Professional Documents

Culture Documents

Technical Data - HVR International - Resistors For Compact Circuitry

Uploaded by

Numa LumaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Technical Data - HVR International - Resistors For Compact Circuitry

Uploaded by

Numa LumaCopyright:

Available Formats

THERMAL PARAMETERS • 100% Active Material

Heat generated by H.V. Resistors for Compact

• High Surge Energy Rating

Circuitry is dissipated mainly by radiation and

convection from the exposed surface areas. Within • High Voltage Withstand

restricted domains, mathematical models may be

employed to permit heat transfer estimations. • Essentially Non-Inductive

Symbols • Wide Resistivity Range

∆T = Temperature Rise (°C) • Wide Range of Geometries

Wa = Watts / Unit Exposed Surface Area (W.cm-2)

v = Volume of Active Material (cm3) • Custom Solutions Readily Available

cm = Specific Heat Capacity of Active Material

• Suitable for PCB Assembly

= 2J. cm-3.°C-1

Do = Overall Diameter (mm) • Free Design Service

τ = Resistor Thermal Time Constant (s)

Radiation and Convection Wa = 0.00026(∆T)1.4

(∆T = 50°C to 175°C, Do = 10 mm to 151 mm, Ambient 25°C)

HVR’s range of High Voltage Resistors for Compact Circuitry are manufactured from a carefully

Thermal Conductivity 0.04 W / cm2.°C / cm

Maximum Insertion Energy Ratings For a Resistor initially at 25°C : 350 Joules / cm3 (Infrequently) selected mixture of clays, alumina and carbon. After blending, the material is pressed to the

For a Resistor initially at 25°C : 250 Joules / cm3 (Continuously) required shape and then fired, in a controlled atmosphere, at high temperature.

Recommended Operating Temperatures 200 °C (Infrequent Operation)

150 °C (Continuous Operation)

Temperature Rise from Energy Injection ∆T (°C) = Joules (per Resistor) / (v x cm ) (Free Air) This sintering process produces a Ceramic Carbon

Thermal Time Constant τ (s) = Max Joules @ 25°C / Max Watts @ 25°C Resistor which is 100% active material and therefore

Full Cooling ≥ 4τ

of minimum size. The H.V. Resistors for Compact

Circuitry range feature radial lead terminations and

De-rating for other ambient Temperatures (Ta°C) Multiply Max Joules @ 25°C & Max Watts @ 25°C by

the ratio (150 - Ta) / 125 a high quality epoxy resin coating to improve both

dielectric withstand and mechanical robustness.

Repetitive Thermal Impulsing:

Assuming that the Heat Transfer Coefficient α (W / cm2.°C / cm ) is constant over the operating temperature range,

then the Peak Temperature Rise (∆Tp) associated with repetitive impulsing can be estimated by way of reference to

a classical geometric progression ...

∆Tp (°C) = ∆T x (1 - (e-(t/ τ))n) ÷ (1 - e-(t/ τ)) .................1

where: ∆T is the Temperature Rise associated with each electrical impulse (°C)

τ is the Resistor Thermal Time Constant (s) Inherently non-inductive and capable of

t is the Repetition Rate (s)

n is the number of impulses withstanding transient high voltage

_

If the number of impulses (n) > ∞ (ie continuous duty), then equation 1 can be simplified thus ... impulses, this range is ideally suited to

∆Tp (°C) = ∆T ÷ (1 - e-(t/ τ)) .................. 2

charging, discharge, snubber, voltage

divider and overvoltage protection

Custom Variants No additonal charges are made for creating specific length versions or specific

Resistance Value versions of the above types. Similarly, crimped lead versions applications. These typical applications

(fixed stand off height) and double leaded versions (greater stability) are

available as standard.

feature within high voltage power supplies,

lasers, radar, medical and military

Similarly, Stud (male) and Ferrule (female) metric (M4 - M8) threaded

termination variants (mechanical mounting) are available at extra charge. equipment.

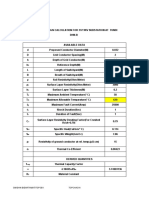

ACTIVE VOLUME OF THERMAL MAXIMUM WORKING VOLTAGE MAXIMUM WORKING VOLTAGE MAXIMUM WORKING VOLTAGE MAXIMUM WORKING VOLTAGE

RESISTOR MATERIAL OVERALL DIMENSIONS ACTIVE MAXIMUM MAXIMUM TIME WEIGHT A/L RESISTANCE RANGE (VWorking) (VWorking) (VWorking) (VWorking)

TYPE DIMENSION MATERIAL JOULES WATTS CONSTANT

CODE Do Lo Lp

MAXIMUM MAXIMUM PITCH (v) @ 25°C @ 25°C (τ) MINIMUM MAXIMUM ( 1/10 µs IMPULSE ) ( 1.2/50 µs IMPULSE ) ( 10/1000 µs IMPULSE ) ( 500/5000 µs IMPULSE )

Units (mm) (mm) (mm) (cm3) (J) (W) (Seconds) (g) (cm) (Ohms) (Ohms) (kV) (kV) (kV) (kV)

AB 912 1104 13 9 4.5 - 6.0 0.4 100 1.00 100 2.0 2.4 1R2 8K2

AB 903 1107 13 12 7.5 - 9.0 0.7 175 1.25 140 2.5 1.4 2R2 15K0

AB 017 1111 13 16 11.5 - 13.0 1.0 250 1.50 165 3.5 0.9 3R3 22K0

AB 892 1114 13 19 14.5 - 16.0 1.3 325 1.75 185 4.0 0.7 4R7 27K0

AJ 149 1117 13 22 17.5 - 19.0 1.6 400 2.00 200 5.0 0.6 5R6 33K0

AB 986 1414 16 19 14.5 - 16.0 2.2 550 2.25 245 6.5 1.1 2R7 18K0

AB 993 1417 16 22 17.5 - 19.0 2.6 650 2.50 260 7.0 0.9 3R3 22K0

AB 058 1911 21 16 11.5 - 13.0 3.1 775 2.75 280 9.0 2.6 1R2 8K2

AB 840 1915 21 20 15.5 - 17.0 4.3 1075 3.25 330 11.5 1.9 1R5 10K0

AB 893 1917 21 22 17.5 - 19.0 4.8 1200 3.50 345 13.0 1.7 1R8 12K0

AB 620 1920 21 25 20.5 - 22.0 5.7 1425 4.00 355 15.0 1.4 2R2 15K0

AB 663 1927 21 32 27.5 - 29.0 7.7 1925 4.75 405 20.0 1.1 2R7 18K0

AB 880 2410 26 15 10.5 - 12.0 4.5 1125 3.75 300 12.5 4.5 0R68 4K7

AB 885 2415 26 20 15.5 - 17.0 6.8 1700 4.50 380 17.5 3.0 1R0 6K8

AB 881 2420 26 25 20.5 - 22.0 9.0 2250 5.25 430 22.5 2.3 1R5 8K2

AB 662 2425 26 30 25.5 - 27.0 11.3 2825 6.00 470 28.0 1.8 1R8 12K0

AB 241 2435 26 40 35.5 - 37.0 15.8 3950 7.75 510 38.0 1.3 2R2 15K0

AB 664 2450 26 55 50.5 - 52.0 22.6 5650 10.00 565 54.0 0.9 3R3 22K0

AB 252 3115 33 20 15.5 - 17.0 11.3 2825 6.50 435 28.0 5.0 0R56 3K9

AB 857 3127 33 32 27.5 - 29.0 20.4 5100 9.00 565 48.5 2.8 1R0 6K8

AB 185 3135 33 40 35.5 - 37.0 26.4 6600 10.50 630 62.5 2.2 1R5 10K0

AB 186 3150 33 55 50.5 - 52.0 37.7 9425 13.75 685 88.0 1.5 2R2 15K0

PHYSICAL / MECHANICAL PARAMETERS ELECTRICAL PARAMETERS

Explanation of Dimension Code Each Resistor type is assigned a 4 digit code, the first 2 digits give the nominal Active Diameter (D) Resistance Values Whilst E24 values are preferred, other values are readily available at no additional cost.

in mm and the last 2 digits give the nominal Active Length (L) of the Resistor in mm. From this information Resistance Tolerance +/- 20%, +/- 10% and +/- 5% available as standard.

the Volume of Active Material (v) may be determined. Resistivity Range - ρ 3 Ohm cm to 20000 Ohm cm ρ = R x A/L where R = Resistance Value

Construction The Tinned Copper lead terminations are attached to the Copper metallised contact on the Resistor body Temperature Coefficient - TCR -0.05% to -0.15% per °C Temperature Rise depending on Resistivity Value.

opposing flat surfaces, with high melting point solder. This permits reliable short time operation at TCR = 0.16 x e-(logρ/1.4) - 0.135 (%/°C Temperature Rise)

temperatures up to 200°C.

Voltage Coefficient - VCR -0.5% to -7.5% / kV / cm

Coating The coating consists of a high quality epoxy resin applied by fluidised bed technique. The coating finish VCR = -0.62 x ρ0.22 (%/kV/cm) For ρ domain 10 to 7500 Ohm cm

is hard, smooth and has good appearance to harmonise with other electronic components.

Inductance This is negligible (nH) and the Resistors may be described as non-inductive. In

The Resistor leads may be preformed to fit Printed Circuit Boards (PCB's) provided certain precautions practice the inductance of connecting leads will be greater than that of the Resistors.

are observed. During preforming, the Resistor ends should be grasped between thumb and forefinger.

Examine the wire at the Resistor body junction to ensure the coating is not cracked.

Maximum Working Voltages The Maximum Working Voltage levels (Vworking) can be derived from the appropriate formulae

If this range of Resistors experience surface temperatures regularly in excess of 150°C, the coating will illustrated in the table above. Waveforms are defined in the usual manner: 1.2/50µs indicates

tend to degrade slightly, becoming 'coffee coloured'. Though unsightly, performance is not compromised. a rise time to peak value in 1.2µs and an exponential decay to half amplitude in a total time

of 50µs.

Whilst the coating can reduce the rate of moisture ingress, it is not impervious to liquids.

Worked example : Consider an AB 664 Resistor with a Resistance Value of 1K0 and

Terminations / Soldering The Tinned Copper wire lead terminations are 0.9mm in Diameter (AB 912 - AB 993) and 1.1mm in waveform of 10/1000µs.

Diameter (AB 058 - AB 186) and require, as a minimum, PCB mounting holes of 1.2 mm and 1.5 mm

Diameter respectively. Vworking = 0.0659 R x ( -1 + √ (1 + 1315 / R)) = 34.36 kV (Say 34kV)

Soldering is permissible with mildly activated fluxed solders with liquidous properties less than 230°C.

Coefficient of Linear Expansion In the range +4 x 10-6 to +10 x 10-6 per °C depending on material Resistivity.

You might also like

- 920 325D LR 245176Document5 pages920 325D LR 245176Avijit SharmaNo ratings yet

- Zahra-HV Cables - Aug 2010Document66 pagesZahra-HV Cables - Aug 2010Yvonne TohNo ratings yet

- Disc Data 20140918Document2 pagesDisc Data 20140918Nitro anguianoNo ratings yet

- How To Select NTC ThermistorDocument3 pagesHow To Select NTC ThermistornassimNo ratings yet

- Eytu Lecture4Document57 pagesEytu Lecture4David MurilloNo ratings yet

- 2004 Article - Ripple Current ConfusionDocument2 pages2004 Article - Ripple Current ConfusiondaveNo ratings yet

- VHT Aa: High Temperature SeriesDocument2 pagesVHT Aa: High Temperature SeriesMallampati RamakrishnaNo ratings yet

- Application Note AN-1057: Heatsink CharacteristicsDocument17 pagesApplication Note AN-1057: Heatsink CharacteristicsAndre LimaNo ratings yet

- Basics of Thermal Resistance and Heat Dissipation An-EDocument6 pagesBasics of Thermal Resistance and Heat Dissipation An-ERahul RaiNo ratings yet

- DPAK Surface Mount Package: Semiconductor Technical DataDocument4 pagesDPAK Surface Mount Package: Semiconductor Technical DataJeanpierre H. AsdikianNo ratings yet

- Earthing System Design Tool For Low Voltage InstallationsDocument43 pagesEarthing System Design Tool For Low Voltage InstallationsSayed Abo ElkhairNo ratings yet

- High Efficiency Solid State Amplifiers - 1Document44 pagesHigh Efficiency Solid State Amplifiers - 1wingchaoNo ratings yet

- Integrated Electro-Thermal Simulation in ADSDocument70 pagesIntegrated Electro-Thermal Simulation in ADSRAJA RAMALINGAMNo ratings yet

- Earthing Tool CalculatorDocument36 pagesEarthing Tool CalculatorJejomar ErebarenNo ratings yet

- High Voltage Chapter 1 - InTRODUCTIONDocument18 pagesHigh Voltage Chapter 1 - InTRODUCTIONZiyan SinNo ratings yet

- Transducers - Types and ApplicationsDocument102 pagesTransducers - Types and Applicationsdekhte rahoNo ratings yet

- LED Thermal Management Basics For PCB DesignersDocument63 pagesLED Thermal Management Basics For PCB DesignersSaturn Electronics CorporationNo ratings yet

- Principles of Cable Sizing PDFDocument57 pagesPrinciples of Cable Sizing PDFSyed ZainNo ratings yet

- General Information: Current TransformersDocument1 pageGeneral Information: Current TransformersPardeep KhosaNo ratings yet

- New Microsoft Word DocumentDocument3 pagesNew Microsoft Word DocumentNripesh PokhrelNo ratings yet

- Manual Del Sensor Termistor CI-6527ADocument5 pagesManual Del Sensor Termistor CI-6527AAlonsoAguirreTobarNo ratings yet

- SCT 50 N 120Document11 pagesSCT 50 N 120JaimeNo ratings yet

- Capacitor Information (PT 2) PDFDocument18 pagesCapacitor Information (PT 2) PDFwillchamNo ratings yet

- Equation 1: The Following Products/services Are Available: 1 A Range of Standard Heatsinks and AccessoriesDocument6 pagesEquation 1: The Following Products/services Are Available: 1 A Range of Standard Heatsinks and AccessoriesgoaltechNo ratings yet

- Emi 7Document79 pagesEmi 7viju_310No ratings yet

- Ieee80 Step and Touch CalculationDocument24 pagesIeee80 Step and Touch Calculationwaleed.liaquat.kkNo ratings yet

- VHT D: High Temperature SeriesDocument2 pagesVHT D: High Temperature SeriesMallampati RamakrishnaNo ratings yet

- SEMIKRON Technical Explanation Discrete Thyristors and Diodes EN 2005-04-15 Rev-00Document10 pagesSEMIKRON Technical Explanation Discrete Thyristors and Diodes EN 2005-04-15 Rev-00Izzudin YafiNo ratings yet

- Sctwa50N120: Silicon Carbide Power Mosfet 1200 V, 65 A, 59 Mω (Typ., Tj=150 °C) In An Hip247™ Long Leads PackageDocument11 pagesSctwa50N120: Silicon Carbide Power Mosfet 1200 V, 65 A, 59 Mω (Typ., Tj=150 °C) In An Hip247™ Long Leads PackageFurkan Berk KayaNo ratings yet

- Instrumentation - Unit 5Document125 pagesInstrumentation - Unit 5Rinki KeswaniNo ratings yet

- Unit1: Electrical Resistance Strain GaugesDocument29 pagesUnit1: Electrical Resistance Strain GaugesZaid MohammedNo ratings yet

- Technical Information Omnigrad S TR62, TC62: Modular Thermometer, Explosion-Protected, For Screwing Into A ThermowellDocument20 pagesTechnical Information Omnigrad S TR62, TC62: Modular Thermometer, Explosion-Protected, For Screwing Into A ThermowellKarlNo ratings yet

- MBRS140T3 Surface Mount Schottky Power RectifierDocument4 pagesMBRS140T3 Surface Mount Schottky Power RectifierfreddyNo ratings yet

- Kim 2011Document6 pagesKim 2011Carlos VelásquezNo ratings yet

- 13-Concept of Critical Radius of Insulation With Numerical-31!01!2024Document10 pages13-Concept of Critical Radius of Insulation With Numerical-31!01!2024johann pintoNo ratings yet

- Lighning Prblms2003 1Document52 pagesLighning Prblms2003 1Sithumini SankalpanaNo ratings yet

- SHORT CIRCUIT WITHSTAND OF POWER CABLESDocument42 pagesSHORT CIRCUIT WITHSTAND OF POWER CABLESDheeraj Yadav100% (1)

- SB3H90 and SB3H100 High Voltage Schottky RectifiersDocument2 pagesSB3H90 and SB3H100 High Voltage Schottky RectifiersKatusso AyalaNo ratings yet

- NTC Inrush Current Limiter: Thermometrics ThermistorsDocument4 pagesNTC Inrush Current Limiter: Thermometrics ThermistorsPham LongNo ratings yet

- Earthmat CalculationDocument4 pagesEarthmat CalculationpradipNo ratings yet

- Esa NotesDocument114 pagesEsa NotesSagar GowdaNo ratings yet

- FP - B.1 - MSR - Neutral Earthing Resistors and Temperature Coefficient - 1 PDFDocument16 pagesFP - B.1 - MSR - Neutral Earthing Resistors and Temperature Coefficient - 1 PDFkokonut1128No ratings yet

- Thick Film Chip Resistors: DescriptionDocument1 pageThick Film Chip Resistors: DescriptionAutor AutorNo ratings yet

- Endress Modular Thermometer TR66 TC66Document24 pagesEndress Modular Thermometer TR66 TC66saeed_393512703No ratings yet

- Elex MergeDocument94 pagesElex MergenicoleNo ratings yet

- Hmov Varistor SeriesDocument12 pagesHmov Varistor Serieseverton damatoNo ratings yet

- Strain Gage Technical Data PDFDocument5 pagesStrain Gage Technical Data PDFLudy FajardoNo ratings yet

- N-Channel Enhancement-Mode Silicon Gate: Semiconductor Technical DataDocument10 pagesN-Channel Enhancement-Mode Silicon Gate: Semiconductor Technical DataHAROL ALEXIS VALENCIA OSPINANo ratings yet

- Condensadores ElectroniconDocument22 pagesCondensadores ElectroniconVincent PorhelortNo ratings yet

- Capacitors: MKP Series 276.Xxx MKPG Series 275.XxxDocument22 pagesCapacitors: MKP Series 276.Xxx MKPG Series 275.XxxRobin CruzNo ratings yet

- Thyristor: EE448 Spring 2021 Lecture#3 Dr. Abosalah AlsalmiDocument7 pagesThyristor: EE448 Spring 2021 Lecture#3 Dr. Abosalah AlsalmiMohammed AunNo ratings yet

- 14D Series Metal-Oxide Varistor: FeaturesDocument3 pages14D Series Metal-Oxide Varistor: Featuresch_menesesNo ratings yet

- PTC Ee Tee 7 Us MPDocument4 pagesPTC Ee Tee 7 Us MPbmmostefaNo ratings yet

- Product Information: NTC-thermistorsDocument3 pagesProduct Information: NTC-thermistorsRicardo CruzNo ratings yet

- Technical Information Omnigrad S TR66, TC66Document20 pagesTechnical Information Omnigrad S TR66, TC66oliNo ratings yet

- Sensors and Transducer Part 2Document37 pagesSensors and Transducer Part 2Charize Angeli LumidaoNo ratings yet

- SS 316 03Document12 pagesSS 316 03Muhammad Asif IqbalNo ratings yet

- MUR480EG, MUR4100EG Switchmode Power Rectifiers: Ultrafast "E'' Series With High Reverse Energy CapabilityDocument6 pagesMUR480EG, MUR4100EG Switchmode Power Rectifiers: Ultrafast "E'' Series With High Reverse Energy Capabilitycorrales_86No ratings yet

- Icar DC Link CapacitorsDocument48 pagesIcar DC Link CapacitorsAnonymous TNbs7cNo ratings yet

- Electronic Devices and Circuits: The Commonwealth and International Library: Electrical Engineering Division, Volume 1From EverandElectronic Devices and Circuits: The Commonwealth and International Library: Electrical Engineering Division, Volume 1No ratings yet

- Introduction To Terahertz Electronics (2021)Document371 pagesIntroduction To Terahertz Electronics (2021)Numa Luma100% (1)

- AN-202 - An IC Amplifier User's Guide To Decoupling - Grounding - and Making Things Go Right For A ChangeDocument8 pagesAN-202 - An IC Amplifier User's Guide To Decoupling - Grounding - and Making Things Go Right For A ChangeyusufwpNo ratings yet

- Introduction To Terahertz Electronics (2021)Document371 pagesIntroduction To Terahertz Electronics (2021)Numa Luma100% (1)

- Article-Application Note For ST MICROELECTRONICS Timekeepers-Rolling Into The Year 2000Document2 pagesArticle-Application Note For ST MICROELECTRONICS Timekeepers-Rolling Into The Year 2000Numa LumaNo ratings yet

- 0507Document4 pages0507Jitender SharmaNo ratings yet

- Bonitron - Common DC BusDocument4 pagesBonitron - Common DC BusNuma LumaNo ratings yet

- Article-ATLAS COPCO ELEKTRONIKON MK III Chassis (Main Board) 1900 0700 08 Ed.00Document5 pagesArticle-ATLAS COPCO ELEKTRONIKON MK III Chassis (Main Board) 1900 0700 08 Ed.00Numa LumaNo ratings yet

- Application Note AT89S8253 Primer 8051 Flash MicrocontrollerDocument20 pagesApplication Note AT89S8253 Primer 8051 Flash MicrocontrollerNuma LumaNo ratings yet

- Technical Notes - Find The Right ESD or TVS DiodeDocument2 pagesTechnical Notes - Find The Right ESD or TVS DiodeNuma LumaNo ratings yet

- Article-ATLAS COPCO ELEKTRONIKON MK III Regulator Chassis (Main Board) 1900 0700 05 Ed.00 FF (Full Featured) 10 BarDocument2 pagesArticle-ATLAS COPCO ELEKTRONIKON MK III Regulator Chassis (Main Board) 1900 0700 05 Ed.00 FF (Full Featured) 10 BarNuma LumaNo ratings yet

- VISHAY SEMICONDUCTOR RECTIFIER TERMINOLOGYDocument3 pagesVISHAY SEMICONDUCTOR RECTIFIER TERMINOLOGYravindarsinghNo ratings yet

- Technical Data - TT Electronics - High Voltage Precision Thick Film ResistorsDocument3 pagesTechnical Data - TT Electronics - High Voltage Precision Thick Film ResistorsNuma LumaNo ratings yet

- Littelfuse Tvs Diode Catalog PDFDocument174 pagesLittelfuse Tvs Diode Catalog PDFjvs57No ratings yet

- Bonitron - Manual - Solutions For AC Drives - M3628PCT Portable Capacitor TesterDocument32 pagesBonitron - Manual - Solutions For AC Drives - M3628PCT Portable Capacitor TesterNuma LumaNo ratings yet

- Bonitron - M3628PCT Portable Capacitor TesterDocument1 pageBonitron - M3628PCT Portable Capacitor TesterNuma LumaNo ratings yet

- How To Build A Transient Voltage Suppressor (TVS) CircuitDocument4 pagesHow To Build A Transient Voltage Suppressor (TVS) CircuitNuma LumaNo ratings yet

- Axial Leaded - 1500W 1.5KE SeriesDocument6 pagesAxial Leaded - 1500W 1.5KE SeriesАндрей ЕвтодиевNo ratings yet

- Technical Data - TT Electronics - Semi-Precision Power Wirewound ResistorDocument3 pagesTechnical Data - TT Electronics - Semi-Precision Power Wirewound ResistorNuma LumaNo ratings yet

- AND8230/D Application Hints For Transient Voltage Suppression Diode CircuitsDocument7 pagesAND8230/D Application Hints For Transient Voltage Suppression Diode Circuitssubithk4906No ratings yet

- Diodes Group Body MarkingDocument25 pagesDiodes Group Body MarkingNuma LumaNo ratings yet

- Article-A Brief Survey of AC Drive Fault Diagnosis & DetectionDocument24 pagesArticle-A Brief Survey of AC Drive Fault Diagnosis & DetectionNuma LumaNo ratings yet

- Technical Data - HVR Resistor Technology - High Voltage ResistorsDocument2 pagesTechnical Data - HVR Resistor Technology - High Voltage ResistorsNuma LumaNo ratings yet

- Tutorial - How To Limit Inrush Current in A AC-DC Power SupplyDocument5 pagesTutorial - How To Limit Inrush Current in A AC-DC Power SupplyNuma LumaNo ratings yet

- Fundamentals of RectifiersDocument2 pagesFundamentals of RectifiersNuma LumaNo ratings yet

- Technical Data - HVR APC - U Series ResistorsDocument2 pagesTechnical Data - HVR APC - U Series ResistorsNuma LumaNo ratings yet

- Understanding: Variable Frequency DriveDocument50 pagesUnderstanding: Variable Frequency DriveNo HopeNo ratings yet

- Designing battery management systemsDocument7 pagesDesigning battery management systemsNuma LumaNo ratings yet

- Chords For Luna Blanca Guitar Island AlbumDocument12 pagesChords For Luna Blanca Guitar Island AlbumNuma LumaNo ratings yet

- Article-A Brief Introduction To Common Bus and Line RegenerationDocument7 pagesArticle-A Brief Introduction To Common Bus and Line RegenerationNuma LumaNo ratings yet

- GIS Overview PresentationDocument30 pagesGIS Overview PresentationHaripriya PalemNo ratings yet

- Singlemultiplelimitswitches TecknicDocument18 pagesSinglemultiplelimitswitches Tecknicchidambaram kasiNo ratings yet

- Centrifuges Training GuideDocument19 pagesCentrifuges Training GuideMoe MoeNo ratings yet

- Flowcon Ft.0.2, Ft.0.3 and Ft.0.4 Actuators: Installation and Operation InstructionDocument2 pagesFlowcon Ft.0.2, Ft.0.3 and Ft.0.4 Actuators: Installation and Operation Instructionimron hilmanNo ratings yet

- W2-Off-Grid PV System Components, Design and Installation ConsiderationsDocument43 pagesW2-Off-Grid PV System Components, Design and Installation ConsiderationsAftab RaniyaNo ratings yet

- Understanding The Behavior of ExciterDocument4 pagesUnderstanding The Behavior of Exciterschauhan12No ratings yet

- Solid State Electric Generator Uses Magnetic FluxDocument9 pagesSolid State Electric Generator Uses Magnetic FluxDan Beeson100% (2)

- Snubber CircuitsDocument8 pagesSnubber CircuitsHarri Makkonen100% (3)

- 2CDC112192D0201Document9 pages2CDC112192D0201Slobodan SavicNo ratings yet

- Miniature PCB Relay with 17A 277VAC SPDT RatingDocument6 pagesMiniature PCB Relay with 17A 277VAC SPDT RatingagilsonlibreNo ratings yet

- Technology and Livelihood Education: Exploratory Course in Electrical Installation and MaintenanceDocument13 pagesTechnology and Livelihood Education: Exploratory Course in Electrical Installation and MaintenanceSteven Escarmosa100% (1)

- UAT No.1 & No.2 Protection Relay Setting & TestingDocument39 pagesUAT No.1 & No.2 Protection Relay Setting & TestingErwin SambasNo ratings yet

- Electronics Circuits Lab ManualDocument109 pagesElectronics Circuits Lab ManualIndische Mädchen100% (2)

- CDVR General InformationDocument6 pagesCDVR General InformationTTIBCCANo ratings yet

- Tonepad BigmuffDocument2 pagesTonepad BigmuffMarceloMeirellesNo ratings yet

- Physics MCQ Guide on Capacitors and Electric CircuitsDocument7 pagesPhysics MCQ Guide on Capacitors and Electric CircuitsEhtisham KhattakNo ratings yet

- BTE2122 Lab (2) SuperpositionDocument6 pagesBTE2122 Lab (2) SuperpositionLee yi kangNo ratings yet

- Ark Platform Pl4000 Brochure Rev-00Document6 pagesArk Platform Pl4000 Brochure Rev-00Murat ArıkanNo ratings yet

- ABB Load Interrupter Switchgear Customer PresentationR2Document14 pagesABB Load Interrupter Switchgear Customer PresentationR2Mahyar MashayekhiNo ratings yet

- Diode Circuit AnalysisDocument13 pagesDiode Circuit AnalysisPhaniendra Kundeti0% (1)

- Tesla's Electric CarDocument5 pagesTesla's Electric CarRossen Petrov0% (1)

- Measuring Distortion in Switching AmplifiersDocument7 pagesMeasuring Distortion in Switching AmplifierssimonNo ratings yet

- PROCOM r-70-7Document2 pagesPROCOM r-70-7Milic MilicevicNo ratings yet

- RD-240TV - Aa1 - 013289 2014Document135 pagesRD-240TV - Aa1 - 013289 2014Artur RutraNo ratings yet

- 12 132KV DiscDocument3 pages12 132KV DiscArslan AhmadNo ratings yet

- Plugin LF351Document8 pagesPlugin LF351mark777markNo ratings yet

- Manual HP 608D - Signal GeneratorDocument100 pagesManual HP 608D - Signal GeneratorrafaelhesselNo ratings yet

- STR W6735 DatasheetDocument13 pagesSTR W6735 DatasheetloagerNo ratings yet

- The Technical and Economic Efficiency ofDocument7 pagesThe Technical and Economic Efficiency ofmark mywordNo ratings yet

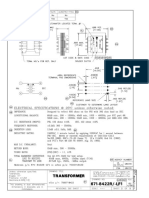

- Midcom 671-8422 Transformer 600 OhmDocument1 pageMidcom 671-8422 Transformer 600 OhmBenjamin DoverNo ratings yet