Professional Documents

Culture Documents

One Direct Method Statement: Main Hazards Work Equipment

One Direct Method Statement: Main Hazards Work Equipment

Uploaded by

Ayu Wanda SaraswatiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

One Direct Method Statement: Main Hazards Work Equipment

One Direct Method Statement: Main Hazards Work Equipment

Uploaded by

Ayu Wanda SaraswatiCopyright:

Available Formats

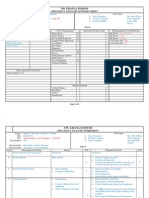

ONE DIRECT METHOD STATEMENT

NUMBER: MS0001

Start Date 01/05/2016

Task / Activity Safe Use of Ladders & Step Up

Review Date 01/05/2018

Accompanying Risk

Site Address /Location OHG Properties SRA 17

Assessment

Personnel Involved One Direct Operatives Role /Trade All

Mark Bloxidge – H&S Manager Tel: 07900 160656

Health & Safety

Jessica Langley – H&S Advisor Tel: 07966 348804

Main Hazards Work Equipment

yy Falls from height/ slips yy Contact with overhead yy Ladders, step ladders,

trips and falls services step ups, spreaders,

yy Materials falling from yy Security of working area spacers, ties

height yy Inclement weather

Preventative Measures yy Paint pots etc. to be secured to ladder

yy Work area to be cordoned off

Falls from height/ slips trips and falls yy No items greater than 10kg carried

yy Ladders and steps visually inspected before Contact with overhead services

use yy Ladders not to be used within 6m of

yy Operatives are trained and competent in overhead services unless they have been

the use of ladders and steps made dead

yy Ladders and steps are only used for light yy Insulating ladders used for electrical work

work and short periods of times (no longer

Security of work area

than 30 mins)

yy Ensure ground surface and upper resting yy Work area around ladder to be cordoned off

level are firm and level with visible barriers or tape, place warning

signs at the perimeter of work area

yy Ladders inspections documented by

supervisors yy Ladders not to be left unattended and

removed from site at the end of the working

yy 3 points of contact kept on the ladder at all

day

times

yy Ground access ladders on scaffolding to be

yy Ladders to be footed or tied into position

secure from use or removed from site at the

yy Gradient of ladder to be no more than 1 in 4

end of the working day

yy Ladder to be facing direction of work

Inclement weather

yy Spreaders or spacers to be used if required

yy Working at height during inclement weather

Materials falling from ladders

to be delayed of stopped if assessed to be

yy Items to be carried up ladders in tool belt unsafe

Prepared By M Bloxidge (H&S Manager) Date: 01/05/2016

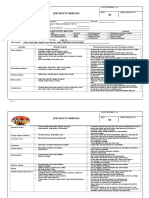

ONE DIRECT METHOD STATEMENT

NUMBER: MS0016

Sequence of Operations for Task

yy Work to be carried out during day time hours yy Make visual check of ladder or steps

yy Operatives to put on appropriate PPE yy Ensure ladders are appropriate for the task

yy Work area to be assessed for hazards and and are correctly assembled

task reviewed for suitability of ladder or yy Ensure base of ladder is placed on a firm,

steps use level surface, it is place at a safe angle (1 out

yy Check ground conditions are suitable 4 up) and the bottom is either secured by

yy Check height and width restrictions stabilisers, ties or footed by a colleague

yy Check for overhead services and other yy Always climb with your body facing the

obstacles ladder maintaining 3 points of contact at all

times with any items secured to your tool

yy Cordon off appropriate work area and

belt

display safety signage

PPE Required

HARD HAT HAND PROTECTION SAFETY VISOR

Optional, depending YES NO

on hazards present

HIGH VIZ SAFETY FOOTWEAR DUST MASK

YES YES NO

EYE PROTECTION EAR PROTECTION

YES NO

Environmental Protection Measures

yy Dispose of all waste in designated area or skip provided for waste and in accordance with

manufactures instructions

Prepared By M Bloxidge (H&S Manager) Date: 01/05/2016

ONE DIRECT METHOD STATEMENT

NUMBER: MS0016

Hazardous Substances

IRRITANT/ RESPIRATORY

FLAMMABLE

SENSITISER SENSITISER

NO

NO NO

TOXIC CORROSIVE DANGEROUS TO

NO NO THE ENVIRONMENT

NO

GAS UNDER PRESSURE

NO

Emergency procedures

First Aid:

yy First Aid box provided on all vehicles

yy Local arrangements for contacting emergency services to be identified

yy Location or nearest hospital A&E must be known

yy In case of serious accident or injury requiring immediate medical attention call 999

yy Always inform supervisor or H&S Manager of all accidents, incidents and near misses

yy Ensure that accident, incident or near miss is logged

Fire:

yy Fire extinguisher on all vehicles

yy Only attempt to extinguisher f safe to do so

yy Local arrangements for contacting emergency services to be identified

yy Maintain adequate emergency access route in working location at all times

Prepared By M Bloxidge (H&S Manager) Date: 01/05/2016

ONE DIRECT METHOD STATEMENT

NUMBER: MS0016

Training & Supervision Permit to work

yy All staff have received H&S Induction training yy N/A

yy All staff carrying out the task will be deemed to

be competent and will not be allowed to carry out

tasks that they have not been trained for

yy All Operatives are supervised

Safety of Other Contractors Refuelling Procedure

or Members of the Public of Plant Machinery

yy Ensure that other contractors are aware

or Equipment

of hazards present

yy N/A

yy Ensure that work area is secured

yy No works will be left in a dangerous

condition or with risk to themselves,

contractors, tenants or members of the

public

yy All tools and equipment will be securely

stored or removed from site at the end of

each working day

Prepared By M Bloxidge (H&S Manager) Date: 01/05/2016

You might also like

- Construction Site Safety PlanDocument12 pagesConstruction Site Safety Planemmanueloboh100% (1)

- Risk Assessment Air Conditioning Sample PDFDocument7 pagesRisk Assessment Air Conditioning Sample PDFFaisal Raza100% (1)

- Accessing Loft Spaces Method Statement PDFDocument3 pagesAccessing Loft Spaces Method Statement PDFFaisal RazaNo ratings yet

- Accessing Loft Spaces Method Statement PDFDocument3 pagesAccessing Loft Spaces Method Statement PDFFaisal RazaNo ratings yet

- Jsa ExcavatorDocument1 pageJsa Excavatorbladeliger220% (1)

- Mastic Sealing Method StatementDocument4 pagesMastic Sealing Method StatementFaisal RazaNo ratings yet

- JSA Installation of Equipment For Electrical and InstrumentDocument3 pagesJSA Installation of Equipment For Electrical and InstrumentHong Hai Pham80% (5)

- JSA No 3 - Operate Dozer - Push ScraperDocument3 pagesJSA No 3 - Operate Dozer - Push ScraperBenjamin Fabin100% (1)

- Mastic Sealing Method StatementDocument4 pagesMastic Sealing Method StatementFaisal RazaNo ratings yet

- JSA - Rig Move OperationsDocument3 pagesJSA - Rig Move OperationsShahid Alam100% (4)

- Equipment MobilizationDocument2 pagesEquipment MobilizationSn Ahsan0% (1)

- ms0001 Ladders Step UpDocument4 pagesms0001 Ladders Step UpMD WARISNo ratings yet

- One Direct Method Statement: Main HazardsDocument4 pagesOne Direct Method Statement: Main HazardsAyu Wanda SaraswatiNo ratings yet

- One Direct Method Statement: Main Hazards Preventative MeasuresDocument4 pagesOne Direct Method Statement: Main Hazards Preventative MeasuresAyu Wanda SaraswatiNo ratings yet

- ms0019 Dismantling of Non Load Bearing Wall-1Document4 pagesms0019 Dismantling of Non Load Bearing Wall-1SonukrishnaNo ratings yet

- One Direct Method Statement: Preventative MeasuresDocument4 pagesOne Direct Method Statement: Preventative MeasuresAyu Wanda SaraswatiNo ratings yet

- Electrical - Consumer Unit Method StatmentDocument4 pagesElectrical - Consumer Unit Method StatmentFaisal RazaNo ratings yet

- One Direct Method Statement: Main Hazards Preventative MeasuresDocument4 pagesOne Direct Method Statement: Main Hazards Preventative Measurestrravi1983No ratings yet

- One Direct Method Statement: Main Hazards Preventative MeasuresDocument4 pagesOne Direct Method Statement: Main Hazards Preventative MeasuresAyu Wanda SaraswatiNo ratings yet

- One Direct Method Statement: Main Hazards Preventative MeasuresDocument5 pagesOne Direct Method Statement: Main Hazards Preventative MeasuresMOHD JIDINo ratings yet

- Method Statement and Risk AssessmentDocument4 pagesMethod Statement and Risk AssessmentAfaan gani InamdarNo ratings yet

- One Direct Method Statement: Main Hazards Preventative MeasuresDocument5 pagesOne Direct Method Statement: Main Hazards Preventative MeasuresFaisal RazaNo ratings yet

- One Direct Method Statement: Main Hazards Preventative MeasuresDocument4 pagesOne Direct Method Statement: Main Hazards Preventative MeasuresAyu Wanda SaraswatiNo ratings yet

- One Direct Method Statement: Main Hazards Preventative MeasuresDocument5 pagesOne Direct Method Statement: Main Hazards Preventative MeasuresAyu Wanda SaraswatiNo ratings yet

- WSWP For Hamisa Cutting of ConcreateDocument8 pagesWSWP For Hamisa Cutting of ConcreateVictor Thembinkosi MakhubeleNo ratings yet

- Safety in Masonry WorksDocument32 pagesSafety in Masonry Workskarthika18maniNo ratings yet

- Genie Scissor Lift GS 2632 - SWP Nov 12 2013Document5 pagesGenie Scissor Lift GS 2632 - SWP Nov 12 2013Cvijic DejanNo ratings yet

- Earthmoving Attachment Maintenance: Safe Operational ProcedureDocument3 pagesEarthmoving Attachment Maintenance: Safe Operational ProcedureJamesNo ratings yet

- JSA - Field Instruments InstallationDocument4 pagesJSA - Field Instruments InstallationSagar PadhiyarNo ratings yet

- Landscaping Victoria SWMSDocument9 pagesLandscaping Victoria SWMScjNo ratings yet

- Crane Jsa TGPDocument2 pagesCrane Jsa TGPSuryakant SurajNo ratings yet

- AMPTPL MHS Conv Belt ReplacementDocument2 pagesAMPTPL MHS Conv Belt ReplacementsamNo ratings yet

- RA 13 Belle Vue AvenueDocument5 pagesRA 13 Belle Vue AvenueJoshHumphreyNo ratings yet

- Whs f014 Safe Work Method Statement FormDocument9 pagesWhs f014 Safe Work Method Statement FormTamo Kim ChowNo ratings yet

- 18 TBT - TopicsDocument41 pages18 TBT - TopicsGyanendra Narayan Nayak100% (1)

- Ehv SWP Form Lifting Lowering Operation PDF NewDocument3 pagesEhv SWP Form Lifting Lowering Operation PDF NewSn AhsanNo ratings yet

- Jsa - SWP For Lifting and Lowering MaterialDocument4 pagesJsa - SWP For Lifting and Lowering MaterialSantosh Singh50% (2)

- SWP Excavation Near Overhead Electrical Live LinesDocument2 pagesSWP Excavation Near Overhead Electrical Live LinesSn AhsanNo ratings yet

- NEW CL - JLA Steel Hand Tool - SWPDocument3 pagesNEW CL - JLA Steel Hand Tool - SWPAbdul Rafiq100% (1)

- Jsa HDD DrillingDocument6 pagesJsa HDD Drillingshaibaz chafekarNo ratings yet

- Checklist On Daily InspectionDocument2 pagesChecklist On Daily InspectionR Sahadeo ReddyNo ratings yet

- Interview QuestionsDocument7 pagesInterview Questionsjeba kumarNo ratings yet

- Bedroom Site Safety PlanDocument13 pagesBedroom Site Safety Planm.ehabNo ratings yet

- Stretford Hills RA Presentation On The Construction or Eco-Friendly Rice MillDocument24 pagesStretford Hills RA Presentation On The Construction or Eco-Friendly Rice MillAz CorkerNo ratings yet

- UntitledDocument1 pageUntitledSaifulNo ratings yet

- Block Work MethodDocument12 pagesBlock Work MethodsherNo ratings yet

- 180 and 360 Degree Excavators Builth Wells Tennis CourtDocument3 pages180 and 360 Degree Excavators Builth Wells Tennis CourtMarkNo ratings yet

- For Work Site Activities: Safety Observation and Communication (Soc)Document2 pagesFor Work Site Activities: Safety Observation and Communication (Soc)Aung Pyae PhyoNo ratings yet

- OSH Act of 1970Document8 pagesOSH Act of 1970Tyson ShippNo ratings yet

- Job Hazard Analysis: Minimum Required Personal Protective Equipment For This JobDocument3 pagesJob Hazard Analysis: Minimum Required Personal Protective Equipment For This JobvalerieNo ratings yet

- She Policy PlanDocument25 pagesShe Policy PlanMDUDUZI SIBANDANo ratings yet

- Children & Young People's Services RISK ASSESSMENTDocument2 pagesChildren & Young People's Services RISK ASSESSMENThaziq ziqNo ratings yet

- Job Hazard Analysis SampleDocument1 pageJob Hazard Analysis SampleLevy Vikko GasconNo ratings yet

- BOSHDocument5 pagesBOSHJeffrey RegondolaNo ratings yet

- Wah InductionDocument38 pagesWah InductionkashralNo ratings yet

- Rams For Repair of Leakage On Sludge Aeration Tank in Owerri EtpDocument12 pagesRams For Repair of Leakage On Sludge Aeration Tank in Owerri EtpBrendan I.KanwanyeNo ratings yet

- Method-Statement SignageDocument4 pagesMethod-Statement SignageGopan V NairNo ratings yet

- General Hazard Identification Form Sample ReportDocument10 pagesGeneral Hazard Identification Form Sample ReportJavanshir AkbariNo ratings yet

- SWP Access Road RepairDocument2 pagesSWP Access Road RepairSn AhsanNo ratings yet

- Risk AssessmentDocument4 pagesRisk AssessmentThoufeer NETTERYNo ratings yet

- The Handbook of Safety Engineering: Principles and ApplicationsFrom EverandThe Handbook of Safety Engineering: Principles and ApplicationsRating: 4 out of 5 stars4/5 (1)

- Project Identification: REGULATION VIII - Rules 800-805Document14 pagesProject Identification: REGULATION VIII - Rules 800-805Faisal RazaNo ratings yet

- 0000000working in Live AreasDocument1 page0000000working in Live AreasFaisal RazaNo ratings yet

- Saf-Hazard Identification ABE-SA-HI-01Document5 pagesSaf-Hazard Identification ABE-SA-HI-01Faisal RazaNo ratings yet

- HSE-Objectives & Targets ABE-HSE-OB-01 PDFDocument3 pagesHSE-Objectives & Targets ABE-HSE-OB-01 PDFFaisal RazaNo ratings yet

- Saf-Emergency Response ABE-SA-ER-01Document5 pagesSaf-Emergency Response ABE-SA-ER-01Faisal RazaNo ratings yet

- HSE - Operation Controls ABE-HSE-OP-01Document6 pagesHSE - Operation Controls ABE-HSE-OP-01Faisal RazaNo ratings yet

- Env-Legal Requirements R2 ABE-EM-LR-01 PDFDocument3 pagesEnv-Legal Requirements R2 ABE-EM-LR-01 PDFFaisal RazaNo ratings yet

- One Direct Method Statement: Main Hazards Preventative MeasuresDocument5 pagesOne Direct Method Statement: Main Hazards Preventative MeasuresFaisal RazaNo ratings yet

- Persons at Risk (Groups) Risk Assessor Appointment Tel. No. Description of Task or ActivityDocument4 pagesPersons at Risk (Groups) Risk Assessor Appointment Tel. No. Description of Task or ActivityFaisal RazaNo ratings yet

- Electrical - Consumer Unit Method StatmentDocument4 pagesElectrical - Consumer Unit Method StatmentFaisal RazaNo ratings yet

- Rcl-Hse-Fm-08.2 - Orientation Driver SafetyDocument2 pagesRcl-Hse-Fm-08.2 - Orientation Driver SafetyFaisal RazaNo ratings yet

- Is 3786Document30 pagesIs 3786Faisal RazaNo ratings yet

- OCP 6-Gas Cutting - Oxy-AcetyleneDocument1 pageOCP 6-Gas Cutting - Oxy-AcetyleneFaisal Raza100% (1)

- Backhoe Loader: Equipment Inspection SheetDocument2 pagesBackhoe Loader: Equipment Inspection SheetFaisal RazaNo ratings yet

- Appvd. Scafold Errection, For ColubmDocument5 pagesAppvd. Scafold Errection, For ColubmFaisal RazaNo ratings yet

- Apprvd. Movilazation of Temporary Site OfficeDocument6 pagesApprvd. Movilazation of Temporary Site OfficeFaisal RazaNo ratings yet

- Construction of Masjid and CafeteriaDocument10 pagesConstruction of Masjid and CafeteriaFaisal RazaNo ratings yet

- Apprvd. Foundation, Grade Beam Final For Isham 1Document7 pagesApprvd. Foundation, Grade Beam Final For Isham 1Faisal RazaNo ratings yet

- Human Resource Practices and Their Impact On Employee Commitment in The Catholic Education Agency, Diocese of Buea, SWR CameroonDocument12 pagesHuman Resource Practices and Their Impact On Employee Commitment in The Catholic Education Agency, Diocese of Buea, SWR CameroonEditor IJTSRDNo ratings yet

- Features of Blue4Est: The Blue Thermal Paper From The Black ForestDocument2 pagesFeatures of Blue4Est: The Blue Thermal Paper From The Black Forestsimohamed alaoui aziziNo ratings yet

- DragonMagazine114 PDFDocument108 pagesDragonMagazine114 PDFhunter lawson100% (2)

- Reflective LetterDocument6 pagesReflective Letterapi-658683346No ratings yet

- ch15 Ques 2013Document43 pagesch15 Ques 2013av94% (31)

- IdeologiesDocument15 pagesIdeologiesGinieva Perigrino SiegaNo ratings yet

- Sciencedirect: Effect of Subcritical Annealing Temperature On Microstructure and Mechanical Properties of Scm435 SteelDocument6 pagesSciencedirect: Effect of Subcritical Annealing Temperature On Microstructure and Mechanical Properties of Scm435 SteelShyam VsNo ratings yet

- Chemistry 9 Class Paper JalalDocument1 pageChemistry 9 Class Paper JalalCRO TJSSNo ratings yet

- Measures of DispersionDocument7 pagesMeasures of DispersionBloody Gamer Of BDNo ratings yet

- Bibliografía: Society, London, Special Publications, 395 (1), 149-165Document5 pagesBibliografía: Society, London, Special Publications, 395 (1), 149-165api-712441521No ratings yet

- Thesis For Boy in The Striped PajamasDocument7 pagesThesis For Boy in The Striped Pajamasdwfp5m7d100% (2)

- Joel Coen's Macbeth'Document16 pagesJoel Coen's Macbeth'Cicero EscobarNo ratings yet

- Democracy and Human Rights: David BeethamDocument1 pageDemocracy and Human Rights: David Beethammoazinkhan.mkNo ratings yet

- Lec 2Document2 pagesLec 2ibrahim aminNo ratings yet

- Organizational Structure and ControlsDocument66 pagesOrganizational Structure and Controls--bolabolaNo ratings yet

- KKDocument15 pagesKKFanstaNo ratings yet

- Gentle - Lesson PlanDocument5 pagesGentle - Lesson PlanCarlito DoringoNo ratings yet

- Economic Policy Theory and Practice 2Nd Edition Agnes Benassy Quere Full ChapterDocument67 pagesEconomic Policy Theory and Practice 2Nd Edition Agnes Benassy Quere Full Chapterjames.farnham174100% (13)

- 6 Rizal in France and Germany Hand OutsDocument5 pages6 Rizal in France and Germany Hand OutsKhemme Lapor Chu UbialNo ratings yet

- Chemical Kinetics Part IDocument45 pagesChemical Kinetics Part IKarthikanAmirthalingamNo ratings yet

- WCRDocument6 pagesWCRArpit S SavarkarNo ratings yet

- Oxford AI BrochureDocument32 pagesOxford AI BrochureKarthik MariappanNo ratings yet

- 3 P 132 9301 1a3a N 04 - Rev01Document1 page3 P 132 9301 1a3a N 04 - Rev0146 JOSHI SWAPNIL OMNo ratings yet

- FOLDER Gesamt Hospital ENG 2105 SCREEN LOW Brosch PDFDocument74 pagesFOLDER Gesamt Hospital ENG 2105 SCREEN LOW Brosch PDFCristina EnculescuNo ratings yet

- Mach's Razor Applied To Itself: Sober, Einstein's Mach's Principle, and The Cosmological ConstantDocument28 pagesMach's Razor Applied To Itself: Sober, Einstein's Mach's Principle, and The Cosmological ConstantVasil PenchevNo ratings yet

- 2022 APU UG Handbook Outside Japan 2 EDocument42 pages2022 APU UG Handbook Outside Japan 2 EQuang HuyNo ratings yet

- Chapter I: The Problem and It'S BackgroundDocument45 pagesChapter I: The Problem and It'S BackgroundBriel SanchezNo ratings yet

- English Essay by Mureed Hussain JasraDocument63 pagesEnglish Essay by Mureed Hussain Jasradu896074No ratings yet

- 2013 Direct Anterior Composites A Practical GuideDocument16 pages2013 Direct Anterior Composites A Practical Guidemaroun ghalebNo ratings yet

- Newtons CradleDocument1 pageNewtons CradlepenkmanjacobNo ratings yet