Professional Documents

Culture Documents

Task Risk Assessment Engineering Kinetics (PVT) LTD: Risk Evaluation (Refer To Evaluation Form)

Task Risk Assessment Engineering Kinetics (PVT) LTD: Risk Evaluation (Refer To Evaluation Form)

Uploaded by

andreOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Task Risk Assessment Engineering Kinetics (PVT) LTD: Risk Evaluation (Refer To Evaluation Form)

Task Risk Assessment Engineering Kinetics (PVT) LTD: Risk Evaluation (Refer To Evaluation Form)

Uploaded by

andreCopyright:

Available Formats

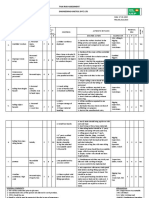

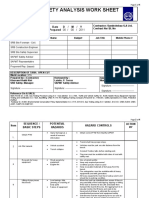

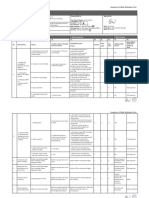

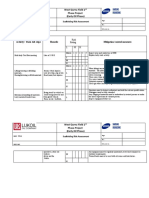

TASK RISK ASSESSMENT

ENGINEERING KINETICS (PVT) LTD

TASK TITLE: Naimat Phase-V Expansion Project Date: 27-11-2014

Activity: Lifting & Assembling through Crane TRA.No.007. EKL

Location: Naimat Phase-V Expansion Project (Green Field area)

Description: offloading of Containers (Camp/Site Office/Workshop)

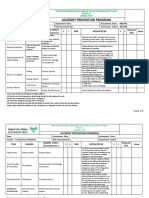

RISK

Y/NALARP

EVALUATION RESIDUAL

S/No.

HAZARD (Refer to

ACTION TO BE TAKEN

HAZARD CONTROLS RISK

EFFECT Evaluation form)

S P R DESCRIBE ACTION MANPOWER S P R

SPA: Lifting &

Rigging

1. Personal 1. Skilled workforce 1. Ensure the workers involved in the

Supervisor,

Unskilled Workers injury, F 6 8 deployed. activity are trained, qualified and F 3 5 Yes

1. Safety

2. accident competent to carry out the work safely.

Watchman

1. Look out to be deployed for safe

1. Look outs deployment reverse movement.

2. Slow reverse 2. Look out should use reflective vest. SPA: Lifting &

movement. 3. Reverse alarm should be used during Rigging

Personal injury,

3. Reverse alarm reverse movement. Supervisor,

2. Damage to the G 6 7 G 2 3 Yes

Struck with crane functional. 4. Boom should be closed during any Safety

Equipment

4. Defensive driving movement of the crane. Watchman

certified operator 5. Follow the speed limits (10 Km/Hr) as Lookouts.

per UEPL standard.

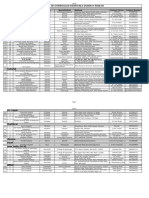

1. Place crane on leveled/compacted

ground with fully extended outriggers. SPA: Lifting &

Crane collapse due Property 2. Provide wooden pads underneath the Rigging

1. Assess the ground

3. to poor ground damage, float pads of outriggers with area at least Supervisor, Yes

F 5 7 condition prior to lift. F 3 5

condition personal injury 3 times larger than that of float. Safety

4. If the poor ground conditions Watchman

encountered change the location.

1. Never stand between

the load and a barrier. 1. Position of the crane will be controlled

Personnel

2. Place Crane on leveled by supervisor. Certified

injury. /

& compacted ground 2. Follow controls for exclusion zone as Riggers.

Improper Crane damage to light

4. F 6 8 with fully extended out marked on lifting plan. Competent G 3 5 Y

setup pole, panel

riggers on wooden 3.Tool box to share movement Rigging & Lifting

skid, trees &

sleepers. arrangement with crane driver/ Supervisor.

cont. room

operator/lookout/ supervisor

1. Ensure all lifting gears should be third

1. Pre Use inspection of party certified.

SPA: Lifting &

Lifting Collapse, lifting accessories & 2. Inspect the equipment and accessories

Damaged lifting Rigging

Serious equipments. also Check prior to using any lifting

5. gears E 4 7 Supervisor, E 2 5 Yes

personal 2. Check the valid 3rd accessory

Safety

injury/Fatality party certification. 3. Trial lifts to be ensured.

Watchman

4. Ensure proper anchorage with the help

of eye bolt.

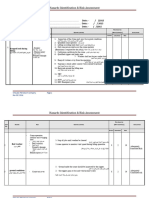

Slowly raise / lower the load , Lifting plan Safety

should be available at site Supervisor,

Physical Injury, Lifting plan, Weight of

6. Falling / Slipping G 6 7 Lifting gear certification, trial lift. Rigger, G 2 3

Load Hit with load should be known, Yes

2.Rigging study should be available at job Banks man,

Existing Piping. Trail Lift

site Supervisor

1. Area to be cordoned off with full time

Unnecessary Safety

1.Area cordon off supervision.

7. movement of Personal Injury G 6 7 Supervisor, G 2 3 Yes

2.No parallel activities 2. Stop other activities in that working

personnel Banks man

area.

1.Site/area/location

1. Rigger/signal/outlook man visit site

survey before moving

before moving equipment at site.

equipment at site i.e.

Equipment 2. HSE supervisor will ensure wind speed

Soil condition Rigging Sup,

stuck in muddy limit before starting lifting operation if

Weather 2.Wait till clear visibility (SPA)

8. area due to F 5 7 wind speed exceeds from 25 knots TRA F 3 5 Yes

conditions achieved (in case of wind Crane Opt, HSE

rain, High Wind should be revised.

storm) Sup

speed 3. No lifting if wind speed cross 30 knots

3. Observe plant wind

4. Wind speed Reading should be from

speed limit before any

radio room

lifting operations.

Harnesses are to be worn and lanyards Safety

Ensure all relevant PPE

attached at heights Supervisor,

Working at height Personnel equipment is used at all

9. F 5 7 Greater than 2m or where there is a risk Competent F 3 5 Y

(> 6.0 ft) Injury times.

of slipping & falling. Lifting

Supervisor

Cross reference this task

with all relevant PTW's,

Conduct a permit planning meeting with

Injuries, plans certificates one PI, SPA

SIMPOS E 7 10 stakeholders one day before job E 2 5 Yes

Fatalities day before job execution AA

execution

subject to SIMPOS

operation

GENERAL COMMENTS:

1. TBT will be conducted prior to job start.

2. Unauthorized entry of the person not allowed in work premises.

3. Proper PPE’s are must for all the crew.

4. Stand by vehicle must be present at the site in case of emergency.

5. Adequate cold drinking water readily is available at the site to prevent dehydration.

6. Housekeeping of the area should be done on prior basis before and after completion of job.

NAME OF TEAM MEMBERS Signature RISK ASSISMENT APPROVAL

I’m satisfied that the safeguard put in place will reduce the level of Risk to an acceptable level

Muhammad Asif (Project Manager) and the Task/Action is permitted to proceed.

Kawish Zafar (Rigging & Lifting Supervisor)

Reviewed by: ___FARUKH MALIK_________

Farhat Ali HITRA (HSE Engineer)

Date: ________________________ Time: ____________________

Authorizing

S = Severity; P = Probability, R = Risk

Signatory: _______________ DATE: ________________

You might also like

- Risk Assessment ReferenceDocument12 pagesRisk Assessment Referenceramilnavarra62No ratings yet

- Win Joo Enterprise: Hazard Identification Risk Assessment & Determining Control (Hiradc)Document8 pagesWin Joo Enterprise: Hazard Identification Risk Assessment & Determining Control (Hiradc)anas zubir100% (2)

- Lifting Risk AssessmentDocument4 pagesLifting Risk AssessmentMohamedSaid100% (2)

- Jacques Alain Miller MarginaliaDocument22 pagesJacques Alain Miller Marginaliasantanu6100% (2)

- RH340Document8 pagesRH340ericNo ratings yet

- Modeling and Understanding BLEVEsDocument27 pagesModeling and Understanding BLEVEsAnonymous gFVMelwgnNo ratings yet

- TRA of Cladding Using LadderDocument2 pagesTRA of Cladding Using LadderAsh SoliNo ratings yet

- TRA of Lifting - TailDocument3 pagesTRA of Lifting - TailTharaka Perera100% (1)

- TRA of Ladder & PlatformDocument2 pagesTRA of Ladder & PlatformASIF MUZAFFARNo ratings yet

- TRA of Lifting of EquipmentsDocument4 pagesTRA of Lifting of EquipmentsSatyadip TeraiyaNo ratings yet

- RA For Lifting Assembling of Equipments Skids 1708672388Document4 pagesRA For Lifting Assembling of Equipments Skids 1708672388anilkumaranoop74No ratings yet

- TRA of Lifting of EquipmentsDocument3 pagesTRA of Lifting of EquipmentsandreNo ratings yet

- RA For Lifting & Assembling of Equipments (Skids)Document3 pagesRA For Lifting & Assembling of Equipments (Skids)andi warsitoNo ratings yet

- TRA of Ladder & PlatformDocument2 pagesTRA of Ladder & PlatformandreNo ratings yet

- Risk Evaluation (Refer To Evaluation Form)Document3 pagesRisk Evaluation (Refer To Evaluation Form)Obie86 BahhierNo ratings yet

- Task Risk Assessment For Lifting & Installation of Ladder and PlatformDocument3 pagesTask Risk Assessment For Lifting & Installation of Ladder and PlatformAftab QadirNo ratings yet

- Task Risk Assessment Enter Company Name: Risk Evaluation (Refer To Evaluation Form)Document3 pagesTask Risk Assessment Enter Company Name: Risk Evaluation (Refer To Evaluation Form)Aftab QadirNo ratings yet

- TRA For ScaffoldingDocument3 pagesTRA For Scaffoldingaparna_losariNo ratings yet

- HSE Risk Assesment Lifting & Assembling of EquipmentsDocument4 pagesHSE Risk Assesment Lifting & Assembling of Equipmentsshaibaz chafekarNo ratings yet

- HSE Risk AssessmentDocument4 pagesHSE Risk Assessmentwhtez0neNo ratings yet

- Risk Evaluation (Refer To Evaluation Form)Document3 pagesRisk Evaluation (Refer To Evaluation Form)Parvez Taslim OfficialNo ratings yet

- Task Risk Assessment Engineering Kinetics (PVT.) LTD: Risk Evaluation (Refer To Evaluation Form)Document2 pagesTask Risk Assessment Engineering Kinetics (PVT.) LTD: Risk Evaluation (Refer To Evaluation Form)andreNo ratings yet

- Engineering Kinetics (PVT.) Limited: Task Risk AssessmentDocument3 pagesEngineering Kinetics (PVT.) Limited: Task Risk AssessmentandreNo ratings yet

- Risk Evaluation (Refer To Evaluation Form)Document3 pagesRisk Evaluation (Refer To Evaluation Form)Aftab QadirNo ratings yet

- TRA of Manual Chipping NightDocument2 pagesTRA of Manual Chipping NightmarvinNo ratings yet

- RA Sandblasting and Painting of SheetsSpoolsDocument3 pagesRA Sandblasting and Painting of SheetsSpoolshashibpervez.shvenergybdNo ratings yet

- TRA For Fabrication, Cutting, Grinding and WeldingDocument3 pagesTRA For Fabrication, Cutting, Grinding and WeldingSaif Ali100% (1)

- Hot Work TRA Workshop NightDocument3 pagesHot Work TRA Workshop Nightmarvin100% (1)

- RA - For Precast ChambersDocument5 pagesRA - For Precast ChambersKallem RajashekarNo ratings yet

- RA of Manual ChippingDocument2 pagesRA of Manual ChippingMohamedSaidNo ratings yet

- Task Risk Assessment Engineering Kinetics (PVT.) LTD: Risk Evaluation (Refer To Evaluation Form)Document3 pagesTask Risk Assessment Engineering Kinetics (PVT.) LTD: Risk Evaluation (Refer To Evaluation Form)andreNo ratings yet

- Task Risk Assessment Engineering Kinetics (PVT.) LTD: Risk Evaluation (Refer To Evaluation Form)Document3 pagesTask Risk Assessment Engineering Kinetics (PVT.) LTD: Risk Evaluation (Refer To Evaluation Form)andreNo ratings yet

- Attachment 7505Document11 pagesAttachment 7505Charles DoriaNo ratings yet

- WAREHOUSEDocument3 pagesWAREHOUSERandy PedrozaNo ratings yet

- RA Sand BlastingDocument2 pagesRA Sand BlastingAbdus Samad100% (1)

- 781 Prject Area Its BTPDocument7 pages781 Prject Area Its BTPferielvpkNo ratings yet

- RA Radiography of Pipe SpoolsDocument3 pagesRA Radiography of Pipe SpoolsQADEER SHANNo ratings yet

- Job Safety Analysis (Jsa) : Country / Location: MZLN-09 Date Description of Job or Work Activity: Rig: Jsa #Document2 pagesJob Safety Analysis (Jsa) : Country / Location: MZLN-09 Date Description of Job or Work Activity: Rig: Jsa #madjid bobNo ratings yet

- Lifting Risk AssessmentDocument6 pagesLifting Risk AssessmentKhaled ElsayedNo ratings yet

- Hira-Exide-Pipe Rack Member, Angle, Sagrod Lifting by Rope PullyDocument1 pageHira-Exide-Pipe Rack Member, Angle, Sagrod Lifting by Rope Pullyshankar.murugesanNo ratings yet

- Scaffolding Risk Assessment: Rev SECL Job NoDocument5 pagesScaffolding Risk Assessment: Rev SECL Job NoSaleem AkhtarNo ratings yet

- Task Risk Assessment For Sandblasting and Painting of Sheets SpoolsDocument3 pagesTask Risk Assessment For Sandblasting and Painting of Sheets SpoolsSeapara SathekgeNo ratings yet

- TRA CylindersDocument2 pagesTRA Cylindersaparna_losariNo ratings yet

- Risk Assessment - Installation of Cable Trays & DCAC CablesDocument5 pagesRisk Assessment - Installation of Cable Trays & DCAC CablesIbrahim Esmat100% (1)

- Risk A For Fabrication, Welding, Cutting and GrindingDocument3 pagesRisk A For Fabrication, Welding, Cutting and GrindingSaravanaNo ratings yet

- Risk Assessment Ubderground Electric Power SupplyDocument4 pagesRisk Assessment Ubderground Electric Power SupplySameer Abdul RaufNo ratings yet

- Task Risk Assessment For RT - 230306 - 135207Document4 pagesTask Risk Assessment For RT - 230306 - 135207philippe landry NDJOCKNo ratings yet

- Task Risk Assessment Form: TASK TITLE: Fire Water Network Naimat Phase VA & VBDocument2 pagesTask Risk Assessment Form: TASK TITLE: Fire Water Network Naimat Phase VA & VBmyo lwinNo ratings yet

- Task Risk Assessment For Sandblasting and Painting of Sheets SpoolsDocument3 pagesTask Risk Assessment For Sandblasting and Painting of Sheets SpoolsAftab Qadir100% (1)

- Risk Assessment For Installation of Light FittingsDocument11 pagesRisk Assessment For Installation of Light FittingsHerdhiska Pradhiarta AjiprayogaNo ratings yet

- Risk Assessment KURA WEST XINGDocument14 pagesRisk Assessment KURA WEST XINGMamuka ShaorshadzeNo ratings yet

- Job Safety Analysis Work Sheet: Date Prepared D / M / YDocument4 pagesJob Safety Analysis Work Sheet: Date Prepared D / M / Ykkalvi0% (1)

- ISK Ssessment ORM: Inventory of Work Activities FormDocument5 pagesISK Ssessment ORM: Inventory of Work Activities Form林诗倩100% (1)

- MF 02 01 Hazards Identification Risk Assessments and Controls Issue 1Document11 pagesMF 02 01 Hazards Identification Risk Assessments and Controls Issue 1Bhanu Pratap ChoudhuryNo ratings yet

- Samsung Scaffold Risk Assesment 2Document7 pagesSamsung Scaffold Risk Assesment 2Saleem AkhtarNo ratings yet

- Underground Above Ground Drainage Works and Plumbing Works Risk AssessmentDocument4 pagesUnderground Above Ground Drainage Works and Plumbing Works Risk Assessmentmohsin.meizaNo ratings yet

- 20-RAS-Transformer InstallationDocument2 pages20-RAS-Transformer InstallationWalid MarhabaNo ratings yet

- Task Risk Assessment For Fabrication, Welding, Cutting and GrindingDocument3 pagesTask Risk Assessment For Fabrication, Welding, Cutting and GrindingAftab Qadir100% (1)

- 16 Risk Assessment ManagementDocument5 pages16 Risk Assessment ManagementBasit HaswareNo ratings yet

- Risk Assessment For Concrete Repair WorkDocument11 pagesRisk Assessment For Concrete Repair WorkSaeed AhmadNo ratings yet

- B1 Rigging Up - Spotting Rig PDFDocument1 pageB1 Rigging Up - Spotting Rig PDFmohamed kalfatNo ratings yet

- Appendix BDocument14 pagesAppendix Bmohsin.meizaNo ratings yet

- The Instant Handbook of Boat Handling, Navigation, and Seamanship: A Quick-Reference Guide for Sail and PowerFrom EverandThe Instant Handbook of Boat Handling, Navigation, and Seamanship: A Quick-Reference Guide for Sail and PowerRating: 5 out of 5 stars5/5 (1)

- 208-Article Text-608-1-10-20210426Document6 pages208-Article Text-608-1-10-20210426Adjie AntyeNo ratings yet

- Announcement 01 Oct PDFDocument2 pagesAnnouncement 01 Oct PDFgaurav chauhanNo ratings yet

- Not Recommended For New Design USE: Universal DC/DC ConverterDocument11 pagesNot Recommended For New Design USE: Universal DC/DC ConverterEdduar GaleaNo ratings yet

- Bayflex 180Document2 pagesBayflex 180Omar Tadeo Fajardo NavaNo ratings yet

- Create Your Own Genetically Modified Organism 1Document2 pagesCreate Your Own Genetically Modified Organism 1api-264041142No ratings yet

- Updates in The Eighth Edition of The Tumor-Node-Metastasis Staging Classification For Urologic CancersDocument10 pagesUpdates in The Eighth Edition of The Tumor-Node-Metastasis Staging Classification For Urologic CancersAbhishek PandeyNo ratings yet

- ReadDocument40 pagesReadManiNo ratings yet

- Handbook of Mechanical Engineering CalculationsDocument15 pagesHandbook of Mechanical Engineering CalculationsBkhari Haran100% (1)

- A Report On NanorobotsDocument14 pagesA Report On NanorobotsMd AliujjamanNo ratings yet

- Government of Rajasthan Public Works Dep PDFDocument366 pagesGovernment of Rajasthan Public Works Dep PDFplanning.hoNo ratings yet

- NLUJAA Lex Terra Submission Issue 39Document31 pagesNLUJAA Lex Terra Submission Issue 39Rachita RajputNo ratings yet

- TFNVirginia HendersonDocument13 pagesTFNVirginia HendersonJheslyn BalagulanNo ratings yet

- Examples Turnover ReportingDocument3 pagesExamples Turnover ReportingnavatoNo ratings yet

- Aldosterone Renin RatioDocument2 pagesAldosterone Renin RatioPoon CaniceNo ratings yet

- Burner Control Unit BCU 440: Technical Information GBDocument37 pagesBurner Control Unit BCU 440: Technical Information GBjose luizNo ratings yet

- PTERYGIUMDocument33 pagesPTERYGIUMdiana0% (1)

- Raymond 4000 Series Sit Down Sell SheetDocument1 pageRaymond 4000 Series Sit Down Sell SheetchrisoffNo ratings yet

- Depth June 19 - OCRDocument20 pagesDepth June 19 - OCRtaaniya sadiqNo ratings yet

- Guide To Site - Box CulvertDocument4 pagesGuide To Site - Box Culvertjs kalyana ramaNo ratings yet

- TO - Time: - TO - : Contract Name: Contract No.: Hot Work To Be Performed: Authorised Duration DateDocument1 pageTO - Time: - TO - : Contract Name: Contract No.: Hot Work To Be Performed: Authorised Duration Datepony loverNo ratings yet

- Apocalypse by Junot DíazDocument6 pagesApocalypse by Junot DíazClyde PasagueNo ratings yet

- Item 25045 Power SupplyDocument11 pagesItem 25045 Power SupplyGerman ToledoNo ratings yet

- Classification of MatterDocument27 pagesClassification of MatterLiz EvermoreNo ratings yet

- Display PDFDocument8 pagesDisplay PDFSri BalajiNo ratings yet

- Pure Water SpecDocument2 pagesPure Water SpecRisma Berliana PanjaitanNo ratings yet

- The Effects of Unbalanced Circuit in Power Losses and EfficienyDocument9 pagesThe Effects of Unbalanced Circuit in Power Losses and EfficienyInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Kubernetes DevOps Engineer ResumeDocument1 pageKubernetes DevOps Engineer ResumeAnil KumarNo ratings yet