Professional Documents

Culture Documents

System Service Service Report: Case, Fault Description

Uploaded by

matiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

System Service Service Report: Case, Fault Description

Uploaded by

matiCopyright:

Available Formats

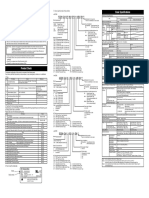

System Service Service Report

Customer: Presence at Service visit:

DOF From Customer:

Plant:

Skandi Patagonia Chief Engineer

Service Date: Electrician

03-07.March 2014 Kjell Ivar Ivarsen

From Siemens:

Arpad von Kesselbauer

Service job ordered by/ Customer Ref. No.: Report distributed to:

Kjell Ivar Iversen

SAP Order Number Siemens: Chief Engineer

Electrician

Report prepared by:

Arpad von Kesselbauer Kjell Ivar Iversen

Place / Date: Marineservice.no@siemens.com

Argentina 06.March 2014 Arpad von Kesselbauer

Report approved by:

Place / Date:

Case, fault description:

Tunnel Thruster No.2

1.Precharge transformer Burned

2.Rectifier Capacitor Burned

3.General work in the Tunnel thrusters cabinet

4.Problems with Emergency Switchboard Breaker

Summary and conclusions:

1.The precharge transformer was burned by what seems to be a short circuit because of

phase mis alligment. The transformer was taken out and a replacement transformer was

installed. All the wires was changed between contactor and transformer. Also some wires

that was nearby the transformer when it burned was changed because of damage.

Tested the precharge transformator with “Break before Make” and measured the phase

alligment over contactor –K1. All three phases had values under 60V. Then it was again

tested with “Make before Break” and everything was fine.

2.A new complete rectifier bridge was installed. Before installation it was megged with

500V and had over 550MOhm. It was again megged after installation then with the whole

transformer and cable connection and I had the same values. The rectifier was tested with

the Inverter disabled and correct voltage on the DC-link was confirmed. Inverter was then

enabled and Tunnel thruster no2 was started. Step by step the load was increased until

95% Load. No alarms no faults.

3.Because of the state of the cabinet all components was cleaned, and all connections

checked for damage. I changed the Bender-Unit and the 24V power supplies for both

internal signals and external signals. Both SCI cards are also changed.

Customer Service, Siemens, Industry Solutions Division:

Site Telephone 24/7 e-mail

Norway +47 815 365 24 (24 hrs ) INDUSTRY: systemservice.no@siemens.com

MARINE: marineservice.no@siemens.com

Dato: 28.01.2010, v.05 Side 1 av 2

Dok.eier: MaSt

Servicereport_Skandi_Patagonia.docx

System Service Service Report

4.The Emergency Switchboard Generator breaker does not close on first attempt. The

breaker does not even close with manual push button or mechanical push button. After the

first attempt the breaker closes every time. The electrician onboard tells me that after the

first attempt it will close every time. If they do not start the generator in a week and test it,

the first attempt will fail. Since There is no way of replicating the failure twice in a row it is

hard to find the cause of the problem. All interlock signals have been checked and they are

ok. Indication of charged spring is ok. There is no mechanical interlock interfering with the

start-up sequence.

Further actions and recommendations:

Tunnel Thruster No.2:

The parts that have been replaced still work, but the smoke pollution could potentially

destroy these parts over time.

The parts that have been replaced should be kept as spares until new spare parts have

been ordered and in stock onboard.

Emergency switchboard:

New Cirquit breaker should be ordered and old one sent in for testing.

Report:

Time of Departure from Siemens: 01 March 2014 H1630

Time of arrival at site: 03 March 2014 H1100 Local time

Time of Departure from site: 07 March 2014 H1400 Local time

Time of arrival at Siemens : 11 March 2014 H1900

Customer Service, Siemens, Industry Solutions Division:

Site Telephone 24/7 e-mail

Norway +47 815 365 24 (24 hrs ) INDUSTRY: systemservice.no@siemens.com

MARINE: marineservice.no@siemens.com

Dato: 28.01.2010, v.05 Side 2 av 2

Dok.eier: MaSt

Servicereport_Skandi_Patagonia.docx

You might also like

- PTES Sample IR Scan ReportDocument22 pagesPTES Sample IR Scan ReportAkshay GatkalNo ratings yet

- TD Esc 03 de en 15 048 Rev001 Electrical SiteworksDocument19 pagesTD Esc 03 de en 15 048 Rev001 Electrical SiteworksarhipadrianNo ratings yet

- Siemens Service Report AVR Adjustment September 2012 Report-2712 PDFDocument4 pagesSiemens Service Report AVR Adjustment September 2012 Report-2712 PDFJurekNo ratings yet

- Installation and Operating Manual For TransformerDocument427 pagesInstallation and Operating Manual For TransformerEddie Castañeda MonroeNo ratings yet

- Quotation ASl HARMONY ELECTRICDocument4 pagesQuotation ASl HARMONY ELECTRICalim mukhtarNo ratings yet

- Near Miss Report: Complete This Form and Email It ToDocument1 pageNear Miss Report: Complete This Form and Email It ToAnonymous BxoDznYImNo ratings yet

- ISMS 2006005528: 01 - Black Anodising FacilityDocument5 pagesISMS 2006005528: 01 - Black Anodising FacilityTiger SahyadriNo ratings yet

- Electrical Marine Thermal Imaging Survey Sample ReportDocument14 pagesElectrical Marine Thermal Imaging Survey Sample ReportRachit SharmaNo ratings yet

- Report On Tonota Main Genset FailureDocument2 pagesReport On Tonota Main Genset FailureFrancistown LR Diagnostic CentreNo ratings yet

- TFR - 200902678 - 015 (Van Hanh Dinh Muc)Document14 pagesTFR - 200902678 - 015 (Van Hanh Dinh Muc)Nguyen ngoc thongNo ratings yet

- Technical-Note Failure-Process Global en V202108Document9 pagesTechnical-Note Failure-Process Global en V202108rxmymNo ratings yet

- EAP BUILDING SCOPE OF WORK updatedDocument7 pagesEAP BUILDING SCOPE OF WORK updatedMasesi RadebeNo ratings yet

- Method Statement of Rectification of Defect No. E398Document13 pagesMethod Statement of Rectification of Defect No. E398Aous HNo ratings yet

- 3 Monthly Routine Fire PumpsDocument2 pages3 Monthly Routine Fire PumpsMarciokronembergerNo ratings yet

- DH3-31BB-T-SCT-0009 Commissioning Procedure of 6.6kv Transformer System REV.0Document8 pagesDH3-31BB-T-SCT-0009 Commissioning Procedure of 6.6kv Transformer System REV.0hungNo ratings yet

- CCM 2.5MVATX QASCO CommissioningTest Report.Document13 pagesCCM 2.5MVATX QASCO CommissioningTest Report.Ginger TurnerNo ratings yet

- Savina TSB 3 PDFDocument2 pagesSavina TSB 3 PDFgameel alabsiNo ratings yet

- Savina Technical Service Bulletin # 3Document2 pagesSavina Technical Service Bulletin # 3gameel alabsiNo ratings yet

- Innovation at Umaria CollieryDocument7 pagesInnovation at Umaria CollieryShaileshNo ratings yet

- 007-Commissioning Procedure Of Fault Reorder System-R1Document9 pages007-Commissioning Procedure Of Fault Reorder System-R1SalmanEjazNo ratings yet

- Final Report Filter House Jan.2024Document13 pagesFinal Report Filter House Jan.2024julianrmz87No ratings yet

- L2 Eln Spe 030Document15 pagesL2 Eln Spe 030CK TangNo ratings yet

- Technical Handover Notes for Chief Electrical EngineerDocument23 pagesTechnical Handover Notes for Chief Electrical EngineerDimitrii MoisyeyevNo ratings yet

- NEOTHERM 70 EVO - 60V Manual - P1600 PDFDocument23 pagesNEOTHERM 70 EVO - 60V Manual - P1600 PDFm_armouti100% (1)

- Submittal Rev 2Document264 pagesSubmittal Rev 2Haythamberg AhmedNo ratings yet

- Ac Panel Test ProsedureDocument6 pagesAc Panel Test ProsedureUtku Can KılıçNo ratings yet

- EMC Test Report: Full Compliance MeasurementsDocument23 pagesEMC Test Report: Full Compliance MeasurementsenekomNo ratings yet

- 4 Jsa (Sie-Hse-005-F11 r1) - Precomm Ess001Document3 pages4 Jsa (Sie-Hse-005-F11 r1) - Precomm Ess001Jannuar Ilham100% (2)

- Civil & Mech. Daily Report # 17-12-16Document2 pagesCivil & Mech. Daily Report # 17-12-16haaliNo ratings yet

- Alef GG1Document1 pageAlef GG1VILAS VIJAYANNo ratings yet

- 2013 Examination Paper AugustDocument23 pages2013 Examination Paper AugustUzair Ijaz KhanNo ratings yet

- Emergencia de AguaDocument9 pagesEmergencia de AguaangelysccNo ratings yet

- P DC Engineering BDocument6 pagesP DC Engineering BronfrendNo ratings yet

- MOS For Electrical Board Turn OnDocument8 pagesMOS For Electrical Board Turn OnYuz FiNo ratings yet

- Pcea: ": Electrical Preventive Maintenance - Spend A Little - Save A Lot"Document30 pagesPcea: ": Electrical Preventive Maintenance - Spend A Little - Save A Lot"Arnulfo LavaresNo ratings yet

- 1W Manutencao Semanal Das Bombas de IncendioDocument2 pages1W Manutencao Semanal Das Bombas de IncendioMarciokronembergerNo ratings yet

- Zero Defect TestingDocument4 pagesZero Defect TestingNagamuthu PandianNo ratings yet

- General RequirementsDocument7 pagesGeneral RequirementsFranklin GarlejoNo ratings yet

- Polymer Utility HT Panel - 1385 - ITEM-200 - 14 07 21Document87 pagesPolymer Utility HT Panel - 1385 - ITEM-200 - 14 07 21jay manekNo ratings yet

- Initial Product/Process Change Notification: Document #:IPCN23483XA Issue Date:01 Jul 2021Document7 pagesInitial Product/Process Change Notification: Document #:IPCN23483XA Issue Date:01 Jul 2021Douglas AlbertNo ratings yet

- A4-P 1.0 enDocument1,020 pagesA4-P 1.0 enTrần Văn Phúc100% (1)

- MERALCO Service Application ProcessDocument33 pagesMERALCO Service Application Processecruz_yhwh67% (3)

- 002 - ManualC - G - 47-50 - ING Rev.2 20.10.11Document13 pages002 - ManualC - G - 47-50 - ING Rev.2 20.10.11aiabbasi9615No ratings yet

- 049 - CRT With OLTC - 2500 KVA - 33-0.433 KV - GODAVARI PROJECTS PRIVATE LIMITED - Dt. 25.05.2021Document5 pages049 - CRT With OLTC - 2500 KVA - 33-0.433 KV - GODAVARI PROJECTS PRIVATE LIMITED - Dt. 25.05.2021Ajay MedikondaNo ratings yet

- Model 350M77 ICP® Accelerometer Installation and Operating ManualDocument16 pagesModel 350M77 ICP® Accelerometer Installation and Operating ManualCaio AlmeidaNo ratings yet

- Offer Unitech Solutions W1314100Document8 pagesOffer Unitech Solutions W1314100Tomuta StefanNo ratings yet

- Aristocrat BallastsDocument7 pagesAristocrat BallastsSanju GohilNo ratings yet

- MIghty Machine RejectDocument1 pageMIghty Machine RejectMohammad Shanawaz MNo ratings yet

- Polymat Plus S PDFDocument116 pagesPolymat Plus S PDFEdward Pérez ArangurenNo ratings yet

- 1.0: Purpose: Document No. DSC-WI 13400Document2 pages1.0: Purpose: Document No. DSC-WI 13400Satpal SinghNo ratings yet

- 1 - Hi Pot Test Procedure For SwitchyardDocument6 pages1 - Hi Pot Test Procedure For Switchyardbayu dewanto100% (1)

- User Manual Single Phase, Single Rate, Credit Meter TYPE: 5193ADocument9 pagesUser Manual Single Phase, Single Rate, Credit Meter TYPE: 5193AVivek SinghNo ratings yet

- Service Manual: Microwave Oven AVM 562Document8 pagesService Manual: Microwave Oven AVM 562Csaba KohegyiNo ratings yet

- HT PANEL CommissioningDocument42 pagesHT PANEL Commissioningsantoshkumar33% (3)

- Equipo RX Poly PlusDocument58 pagesEquipo RX Poly PlusEnrique C. Bravo C0% (1)

- Low Discharge in HydropowerDocument5 pagesLow Discharge in Hydropowerprbthapa2055No ratings yet

- TD-esc-02-De-En-16-016 Rev000 Scrapping of Water Heater SAP 99399Document3 pagesTD-esc-02-De-En-16-016 Rev000 Scrapping of Water Heater SAP 99399Felipe SilvaNo ratings yet

- System Description: NEMP Test Systems MIL-STD-461E&F RS105 at 50 KV/MDocument19 pagesSystem Description: NEMP Test Systems MIL-STD-461E&F RS105 at 50 KV/MnanimedichaNo ratings yet

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 3.5 out of 5 stars3.5/5 (3)

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- Catalog Inverter Huawei SUN2000-100KTL-M1Document2 pagesCatalog Inverter Huawei SUN2000-100KTL-M1Nivet chanaiklangNo ratings yet

- P89LPC912/913/914: 1. General DescriptionDocument63 pagesP89LPC912/913/914: 1. General Descriptionashish gautamNo ratings yet

- TN NewDocument6,322 pagesTN Newdeva nesan83% (6)

- WHP02 Gene Asyyy 07 340001 01Document43 pagesWHP02 Gene Asyyy 07 340001 01Krishnan KrishNo ratings yet

- Dogm Graphic Series: 128x64 DOTSDocument8 pagesDogm Graphic Series: 128x64 DOTSLubos MatuskaNo ratings yet

- Solid-State Timer H3T: Ordering InformationDocument8 pagesSolid-State Timer H3T: Ordering Informationheart prince0% (1)

- DEA 2342 Basic of Electronic Engineering: Lab Sheet 4Document6 pagesDEA 2342 Basic of Electronic Engineering: Lab Sheet 4Afieza TumijanNo ratings yet

- Pioneer VSX 519v K VSX 519v SDocument94 pagesPioneer VSX 519v K VSX 519v SDamir VidakovicNo ratings yet

- SSC Unit - I Lecture 0Document24 pagesSSC Unit - I Lecture 0Girish Shankar MishraNo ratings yet

- Level Gauging System GL 100Document625 pagesLevel Gauging System GL 100D Arsen50% (2)

- List of Emerging Technologies - Wikipedia, The Free EncyclopediaDocument37 pagesList of Emerging Technologies - Wikipedia, The Free EncyclopediaSrini RaoNo ratings yet

- Presentacion HDC MolexDocument68 pagesPresentacion HDC MolexmathconsNo ratings yet

- TV Led & LCD Terbaik Hanya Sharp Aquos - Lc-32le348iDocument2 pagesTV Led & LCD Terbaik Hanya Sharp Aquos - Lc-32le348iSukawan ZakyNo ratings yet

- Battery Tester Circuit Schematic - EEWeb CommunityDocument8 pagesBattery Tester Circuit Schematic - EEWeb Communitybnc1No ratings yet

- KNR2443 - Electrical Engineering Technology: Chapter 1 & 2 International System of Measurement & Electrical CircuitDocument65 pagesKNR2443 - Electrical Engineering Technology: Chapter 1 & 2 International System of Measurement & Electrical CircuitCyprian Mikael CorgedoNo ratings yet

- HCF4007Document9 pagesHCF4007Charlie DavidsNo ratings yet

- Vibração SensorDocument4 pagesVibração SensorLourismar VicenteNo ratings yet

- Aoz1360 A&oDocument12 pagesAoz1360 A&oAnthony SaltNo ratings yet

- Manual Cdi 3102Document56 pagesManual Cdi 3102rusf123No ratings yet

- Fisheasy 250 Ds & Seafinder 250 DF: Installation and Operation InstructionsDocument72 pagesFisheasy 250 Ds & Seafinder 250 DF: Installation and Operation InstructionsstaicuNo ratings yet

- A Noninvasive Blood Pressure Monitoring System: Balamurugan. S, Ramasubba Reddy, Muthan SDocument3 pagesA Noninvasive Blood Pressure Monitoring System: Balamurugan. S, Ramasubba Reddy, Muthan SMohamed TahaNo ratings yet

- Some Aspects On Integrated Current Shunts For High Frequency Switching Power Electronic ConvertersDocument6 pagesSome Aspects On Integrated Current Shunts For High Frequency Switching Power Electronic ConvertersElena RamonaNo ratings yet

- Samsung Bonn-Int Rev 1.0Document56 pagesSamsung Bonn-Int Rev 1.0camilo jimenez catañoNo ratings yet

- Nexgenie Base Unit InstallationManualDocument2 pagesNexgenie Base Unit InstallationManualSteps Knowledge Services Pvt Ltd.No ratings yet

- Pcon-Ca/Cfa/Cb/Cfb, Acon-Ca/Cb/Cgb, Dcon-Ca/Cb/Cgb First Step Guide Sixth EditionDocument5 pagesPcon-Ca/Cfa/Cb/Cfb, Acon-Ca/Cb/Cgb, Dcon-Ca/Cb/Cgb First Step Guide Sixth EditionKhải PhạmNo ratings yet

- Hgd-113, Hgd-133 For CeDocument55 pagesHgd-113, Hgd-133 For CeRays RwpNo ratings yet

- LRT Rectifier: Power Supply and Overhead Catenary SystemDocument3 pagesLRT Rectifier: Power Supply and Overhead Catenary SystemToffee BebeNo ratings yet

- Idosr JST 41 81 105 2019. PuDocument25 pagesIdosr JST 41 81 105 2019. Pujamiu1175No ratings yet

- PT2060 Monitor: PVTVM, IncDocument69 pagesPT2060 Monitor: PVTVM, Incnino16041973No ratings yet

- Solved ISRO Scientist or Engineer Electronics 2006 Paper With SolutionsDocument23 pagesSolved ISRO Scientist or Engineer Electronics 2006 Paper With SolutionsAnitha JersonNo ratings yet