Professional Documents

Culture Documents

Preventive, Performance Monitoring

Uploaded by

hasmirah salehCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Preventive, Performance Monitoring

Uploaded by

hasmirah salehCopyright:

Available Formats

PREVENTIVE & MAINTENANCE WORK SCHEDULE

Check all the measuring instruments and equipment every day. Make sure all of the measuring

instruments and equipment in good condition and functioned properly.

NO EQUIPMENT QUANTITY MAINTENANCE

1. Exhaust fan (Centrifugal 1 unit • Functionality of exhaust fan

fan for ventilation • Abnormal vibration and noise

system) • Repair any minor leakage

• Changing of oil lubricant & grease (when

necessary)

2. Pleated carbon panel 4 pcs • Check efficiency of the carbon filter once

filter per month

• Replace panel filter when hloss > 1” wg

3. Control panel 1 unit • Inspection on the functionality of the

control panel display LED lighting,

overloads and interlockings.

Typical forms to record performance monitoring data/activities of ducting and chimney

(A) Daily: Month: ………………...

Pressure, Temperature

mmHg/H2O (oC) Opacity or Surface/

Flowrate,

Date stack screen

m3/s

In Out In Out condition condition

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

26.

27.

28.

29.

30.

31.

Entries made by: Checked by: (daily/weekly)

Operator’s name: Supervisor’s name:

Signature: Signature:

Date: Date:

Table 2: Records of performance data of LEV system

Parameter Comments

Pressure drop Pressure drop information can indicate if blockage has occurred.

Pressure drop information cannot be interpreted properly unless

Flowrate

flowrate information is known.

Whether a continuous transmissometer/smoke meter/opacity meter

is incorporated into the system or not, the output on opacity/stack

observation should be recorded. The cause of abnormal change in

Opacity

opacity level should be identified and corrective action taken. If

operator is not trained to conduct smoke observation, a descriptive

statement on the condition of stack emission is sufficient.

Frequency Procedure/ task

Daily • Record ducting pressure drops.

• Check stack.

• Record fan motor amperage.

Weekly • Check fan bearings.

• Check gaskets, valves, and other opening for

leakage.

Monthly • Check for sign of corrosion and other signs of

deterioration.

• Inspect inlet and outlet for dust-build up

You might also like

- Instructions For Repairing AlternatorDocument3 pagesInstructions For Repairing AlternatordamoccaNo ratings yet

- EC160B/180B/210B/240B/290B/360B/460B: Click The Volvo-Logo in The Lower Right Corner To Return To This Menu Main MenuDocument31 pagesEC160B/180B/210B/240B/290B/360B/460B: Click The Volvo-Logo in The Lower Right Corner To Return To This Menu Main MenuMACHINERY101GEAR97% (71)

- EEX20207 Maintenance Inspection of TransformerDocument26 pagesEEX20207 Maintenance Inspection of TransformerHonesto Bautista100% (1)

- LT Loads&SwitchgearDocument48 pagesLT Loads&SwitchgearsreekanthbammidiNo ratings yet

- ACMV Maintenance Check ListDocument7 pagesACMV Maintenance Check ListHtet Linn Aung100% (2)

- PPM Task Sheet - MPGSDocument4 pagesPPM Task Sheet - MPGSJacobNo ratings yet

- Flow Calibration Procedure PDFDocument32 pagesFlow Calibration Procedure PDFkfathi55100% (1)

- Fire ProtectionDocument44 pagesFire ProtectionAbdul JabbarNo ratings yet

- DuPont Sontara Wipes Technical SpecsDocument2 pagesDuPont Sontara Wipes Technical SpecsSkySupplyUSANo ratings yet

- Helicopter Refuelling System For H1103 CSBC LPD Project: Operating Manual & Commissioning ProcedureDocument17 pagesHelicopter Refuelling System For H1103 CSBC LPD Project: Operating Manual & Commissioning ProcedureMuhammad JabirNo ratings yet

- 06-DC Compound MotorDocument44 pages06-DC Compound MotorN. iManNo ratings yet

- R.O Check ListDocument4 pagesR.O Check ListRavi MadhavanNo ratings yet

- Condition MonitoringDocument10 pagesCondition MonitoringRoy Samia100% (1)

- Air Handling Units GuidelineDocument5 pagesAir Handling Units GuidelineImam MansyurNo ratings yet

- Aga 7Document37 pagesAga 7vaibhav100% (1)

- Production LoggingDocument8 pagesProduction Logginghaarika1006No ratings yet

- Flowmeter Selection and Sizing: Nidhin ManoharDocument75 pagesFlowmeter Selection and Sizing: Nidhin ManoharShahnaz DarNo ratings yet

- Technical Specification of Stay InsulatorDocument11 pagesTechnical Specification of Stay Insulatorraj_stuff006No ratings yet

- CelQuant 3i - Service ManualDocument18 pagesCelQuant 3i - Service ManualKeigo ChewNo ratings yet

- Guide Grind Plants 3rd Edition11 PDFDocument53 pagesGuide Grind Plants 3rd Edition11 PDFTOULASSI-ANANI Yves Lolo0% (1)

- Total Chloride in Alumina Supported Catalysts by Wavelength Dispersive X-Ray FluorescenceDocument5 pagesTotal Chloride in Alumina Supported Catalysts by Wavelength Dispersive X-Ray FluorescenceJesus Gonzalez GracidaNo ratings yet

- Service Guide: Section TwoDocument78 pagesService Guide: Section TworemguNo ratings yet

- Fcu OjtDocument3 pagesFcu OjtHuzairi SulaimanNo ratings yet

- Technical Health DCCMDocument25 pagesTechnical Health DCCMibsamengistu29No ratings yet

- VESDA SDM Maintenance Schedule SummaryDocument1 pageVESDA SDM Maintenance Schedule SummaryhemantrathodNo ratings yet

- DA UFM3030 en 060424Document16 pagesDA UFM3030 en 060424Rafael Sanzio Fernandes SousaNo ratings yet

- Instrument Field Engineering: Prepared By: M.P.ALAMDocument99 pagesInstrument Field Engineering: Prepared By: M.P.ALAMsakendos torrosNo ratings yet

- MPFM Field DisplayDocument9 pagesMPFM Field DisplaySrewaBenshebilNo ratings yet

- GCC 2014 GC Troubleshooting Tips and Tricks 1Document64 pagesGCC 2014 GC Troubleshooting Tips and Tricks 1Duy DangNo ratings yet

- RFT & MDT Formation TesterDocument33 pagesRFT & MDT Formation Testerjdaksh204No ratings yet

- Eexi - MEPC 1 Circ901Document16 pagesEexi - MEPC 1 Circ901Canberk KarahanNo ratings yet

- H-10207 99cka 00-102f Dc-Cscs Controlog Function Test Procedule - ADocument31 pagesH-10207 99cka 00-102f Dc-Cscs Controlog Function Test Procedule - Anguyen rinNo ratings yet

- Koncar - Manual de Mantenimiento - 32MVADocument13 pagesKoncar - Manual de Mantenimiento - 32MVAruddy matiasNo ratings yet

- MANTENIMIENTODocument5 pagesMANTENIMIENTOalextlv1996cvNo ratings yet

- Maintenance Procedure DetectorDocument1 pageMaintenance Procedure DetectorloayNo ratings yet

- Water Meter & Spare Parts 31.07.2018Document19 pagesWater Meter & Spare Parts 31.07.2018Kishan ChandrasekaraNo ratings yet

- SURE - Gas Turbine Flowmeter Manual - V2 LWQDocument24 pagesSURE - Gas Turbine Flowmeter Manual - V2 LWQMichael roa parra100% (1)

- LL Dimgatestat PDFDocument12 pagesLL Dimgatestat PDFsalasineNo ratings yet

- TruckLoadingSystem (D 31)Document8 pagesTruckLoadingSystem (D 31)Elias EliasNo ratings yet

- Catalogo Vortex FlowmeterDocument24 pagesCatalogo Vortex FlowmeterIzanNo ratings yet

- Brookfield Process CatalogDocument24 pagesBrookfield Process CatalogenzopandolfiNo ratings yet

- 1 OIML R 49-1 New TemplateDocument60 pages1 OIML R 49-1 New TemplatepurwantoNo ratings yet

- Presentasi Kelompok 4 - Case StudyDocument16 pagesPresentasi Kelompok 4 - Case StudyRiswan Adhitya SaputraNo ratings yet

- Ultrasonic Valve Controlled Water MeterDocument11 pagesUltrasonic Valve Controlled Water MeterManivannan ManikamNo ratings yet

- Gallagher ScottDocument16 pagesGallagher Scottiqbal_abudNo ratings yet

- Hydrant Inspection, Testing, and Maintenance SopDocument8 pagesHydrant Inspection, Testing, and Maintenance SopAzamta ZaVrian Rohman100% (1)

- 2300GL User Manual PDFDocument141 pages2300GL User Manual PDFHicham_bennyaNo ratings yet

- Monitoring Strategy of LNG Reciprocating CompressorsDocument4 pagesMonitoring Strategy of LNG Reciprocating Compressorsalhumaid28No ratings yet

- Example Baghouse Agency Operation & Maintenance PlanDocument8 pagesExample Baghouse Agency Operation & Maintenance Plankashifbutty2kNo ratings yet

- Session 2000: Power Transformer On-Site Condition Assessment Testing Tim Noonan ESB International IrelandDocument6 pagesSession 2000: Power Transformer On-Site Condition Assessment Testing Tim Noonan ESB International Irelandjavier salazarNo ratings yet

- MTMLDII-U01 Cap4Document33 pagesMTMLDII-U01 Cap4Ãbdøū Èqúípmeńť MédîcàlNo ratings yet

- TJB-BM-XXXX-XX-WIXXX Work Instruction Turbine CV Disassembly and InspectionDocument6 pagesTJB-BM-XXXX-XX-WIXXX Work Instruction Turbine CV Disassembly and InspectiondikiNo ratings yet

- Production EvalutionDocument22 pagesProduction Evalutionhaarika1006No ratings yet

- Guidance Document For Design of Axial-Flow Vortex Tube Dust CollectorDocument13 pagesGuidance Document For Design of Axial-Flow Vortex Tube Dust CollectorYong JunNo ratings yet

- 2.4 Urgency Handling: 3.1 Brief IntroductionDocument46 pages2.4 Urgency Handling: 3.1 Brief IntroductionClip nhungcaunoihayNo ratings yet

- SAT and Commissioning ProcedureDocument11 pagesSAT and Commissioning ProcedureWalid AlhasanNo ratings yet

- Erba Laura M User ManualDocument30 pagesErba Laura M User ManualDaniel VargasNo ratings yet

- 24 Fixed Co2 Fire Extinguishing SystemDocument4 pages24 Fixed Co2 Fire Extinguishing SystemJayant Khedkar100% (1)

- C09702880 8Document65 pagesC09702880 8Prince AdibNo ratings yet

- Data Logging and Performance NormalizationDocument5 pagesData Logging and Performance NormalizationCherifi ChawkiNo ratings yet

- Fdocuments - in Flowirl 87002Document77 pagesFdocuments - in Flowirl 87002johnNo ratings yet

- Raam p5 3 Fta QuantificationDocument17 pagesRaam p5 3 Fta QuantificationGabo Montaño MendozaNo ratings yet

- Monitoreo Comp PDFDocument35 pagesMonitoreo Comp PDFJeshua Rivera100% (1)

- A Production Logging Tool With Simultaneous Measurements: February 1980 191Document8 pagesA Production Logging Tool With Simultaneous Measurements: February 1980 191Lulut Fitra FalaNo ratings yet

- Sysmex CA-1500 - PMI - ProDocument2 pagesSysmex CA-1500 - PMI - ProBakhrom KasimovNo ratings yet

- VG7 Maintenance ManualDocument18 pagesVG7 Maintenance ManualGustavo RodriguezNo ratings yet

- SPE Stavanger - Level Design and ControlDocument32 pagesSPE Stavanger - Level Design and ControlSushil KunduNo ratings yet

- Sbi Clerk MainsDocument4 pagesSbi Clerk MainspurushothamNo ratings yet

- Optical Character Recognition Using MATLAB: J.Sashank Varma, G.V.N.S.Varma, K.Vikranth ReddyDocument5 pagesOptical Character Recognition Using MATLAB: J.Sashank Varma, G.V.N.S.Varma, K.Vikranth Reddyvikky23791No ratings yet

- 2016 GME Steel ProductsDocument16 pages2016 GME Steel ProductsMarco Dos Santos NevesNo ratings yet

- A Time To Build: People's Housing in Asia: Photograph By: Yann Arthus-BertrandDocument14 pagesA Time To Build: People's Housing in Asia: Photograph By: Yann Arthus-BertrandarchitectsforumNo ratings yet

- PetroMod 1NEWDocument20 pagesPetroMod 1NEWAbdalrhman MuhammadNo ratings yet

- Road Geometry & Transition CurveDocument8 pagesRoad Geometry & Transition CurveNann Kay Thari KyawNo ratings yet

- Banana ChipsDocument5 pagesBanana Chipsbikram limbuNo ratings yet

- Standard Operating Procedure-Standard Maintenace ProcedureDocument11 pagesStandard Operating Procedure-Standard Maintenace ProcedureVikram JitNo ratings yet

- Topic 05 All Possible QuestionsDocument9 pagesTopic 05 All Possible QuestionsMaxamed Cabdi KariimNo ratings yet

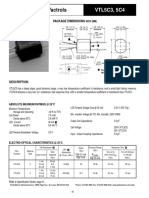

- Low Cost Axial Vactrols: VTL5C3, 5C4Document2 pagesLow Cost Axial Vactrols: VTL5C3, 5C4sillyNo ratings yet

- Cebo Ycc50 ManualDocument16 pagesCebo Ycc50 ManualAngelevNo ratings yet

- Chemistry Lab 2 Flame TestsDocument7 pagesChemistry Lab 2 Flame Testshpcoutinho36No ratings yet

- TemperaturaDocument2 pagesTemperaturakamalNo ratings yet

- RSAFRAMEDocument2 pagesRSAFRAMETIOCA01No ratings yet

- PALRUF 100 Technical Guide (En)Document6 pagesPALRUF 100 Technical Guide (En)mohammed nafethNo ratings yet

- Wolkite University Clearance SystemDocument16 pagesWolkite University Clearance SystemZa Yâ Yâ80% (10)

- Catalyser: Magnetic Effects of Electric Current Faculty Sheet SolutionDocument4 pagesCatalyser: Magnetic Effects of Electric Current Faculty Sheet SolutionShalika SinhaNo ratings yet

- Features: Self Reset Auxiliary Flag Relay - Two ElementDocument3 pagesFeatures: Self Reset Auxiliary Flag Relay - Two ElementbledmikifrNo ratings yet

- Geographic Information System of Public Complaint Testing Based On Mobile WebDocument2 pagesGeographic Information System of Public Complaint Testing Based On Mobile WebArya HardinataNo ratings yet

- Epoxylite TSA 220 - TDS - 2008Document3 pagesEpoxylite TSA 220 - TDS - 2008Anonymous sAmJfcVNo ratings yet

- MSC PracticalsDocument13 pagesMSC PracticalslinubinoyNo ratings yet

- Power SteeringDocument31 pagesPower SteeringpeskeirasNo ratings yet