Professional Documents

Culture Documents

Zapi FC1001 2125 Codes

Uploaded by

Daniel PopescuOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Zapi FC1001 2125 Codes

Uploaded by

Daniel PopescuCopyright:

Available Formats

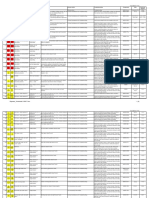

Zapi FC1001 & 2125 Status Codes

Dash Display Controller LED Handset or PC CONDITION

No LEDs or LCDs Handset does not Dash display, controller LED, and truck inoperative with key

illuminated LED OFF operate switch in ON position

TRUCK RESPONSE

Travel and hydraulic functions disabled.

POSSIBLE CAUSES AND TEST PROCEDURES

• B+ and/or B missing at controller.

Confirm battery is connected and of proper voltage.

Verify key switch is ON.

Verify brake override circuit is connected in run

position.

Verify continuity between batteries negative (at

battery) and B power wire connection (at controller).

If no continuity, check:

Power wiring between battery and controller.

Verify continuity between battery positive (at

battery) and B-12 connection (at controller).

If no continuity, check:

Fuse 3 for open.

Key switch continuity in ON position.

Wiring battery + to main contactor to fuse 3 to

key switch, to controller B-12 connection.

• Defective motor controller.

Check for battery voltage between B-12 and B

power wire connection at controller.

If correct battery voltage, replace controller.

Dash Display Controller LED Handset or PC CONDITION

No LEDs or LCDs

illuminated LED OFF No error codes present Dash display and/or controller LED inoperative.

TRUCK RESPONSE

Travel and hydraulic functions normal.

POSSIBLE CAUSES AND TEST PROCEDURES

• Open connection between dash display and controller.

Verify harness connections at MDI and connector

D on controller.

Verify continuity of wires between MDI and controller.

• Defective dash display.

Connect handset to controller and confirm communication

to handset.

If handset operates correctly, replace MDI.

• Defective LED.

Disconnect LED and connect handset. If handset

works, replace LED.

Dash Display Controller LED Handset or PC CONDITION

No LEDs or LCDs

illuminated LED OFF NO COMMUNICATION Dash display and/or controller LED inoperative.

TRUCK RESPONSE

Travel and hydraulic functions normal.

POSSIBLE CAUSES AND TEST PROCEDURES

• Defective controller.

Connect handset to controller and confirm communication

to handset.

If handset will not communicate with controller,

FOR REFERENCE ONLY 6/15/10 Rev 02

replace controller.

Dash Display Controller LED Handset or PC CONDITION

No Alarm LED OFF - No Flashes INCORRECT START Improper startup sequence by operator.

TRUCK RESPONSE

Traction and hydraulic functions disabled.

POSSIBLE CAUSES AND TEST PROCEDURES

• Check that all switches are in the neutral position.

• Throttle or hydraulic function selected at key ON.

Steer handle in run position at key ON.

Return steer handle to full upright position. Return

throttle to neutral. Release all hydraulic

function controls.

If fault remains, attach handset and go to test menu.

• Check brake switch, it should be off. If steer handle

is in vertical position and reading is not OFF, check

brake switch for damage, interference, or shorts.

• Check accelerator - Should be 0 volts at neutral. If

not, repeat control card calibration. If this does not

correct the problem, replace control card.

• Check hydraulic inputs – Should be 0 volts. If not,

recalibrate tiller card. Follow auto-learn procedure

listed in steering. If this does not clear fault, check

buttons for damage or interference. Replace damaged

or faulty buttons.

Dash Display Controller LED Handset or PC CONDITION

AL66 Continuous Flashing BATTERY LOW Battery discharged and requires charging.

TRUCK RESPONSE

Hydraulic lift function disabled.

POSSIBLE CAUSES AND TEST PROCEDURES

• Battery voltage is low.

Charge or replace battery.

• Controller voltage calibration is incorrect.

Install handset. Go to test menu and select

Battery Voltage. Compare tester voltage to voltage

measured by an accurate digital voltmeter

between B+ and B terminals. Pull down tiller

handle to engage contactor for this measurement.

If these two voltages are more than 1.5

volts difference, replace controller.

Dash Display Controller LED Handset or PC CONDITION

AL99 Continuous Flash BATTERY KO Improper battery connection or defective battery.

TRUCK RESPONSE

Traction and hydraulic functions disabled.

POSSIBLE CAUSES AND TEST PROCEDURES

• Incorrect battery selected.

Verify correct battery voltage for truck.

• Damaged or extremely discharged battery.

Disconnect battery and check voltage at connector.

Inspect battery for correct water level and

damage. Repair or replace battery.

• Defective or damaged connection to battery.

Inspect cable crimps and cables from battery to

connector.

Inspect cable crimps and cables frombattery contactor

to controller and contactor.

FOR REFERENCE ONLY 6/15/10 Rev 02

Dash Display Controller LED Handset or PC CONDITION

Connection/communication error between tiller card and

AL01 1 Flash VACC NOT OK traction controller.

TRUCK RESPONSE

Traction and hoist functions disabled.

POSSIBLE CAUSES AND TEST PROCEDURES

• Control card throttle calibration is out of range.

Install handset. Go to tester function of handset.

If accelerator output is >1V (20%) and the enable

switch is open, recalibrate control card.

• Control card throttle damaged or defective.

If card cannot be recalibrated, replace card.

Dash Display Controller LED Handset or PC CONDITION

AL01 1 Flash PUMP VACC NOT OK Connection/communication error between control

card and traction controller.

TRUCK RESPONSE

Traction and hoist functions disabled.

POSSIBLE CAUSES AND TEST PROCEDURES

• A lift/lower switch is damaged or defective.

Install handset. Go to tester function. Check

lifting control and EVP voltage.” Check on/off

switches and proportional switches for smooth,

linear operation. Replace damaged switches.

• Control card lift/lower switch calibration is out of range.

Install handset. Go to tester function. Check lifting

control and EVP voltage. Output of proportional

hydraulic controls should be less than 1V

(20%) at neutral.

Recalibrate control card.

• Control card is damaged or defective.

Replace card.

Dash Display Controller LED Handset or PC CONDITION

AL01 1 Flash FORW + BACK Connection/communication error between control

card and traction controller.

TRUCK RESPONSE

Traction and hoist functions disabled.

POSSIBLE CAUSES AND TEST PROCEDURES

• Control card throttle device is damaged or defective.

Install handset. Go to tester function. If forward

switch and backward switch are both on at the

same time, card is damaged.

Replace control card.

Dash Display Controller LED Handset or PC CONDITION

AL01 1 Flash SERIAL ERROR #1 Connection/communication error between control

card and traction controller.

TRUCK RESPONSE

Traction and hoist functions disabled.

POSSIBLE CAUSES AND TEST PROCEDURES

• Loose or damaged electrical connection between

control card and controller.

Verify connection at controller.

Verify wire harness connection at base of steer handle.

Verify connection at control card.

• Damaged or defective control card.

Measure voltage at pin 5, connector C, on the

controller. With control card disconnected, this

FOR REFERENCE ONLY 6/15/10 Rev 02

should be about 12V; with the card connected, it

should be about 5V. 0V or 12V with the card connected

means that the card is damaged.

Replace control card.

Dash Display Controller LED Handset or PC CONDITION

AL01 1 Flash INPUT ERROR #1 Connection/communication error between control

card and traction controller.

TRUCK RESPONSE

Traction and hoist functions disabled.

POSSIBLE CAUSES AND TEST PROCEDURES

• Traction reversing switch is not connected.

Install handset. Go to tester function. Check for

operation of traction reversing switch.

Verify that traction reversing switch cover is

making contact with switch on control card.

• Damaged or defective control card.

Replace control card.

Dash Display Controller LED Handset or PC CONDITION

AL01 1 Flash INPUT ERROR #2 Connection/communication error between control

card and traction controller.

TRUCK RESPONSE

Traction and hoist functions disabled.

POSSIBLE CAUSES AND TEST PROCEDURES

• Traction reversing switch is not connected.

Install handset. Go to tester function. Check for

operation of traction reversing switch.

Verify that traction reversing switch cover is

making contact with switch on control card.

• Damaged or defective cable.

Check steer handle control cable for loose connections

or broken wires.

• Damaged or defective control handle card.

Replace control card.

Dash Display Controller LED Handset or PC CONDITION

AL01 1 Flash BATTERY CHARGING Controller waits in standby mode while a

battery charger is connected.

TRUCK RESPONSE

Traction and hoist functions disabled.

POSSIBLE CAUSES AND TEST PROCEDURES

• Connector E is loose at base of controller or defective.

Inspect connector E. Check wire 100 between position

E6 and E16 for continuity.

Dash Display Controller LED Handset or PC CONDITION

AL02 2 Flashes CONTACTOR CLOSED Main contactor circuit is damaged.

TRUCK RESPONSE

Traction and hydraulic functions disabled.

POSSIBLE CAUSES AND TEST PROCEDURES

• Main contactor tips are welded closed.

Disconnect power leads at contactor. Use meter

to confirm open circuit across power terminals.

If short circuit is measured, replace contactor.

• Problem in motor field circuit.

Verify electrical connections between motor field

and controller.

Check motor field for shorts to chassis. See Traction

FOR REFERENCE ONLY 6/15/10 Rev 02

Motor Test.

• Controller is damaged.

Replace controller.

Dash Display Controller LED Handset or PC CONDITION

AL4 4 Flashes EVP NOT OK Lowering valve will not operate correctly.

TRUCK RESPONSE

Traction and hydraulic functions disabled.

POSSIBLE CAUSES AND TEST PROCEDURES

• Damaged or loose electrical connection to proportional

lowering valve.

Verify electrical connections between proportional

valve coil and controller.

• Lowering coil damaged.

Check lowering valve coil for correct resistance.

Coil resistance should be approximately 17.8 ohms.

Replace coil if damaged.

• Lowering valve cartridge is damaged.

Replace lowering valve cartridge.

Dash Display Controller LED Handset or PC CONDITION

AL5 5 Flashes EB DRIVER KO Electric brake does not release or remains

released at all times.

TRUCK RESPONSE

Traction and hydraulic functions disabled.

POSSIBLE CAUSES AND TEST PROCEDURES

• Damaged or loose electrical connection to brake.

Verify electrical connection between electric

brake and controller.

• Check brake coil for correct coil resistance.

Disconnect brake. Measure brake coil resistance

in both directions. Coil resistance should be 14.3 ohms.

• Damaged fly-back diode at brake.

Check coil resistance. Short circuit measured at

brake connector may indicate a damaged diode.

Cut one lead of diode and check with meter. If

damaged, replace diode.

• Damaged controller.

Activate the brake switch. Use voltmeter to

measure voltage on wire 2C and 17 with brake

connected in circuit. If both measurements are

24V and the alarm is displayed, then controller

is damaged.

Dash Display Controller LED Handset or PC CONDITION

AL6 6 Flashes I = 0 EVER Motor current levels do not exceed a preset

minimum value while driving.

TRUCK RESPONSE

Traction and hydraulic function disabled.

POSSIBLE CAUSES AND TEST PROCEDURES

• Damaged or loose electrical connections to traction

motor.

Verify electrical connections between traction

motor and controller.

• Traction motor armature resistance is too low.

Check traction motor armature for shorts. Perform

traction motor test. See TractionMotor Test

in this section.

• Controller is damaged.

FOR REFERENCE ONLY 6/15/10 Rev 02

Cycle key switch. Place steer handle in drive position

and select throttle. If the truck starts to drive but

then stops and presents code AL6, replace controller.

Dash Display Controller LED Handset or PC CONDITION

HIGH FIELD CURR,

BW HIGH FLD CURR,

AL6 6 Flashes FW HIGH FLD CURR High field current values measured by controller.

TRUCK RESPONSE

Traction and hydraulic functions disabled.

POSSIBLE CAUSES AND TEST PROCEDURES

• Field wires are loose, damaged, or shorted.

Verify connection of field wires to motor and controller.

• Motor field winding is shorted or too low.

Check motor field for correct resistance and

continuity. It should measure approximately 0.5

ohms. Perform traction motor test. See Traction

Motor Test in this section.

• Failure of current sensor in controller.

Replace controller.

• Failure of field current driver in controller.

Replace controller.

Dash Display Controller LED Handset or PC CONDITION

AL6 6 Flashes NO FIELD CURR Low field current values measured by controller.

TRUCK RESPONSE

Traction and hydraulic functions disabled.

POSSIBLE CAUSES AND TEST PROCEDURES

• Cable connection to motor field is loose or damaged.

Verify connection of field wires to motor and controller.

• Motor field winding is open or too high.

Check motor field for correct resistance and

continuity. It should measure approximately 0.5

ohms. Perform traction motor test. See Traction

Motor Test in this section.

• Field current sensor in controller has failed.

Replace controller.

• Main contactor circuit damaged or disconnected.

Verify electrical connection between controller

and contactor.

Check contactor coil for correct resistance of 22.0

ohms (12.5 ohms for models W20-25ZA).

• Field current drivers in controller are damaged.

Replace controller.

Dash Display Controller LED Handset or PC CONDITION

AL6 6 Flashes STBY I HIGH Controller detects motor current during standby

mode. Standby mode occurs while the truck is

at rest with the contactor closed.

TRUCK RESPONSE

Traction and hydraulic functions disabled.

POSSIBLE CAUSES AND TEST PROCEDURES

• Damaged controller.

Replace controller.

Dash Display Controller LED Handset or PC CONDITION

AL7 7 Flashes THERMAL PROTECT Controller temperature is out of operating range.

TRUCK RESPONSE

Traction functions reduced below 10 C (14 F)

FOR REFERENCE ONLY 6/15/10 Rev 02

and above 75 C (167 F). Traction and hydraulic

functions disabled above 90 C (194 F).

POSSIBLE CAUSES AND TEST PROCEDURES

• Controller temperature is too hot/cold.

Move truck to cooler or warmer location and allow

controller to return to operating temperature.

• Controller temperature miscalibrated.

Install handset. Go to tester function and check

temperature. Controller and vehicle temperature

should be same as room temperature at initial

startup. If these temperatures differ, replace controller.

• Controller temperature sensor damaged.

Replace controller.

• Controller damaged.

Replace controller.

Dash Display Controller LED Handset or PC CONDITION

AL8 8 Flashes POWER FAILURE #1 Short circuit in device connected to controller.

TRUCK RESPONSE

Traction and hydraulic functions disabled.

POSSIBLE CAUSES AND TEST PROCEDURES

• Overcurrent detected in driven component.

Check main harness for damaged or shorted connections

to main contactor, brake, and electric valve coils.

Check main contactor, brake, and proportional

lowering solenoid for correct resistance values.

Value should be within ±10% at room temperature.

Main contactor = 22 ohms (12.5 ohms for models

W20-25ZA).

Brake coil = 14.3 ohms

Proportional lowering valve coil (EV1) = 17.8 ohms

Lifting solenoid (EV2) = 22.2 ohms

A/B directional valve coil (EV3, EV4) = 40.2 ohms

Dash Display Controller LED Handset or PC CONDITION

AL10 LED ON (No Flashing) EEPROM KO Fault in the memory area where parameters

are stored.

TRUCK RESPONSE

Traction and hydraulic functions disabled.

POSSIBLE CAUSES AND TEST PROCEDURES

• Controller damaged.

Clear fault log, recycle key switch OFF and ON.

Operate lift truck to test. If fault reoccurs, Disconnect the

battery and discharge control. Then reconnect battery,

turn key switch ON. Operate lift truck to test.

If fault reoccurs, replace controller.

Dash Display Controller LED Handset or PC CONDITION

AL10 LED ON (No Flashing) CAPACITOR CHARGE Main controller capacitors did not charge

within 500 ms of key ON.

TRUCK RESPONSE

Traction and hydraulic functions disabled.

POSSIBLE CAUSES AND TEST PROCEDURES

• Loose or damaged wire connection.

Inspect and confirm wire connections at contactor,

pump motor, and traction motor.

See Traction Motor Test in this section.

• Short circuit in harness.

Disconnect main harness and check for shorts.

FOR REFERENCE ONLY 6/15/10 Rev 02

• Short circuit in component coil.

Disconnect battery. Disconnect all drive motor,

pump motor, solenoid, brake, and coil connections

at the component end of the harness. Tape

or secure the wire ends to prevent shorts.

Discharge controller by placing 200 , 2W resistor

across B+ and B terminals. Reconnect battery

and turn key ON. Use voltmeter to observe

voltage across B+ and B . If there is no voltage

increase, replace controller. If there is a steady

voltage increase to battery voltage, connect each

accessory one at a time until the fault occurs to

identify damaged component.

• If traction motor malfunction suspected, test for

proper operation.

Perform traction motor test. See Traction Motor

Test in this section.

• Damaged controller.

Replace controller.

Dash Display Controller LED Handset or PC CONDITION

AL10 LED ON (No Flashing) VMN NOT OK Measured voltage at traction motor inputs does

not match battery voltage.

TRUCK RESPONSE

Traction and hydraulic functions disabled.

POSSIBLE CAUSES AND TEST PROCEDURES

• Loose or damaged cable connections to motor.

Verify motor armature cables and connections.

• Ground between motor windings and chassis.

Check for grounds between motor chassis and

terminals. See Traction Motor Test in this section.

• Check for traction motor malfunction.

Perform traction motor test. See Traction Motor

Test in this section.

• Damaged controller.

Voltage at –T terminal on controller should be the

same as the +B terminal.

Replace controller.

Dash Display Controller LED Handset or PC CONDITION

AL10 LED ON (No Flashing) VFIELD NOT OK Voltage measured at field connections is not correct.

TRUCK RESPONSE

Traction and hydraulic functions disabled.

POSSIBLE CAUSES AND TEST PROCEDURES

• Cable connection to motor field is loose or damaged.

Verify connection of field wires to motor and controller.

• Motor field winding is shorted to chassis.

Check motor field for shorts to chassis.

Measure motor field resistance. Motor field

should be approximately 0.5 .

• Check for traction motor malfunction.

Perform traction motor test. See Traction Motor

Test in this section.

• Field current driver circuit has failed.

Use a voltmeter to measure between F1 and B

and F2 and B with battery connected and key

ON. Voltage should measure 1/2 the voltage between

B+ and B .

Replace controller.

FOR REFERENCE ONLY 6/15/10 Rev 02

• Field current drivers in controller are damaged.

Replace controller Verify motor field cable connections.

Dash Display Controller LED Handset or PC CONDITION

AL10 LED ON (No Flashing) WATCHDOG Watchdog hardware circuit is not OK.

TRUCK RESPONSE

Traction and hydraulic functions disabled.

POSSIBLE CAUSES AND TEST PROCEDURES

• Watchdog hardware circuit is damaged.

Clear the fault log and recycle key switch OFF,

then ON. Operate truck to test. If alarmreturns,

replace controller.

Dash Display Controller LED Handset or PC CONDITION

AL10 LED ON (No Flashing) Driver Shorted Voltage measured at field connections is not correct.

TRUCK RESPONSE

Traction and hydraulic functions disabled.

POSSIBLE CAUSES AND TEST PROCEDURES

• Cable connection to motor field is loose or damaged.

Verify connection of field wires to motor and controller.

• Main contactor coil shorted/open.

Check contactor coil for correct resistance of 22.0

ohms (53.4 ohms for models W40Z).

• Motor field winding is shorted to chassis.

Check motor field for shorts to chassis.

Measure motor field resistance. Motor field

should be approximately 0.5 ohms.

• Check for traction motor malfunction.

Perform traction motor test. See Traction Motor

Test in this section.

• Field current driver circuit has failed.

Use a voltmeter to measure between F1 and B

and F2 and B with battery connected and key

ON. Voltage should measure 1/2 the voltage between

B+ and B .

Replace controller.

• Field current drivers in controller are damaged.

Replace controller. Verify motor field cable connections.

Dash Display Controller LED Handset or PC CONDITION

AL94 OFF NONE Controller is installing hourmeter memory to MDI

display if controller or MDI has been replaced.

TRUCK RESPONSE

Traction and hydraulic functions disabled

for 1 minute.

POSSIBLE CAUSES AND TEST PROCEDURES

• No fault is occurring.

Controller will send hourmeter data to MDI and

truck will operate as soon as transfer is complete.

Wait approximately 60 seconds.

FOR REFERENCE ONLY 6/15/10 Rev 02

You might also like

- Zapi FC2125 CodesDocument9 pagesZapi FC2125 CodesDaniel PopescuNo ratings yet

- Zapi FC2086 Codes Rev BDocument9 pagesZapi FC2086 Codes Rev BAfshin GhafooriNo ratings yet

- For Reference Only 1/16/20 Rev BDocument9 pagesFor Reference Only 1/16/20 Rev BMassengoNo ratings yet

- 501-12 - FPV Instrument Panel and ConsoleDocument5 pages501-12 - FPV Instrument Panel and ConsoleDarren ANo ratings yet

- GesxDocument10 pagesGesxJahir FrutosNo ratings yet

- AC TRACTION – DIAGNOSTICS ERROR CODESDocument2 pagesAC TRACTION – DIAGNOSTICS ERROR CODESРухулла АгакеримовNo ratings yet

- Sandvik Mobile Crushers & Screens: Fault Code 800108 Alternator Not ChargingDocument13 pagesSandvik Mobile Crushers & Screens: Fault Code 800108 Alternator Not ChargingJustice MachiwanaNo ratings yet

- Troubleshoot Power Issues & Detect Faults QuicklyDocument10 pagesTroubleshoot Power Issues & Detect Faults QuicklyBala SubramanianNo ratings yet

- 211-05 Steering Column Post Switch PICKUP JMCDocument11 pages211-05 Steering Column Post Switch PICKUP JMCRusonegroNo ratings yet

- 0h9172-k Air Cooled HSB DMDocument418 pages0h9172-k Air Cooled HSB DMANDROS MAYORALNo ratings yet

- Transmission Diagnostic Trouble Codes F323-F329Document5 pagesTransmission Diagnostic Trouble Codes F323-F329Lupin GonzalezNo ratings yet

- Service Manual: Job AidDocument30 pagesService Manual: Job AidJim HarmkeNo ratings yet

- Zapi H2 Traction ControllerDocument5 pagesZapi H2 Traction ControllerHartanto DwiNo ratings yet

- YMM220003 DDocument130 pagesYMM220003 DVinicius NevesNo ratings yet

- Observation Possible Problem Action To Be Taken: Blanketrol Ii TroubleshootingDocument7 pagesObservation Possible Problem Action To Be Taken: Blanketrol Ii TroubleshootinggusfirdausNo ratings yet

- 1423608209.NewHunterTroubleshootingGuide - 04 Oct 12Document34 pages1423608209.NewHunterTroubleshootingGuide - 04 Oct 12scribdNo ratings yet

- Code Fig 1. Fig 2. Description Condition Limits Vehicle Drivers Action Troubleshooting Component Pins Electrical DiagramDocument8 pagesCode Fig 1. Fig 2. Description Condition Limits Vehicle Drivers Action Troubleshooting Component Pins Electrical DiagramIvan ErmolaevNo ratings yet

- Generator Set Troubleshooting GuideDocument1 pageGenerator Set Troubleshooting GuideMohamed SalamaNo ratings yet

- Transmission Diagnostic Trouble Codes F320-F322Document3 pagesTransmission Diagnostic Trouble Codes F320-F322Lupin GonzalezNo ratings yet

- Remote Control Users GuideDocument11 pagesRemote Control Users GuideEduardo IaconoNo ratings yet

- Dia 2723 001Document21 pagesDia 2723 001Sointronic100% (1)

- For Service Technician'S Use Only: Voltage Measurement Safety InformationDocument48 pagesFor Service Technician'S Use Only: Voltage Measurement Safety Informationdan themanNo ratings yet

- 590p Trips and Fault Finding Sds Quick GuidesDocument19 pages590p Trips and Fault Finding Sds Quick GuidesHitesh Panigrahi100% (1)

- A Part 54Document1 pageA Part 54betabet GeorgeNo ratings yet

- Diagnóstic and Repair (10000041488 Rev A) PDFDocument268 pagesDiagnóstic and Repair (10000041488 Rev A) PDFGonzalo Donini100% (1)

- Fault Code 222 Barometric Pressure Sensor Circuit - Voltage Below Normal, or Shorted To Low SourceDocument14 pagesFault Code 222 Barometric Pressure Sensor Circuit - Voltage Below Normal, or Shorted To Low SourceAhmedmahNo ratings yet

- Teco VSD Troubleshooting GuideDocument10 pagesTeco VSD Troubleshooting GuideNabilNo ratings yet

- 9500 Faults 1Document1 page9500 Faults 1José Luis SassoNo ratings yet

- Voltage Safety InfoDocument22 pagesVoltage Safety InfobiggbioNo ratings yet

- Field Repair/Service Blanketrol Iii, Model 233 Operation and Technical ManualDocument9 pagesField Repair/Service Blanketrol Iii, Model 233 Operation and Technical ManualRogerio SilvaNo ratings yet

- Grúa Tadano Faun ATF 130 G5Document37 pagesGrúa Tadano Faun ATF 130 G5Reinaldo ZorrillaNo ratings yet

- 586 Code - Engine Speed Control TestDocument4 pages586 Code - Engine Speed Control TestDibas BaniyaNo ratings yet

- C2 - Testing The Dulas SDD ControllerDocument7 pagesC2 - Testing The Dulas SDD ControllerDulasNo ratings yet

- Techsheet w10740624 RevbDocument44 pagesTechsheet w10740624 RevbPaulStaplesNo ratings yet

- Synchroscope 6714 ManualDocument4 pagesSynchroscope 6714 ManualChris MukalaiNo ratings yet

- 0007 Err DDocument1 page0007 Err DWeeber de SáNo ratings yet

- Diagnostic Trouble Code (DTC) P1737 Solenoid 5 Circuit Open: 5A-120 Automatic TransmissionDocument39 pagesDiagnostic Trouble Code (DTC) P1737 Solenoid 5 Circuit Open: 5A-120 Automatic TransmissionEsquisofNo ratings yet

- Washing Machine Model # 110.26002012 Tech Sheet - W10468342 - Rev CDocument44 pagesWashing Machine Model # 110.26002012 Tech Sheet - W10468342 - Rev CMelissa MorganNo ratings yet

- RLO CableDocument1 pageRLO CableLeiden O'SullivanNo ratings yet

- Operation Manual For: Small Orbital ShakerDocument3 pagesOperation Manual For: Small Orbital ShakerfrodoclNo ratings yet

- 140 - Vehicle Diagnostic Information - Specifications 2 of 2Document150 pages140 - Vehicle Diagnostic Information - Specifications 2 of 2Gedas GvildysNo ratings yet

- 0H9172Document264 pages0H9172Olvan SuazoNo ratings yet

- Error Diagnosis Using The Operation Status: 11-4 TroubleshootingDocument1 pageError Diagnosis Using The Operation Status: 11-4 TroubleshootingDominique KomeyNo ratings yet

- W10240504 Maytag Bravos MVWX600XW0 MCT Washer Tech SheetDocument44 pagesW10240504 Maytag Bravos MVWX600XW0 MCT Washer Tech SheetJason ArnoldNo ratings yet

- HYSTER Forklift Error Code GuideDocument3 pagesHYSTER Forklift Error Code Guidepedro javier carrera jurado100% (3)

- DRIVER COM01 USER'S MANUALDocument89 pagesDRIVER COM01 USER'S MANUALMauricio Rodríguez QuirogaNo ratings yet

- Maruthi TT - 4Document1 pageMaruthi TT - 4nareshNo ratings yet

- Fault Code 452 Injector Metering Rail Number 1 Pressure Sensor Circuit - Voltage Below Normal or Shorted To Low SourceDocument14 pagesFault Code 452 Injector Metering Rail Number 1 Pressure Sensor Circuit - Voltage Below Normal or Shorted To Low SourceAhmedmahNo ratings yet

- SM 89Document36 pagesSM 89Camilo RamosNo ratings yet

- Unigy Troubleshooting Manual R4 PDFDocument13 pagesUnigy Troubleshooting Manual R4 PDFNikolay Velchev100% (2)

- Easily troubleshoot and repair your Powermax45 plasma cutterDocument1 pageEasily troubleshoot and repair your Powermax45 plasma cutterEduardo BarbosaNo ratings yet

- FPS Smart SCADA MANUAL With Exor HmiDocument117 pagesFPS Smart SCADA MANUAL With Exor HmiSHAILESH PATELNo ratings yet

- FAULT CODE 272 (ISC/QSC/ISL/QSL Automotive, Industrial, and Marine Application) High Fuel Pressure Solenoid Valve Circuit - Voltage Above Normal or Shorted To High SourceDocument14 pagesFAULT CODE 272 (ISC/QSC/ISL/QSL Automotive, Industrial, and Marine Application) High Fuel Pressure Solenoid Valve Circuit - Voltage Above Normal or Shorted To High SourceAhmedmah100% (2)

- 730C Articulated Truck TFF0000sss1-UP (MACHINE) POWERED BY C13 Engine (SEBP5991 - 38) - Sistemas y ComponentesDocument4 pages730C Articulated Truck TFF0000sss1-UP (MACHINE) POWERED BY C13 Engine (SEBP5991 - 38) - Sistemas y ComponentesFabrizio JesúsNo ratings yet

- PM 45 78Document1 pagePM 45 78Oficina de Inversoras de soldaNo ratings yet

- Fault Code 428 Water-in-Fuel Indicator Sensor Circuit - Voltage Above Normal or Shorted To High SourceDocument14 pagesFault Code 428 Water-in-Fuel Indicator Sensor Circuit - Voltage Above Normal or Shorted To High SourceAhmedmah100% (2)

- Transfer Coveyor MaunalDocument11 pagesTransfer Coveyor MaunalElena MosnitNo ratings yet

- Fault, Protection and Failure Indications in PSE Soft StarterDocument5 pagesFault, Protection and Failure Indications in PSE Soft StartermichaelNo ratings yet

- Frontier Error Codes PDFDocument2 pagesFrontier Error Codes PDFKing100% (1)

- DRIVE UNIT ComponentsDocument2 pagesDRIVE UNIT ComponentsDaniel PopescuNo ratings yet

- Yale PCST Readme-EN PDFDocument3 pagesYale PCST Readme-EN PDFmoviteknikaNo ratings yet

- CBD/G 2.5 3.0 3.5: Service ManualDocument120 pagesCBD/G 2.5 3.0 3.5: Service ManualHandy Lee100% (2)

- UserManual 885199D03 DLTV83Series v121 EngDocument166 pagesUserManual 885199D03 DLTV83Series v121 EngDaniel PopescuNo ratings yet

- C4000 Om en 16Document91 pagesC4000 Om en 16Daniel PopescuNo ratings yet

- Jung Errors EN PDFDocument214 pagesJung Errors EN PDFcrash2804No ratings yet

- Zapi FC2086 Codes PDFDocument8 pagesZapi FC2086 Codes PDFGabriel BravoNo ratings yet

- Diagnostic Error List SummaryDocument45 pagesDiagnostic Error List SummaryMiguel Alfredo Romero Jimenez88% (8)

- V2403 M T E3bDocument2 pagesV2403 M T E3bPercyLeonNo ratings yet

- HPS/HPT Hand pallet trucks technical specificationsDocument7 pagesHPS/HPT Hand pallet trucks technical specificationsDaniel PopescuNo ratings yet

- Copy PLC Files from One Device to AnotherDocument5 pagesCopy PLC Files from One Device to AnotherDaniel PopescuNo ratings yet

- Crown FC 4500 PDFDocument697 pagesCrown FC 4500 PDFDaniel Popescu100% (1)

- Jungheinrich Ejc112 & E1202Document184 pagesJungheinrich Ejc112 & E1202Thomas Hansen78% (9)

- Jung Errors EN PDFDocument214 pagesJung Errors EN PDFcrash2804No ratings yet

- BT Ac 25Document176 pagesBT Ac 25Daniel PopescuNo ratings yet

- Forklift Safety Training EssentialsDocument47 pagesForklift Safety Training Essentialstu100% (1)

- RAVAS User Manual 3200 FDocument35 pagesRAVAS User Manual 3200 FDaniel PopescuNo ratings yet

- Electronics Workbench Lab 6Document47 pagesElectronics Workbench Lab 6Imran ShaukatNo ratings yet

- Section 1 Simple Circuits: Practice Problems: SolutionDocument5 pagesSection 1 Simple Circuits: Practice Problems: SolutionGULOED Jama JosopHNo ratings yet

- Vox VT50 Service ManualDocument7 pagesVox VT50 Service ManualnilzzonNo ratings yet

- General Description and Circuit OperationDocument3 pagesGeneral Description and Circuit OperationGerardo Arcángel AlvarezNo ratings yet

- Prezentace 09 1106Document140 pagesPrezentace 09 1106Athiesh KumarNo ratings yet

- (G02-00-693) - RTP-8706 - Release 3Document2 pages(G02-00-693) - RTP-8706 - Release 3chuseNo ratings yet

- ES MANUAL Cafetera Bomba Tradicional EC155 DelonghiDocument10 pagesES MANUAL Cafetera Bomba Tradicional EC155 DelonghiEduardo GonzalezNo ratings yet

- A' (Enqk Govn Vqqelq XQL Py: (Vacuum Tubes - Valves)Document28 pagesA' (Enqk Govn Vqqelq XQL Py: (Vacuum Tubes - Valves)Lahiru MadushanNo ratings yet

- PQ1CY1032Z: TO-263 Surface Mount Type Chopper RegulatorDocument9 pagesPQ1CY1032Z: TO-263 Surface Mount Type Chopper RegulatorJm'kosongtujuh RudiNo ratings yet

- 5TT41011 Datasheet enDocument4 pages5TT41011 Datasheet enAndres AlvarezNo ratings yet

- IP5A (5.5 2800KW) Part List - 100827Document35 pagesIP5A (5.5 2800KW) Part List - 100827cocodrilo360No ratings yet

- Felsic 125 Frs v4Document13 pagesFelsic 125 Frs v4ویرا محاسب پاسارگادNo ratings yet

- Answer All Questions, Each Carries 5 Marks.: EE405 Electrical System DesignDocument19 pagesAnswer All Questions, Each Carries 5 Marks.: EE405 Electrical System DesigneeetistNo ratings yet

- Ingecon Sun 1165tl b420 IndoorDocument4 pagesIngecon Sun 1165tl b420 IndoorfdasfNo ratings yet

- BreakeDocument5 pagesBreakewillian zapataNo ratings yet

- DTD 48Document7 pagesDTD 48willofmNo ratings yet

- Voyants Diviseurs Capacitifs KUVIN Indicating System - 8801Document7 pagesVoyants Diviseurs Capacitifs KUVIN Indicating System - 8801Io tuNo ratings yet

- 2014 05-08 ARRI Lighting Poster WebDocument1 page2014 05-08 ARRI Lighting Poster WebThomas Eduard Jessie MartinezNo ratings yet

- Maintenance Testing Specifications For Electrical Power DistributionDocument15 pagesMaintenance Testing Specifications For Electrical Power DistributionalanNo ratings yet

- Rain AlramDocument7 pagesRain AlramFatima Azam Chattha100% (2)

- AVTRON LoadbankDocument2 pagesAVTRON LoadbankAris DaylagNo ratings yet

- Kyoritsu 1011 KewDocument12 pagesKyoritsu 1011 Kewwanna_acNo ratings yet

- Transformer Fuse SelectionDocument4 pagesTransformer Fuse SelectionandrewNo ratings yet

- GRS Electrical IFC PDFDocument9 pagesGRS Electrical IFC PDFHendrix LevaNo ratings yet

- EE-422-Final-Examination PETE 2207Document6 pagesEE-422-Final-Examination PETE 2207Christian Rogel De TorresNo ratings yet

- LB Series: 12 D F S Lb1 NDocument4 pagesLB Series: 12 D F S Lb1 NPasindu PriyankaraNo ratings yet

- Coe TrainingDocument146 pagesCoe Trainingeko heruNo ratings yet

- Topik 1 InggrissssDocument12 pagesTopik 1 InggrissssElgaham RossianantoNo ratings yet

- Logic Families: Designed By: Asadullah JamalovDocument6 pagesLogic Families: Designed By: Asadullah JamalovAsadullah JamalovNo ratings yet

- Doule Rail TRK CCT Data Sheet (CAP)Document4 pagesDoule Rail TRK CCT Data Sheet (CAP)sudhir555eeeNo ratings yet

- The Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionFrom EverandThe Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionRating: 4.5 out of 5 stars4.5/5 (543)

- Practical Electronics for Inventors, Fourth EditionFrom EverandPractical Electronics for Inventors, Fourth EditionRating: 4 out of 5 stars4/5 (3)

- Conquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeFrom EverandConquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeRating: 5 out of 5 stars5/5 (8)

- Teach Yourself Electricity and Electronics, 6th EditionFrom EverandTeach Yourself Electricity and Electronics, 6th EditionRating: 3.5 out of 5 stars3.5/5 (15)

- Upcycled Technology: Clever Projects You Can Do With Your Discarded Tech (Tech gift)From EverandUpcycled Technology: Clever Projects You Can Do With Your Discarded Tech (Tech gift)Rating: 4.5 out of 5 stars4.5/5 (2)

- Power Quality in Power Systems and Electrical MachinesFrom EverandPower Quality in Power Systems and Electrical MachinesRating: 4.5 out of 5 stars4.5/5 (11)

- Practical Troubleshooting of Electrical Equipment and Control CircuitsFrom EverandPractical Troubleshooting of Electrical Equipment and Control CircuitsRating: 4 out of 5 stars4/5 (5)

- C++ Programming Language: Simple, Short, and Straightforward Way of Learning C++ ProgrammingFrom EverandC++ Programming Language: Simple, Short, and Straightforward Way of Learning C++ ProgrammingRating: 4 out of 5 stars4/5 (1)

- 2022 Adobe® Premiere Pro Guide For Filmmakers and YouTubersFrom Everand2022 Adobe® Premiere Pro Guide For Filmmakers and YouTubersRating: 5 out of 5 stars5/5 (1)

- Practical Electrical Wiring: Residential, Farm, Commercial, and IndustrialFrom EverandPractical Electrical Wiring: Residential, Farm, Commercial, and IndustrialRating: 3.5 out of 5 stars3.5/5 (3)

- Off-Grid Projects: Step-by-Step Guide to Building Your Own Off-Grid SystemFrom EverandOff-Grid Projects: Step-by-Step Guide to Building Your Own Off-Grid SystemNo ratings yet

- Open Radio Access Network (O-RAN) Systems Architecture and DesignFrom EverandOpen Radio Access Network (O-RAN) Systems Architecture and DesignNo ratings yet

- The Fast Track to Your Technician Class Ham Radio License: For Exams July 1, 2022 - June 30, 2026From EverandThe Fast Track to Your Technician Class Ham Radio License: For Exams July 1, 2022 - June 30, 2026Rating: 5 out of 5 stars5/5 (1)

- Digital Gold: The Beginner's Guide to Digital Product Success, Learn Useful Tips and Methods on How to Create Digital Products and Earn Massive ProfitsFrom EverandDigital Gold: The Beginner's Guide to Digital Product Success, Learn Useful Tips and Methods on How to Create Digital Products and Earn Massive ProfitsRating: 5 out of 5 stars5/5 (3)

- The Phone Fix: The Brain-Focused Guide to Building Healthy Digital Habits and Breaking Bad OnesFrom EverandThe Phone Fix: The Brain-Focused Guide to Building Healthy Digital Habits and Breaking Bad OnesRating: 5 out of 5 stars5/5 (1)

- Lithium-Ion Battery: The Power of Electric Vehicles with Basics, Design, Charging technology & Battery Management SystemsFrom EverandLithium-Ion Battery: The Power of Electric Vehicles with Basics, Design, Charging technology & Battery Management SystemsRating: 5 out of 5 stars5/5 (2)

- Collection of Raspberry Pi ProjectsFrom EverandCollection of Raspberry Pi ProjectsRating: 5 out of 5 stars5/5 (1)