagesSample WorkpackKhairun Mohamad IshakNo ratings yet

- Client: Project: Sheet 1 of 1 Date: Area: Pump Alignment ReportDocument8 pagesClient: Project: Sheet 1 of 1 Date: Area: Pump Alignment ReportEky Aditya PutraNo ratings yet

- Painting & Sand Blasting Report For Trussed StructureDocument1 pagePainting & Sand Blasting Report For Trussed StructureAshwani Dogra33% (3)

- Check List For Testing & Commissioning of Foam SystemDocument1 pageCheck List For Testing & Commissioning of Foam SystemUmair BaBer0% (1)

- Quality Tool Box Meeting - FormatDocument2 pagesQuality Tool Box Meeting - FormatRam100% (2)

- Tank Test CertificatesDocument1 pageTank Test CertificatesRoshin99No ratings yet

- KEI-PL-2102T 0 - Flowline Carbon Steel SpecDocument41 pagesKEI-PL-2102T 0 - Flowline Carbon Steel Specajaykg100% (1)

- Pneumatic Test ReportDocument5 pagesPneumatic Test ReportMohd Ashraf50% (2)

- Storage Tank Hydrostatic Test Quality Control and Inspection Report Form PDFDocument1 pageStorage Tank Hydrostatic Test Quality Control and Inspection Report Form PDFJaco CalitzNo ratings yet

- Dimensional Inspection ProcedureDocument3 pagesDimensional Inspection ProcedureWalter Unabia Rendon100% (5)

- Storage Tank Hydrostatic Test Quality Control and Inspection Report Form PDFDocument1 pageStorage Tank Hydrostatic Test Quality Control and Inspection Report Form PDFNatarajan Raja100% (2)

- Training Manual For PVelite Basic LevelDocument41 pagesTraining Manual For PVelite Basic LevelsudokuNo ratings yet

- Rsae-Frm-227 Inspection Check List For Motor Solo RunDocument1 pageRsae-Frm-227 Inspection Check List For Motor Solo RunkamilNo ratings yet

- Hydrostatic Pressure Test ReportDocument2 pagesHydrostatic Pressure Test Reportmaani7zero86% (7)

- Qualified Welders ListDocument3 pagesQualified Welders ListdavNo ratings yet

- Air Leak Test ReportDocument2 pagesAir Leak Test ReportvinothNo ratings yet

- Safety Relife Valve Test Certificate PDFDocument0 pagesSafety Relife Valve Test Certificate PDFmroostaeianNo ratings yet

- Surface Preparation & Painting ReportDocument1 pageSurface Preparation & Painting ReportChethan100% (1)

- Precommisioning and CommissioningDocument24 pagesPrecommisioning and CommissioningPablo Quiroga L.100% (3)

- Testing & Commissioning Certificate For SPRKDocument2 pagesTesting & Commissioning Certificate For SPRKgururaj100% (2)

- Hydrostatic Testing Requirements in API 650Document3 pagesHydrostatic Testing Requirements in API 650Karwan100% (6)

- Hydrotest ProcedureDocument6 pagesHydrotest Procedurebagusu_6No ratings yet

- Vacume Box Test ProcedureDocument5 pagesVacume Box Test ProcedureFarhan Sheikh100% (3)

- Fit Up Report Format-1Document1 pageFit Up Report Format-1BalkishanDyavanapellyNo ratings yet

- Dosing Pumps ChecklistDocument2 pagesDosing Pumps ChecklistDeshan Sing100% (1)

- Sample Leak Testing Report For Ast TankDocument1 pageSample Leak Testing Report For Ast TankArimoro Cyril Obuse43% (7)

- 24 Pressure Testing Report - FormatDocument1 page24 Pressure Testing Report - FormatRrgs Bandara100% (1)

- Stage Wise Inspection ReportDocument2 pagesStage Wise Inspection ReportKarthi Keyan100% (2)

- M - CW - Storage Tank INSPECTION CHECKLISTDocument1 pageM - CW - Storage Tank INSPECTION CHECKLISTmandelaria01100% (1)

- Dye Pentrant Test ProcedureDocument6 pagesDye Pentrant Test ProcedurePer DCNo ratings yet

- Storage Tank Hydrostatic Test Quality Control and Inspection Report Form PDFDocument1 pageStorage Tank Hydrostatic Test Quality Control and Inspection Report Form PDFAdhi PrihastomoNo ratings yet

- Pig Trap End Closure105671465 PDFDocument24 pagesPig Trap End Closure105671465 PDFashishNo ratings yet

- Valve DatasheetsDocument21 pagesValve Datasheetsmainur mechanical engineerNo ratings yet

- 5) Oil Chalk Test PDFDocument2 pages5) Oil Chalk Test PDFkyeong cheol lee75% (16)

- Hydro Test Certificate Template (Soft Copy)Document1 pageHydro Test Certificate Template (Soft Copy)zineddine sofiene75% (4)

- Sample Leak Testing Report For Ast TankDocument1 pageSample Leak Testing Report For Ast Tankchandra sonar100% (2)

- Asme SB466Document9 pagesAsme SB466Stéphane LevasseurNo ratings yet

- Pressure Test CertificateDocument10 pagesPressure Test CertificateDav LalNo ratings yet

- Hydrostatic Pressure Test ReportDocument2 pagesHydrostatic Pressure Test Reportmaani7zero50% (10)

- Complete PackageDocument105 pagesComplete PackagesarangpuneNo ratings yet

- Leak Test Report: Primary Structures CorporationDocument5 pagesLeak Test Report: Primary Structures CorporationJyles SirabNo ratings yet

- Material Receiving FormDocument1 pageMaterial Receiving FormZENJI1624No ratings yet

- Boiler License Exam GuideDocument45 pagesBoiler License Exam Guidemen100% (1)

- Storage Tank Hydrostatic Test Quality Control and Inspection Report FormDocument1 pageStorage Tank Hydrostatic Test Quality Control and Inspection Report FormsugiantobarusNo ratings yet

- Ical Panels MCB Cable Size Calculation 1.1.15Document29 pagesIcal Panels MCB Cable Size Calculation 1.1.15abdulnadeemuddinNo ratings yet

- Gas Pipeline & Instrumentation SystemDocument66 pagesGas Pipeline & Instrumentation Systemanon_484647789No ratings yet

- Quiz For PMP MasterDocument46 pagesQuiz For PMP MasterNareshNo ratings yet

- SCTPL Q SP 002 A1 Vaccum Box Testing ProcedureDocument6 pagesSCTPL Q SP 002 A1 Vaccum Box Testing ProcedureKandula Raju100% (1)

- Msds - VK JellyDocument3 pagesMsds - VK JellyArun33% (3)

- Sis Book 6Document120 pagesSis Book 6Hamza AlamNo ratings yet

- Pressure Tests of Piping SystemsDocument14 pagesPressure Tests of Piping SystemsharishcsharmaNo ratings yet

- Hydrotest CertificateDocument1 pageHydrotest CertificateAmit Singh50% (4)

- Non-Employee Duty Pass Application Form For The Oil and Natural Gas Corporation Limited ONGCDocument14 pagesNon-Employee Duty Pass Application Form For The Oil and Natural Gas Corporation Limited ONGCNeil AlphonsoNo ratings yet

- LAser Alignment ChecklistDocument1 pageLAser Alignment ChecklistAnand Narayanan100% (1)

- Check List For DI Pipe InstallationDocument1 pageCheck List For DI Pipe InstallationSaifur Rahman0% (1)

- Safety Man Hour ReportDocument1 pageSafety Man Hour ReportAurelius Moses GarciaNo ratings yet

- LIFTING POINT Color Code Requirements in PR-1708 PDFDocument2 pagesLIFTING POINT Color Code Requirements in PR-1708 PDFNibin OdukkathilNo ratings yet

- Cir-Seam Fit-Up Inspection Report.Document4 pagesCir-Seam Fit-Up Inspection Report.Akhilesh KumarNo ratings yet

- CERTIFICATE NO 2 Electric Welding MachineDocument2 pagesCERTIFICATE NO 2 Electric Welding MachineOwais MalikNo ratings yet

- Qa Form 26Document1 pageQa Form 26ERICK RALPH MONTENEGRO CASTRONo ratings yet

- SATRDocument1 pageSATRAhmed BoraeyNo ratings yet

- Perar ProcedureDocument21 pagesPerar ProcedurejeswinNo ratings yet

- Ac 3155510319 Ar 9101509008 3Document2 pagesAc 3155510319 Ar 9101509008 3RavijNo ratings yet

- Asc-20-2888-C3 (Screw Compressor)Document2 pagesAsc-20-2888-C3 (Screw Compressor)AkhilNo ratings yet

- National Oil Corporation: Rev Date Description Checked ApprovedDocument17 pagesNational Oil Corporation: Rev Date Description Checked ApprovedRochdi SahliNo ratings yet

- Ip 68Document1 pageIp 68mrhomNo ratings yet

- List of ISO Standards, 2016Document32 pagesList of ISO Standards, 2016zineddine sofieneNo ratings yet

- Daily Activity Accomplishments and Materials Monitoring Sheet For Fire FightingDocument4 pagesDaily Activity Accomplishments and Materials Monitoring Sheet For Fire Fightingzineddine sofieneNo ratings yet

- List of ISO Standards, 2016Document32 pagesList of ISO Standards, 2016zineddine sofieneNo ratings yet

- ENGINEERING STUDY FOR DEVELOPPMENT OF SOLAR POWER SYSTEM Project Schedule PDFDocument1 pageENGINEERING STUDY FOR DEVELOPPMENT OF SOLAR POWER SYSTEM Project Schedule PDFzineddine sofieneNo ratings yet

- IP (Ingress Protection) Standards PDFDocument1 pageIP (Ingress Protection) Standards PDFzineddine sofieneNo ratings yet

- Compex Price List RSIDocument3 pagesCompex Price List RSIzineddine sofieneNo ratings yet

- Atex GuidelinesDocument76 pagesAtex GuidelinesAN.ADAMMSNo ratings yet

- Comparison FM Vs ATEX Flow Chart PDFDocument1 pageComparison FM Vs ATEX Flow Chart PDFGoogool YNo ratings yet

- Comparison FM Vs ATEX Flow Chart PDFDocument1 pageComparison FM Vs ATEX Flow Chart PDFGoogool YNo ratings yet

- Atex GuidelinesDocument76 pagesAtex GuidelinesAN.ADAMMSNo ratings yet

- ENGINEERING STUDY FOR DEVELOPPMENT OF SOLAR POWER SYSTEM Project Schedule PDFDocument1 pageENGINEERING STUDY FOR DEVELOPPMENT OF SOLAR POWER SYSTEM Project Schedule PDFzineddine sofieneNo ratings yet

- You Exec - Marketing Communications FreeDocument12 pagesYou Exec - Marketing Communications Freezineddine sofieneNo ratings yet

- Cylinder Visual Inspection FormDocument2 pagesCylinder Visual Inspection Formzineddine sofieneNo ratings yet

- Compex Price List RSIDocument3 pagesCompex Price List RSIzineddine sofieneNo ratings yet

- Smartech Brochure 2020Document16 pagesSmartech Brochure 2020zineddine sofieneNo ratings yet

- You Exec - Productivity Planner Light FreeDocument8 pagesYou Exec - Productivity Planner Light Freezineddine sofieneNo ratings yet

- Solar Training Site KeyDocument1 pageSolar Training Site Keyzineddine sofieneNo ratings yet

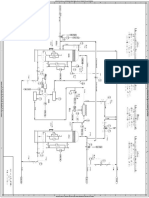

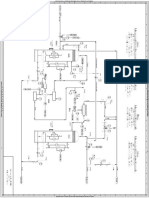

- A-P&id 1-2 Fuel Gas Compressor PDFDocument1 pageA-P&id 1-2 Fuel Gas Compressor PDFzineddine sofieneNo ratings yet

- A-P&id 1-2 Fuel Gas Compressor PDFDocument1 pageA-P&id 1-2 Fuel Gas Compressor PDFzineddine sofieneNo ratings yet

- Pdvsa: Material Technical SpecificationDocument15 pagesPdvsa: Material Technical SpecificationAryelys PadillaNo ratings yet

- Hellenic Maritime BulletinDocument10 pagesHellenic Maritime BulletinsolasmarineNo ratings yet

- ITP Pipe Sectional Replacement Rev CDocument3 pagesITP Pipe Sectional Replacement Rev CAmyNo ratings yet

- Summer Internship Report IOCLDocument53 pagesSummer Internship Report IOCLRAMJAS RAJPUROHITNo ratings yet

- PQC-01 REV 0 PROCEDIMIENTO PRUEBA HIDROSTATICA RevDocument5 pagesPQC-01 REV 0 PROCEDIMIENTO PRUEBA HIDROSTATICA Revjose alberto gamiñoNo ratings yet

- Oisd 159Document37 pagesOisd 159Ritika VermaNo ratings yet

- Gadkar Anwers PrabhatDocument191 pagesGadkar Anwers PrabhatRachit100% (1)

- Nawppl-Bims-Nppl-000-Yl-Spe-00002-004 - Pipeline Hydrostatic Pressure Test SpecificationDocument44 pagesNawppl-Bims-Nppl-000-Yl-Spe-00002-004 - Pipeline Hydrostatic Pressure Test Specificationradhwen chammakhi100% (1)

- Anexo II Da NR 30 in EnglishDocument22 pagesAnexo II Da NR 30 in EnglishVítor Andrade SoaresNo ratings yet

- Your Company Name: COMPRESS Pressure Vessel Design CalculationsDocument4 pagesYour Company Name: COMPRESS Pressure Vessel Design Calculationsdskr fkshNo ratings yet

- Ras Markaz Crude Oil Park Project (Phase1)Document17 pagesRas Markaz Crude Oil Park Project (Phase1)ANIL PLAMOOTTILNo ratings yet

- Typical Hydrostatic-Vents DrainsDocument1 pageTypical Hydrostatic-Vents Drainsrats182No ratings yet

- 6 RC2 30 Vess JSS 95 000 0610Document16 pages6 RC2 30 Vess JSS 95 000 0610Shaaban NoamanNo ratings yet

- Standard Operation Procedure: H2 Storage Tank Draining, Hydrotest & Filling 4X600 MW TPP Val, Jharsuguda, OdishaDocument4 pagesStandard Operation Procedure: H2 Storage Tank Draining, Hydrotest & Filling 4X600 MW TPP Val, Jharsuguda, Odishaabhrrajjit SANo ratings yet