Professional Documents

Culture Documents

Manufacturing Concrete

Uploaded by

M Baqir IsmailOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Manufacturing Concrete

Uploaded by

M Baqir IsmailCopyright:

Available Formats

CONSTRUCTION & GRAPHICS

CONCRETE:

Concrete is a construction material composed of cement, fine aggregates (sand) and coarse

aggregates mixed with water which hardens with time. Portland cement is the commonly used

type of cement for production of concrete and sometimes admixtures in required proportions

. Following are the major steps

which involved in concreting process:

STAGES OF MANUFACTURING OF CONCRETE:

`BATCHING:

The process of measuring different concrete materials such as cement, coarse aggregate, sand,

water for the making of concrete is known as batching. Batching can be done in two different

ways.

1. Volume Batching

2. Weight Batching.

SHAHROZ SALEEM Page 1

CONSTRUCTION & GRAPHICS

Volume Batching

Volume batching is not a good method for measuring concrete materials.

It is not applicable in case of reinforced concrete structure.

This method of concrete batching may not be economical.

It can be only used for unimportant concrete or for small concrete works.

Weight Batching

Weigh batching is the correct and preferred method of measuring concrete ingredients which

leads to more uniform proportioning. Weigh batching system facilitates simplicity, flexibility

and accuracy. Different types of weigh batchers available in the market and it depends upon the

type of job.

MIXING:

In this process, all the materials are thoroughly mixed in required proportions until the paste

shows uniform color and consistency. Hand mixing and machine mixing are the two different

methods of mixing, but mixing by machine gives good quality concrete, and different types of

mixers are given below,

SHAHROZ SALEEM Page 2

CONSTRUCTION & GRAPHICS

Tilting drum mixers

Non-tilting drum mixers

Reversing drum mixers

Pan type concrete mixers

Continuous concrete mixers

Tilting drum mixers:

Tilting drum mixer means the drum will discharge concrete by tilting downwards. It is rapid

discharge process and used for larger projects. Rapid means it delivers concrete by gravity that is

tilting the drum downwards because of this the concrete mix obtained will be not subjected to

segregation.

Non-Tilting drum mixers:

Non- tilting drum mixers are not allowed to tilt and the drum rotates about its horizontal

axis. For the discharge of concrete a chute is arranged in inclined position which will

receives the concrete mix from drum and discharges out.

SHAHROZ SALEEM Page 3

CONSTRUCTION & GRAPHICS

Reversing drum mixers:

Reversing drum mixers are similar to non-tilting type mixers but in this case reversal of

rotation takes place for different action.The drum has two openings, one end is for

pouring materials and other end is for discharge of mix. The drum rotates about its

horizontal axis. The rotation of drum takes place in one direction for mixing and in

opposite direction for discharging.

Pan type mixers:

Pan type mixers consists a circular pan in which concrete is mixed. The mixing is done by blades

which are arranged in star shape inside the pan. There are two types of pan mixers are available.

In one case, the circular pan is constant and only star blades rotate about vertical axis of pan. In

the other case, circular pan rotates while the blades are at static position.

Continous concrete mixers:

SHAHROZ SALEEM Page 4

CONSTRUCTION & GRAPHICS

Continuous mixer, the name itself telling its duty that the loading, mixing and discharging of mix

is continuously done until the work is complete or work break occurs. The loading of materials is

done continuously by screw feeders.

TRANSPORTATION:

When the mixing is done properly the freshly made concrete is then transported to the

construction site, this process is known as transportation. After that, the concrete is correctly

placed on the formworks. Concrete can be transported to the site location in two ways

Manual Transportation.

Mechanical Transportation.

COMPACTION:

Compaction is the process in which the air bubbles are eliminated from the freshly placed

concrete. It is required to increase the ultimate strength of concrete by enhancing the bond with

SHAHROZ SALEEM Page 5

CONSTRUCTION & GRAPHICS

reinforcement.

CURING

Curing is the process in which the concrete keeps its moisture for a certain time period to

complete the hydration process . Curing should be done properly to increase the strength of

concrete.

SHAHROZ SALEEM Page 6

You might also like

- Equipment For Cocrete MixingDocument14 pagesEquipment For Cocrete MixingPawan BhugaiNo ratings yet

- Concreting PlantsDocument9 pagesConcreting Plantsjoycekanyiri13No ratings yet

- Concrete BatchingDocument41 pagesConcrete BatchingMuhammad ZeeshanNo ratings yet

- Presentation1 ConstructionDocument23 pagesPresentation1 Constructionnebiyat tadiwosNo ratings yet

- 1-Concrete Mixer SummaryDocument4 pages1-Concrete Mixer SummaryDenise Ann CuencaNo ratings yet

- Lec-1 Batching Transportation and Placing Od ConcreteDocument58 pagesLec-1 Batching Transportation and Placing Od ConcreteHasnain MehmoodNo ratings yet

- Concrete Mixer What Do These Machines Do, Their Types and Applications in ConstructionDocument3 pagesConcrete Mixer What Do These Machines Do, Their Types and Applications in ConstructionM iqbalNo ratings yet

- 20mm Thick External Plaster in CMDocument5 pages20mm Thick External Plaster in CMReshma lalNo ratings yet

- RMC Batching PlantDocument28 pagesRMC Batching PlantPradip ParidaNo ratings yet

- Concreting Plant 01 PDFDocument6 pagesConcreting Plant 01 PDFAhmedNo ratings yet

- Machines For Manufacture of ConcreteDocument4 pagesMachines For Manufacture of ConcreteRAJMOHAN B100% (1)

- Concrete Technology - Reading Material - Units 4Document21 pagesConcrete Technology - Reading Material - Units 4s200708 KAMATHAM KEERTHINo ratings yet

- Chapter 7 HeavyDocument18 pagesChapter 7 HeavyHaftamu HilufNo ratings yet

- Concreting OperationDocument58 pagesConcreting OperationChinnu NinanNo ratings yet

- Concrete - MixingDocument8 pagesConcrete - Mixingdevil destroyerNo ratings yet

- Concreting Equipment NotesDocument16 pagesConcreting Equipment NotesChinnu NinanNo ratings yet

- BatchingDocument20 pagesBatchingkolithasamarasekaraNo ratings yet

- Concrete MaterialsDocument56 pagesConcrete MaterialsMUNIB CHOHANNo ratings yet

- Segregation and BleedingDocument3 pagesSegregation and BleedingMurtuza khan TkNo ratings yet

- Components of ConcreteDocument42 pagesComponents of ConcreteniravNo ratings yet

- Concrete Construction StagesDocument22 pagesConcrete Construction StagesSophia Chin100% (1)

- Batching Mixing TransportatingDocument6 pagesBatching Mixing Transportatingحسين عمران محيسنNo ratings yet

- 2.0 Fresh ConcreteDocument10 pages2.0 Fresh Concretesydney augustNo ratings yet

- BCM NotesDocument25 pagesBCM NotesShreyas SuryavanshiNo ratings yet

- Concrete Tech 1 NotesDocument11 pagesConcrete Tech 1 NotesNaisi MASTERNo ratings yet

- RCC Principles - Construction ProcessDocument44 pagesRCC Principles - Construction ProcessDharatiSote100% (1)

- Concrete MixerDocument10 pagesConcrete MixerRafaqat NiaziNo ratings yet

- Cover Page Only 1Document15 pagesCover Page Only 1Zelalem TeshomeNo ratings yet

- Concreting WorksDocument31 pagesConcreting WorksmohibNo ratings yet

- Tools For RCC-1Document33 pagesTools For RCC-1Srushti NaikNo ratings yet

- RCC Part 2Document26 pagesRCC Part 2Anupam KumarNo ratings yet

- Concrt QuizDocument63 pagesConcrt QuizMuhammad HaseebNo ratings yet

- Basic Civil 2nd Sem - ConcreteDocument40 pagesBasic Civil 2nd Sem - Concretebicky agarwalNo ratings yet

- Mixing of ConcreteDocument8 pagesMixing of ConcreteRaj GandhiNo ratings yet

- Concrete: Various Terms Used For Concreting OperationDocument4 pagesConcrete: Various Terms Used For Concreting OperationEngr Amir BhattiNo ratings yet

- Placing of Concrete: Group No: 6 Swaroop Rana Priya Mane Aishwarya NandanwarDocument11 pagesPlacing of Concrete: Group No: 6 Swaroop Rana Priya Mane Aishwarya NandanwarPriya ManeNo ratings yet

- Chapter 4 - Construction PlantsDocument42 pagesChapter 4 - Construction PlantsnaolNo ratings yet

- Process of Manufacture of ConcreteDocument85 pagesProcess of Manufacture of ConcretePrasoon Prasenan PNo ratings yet

- Unit 3 - 2Document10 pagesUnit 3 - 2Painted MindsNo ratings yet

- 7 Industrial Concrete Mixers Key Advantages and Also ApplicationstrhbxDocument4 pages7 Industrial Concrete Mixers Key Advantages and Also Applicationstrhbxcurveactor12No ratings yet

- UNIT-1-Concrete (BCE & BT-204)Document21 pagesUNIT-1-Concrete (BCE & BT-204)Vikash SinghNo ratings yet

- Masini Si Scule in EnglezaDocument38 pagesMasini Si Scule in Englezastefax2010No ratings yet

- Concrete Works Construction MethodologyDocument36 pagesConcrete Works Construction MethodologyJose Rowell MacabantiNo ratings yet

- Manufacturing of ConcreteDocument2 pagesManufacturing of ConcreteBAVIRISHETTY JAYKUMARNo ratings yet

- 02-Production of ConcreteDocument2 pages02-Production of ConcreteSHARATH GOWDA JNo ratings yet

- University of Engineering and TechnologyDocument8 pagesUniversity of Engineering and Technologyabdulhannanchaudary53No ratings yet

- 5-Quality Control of ConcreteDocument101 pages5-Quality Control of ConcreteKanishka roll28No ratings yet

- Ajay and PuruDocument20 pagesAjay and PuruKishan SirohiNo ratings yet

- Civil Engineering Workshop Practice: Course Code: CVL 1013 Program: B. Tech. Semester: First (Credit: 4)Document43 pagesCivil Engineering Workshop Practice: Course Code: CVL 1013 Program: B. Tech. Semester: First (Credit: 4)Díbyã PaniNo ratings yet

- Concrete 180905115821Document83 pagesConcrete 180905115821A AaNo ratings yet

- Concrete Pumps and Mixers For Ready Made ConcreteDocument15 pagesConcrete Pumps and Mixers For Ready Made ConcreteRhythm SatyaNo ratings yet

- ConcreteDocument83 pagesConcreteashwin.j.nair03No ratings yet

- What Is Shrink Mixed ConcreteDocument6 pagesWhat Is Shrink Mixed ConcreteDTM SkipsNo ratings yet

- C.C Road ConstructionDocument18 pagesC.C Road ConstructionJayesh GojiyaNo ratings yet

- Gambella University: Department of Civil Engineering Construction Material Chapter Three (B) - ConcreteDocument117 pagesGambella University: Department of Civil Engineering Construction Material Chapter Three (B) - ConcreteGetahun TadesseNo ratings yet

- Working With ConcreteDocument6 pagesWorking With ConcreteEng. victor kamau NjeriNo ratings yet

- Concrete MixtureDocument21 pagesConcrete MixtureRachel BasistoNo ratings yet

- Unit-Iii BMCT-1Document52 pagesUnit-Iii BMCT-1Sumanth ChallaNo ratings yet

- Agitator TrucksDocument4 pagesAgitator TrucksKalai OrtanNo ratings yet

- Hospital Building: Construction & GraphicsDocument9 pagesHospital Building: Construction & GraphicsM Baqir IsmailNo ratings yet

- Bisection MethodDocument4 pagesBisection MethodM Baqir IsmailNo ratings yet

- Windows:: Parts of WindowDocument4 pagesWindows:: Parts of WindowM Baqir IsmailNo ratings yet

- Doors:: A Is A Of,, Or, Which Is To and Close The Entrance To A Building, Room, Cupboard, orDocument10 pagesDoors:: A Is A Of,, Or, Which Is To and Close The Entrance To A Building, Room, Cupboard, orM Baqir IsmailNo ratings yet

- Hospital Building: Construction & GraphicsDocument9 pagesHospital Building: Construction & GraphicsM Baqir IsmailNo ratings yet

- Door:: M Abdullah 2017-UET-QET-SWL-CIVIL-17Document12 pagesDoor:: M Abdullah 2017-UET-QET-SWL-CIVIL-17M Baqir IsmailNo ratings yet

- Assignment No .02: CE-207 EE & CM Submitted ToDocument1 pageAssignment No .02: CE-207 EE & CM Submitted ToM Baqir IsmailNo ratings yet

- Types of Windows Used in BuildingsDocument7 pagesTypes of Windows Used in BuildingsM Baqir IsmailNo ratings yet

- Hospital Building: Construction & GraphicsDocument9 pagesHospital Building: Construction & GraphicsM Baqir IsmailNo ratings yet

- Bisection Method: The Intermediate Value Theorem Can Be Presented Graphically As FollowsDocument3 pagesBisection Method: The Intermediate Value Theorem Can Be Presented Graphically As FollowsM Baqir IsmailNo ratings yet

- A Door Is A Panel That Makes An Opening in A Building, Room or Vehicle Which Is Used by The Passenger To Pass The Boundary Wall or Any Other HurdleDocument13 pagesA Door Is A Panel That Makes An Opening in A Building, Room or Vehicle Which Is Used by The Passenger To Pass The Boundary Wall or Any Other HurdleM Baqir IsmailNo ratings yet

- Types of Contract in Procurement Management According To Pmbok 6 EditionDocument3 pagesTypes of Contract in Procurement Management According To Pmbok 6 EditionM Baqir IsmailNo ratings yet

- Department of Civil EngineeringDocument1 pageDepartment of Civil EngineeringM Baqir IsmailNo ratings yet

- HashmiDocument1 pageHashmiM Baqir IsmailNo ratings yet

- Asign 2 HydrologyDocument1 pageAsign 2 HydrologyM Baqir IsmailNo ratings yet

- Types of VibratorsDocument13 pagesTypes of VibratorsM Baqir IsmailNo ratings yet

- Assignment-02 - 2017-2020Document3 pagesAssignment-02 - 2017-2020M Baqir IsmailNo ratings yet

- En17217 (M Abdullah)Document8 pagesEn17217 (M Abdullah)M Baqir IsmailNo ratings yet

- Name: Subject: Assessment Type Clos Addressed Domain & Level Plos Addressed Level Question# Clo'S Total Marks Obtained Marks Obtained TotalDocument2 pagesName: Subject: Assessment Type Clos Addressed Domain & Level Plos Addressed Level Question# Clo'S Total Marks Obtained Marks Obtained TotalM Baqir IsmailNo ratings yet

- Asad Ali kHAN PROJECTDocument20 pagesAsad Ali kHAN PROJECTM Baqir IsmailNo ratings yet

- Assignment HydrologyDocument8 pagesAssignment HydrologyM Baqir IsmailNo ratings yet

- Describe Different Types of Contract in Procurement Management According To PMBOK 6 EditionDocument1 pageDescribe Different Types of Contract in Procurement Management According To PMBOK 6 EditionM Baqir IsmailNo ratings yet

- Asad Seismic Zones of PakistanDocument5 pagesAsad Seismic Zones of PakistanM Baqir IsmailNo ratings yet

- ABDULREHANDocument2 pagesABDULREHANM Baqir IsmailNo ratings yet

- Types of Contract in Procurement Management According To Pmbok 6 EditionDocument3 pagesTypes of Contract in Procurement Management According To Pmbok 6 EditionM Baqir IsmailNo ratings yet

- Describe Different Types of Contract in Procurement Management According To PMBOK 6 EditionDocument1 pageDescribe Different Types of Contract in Procurement Management According To PMBOK 6 EditionM Baqir IsmailNo ratings yet

- Kallue EconomyDocument1 pageKallue EconomyM Baqir IsmailNo ratings yet

- Causes of Sedimentation in Reservoirs and Possible RemediesDocument6 pagesCauses of Sedimentation in Reservoirs and Possible RemediesM Baqir IsmailNo ratings yet

- Department of Civil EngineeringDocument1 pageDepartment of Civil EngineeringM Baqir IsmailNo ratings yet

- ASSET BOOKLET - GRADE 8 - Answers With ExplanationDocument109 pagesASSET BOOKLET - GRADE 8 - Answers With ExplanationdfsfdsNo ratings yet

- Titrations: Taking Advantage of Stoichiometric ReactionsDocument18 pagesTitrations: Taking Advantage of Stoichiometric ReactionsAngelica Camille B. AbaoNo ratings yet

- SR 1 Ch3 Movement Across Membrane - WatermarkDocument25 pagesSR 1 Ch3 Movement Across Membrane - WatermarkBryan LeeNo ratings yet

- Steelmaster 120Sb: Technical Data Sheet Application GuideDocument12 pagesSteelmaster 120Sb: Technical Data Sheet Application GuidekalstarNo ratings yet

- Fundamentals of PharmacyDocument66 pagesFundamentals of PharmacyLHYRA KATHLEEN LOPEZ100% (1)

- Hsslive XI Zoology CH 9 BiomoleculesDocument13 pagesHsslive XI Zoology CH 9 Biomolecules스탠 케이팝No ratings yet

- Commonly Used Refractory 1: Silica Bricks: TMT619214 Bata Tahan Api Dan Terak 2021Document12 pagesCommonly Used Refractory 1: Silica Bricks: TMT619214 Bata Tahan Api Dan Terak 2021Mugi MaulaNo ratings yet

- Nitocote CM210Document91 pagesNitocote CM210Gavriel NgNo ratings yet

- Viking Drill & ToolDocument149 pagesViking Drill & ToolMann Sales & MarketingNo ratings yet

- Applied Electrochemistry: Mekelle UniversityDocument2 pagesApplied Electrochemistry: Mekelle UniversityHagosMebrahtuNo ratings yet

- AlkenesDocument16 pagesAlkenesAbhijeetNo ratings yet

- Chapter - 3 Metals and Non - Metals Gist of The LessonDocument8 pagesChapter - 3 Metals and Non - Metals Gist of The LessonPrasadNo ratings yet

- Hidayati DKK, 2009 (AJI 2)Document7 pagesHidayati DKK, 2009 (AJI 2)Artika Muliany TindaonNo ratings yet

- 908 053 Butylated Hydroxytoluene Sds en Ghs Eu Pdf07012020040031 MSDSDocument9 pages908 053 Butylated Hydroxytoluene Sds en Ghs Eu Pdf07012020040031 MSDSBerkin DereliNo ratings yet

- CHE 411 Assignment 4-2008 PDFDocument1 pageCHE 411 Assignment 4-2008 PDFsuzie annNo ratings yet

- Effects of Vernonia Amygdalina (Bitter Leaf) On The Bio-Marker of Oxidative Stress in Accetaminophen Induced Liver Damage of Albino RatsDocument12 pagesEffects of Vernonia Amygdalina (Bitter Leaf) On The Bio-Marker of Oxidative Stress in Accetaminophen Induced Liver Damage of Albino Ratsiaset123No ratings yet

- Hot Work Pre-Inspection ChecklistDocument2 pagesHot Work Pre-Inspection Checklistஹரிஹரசுதன்No ratings yet

- Medical AnesthesticsDocument39 pagesMedical AnesthesticsAL - 12LJ 682103 Lincoln Alexander SSNo ratings yet

- Lokfix E75 TDS191018Document5 pagesLokfix E75 TDS191018msheshappaNo ratings yet

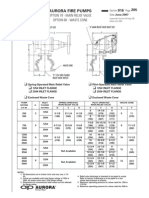

- Fire Pump Relief Valve, Waste Cone, AuroraDocument1 pageFire Pump Relief Valve, Waste Cone, Aurorawvwinters100% (1)

- Section Subject: Shaybah CPF Expansion ProjectDocument21 pagesSection Subject: Shaybah CPF Expansion ProjectAdhie Waelacxh100% (1)

- Heterogeneous Catalysis: Rica Rose L. SantosDocument10 pagesHeterogeneous Catalysis: Rica Rose L. SantosBenedick Jayson Marti100% (1)

- Gear Compound Plus Iso - 68 - enDocument1 pageGear Compound Plus Iso - 68 - enSedin MurtićNo ratings yet

- Chem Lab 4Document15 pagesChem Lab 424 Giang Ngọc Phương ThanhNo ratings yet

- GGB Dp4 Dp10 Dp11 Metal Polymer Self Lubricating Lead Free Bearings BrochureDocument12 pagesGGB Dp4 Dp10 Dp11 Metal Polymer Self Lubricating Lead Free Bearings BrochureGilmar A. NogueiraNo ratings yet

- SDS Ar-Afff 3-3C6Document5 pagesSDS Ar-Afff 3-3C6A K KarmakarNo ratings yet

- Foodpro Epdm Materials enDocument8 pagesFoodpro Epdm Materials enJesus D. Gutierrez G.No ratings yet

- Lecture8 SilicatesDocument7 pagesLecture8 SilicatesSalem GarrabNo ratings yet

- Sengkang Waste Water Treatment DescriptionDocument7 pagesSengkang Waste Water Treatment Descriptionwahyu hidayatNo ratings yet

- Practical No. 2Document4 pagesPractical No. 2Dikshant NagNo ratings yet