Professional Documents

Culture Documents

Welding Procedure Specification for A333 GR6 Steel Butt Welds

Uploaded by

ANIL PLAMOOTTILOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Welding Procedure Specification for A333 GR6 Steel Butt Welds

Uploaded by

ANIL PLAMOOTTILCopyright:

Available Formats

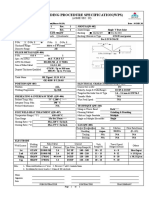

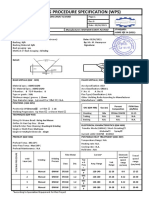

焊接工艺指导书 Welding Procedure Specification

文件号 Doc. No.: PWPS-A333 GR6-BW-01 Rev.0

*焊接位置 POSITIONS (QW-405) *焊后热处理 POST WELD HEAT TREATMENT (QW-407)

坡口位置 Position(s) of Groove 2G 温度范围 Temperature Range None

焊接方向 Welding Progression N/A 保温时间 Soaking Time None

角焊位置 Position(s) of Fillet N/A 升温速率 Increasing rate None

其他 Others N/A 降温速率 Decreasing rate None

其他 Others None

*预热 PREHEAT (QW-406) *气体 GAS (QW-408) 百分比 Percent Composition

气体 混合比 流量

最低预热温度 Preheat Temp. Min. 5℃

Gas(es) (Mixture) (Flow Rate)

250℃

保护气

最高道间温度 Inter Pass Temp. Max. ( Measurement method: Ar 99.995% 15~20L/min

Shielding

Digital thermometer)

尾部保护气

预热保持方式 Preheat Maintenance N/A N/A N/A N/A

Trailing

(采用连续加热或特殊加热法时应有温度记录) 背面保护气

(Continuous or special heating where applicable should be recorded) N/A N/A N/A

Backing

*电特性 ELECTRICAL CHARACTERISTICS (QW-409)

电流 Current AC or DC DC 极性 Polarity See table below 如下表所示

安培 Amps. (Range) See table below 如下表所示 伏特 Volts. (Range) See table below 如下表所示

(安培和伏特范围应按每种焊丝焊条尺寸、位置和厚度等分别记录,可按以下列表的方式记录)

(Amps and volt range should be recorded for each electrode size, position, and thickness, etc. This information may be listed in a

tabular form similar to that shown below.)

钨极尺寸和类型 Tungsten Electrode Size and Type Ф2.4mm EWCe-2

(纯钨极或 2%钍钨极 Pure Tungsten, 2% Thorited, etc.)

金属过渡方式 Mode of Metal Transfer for GMAW N/A

(射流或短路等 Spray arc, short circuiting arc, etc.)

送丝速度范围 Electrode Wire feed speed range N/A

*焊接技术 TECHNIQUE (QW-410)

焊接方法 Welding Process GTAW

焊接设备 Welding Equipment KEMPPI MASTER TIG MLS 4000

直道焊或横摆焊 String or Weave Bead Weave

嘴孔或喷嘴尺寸 Orifice or Gas Cup Size 10 mm

打底焊道和中间焊道的清理方法(刷理或打磨等等)

Brushing or Grinding

Initial and Interpass Cleaning (Brushing, Grinding, etc.)

背面清根方法 Method of Back Gouging None

横摆方法 Oscillation N/A

导电嘴至工作距离 Contact Tube to Work Distance 5~10mm

多道焊或单道焊(每侧) Multiple or Single Pass (per side) Multiple passes

多电极焊或单电极焊 Multiple or Single Electrodes Single Electrode

焊接速度(范围) Travel Speed (Range) See table below 如下表所示

锤击有无 Peening None

室内或室外 Closed to out chamber N/A

焊道间时间间隔 Time Lapse Between Passes N/A

其他 Other None

填充金属 Filler Metal 电流极性 安培范围 焊接速度范围 热输入量

焊缝层次 电压范围

焊接方法 Current Amperage Travel Speed Heat Input

Weld 牌号 直径 Voltage Range

Process Type and Range Range (Arc)

Layer (s) Classification Dia.(mm) (V)

Polarity (A) (mm/min) (KJ//mm)

Root GTAW ER70S-6 Ф2.4 DCEN 100~150 10~16 70~100 TBN

Fill and cap GTAW ER70S-6 Ф2.4 DCEN 100~150 10~16 70~100 TBN

*Heat input(KJ/mm)=[(Volts Arc(V)× Amps Arc (A)× 60]/ [Travel speed(mm/min) × 1000]

*Welding sequence or layers shall be adjusted according to actual joint.焊接顺序或层数必须按照实际焊接要求

编制 Prepared By 审核 Reviewed By 第三方机构 Third party By

签名 Signature

日期 Date 2020-11-12 2020-11-12

2/ 2

You might also like

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- WPS for Gas Field Development WeldingDocument2 pagesWPS for Gas Field Development WeldingAhmed LepdaNo ratings yet

- WPS-ASME-007-1 Rev0Document1 pageWPS-ASME-007-1 Rev0Ahmed LepdaNo ratings yet

- WPS GTAW-SMAW h2Document1 pageWPS GTAW-SMAW h2Jesus Gabrielw Blanco GhostbustersIzNo ratings yet

- WPS-CS-113 Rev.1Document2 pagesWPS-CS-113 Rev.1Muhammad BilalNo ratings yet

- Pwps Jo Wps Asme 016 Rev.001Document2 pagesPwps Jo Wps Asme 016 Rev.001Bagandi ManurungNo ratings yet

- WPS-ASME-009-1 Rev1Document1 pageWPS-ASME-009-1 Rev1Ahmed LepdaNo ratings yet

- CPP Jps1 1 QC Pro 0056 - 0 CPP Wsteel Pipe Welding (Gtaw) .PDF - 17Document1 pageCPP Jps1 1 QC Pro 0056 - 0 CPP Wsteel Pipe Welding (Gtaw) .PDF - 17khuram shahzadNo ratings yet

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document2 pagesWelding Procedure Specification (WPS) : (Asme Sec. Ix)Emmanuel Loayza100% (1)

- Welding Procedure Specifications (WPS) : AWS D1.1Document2 pagesWelding Procedure Specifications (WPS) : AWS D1.1BS AhnNo ratings yet

- Welding Procedure Specification for Stainless SteelDocument5 pagesWelding Procedure Specification for Stainless SteelVarun Malhotra100% (5)

- Aramco Hot Tap Welding Procedure Rev 1Document3 pagesAramco Hot Tap Welding Procedure Rev 1BWQNo ratings yet

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document3 pagesWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed Lepda100% (1)

- PWPS 001Document2 pagesPWPS 001Mehrdad RezaeiNo ratings yet

- Bridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, OdishaDocument5 pagesBridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, Odishaniraj mouryaNo ratings yet

- Aic Asf PQR 0120Document2 pagesAic Asf PQR 0120AHMED MEDANYNo ratings yet

- Asme IxDocument1 pageAsme IxAxel Navarro AlbinesNo ratings yet

- PhuBia-WPS-AWS D1.1-8-6-2011Document3 pagesPhuBia-WPS-AWS D1.1-8-6-2011poulmack100% (1)

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDDocument5 pagesWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDHussein MohamedNo ratings yet

- GTAW Welding Process ParametersDocument12 pagesGTAW Welding Process Parametersmiteshpatel191No ratings yet

- A36 WPSDocument1 pageA36 WPSJamesNo ratings yet

- PWPS 005Document2 pagesPWPS 005Mehrdad RezaeiNo ratings yet

- Pre-Liminary WELDING PROCEDURE Specification (PWPS) : RDMP RU-V Balikpapan ProjectDocument2 pagesPre-Liminary WELDING PROCEDURE Specification (PWPS) : RDMP RU-V Balikpapan ProjectBagandi ManurungNo ratings yet

- PT. TRECONS MITRA GEMILANG PROCEDURE QUALIFICATION RECORDSDocument1 pagePT. TRECONS MITRA GEMILANG PROCEDURE QUALIFICATION RECORDSBudi Setia RahmanNo ratings yet

- WPS CuNiDocument1 pageWPS CuNiDieter Huaman ToscanoNo ratings yet

- GTAW Welding Procedure for ASTM A53 PipeDocument2 pagesGTAW Welding Procedure for ASTM A53 PipeS. K. M. ShujonNo ratings yet

- GTAW WPS for ASTM A240 TP 304LDocument1 pageGTAW WPS for ASTM A240 TP 304LAnand MakasanaNo ratings yet

- Wps API-mwt 2020Document24 pagesWps API-mwt 2020afshohil anamNo ratings yet

- WPS Tsila 010Document2 pagesWPS Tsila 010AslaouiNo ratings yet

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDDocument5 pagesWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDIskak TabriNo ratings yet

- Tungstenelectrodesize and Type' 2,4 MM As Per Sfa 5.12 Ewth - 2Document23 pagesTungstenelectrodesize and Type' 2,4 MM As Per Sfa 5.12 Ewth - 2Abdelkader AbdelkaderNo ratings yet

- WELDING PROCEDURE SPECIFICATION FOR SOUTH PARS GAS FIELD DEVELOPMENTDocument1 pageWELDING PROCEDURE SPECIFICATION FOR SOUTH PARS GAS FIELD DEVELOPMENTAhmed LepdaNo ratings yet

- WPS 03 2014Document2 pagesWPS 03 2014vinuNo ratings yet

- Page No: 01: SA 240 GR 304 SA 240 GR 304Document5 pagesPage No: 01: SA 240 GR 304 SA 240 GR 304jobertNo ratings yet

- WPS New 2Document1 pageWPS New 2Erica SandersNo ratings yet

- Welding Procedure Specification (WPS) : Owner: (As Per QW 482 of ASME Section IX)Document2 pagesWelding Procedure Specification (WPS) : Owner: (As Per QW 482 of ASME Section IX)Saravanan Palanisamy Lakshmi100% (1)

- PQR Saw ProcessDocument1 pagePQR Saw ProcessARUL ARON JOSENo ratings yet

- Smaw Wps FinalDocument3 pagesSmaw Wps FinalsheikmoinNo ratings yet

- Welding Procedure Specification GuideDocument2 pagesWelding Procedure Specification GuidepoulmackNo ratings yet

- ASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Document2 pagesASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Virk Farms100% (1)

- WPS and PQRDocument4 pagesWPS and PQRdandiar1No ratings yet

- Welding Procedure Specification (WPS) : As Per Asme Sec - Ix 2004 EDITIONDocument3 pagesWelding Procedure Specification (WPS) : As Per Asme Sec - Ix 2004 EDITIONJennifer French100% (2)

- Tips Wps FormatDocument5 pagesTips Wps FormatWaqas WaqasNo ratings yet

- PRELIMINARY WELDING PROCEDURE AND QUALIFICATION FOR GTAWDocument8 pagesPRELIMINARY WELDING PROCEDURE AND QUALIFICATION FOR GTAWmegantara maromNo ratings yet

- Manual Standard WeldingDocument192 pagesManual Standard WeldingGEORGE IVAN0% (1)

- Suria Engineering: Procedure Qualification Record (PQR)Document2 pagesSuria Engineering: Procedure Qualification Record (PQR)suria qaqcNo ratings yet

- Toshiba Brazing Procedure SpecificationDocument3 pagesToshiba Brazing Procedure Specificationsheikmoin100% (1)

- Toaz - Info Welding Procedure Specification Format PRDocument3 pagesToaz - Info Welding Procedure Specification Format PRKarim ZahranNo ratings yet

- Preliminary WPS for 12.7mm SMAW WeldingDocument3 pagesPreliminary WPS for 12.7mm SMAW WeldingAnonymous 4e7GNjzGW100% (1)

- Q345B WPSDocument1 pageQ345B WPSJamesNo ratings yet

- WPS Procedure Spec for 316L Steel Single Groove Weld Up to 12mmDocument2 pagesWPS Procedure Spec for 316L Steel Single Groove Weld Up to 12mmvahid mobiniNo ratings yet

- Wps PQR For Reference p1 To p1 Smawxls PDF FreeDocument6 pagesWps PQR For Reference p1 To p1 Smawxls PDF FreeMahmoud GaberNo ratings yet

- WPS Welding Performance SpecialistDocument2 pagesWPS Welding Performance SpecialistGobinath GovindarajNo ratings yet

- Wps & PQR For Valve Installation - XLSX Fix TerbaruDocument20 pagesWps & PQR For Valve Installation - XLSX Fix TerbarufebriNo ratings yet

- Draft WPSDocument3 pagesDraft WPSWale OyeludeNo ratings yet

- BGR Energy Systems Limited: Oil & Gas Equipment Division Welding Procedure Specification (WPS) - Aws D1.1Document1 pageBGR Energy Systems Limited: Oil & Gas Equipment Division Welding Procedure Specification (WPS) - Aws D1.1Eswar Enterprises QcNo ratings yet

- Transistor Electronics: Use of Semiconductor Components in Switching OperationsFrom EverandTransistor Electronics: Use of Semiconductor Components in Switching OperationsRating: 1 out of 5 stars1/5 (1)

- 6.2 Preparation 6.2.1 Inspection and Test Plan: Ras Markaz Crude Oil Park Project (Phase1)Document1 page6.2 Preparation 6.2.1 Inspection and Test Plan: Ras Markaz Crude Oil Park Project (Phase1)ANIL PLAMOOTTILNo ratings yet

- OTTCO RAS MARKAZ CRUDE OIL PARK PROJECT COMMENTS RESOLUTION SHEETDocument2 pagesOTTCO RAS MARKAZ CRUDE OIL PARK PROJECT COMMENTS RESOLUTION SHEETANIL PLAMOOTTILNo ratings yet

- Inspection Report: CPP-RM-PO-0180Document4 pagesInspection Report: CPP-RM-PO-0180ANIL PLAMOOTTIL0% (1)

- Evaporation Pond Reply by SEZADDocument17 pagesEvaporation Pond Reply by SEZADANIL PLAMOOTTILNo ratings yet

- Foundation inspection checklistDocument1 pageFoundation inspection checklistANIL PLAMOOTTILNo ratings yet

- Foundation inspection checklistDocument1 pageFoundation inspection checklistANIL PLAMOOTTILNo ratings yet

- Ras Markaz Crude Oil Park Project (Phase1) : Attachment-1 Check List For New Construction ActivityDocument1 pageRas Markaz Crude Oil Park Project (Phase1) : Attachment-1 Check List For New Construction ActivityANIL PLAMOOTTILNo ratings yet

- RAS MARKAZ CRUDE OIL PARK SITE INSPECTION RECORDSDocument1 pageRAS MARKAZ CRUDE OIL PARK SITE INSPECTION RECORDSANIL PLAMOOTTILNo ratings yet

- C10A GMRHPB Foundations Coating InspectionDocument1 pageC10A GMRHPB Foundations Coating InspectionANIL PLAMOOTTILNo ratings yet

- 6.2.2 Inspection, Measuring and Testing Equipment: Ras Markaz Crude Oil Park Project (Phase1)Document1 page6.2.2 Inspection, Measuring and Testing Equipment: Ras Markaz Crude Oil Park Project (Phase1)ANIL PLAMOOTTILNo ratings yet

- 6.3.10 Ex Certified Equipment Complaince: Ras Markaz Crude Oil Park Project (Phase1)Document1 page6.3.10 Ex Certified Equipment Complaince: Ras Markaz Crude Oil Park Project (Phase1)ANIL PLAMOOTTILNo ratings yet

- Ras Markaz Crude Oil Park Project (Phase1)Document1 pageRas Markaz Crude Oil Park Project (Phase1)ANIL PLAMOOTTILNo ratings yet

- RAS MARKAZ CRUDE OIL PARK PROJECTDocument1 pageRAS MARKAZ CRUDE OIL PARK PROJECTANIL PLAMOOTTILNo ratings yet

- Site Qa / QC Records: Ras Markaz Crude Oil Park Project (Phase1)Document1 pageSite Qa / QC Records: Ras Markaz Crude Oil Park Project (Phase1)ANIL PLAMOOTTILNo ratings yet

- 6.3.4 Final Inspection and Test: Ras Markaz Crude Oil Park Project (Phase1)Document1 page6.3.4 Final Inspection and Test: Ras Markaz Crude Oil Park Project (Phase1)ANIL PLAMOOTTILNo ratings yet

- Site Inspection and Testing: 6 6.1 GeneralDocument1 pageSite Inspection and Testing: 6 6.1 GeneralANIL PLAMOOTTILNo ratings yet

- Ras Markaz Crude Oil Park Project (Phase1) : Site Inspection and Testing ProcedureDocument1 pageRas Markaz Crude Oil Park Project (Phase1) : Site Inspection and Testing ProcedureANIL PLAMOOTTILNo ratings yet

- 6.3.6 Independent Testing Agency: Ras Markaz Crude Oil Park Project (Phase1)Document1 page6.3.6 Independent Testing Agency: Ras Markaz Crude Oil Park Project (Phase1)ANIL PLAMOOTTILNo ratings yet

- General: Ras Markaz Crude Oil Park Project (Phase1)Document1 pageGeneral: Ras Markaz Crude Oil Park Project (Phase1)ANIL PLAMOOTTILNo ratings yet

- RAS MARKAZ CRUDE OIL PARK QA/QC PROCEDURESDocument1 pageRAS MARKAZ CRUDE OIL PARK QA/QC PROCEDURESANIL PLAMOOTTILNo ratings yet

- Ras Markaz Crude Oil Park Project (Phase1) : Site Inspection and Testing ProcedureDocument1 pageRas Markaz Crude Oil Park Project (Phase1) : Site Inspection and Testing ProcedureANIL PLAMOOTTILNo ratings yet

- Ras Markaz Crude Oil Park Project (Phase1) : Site Inspection and Testing ProcedureDocument1 pageRas Markaz Crude Oil Park Project (Phase1) : Site Inspection and Testing ProcedureANIL PLAMOOTTILNo ratings yet

- RAS MARKAZ CRUDE OIL PARK SITE INSPECTION PROCEDUREDocument1 pageRAS MARKAZ CRUDE OIL PARK SITE INSPECTION PROCEDUREANIL PLAMOOTTILNo ratings yet

- Ras Markaz Crude Oil Park Project (Phase1) : Site Inspection and Testing ProcedureDocument1 pageRas Markaz Crude Oil Park Project (Phase1) : Site Inspection and Testing ProcedureANIL PLAMOOTTILNo ratings yet

- Scope: Ras Markaz Crude Oil Park Project (Phase1)Document1 pageScope: Ras Markaz Crude Oil Park Project (Phase1)ANIL PLAMOOTTILNo ratings yet

- Ras Markaz Crude Oil Park Project (Phase1) : Site Inspection and Testing ProcedureDocument1 pageRas Markaz Crude Oil Park Project (Phase1) : Site Inspection and Testing ProcedureANIL PLAMOOTTILNo ratings yet

- 5.4 QC Inspectors: Ras Markaz Crude Oil Park Project (Phase1)Document1 page5.4 QC Inspectors: Ras Markaz Crude Oil Park Project (Phase1)ANIL PLAMOOTTILNo ratings yet

- 9686 6120 PR Po0101Document1 page9686 6120 PR Po0101ANIL PLAMOOTTILNo ratings yet

- 9686 6120 PR Po0101Document1 page9686 6120 PR Po0101ANIL PLAMOOTTILNo ratings yet

- Scope: Ras Markaz Crude Oil Park Project (Phase1)Document1 pageScope: Ras Markaz Crude Oil Park Project (Phase1)ANIL PLAMOOTTILNo ratings yet

- LM340K 12 7812P+Document18 pagesLM340K 12 7812P+abrap_delNo ratings yet

- Controlled Switching Technical Note: The Pre-Arcing PhenomenonDocument3 pagesControlled Switching Technical Note: The Pre-Arcing Phenomenonmic68hc11No ratings yet

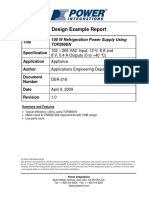

- Design Example Report: Title Specification Application Author Document Number Date RevisionDocument26 pagesDesign Example Report: Title Specification Application Author Document Number Date Revisionhicham boutoucheNo ratings yet

- W MZ T Mini Circuit BreakersDocument11 pagesW MZ T Mini Circuit BreakersaguilavmNo ratings yet

- TransducersDocument26 pagesTransducersamriscribd100% (2)

- Power Electronics PDFDocument17 pagesPower Electronics PDFMadhurima KaveriNo ratings yet

- JLD612 Manual 2011Document8 pagesJLD612 Manual 2011cacaNo ratings yet

- AC Motor WikipediaDocument10 pagesAC Motor WikipediasmeenaNo ratings yet

- Sistema Electrico 7400 Internatinal-1Document350 pagesSistema Electrico 7400 Internatinal-1omar suazoNo ratings yet

- Engineering Design Project Report on PWM Transmitter CircuitDocument9 pagesEngineering Design Project Report on PWM Transmitter Circuitdareghost ytNo ratings yet

- Festo SOEL RTH Q20 PP S 2L TI DatasheetDocument1 pageFesto SOEL RTH Q20 PP S 2L TI DatasheetJesús Emmanuel Zarco SalazarNo ratings yet

- Masterpact NW08-63 User ManualDocument54 pagesMasterpact NW08-63 User ManualCRIS SEDANTONo ratings yet

- Bs 6724 BasecDocument2 pagesBs 6724 BasecMOHAMMED. HAKAMINo ratings yet

- Configurator Version V8.5.3.3.0 MasterPL Version 7.0.16Document4 pagesConfigurator Version V8.5.3.3.0 MasterPL Version 7.0.16MATHIVANNANNo ratings yet

- Electrical Work Safety GuidelineDocument13 pagesElectrical Work Safety GuidelineMogodan GabrielNo ratings yet

- ASi BUSDocument1 pageASi BUSLuis AguilarNo ratings yet

- Flexible Ac Transmission SystemsDocument2 pagesFlexible Ac Transmission Systemskannanchammy0% (1)

- The Simple Z Match Tuner SimplifiedDocument6 pagesThe Simple Z Match Tuner Simplifiedioan biscaNo ratings yet

- Autoclave Service ReportDocument1 pageAutoclave Service ReportKarl MamarilNo ratings yet

- 8437SBTET (C09) DEEE 4th Sem - Ac Machines-I PDFDocument3 pages8437SBTET (C09) DEEE 4th Sem - Ac Machines-I PDFRAJ NAYAAK0% (1)

- Yaesu DMU-2000 ServDocument21 pagesYaesu DMU-2000 ServlarsNo ratings yet

- GL PMG 3500 Vertical Specification SheetDocument1 pageGL PMG 3500 Vertical Specification SheetAamir Sohail100% (1)

- PICAXE-08 Controls Security Lights Based on PIR and LDR SensorsDocument3 pagesPICAXE-08 Controls Security Lights Based on PIR and LDR SensorsEduardo MoyaNo ratings yet

- Vibration Switches IMI Sensors PDFDocument8 pagesVibration Switches IMI Sensors PDFGinanjar Nur KurniawanNo ratings yet

- Site-Uri Cu Scheme Electron IceDocument4 pagesSite-Uri Cu Scheme Electron IceFlorinela EnceanuNo ratings yet

- Quasar Kit No. 1138 0-30 VDC Stabilized Power Supply With Current CONTROL 0.002-3 ADocument7 pagesQuasar Kit No. 1138 0-30 VDC Stabilized Power Supply With Current CONTROL 0.002-3 AIordan Dan FfnNo ratings yet

- User Manual: Upower SeriesDocument28 pagesUser Manual: Upower SeriesRogerio OliveiraNo ratings yet

- CM 03 XDocument5 pagesCM 03 Xfrancisval20100% (1)

- FET Biasing Configurations and Circuit AnalysisDocument9 pagesFET Biasing Configurations and Circuit AnalysisjjeongdongieeNo ratings yet

- TSDM - 08-01-15Document229 pagesTSDM - 08-01-15HamOdy SadeqNo ratings yet