Professional Documents

Culture Documents

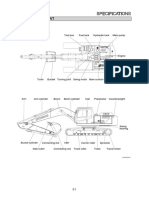

STYP MX-7910 800hp

STYP MX-7910 800hp

Uploaded by

José Leòn OropezaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

STYP MX-7910 800hp

STYP MX-7910 800hp

Uploaded by

José Leòn OropezaCopyright:

Available Formats

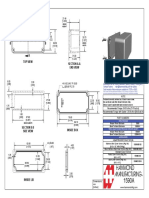

No DE SERIE:

GENERADOR DE VAPOR MX-7910

1.0.0 DIMENSIONES

1.1.0 ENVOLVENTE

1.1.1 DIAMETRO EXTERIOR: (DE) 247.650 [cm] 97.500 [in]

1.1.2 DIAMETRO INTERIOR: (DI) 243.840 [cm] 96.000 [in]

1.1.3 ESPESOR NOMINAL: (t) 1.905 [cm] 0.750 [in]

1.1.4 LONGITUD TOTAL: (Lt) 591.185 [cm] 232.750 [in]

1.2.0 HOGAR

A G

M 1.2.1 DIAMETRO EXTERIOR: (Do) 119.380 [cm] 47.000 [in]

B C D E F F G

1.2.2 DIAMETRO MEDIO: (Dm) 114.300 [cm] 45.000 [in]

1.2.3 ESPESOR NOMINAL: (to) 1.905 [cm] 0.750 [in]

1.2.4 LONGITUD EFECTIVA: (Lf) 545.465 [cm] 214.750 [in]

1.3.0 ESPEJOS

1.3.1 DIA. ESPEJO FRONTAL: (Dfr) 243.840 [cm] 96.000 [in]

L

H 1.3.2 DIA. ESPEJO POSTERIOR: (Dpo) 258.128 [cm] 101.625 [in]

B L

1.3.3 ESPESOR NOMINAL: (te) 1.588 [cm] 0.625 [in]

1.3.4 DISTANCIA: (H) 60.960 [cm] 24.000 [in]

L 1.3.5 DIST./ ESPEJOS EXT.: (Le) 548.640 [cm] 216.000 [in]

I

L 1.4.0 TUBOS FLUX

J 1.4.1 DIAMETRO EXTERIOR: (d) 6.350 [cm] 2.500 [in]

1.4.2 DIAMETRO INTERIOR: (Dit) 5.740 [cm] 2.260 [in]

1.4.3 ESPESOR NOMINAL: (tt) 0.305 [cm] 0.120 [in]

L K L K 1.4.4 CALIBRE: (Cal) 11

1.4.5 No. DE TUBOS: (N) 304

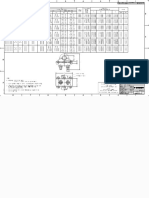

CB-800HP 250[PSI]

2.0.0 5.0.0 TUBOS FLUX 9.0.0 CAPACIDAD DE GENERACION

A.S.M.E BOILER AND PRESSURE VESSEL CODE 5.0.1 MATERIAL: SA-178 GR. A 9.0.1 FORMULA: =(SUP. CALEFACCION NOMINAL)(8)

2.0.2 EDICION: 2013 5.0.2 ESFUERZO MAX. PERM.: (s) 871.821 12400 [psi] (SEC II-D) 9.0.2 CAPACIDAD DE GENERACION : 12700.800 [Kg/hr] 28000 [lb/hr]

2.0.3 SECCION: I 5.0.3 ESPESOR NOMINAL: (tt) 0.305 [cm] 0.120 [in] CAL. 11 9.0.3 REF CODIGO: TABLA A-44 ASME SEC I

(P) 17.577 250 [psi] 5.0.4 CARTA No.: CS-1 (SEC II-D)

10.0.0 VALVULAS DE SEGURIDAD

260.00 500 5.0.5 Le/d= 86.400

371.111 700 5.0.6 d/tt= 20.833 10.0.1 PRESION DE AJUSTE: 17.577 250 [psi]

371.111 700 5.0.7 FACTOR A: 0.00259 (SEC II-D) 10.0.2 MARCA: KUNKLE

2.0.8 PRESION HIDROSTATICA: (=1.5P) 26.366 375 [psi] 5.0.8 FACTOR B: 541.625 7703.594 [psi] (SEC II-D) REQ. MODELO AREA CAPACIDAD

2.0.9 FACTOR DE SEGURIDAD: 3.5 4B 5.080[cm]X6.350[cm] Orif J 7886.743 [Kg/hr]

5.0.9 FORMULA MAWP: Pa = 1 KUNKLE 6010JHE

2.1.0 PWHT: NO APLICA 3(d/tt) 2[in]X2 1/2[in] Orif J 17387 [lb/hr]

3.0.0 CALCULO DE ESPESOR MINIMO, BAJO PRESION INTERNA: ENVOLVENTE 5.1.0 MAWP : (Pa) 34.664 493.030 [psi] 5.080[cm]X6.350[cm] Orif J 7886.743 [Kg/hr]

1 KUNKLE 6010JHE

5.1.1 REF. CODIGO: PG-28,ASME SEC I 2[in]X2 1/2[in] Orif J 17387 [lb/hr]

3.0.1 MATERIAL: SA-516 GR. 70

3.0.2 ESFUERZO MAX. PERM.: (S) 1406.163 20000 [psi] (SEC II-D) 6.0.0 ESPEJOS 15773.486 [Kg/hr]

10.0.3 TOTAL

3.0.3 ALTERNATIVA: SA-515 GR. 70 6.0.1 MATERIAL: SA-516 GR. 70 34774[lb/hr]

3.0.4 ESFUERZO MAX. PERM.: (S) 1406.163 20000 [psi] (SEC II-D) 6.0.2 ESFUERZO MAX. PERM.: (S) 1406.163 20000 [psi] (SEC II-D) [OK]

15773.486[Kg/hr] >12700.800 [kg/hr]

3.0.5 RADIO INTERNO: (R) 121.920 [cm] 48 [in] 6.0.3 ALTERNATIVA: SA-515 GR. 70

3.0.6 EFICIENCIA DE SOLDADURA: (E) 100% (SEC I) 6.0.4 ESFUERZO MAX. PERM.: (S) 1406.163 20000 [psi] (SEC II-D) 11.0.0 CEDULA DE CONEXIONES

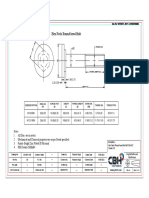

3.0.7 FACTOR : (y) 0.4 (SEC I) 6.0.5 DIAMETRO ESPEJO FONTAL: 243.840 [cm] 96 [in] PART. REQ. TIPO NPS CLASE SERVICIO

3.0.8 FACTOR: (C) 0 (SEC I) 6.0.6 DIAMETRO ESPEJO POSTERIOR: 256.858 [cm] 101 1/8 [in] A 1 BRIDA 20.320[cm] 8[in] SALIDA DE VAPOR

PR 6.0.7 ESPESOR: (te) 1.588 [cm] 5/8 [in] B 3 COPLE [in] COLUMNA PRINCIPAL Y AUXILIAR

3.0.9 FORMULA: tr = +C

SE-(1-y)P 6.0.8 MAX. PITCH: (p) 17.780 [cm] 7 [in] C 1 COPLE 5.080[cm] 2[in] CONTROL WARRICK

3.1.0 MIN. ESPESOR REQ.: (tr) 1.537 [cm] 0.605 [in] D 1 COPLE 1.270[cm] 1/2[in] CALENTADOR

6.0.9 FORMULA: P d

3.1.1 ESPESOR NOMINAL: (t) 1.905 [cm] 0.750 [in] C=2.2 tr= E 1 COPLE [in] PURGA DE SUPERFICIE

CS 4

S E(t-C) 6.1.0 MIN. ESPESOR REQ.: (tr) 1.273 [cm] 0.501 [in] F 2 COPLE 7.620[cm] 3[in] VALVULA DE RELEVO DE PRESION

3.1.2 FORMULA MAWP: Pa =

R+(1-y)(t-C) 6.1.1 REF. CODIGO: PFT-31 ASME SEC I G 2 COPLE 7.620[cm] 3[in] VALVULA DE RELEVO DE PRESION

3.1.3 MAWP: (Pa) 21.767 309.598 [psi] H 1 COPLE 1.270[cm] 1/2[in] IND.TEMPERATURA

7.0.0 TIRANTES

3.1.4 REF. CODIGO: PG-27 ASME SEC I I 1 COPLE 2.540 [cm] 1[in] ALIMEN. QUIMICOS

7.0.1 MATERIAL: SA-36

J 2 ALIMEN. AGUA

4.0.0 CALCULO MAXIMA PRESION DE TRABAJO, BAJO PRESION EXTERNA: HOGAR 7.0.2 ESFUERZO MAX. PERM.: (S) 1167.115 16600 [psi] (SEC II-D)

K 2 5.080 [cm] 2[in] PURGA DE FONDO

4.0.1 MATERIAL: SA-285 GR. C 7.0.3 ALTERNATIVA: SA-675 GR. 70 8.255X11.430 [cm]

L 6 REG. 3.250X4.500 [in] REG. PASA-MANO

4.0.2 ESFUERZO MAX. PERM.: (S) 1005.406 14300 [psi] (SEC II-D) 7.0.4 ESFUERZO MAX. PERM.: (S) 1335.855 19000 [psi] (SEC II-D) 30.480X40.640 [cm]

M 1 REG. 12.000X16.000 [in] REG. ENTRADA-HOMBRE

4.0.3 ALTERNATIVA: SA-516 GR. 70 7.0.5 DIAMETRO TIRANTE: 3.810 [cm] 1 1/2 [in]

4.0.4 ESFUERZO MAX. PERM. : (S) 1272.577 18100 [psi] (SEC II-D) 7.0.6 TIPO DE TIRANTE: DIAGONAL

4.0.5 TIPO DE HOGAR: CORRUGADO TIPO MORISON 7.0.7 No. TIRANTES P/ESPEJO: 20

4.0.6 FACTOR MORISON: (C) 1096.807 15600 [psi] (SEC I) 7.0.8 REF. CODIGO: PFT-25 ASME SEC I

P Dm

4.0.7 FORMULA : tr = 8.0.0 SUPERFICIE DE CALEFACCION

C

4.0.8 MIN. ESPESOR REQ.: (tr) 1.831 [cm] 0.721 [in] 8.0.1 SUPERFICIE DE CALEFACCION DE HOGAR: 19.587 210.830

4.0.9 ESPESOR NOMINAL: (to) 1.905 [cm] 0.750 [in] 8.0.2 SUPERFICIE DE CALEFACCION DE TUBOS: 305.658 3290.077

Ct 8.0.3 SUPERFICIE DE CALEFACCION DE ESPEJOS 3.605 39.450

4.1.0 FORMULA MAWP: Pa =

Dm 8.0.4 SUPERFICIE DE CALEFACCION NOMINAL: 1 325.161 3500

4.1.1 MAWP (Pa): (Pa) 18.280 260.000 [psi] 8.0.5 REF CODIGO: PG-101 ASME SEC I

4.1.2 REF. CODIGO: PFT-18 ASME SEC I

REVISIONES

You might also like

- EIM-Grade 9 Module-1 Q3Document26 pagesEIM-Grade 9 Module-1 Q3Angelo Arriola67% (6)

- Handrail Wall Bracket - 3419-NSHDocument1 pageHandrail Wall Bracket - 3419-NSHWahyu Candra WardanaNo ratings yet

- Ingersoll Rand FA150KGi Man Rider Winch Product Information PDFDocument2 pagesIngersoll Rand FA150KGi Man Rider Winch Product Information PDFNaDeem Nms100% (1)

- Dimensions: Guascor SFGLD 560 Lean Burn GensetDocument2 pagesDimensions: Guascor SFGLD 560 Lean Burn GensetTithy MoniNo ratings yet

- DRC16 24saeDocument2 pagesDRC16 24saeMattia BelliniNo ratings yet

- BK00001302 D ManufacturingDocument1 pageBK00001302 D ManufacturingDaniel CorreiaNo ratings yet

- ECO-147919 A 1 Production Release AC Lep D.Sato 05jun17 Air Intake (Entrada de Ar)Document4 pagesECO-147919 A 1 Production Release AC Lep D.Sato 05jun17 Air Intake (Entrada de Ar)John YangNo ratings yet

- Inside HeightDocument1 pageInside HeightFábio PellegattiNo ratings yet

- 10 Pneumatic Swing ClampsDocument39 pages10 Pneumatic Swing ClampsBe HappyNo ratings yet

- CBH 05 1159 2Document1 pageCBH 05 1159 2qualityNo ratings yet

- OD 26.92mm / 1.060inch: ID 14.73mm HT 11.18mmDocument1 pageOD 26.92mm / 1.060inch: ID 14.73mm HT 11.18mmteh sosoNo ratings yet

- ESPDocument3 pagesESPAdnan Ahmed KidwaiNo ratings yet

- R5000 Power Supply Unit Installation Guide: DetailsDocument2 pagesR5000 Power Supply Unit Installation Guide: DetailsVinesh NaikNo ratings yet

- Cameron: Valves & Measurement General Arrangement 4"-150 CL, MODEL 211, 201 HO Safety Bleed/DtrDocument1 pageCameron: Valves & Measurement General Arrangement 4"-150 CL, MODEL 211, 201 HO Safety Bleed/DtrClarkFedele27No ratings yet

- BVA Accessories CatalogDocument1 pageBVA Accessories CatalogTitanplyNo ratings yet

- 23-21-01-00-01-Assy NR U-Bolt HinoDocument2 pages23-21-01-00-01-Assy NR U-Bolt HinoBINTANG ADYNo ratings yet

- 2 Pole LES 50Hz PDFDocument66 pages2 Pole LES 50Hz PDFhrga.branzbsd55No ratings yet

- 7 1. SpecificationsDocument32 pages7 1. SpecificationsvolvoNo ratings yet

- Conecto Universal DIP (ts0392)Document3 pagesConecto Universal DIP (ts0392)grasia77No ratings yet

- Ansul Foam System Component - Flanged ProportionerDocument1 pageAnsul Foam System Component - Flanged ProportionerNasrul AdliNo ratings yet

- Acuvim II Quick Setup Guide (1040E3103)Document12 pagesAcuvim II Quick Setup Guide (1040E3103)kamran719No ratings yet

- Memoria de Calculo Separadores BifasicosDocument1 pageMemoria de Calculo Separadores BifasicosJhonnatan Fredy Gomez DominguezNo ratings yet

- Power Section: 2.875" 1/2 Lobes 4.9 StagesDocument1 pagePower Section: 2.875" 1/2 Lobes 4.9 StageszbhdzpNo ratings yet

- Air BoxDocument1 pageAir BoxThái TrangNo ratings yet

- Diagrama Constructivo SwitchDocument2 pagesDiagrama Constructivo SwitchEfrain GaheNo ratings yet

- Test & Burn-In SOIC Sockets PDFDocument4 pagesTest & Burn-In SOIC Sockets PDFKSNo ratings yet

- Oprema Oprema: Staircase Swirl Diffuser, Type IRDocument3 pagesOprema Oprema: Staircase Swirl Diffuser, Type IRAnonymous KB3AksTpBNo ratings yet

- Product Overview: Features: Applications: Also AvailableDocument2 pagesProduct Overview: Features: Applications: Also AvailableMAZM17No ratings yet

- Tacos para TubosDocument21 pagesTacos para TubosPedro SantiagoNo ratings yet

- Calculo AntaminaDocument1 pageCalculo AntaminaHernan TiradoBazanNo ratings yet

- Tinh Luc Van NapDocument1 pageTinh Luc Van Napngoc tranNo ratings yet

- sc069674-01 (1) - 220810 - 112715Document2 pagessc069674-01 (1) - 220810 - 112715David Aquino GallegosNo ratings yet

- Sump Adwana H/W: Adopt 1000 MM Dia. Due To Difference Between 1000 & 1100 MM Is MinorDocument10 pagesSump Adwana H/W: Adopt 1000 MM Dia. Due To Difference Between 1000 & 1100 MM Is MinorkkodgeNo ratings yet

- HSB (High Speed Backstops) : Ball Bearing Supported, Sprag ClutchesDocument4 pagesHSB (High Speed Backstops) : Ball Bearing Supported, Sprag ClutchesJUNIOR BAONo ratings yet

- Sheet of 1 1: TL1100F160Q None 6/7/2012 P001099 D DRGDocument1 pageSheet of 1 1: TL1100F160Q None 6/7/2012 P001099 D DRGcesvenegasNo ratings yet

- B38183-MCH RevDocument1 pageB38183-MCH RevJorge HenríquezNo ratings yet

- Condenser Remote Rack TFJ (G600.2QN)Document3 pagesCondenser Remote Rack TFJ (G600.2QN)Wawan NuryanaNo ratings yet

- Katalog Guntner G 2Document3 pagesKatalog Guntner G 2Tritunggal Sampoerna JayaNo ratings yet

- 10W80 FC0A1AA0A4AA Endress+HauserConsultAG 2DDrawing 09 30 2020Document1 page10W80 FC0A1AA0A4AA Endress+HauserConsultAG 2DDrawing 09 30 2020BaskyNo ratings yet

- E-Switch-TL1105SPF250Q C273486Document1 pageE-Switch-TL1105SPF250Q C273486cesvenegasNo ratings yet

- Drawing Office KontainerDocument1 pageDrawing Office KontainerTOLLAUT DESIGNNo ratings yet

- O-Ring CalculatorDocument1 pageO-Ring CalculatorMatyas TakacsNo ratings yet

- NAS1744Document2 pagesNAS1744PabloNo ratings yet

- DZ1040 - 55 Ring - 20231026024801Document4 pagesDZ1040 - 55 Ring - 20231026024801subhashkumarmandalamcivilNo ratings yet

- DZ1040 - 53 Ring - 20231025001049Document4 pagesDZ1040 - 53 Ring - 20231025001049subhashkumarmandalamcivilNo ratings yet

- Valve Sizing Calculation Sheet: Version: V3.1.0 Date: 20/01/2016Document4 pagesValve Sizing Calculation Sheet: Version: V3.1.0 Date: 20/01/2016JOSE MARTIN MORA RIVEROSNo ratings yet

- 04 Se Za 940 1111 PDFDocument175 pages04 Se Za 940 1111 PDFАндрей СилаевNo ratings yet

- 1118mm - Thickness Calculator For MS or DI PipesDocument8 pages1118mm - Thickness Calculator For MS or DI Pipesanirbanpwd76No ratings yet

- 2-1. SpeciticationsDocument26 pages2-1. Speciticationsmargotsilva96No ratings yet

- 350 Legend Public Introduction Rev 2021-06-04Document2 pages350 Legend Public Introduction Rev 2021-06-04John DoeNo ratings yet

- Commscope, Inc. of North Carolina: 3Ft Auto Align Shield Segment - PunchedDocument2 pagesCommscope, Inc. of North Carolina: 3Ft Auto Align Shield Segment - Punchedashfaq shaikhNo ratings yet

- Three View: Title SheetDocument6 pagesThree View: Title SheetWill MedinaNo ratings yet

- All-Round Solutions For Your Industrial Tire Needs: TokaiDocument2 pagesAll-Round Solutions For Your Industrial Tire Needs: TokaiDuong Van HoanNo ratings yet

- Outline Drawing Sst120Document1 pageOutline Drawing Sst120hqnscNo ratings yet

- 44.15 in (1121.5 MM) 6.72 in (170.6 MM) 31.34 in (796.1 MM)Document1 page44.15 in (1121.5 MM) 6.72 in (170.6 MM) 31.34 in (796.1 MM)Jorge LNo ratings yet

- Drive Shaft CalculationDocument106 pagesDrive Shaft CalculationMustu AkolawalaNo ratings yet

- HES 340 UNIT Jack FrameDocument9 pagesHES 340 UNIT Jack FramePRASHANT KANTENo ratings yet

- Physic - XII - ProtectedDocument6 pagesPhysic - XII - ProtectedSmarty JamwalNo ratings yet

- Tesla Electromotive Car EnglishDocument58 pagesTesla Electromotive Car EnglishMihai DanielNo ratings yet

- 9th Physics Assignment-I (1) - CompressedDocument2 pages9th Physics Assignment-I (1) - CompressedJATIN YADAVNo ratings yet

- Why Electrical EngineeringDocument31 pagesWhy Electrical Engineeringsyed42210No ratings yet

- Concrete Volume and Estimate-HSDDocument17 pagesConcrete Volume and Estimate-HSDTeo WwiderNo ratings yet

- Measuring of Gravitational ConstantDocument2 pagesMeasuring of Gravitational Constantns_2mustikaNo ratings yet

- New Senior Secondary Physics at Work (Second Edition)Document10 pagesNew Senior Secondary Physics at Work (Second Edition)Jeffrey YuetNo ratings yet

- Trigonometry 1Document6 pagesTrigonometry 1manojgoyaljuly8No ratings yet

- Bridges Matching Resistors and CapacitorsDocument5 pagesBridges Matching Resistors and CapacitorsChristopher Campbell Sr.No ratings yet

- Iso 6605Document18 pagesIso 6605Fabio StuiNo ratings yet

- Volume Integral FinalDocument26 pagesVolume Integral FinalSreevignesh GNo ratings yet

- ContentDocument12 pagesContentHarishNo ratings yet

- General Description Features: 28V/10A Synchronous Ezbuck RegulatorDocument15 pagesGeneral Description Features: 28V/10A Synchronous Ezbuck RegulatorholinsunNo ratings yet

- Principios Iniciales de Modelado A Partir de La Reacción de Descomposición Del Peróxido de HidrógenoDocument5 pagesPrincipios Iniciales de Modelado A Partir de La Reacción de Descomposición Del Peróxido de HidrógenoDiego PeláezNo ratings yet

- Vertical IndicatorDocument9 pagesVertical IndicatorKent Louie RocaberteNo ratings yet

- Energy Forms and Changes IncompleteDocument4 pagesEnergy Forms and Changes IncompletePhilip Moore100% (1)

- Soiling and Other Optical Losses in Solar Tracking PV Plants in NavarraDocument7 pagesSoiling and Other Optical Losses in Solar Tracking PV Plants in NavarraBunda GrandeNo ratings yet

- College of Science Medical Laboratory Science Medical PhysicsDocument18 pagesCollege of Science Medical Laboratory Science Medical PhysicsFarhang PrintingNo ratings yet

- Weighing Scale PCB User ManualDocument6 pagesWeighing Scale PCB User ManualRam Mohan ChalamalasettyNo ratings yet

- EMI NumericalsDocument3 pagesEMI NumericalsVaibhav SinghNo ratings yet

- Thermal Properties of Matter JEE Main 2023 (January) Chapter-Wise Qs BankDocument19 pagesThermal Properties of Matter JEE Main 2023 (January) Chapter-Wise Qs BankAvijit baruiNo ratings yet

- Fluke 8026B Digital Multimeter Instruction ManualDocument101 pagesFluke 8026B Digital Multimeter Instruction ManualRade ČikarićNo ratings yet

- Procedimento de Calibracion NAV401LDocument26 pagesProcedimento de Calibracion NAV401LEliana GuzmanNo ratings yet

- Sample of Residential Load Computation For Power System AnalysisDocument4 pagesSample of Residential Load Computation For Power System AnalysisMarvin GagarinNo ratings yet

- Electronics Fundamentals Engr. Hassan Sultan Waqar Azeem Engr. Ammar HassanDocument29 pagesElectronics Fundamentals Engr. Hassan Sultan Waqar Azeem Engr. Ammar HassanWaqas AhmadNo ratings yet

- 2850 256 Sample Questions v1 0 PDFDocument7 pages2850 256 Sample Questions v1 0 PDFDavid Blake0% (1)

- ILAC G9 2005 Guidelines For The Selection and Use of Reference MaterialDocument15 pagesILAC G9 2005 Guidelines For The Selection and Use of Reference MaterialVeris Leta FacieNo ratings yet

- Practical Exercises and Challenges: Matter WavesDocument2 pagesPractical Exercises and Challenges: Matter WavesAntoine RobertsNo ratings yet

- TrummeterDocument8 pagesTrummeterGATNo ratings yet