Professional Documents

Culture Documents

Method Statement of Waterway Surge Shaft Sinking

Uploaded by

Joseph NguyenOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Method Statement of Waterway Surge Shaft Sinking

Uploaded by

Joseph NguyenCopyright:

Available Formats

Trung Hieu Construction Joint Stock Company

Nam Long 2 hydropower project

METHOD STATEMENT

FOR

SURGE SHAFT SINKING

Waterway Excavation Method statement for surge shaft sinking

Trung Hieu Construction Joint Stock Company

Nam Long 2 hydropower project

CONTENT

METHOD STATEMENT FOR SURGE SHAFT Page

SINKING

1. General 3

2. Scope of Work 3

3. Reference Documents 3

4. Materials 4

5. Major Equipment and Tools 4

6. Work Procedure 4

7. Ventilation 13

8. Illumination/Lighting 13

9. Dewatering 14

10. Quality Assurance 14

11. Monitoring 14

12. Health and Safety 15

13. Environmental Management 19

14. Appendix 22

Location of Surge Shaft

Reference Design Drawings

Typical Excavation Profiles for

Surge Shaft Sinking

Typical Drilling Pattern

Typical Rock Bolt Installation

Sedimentation Tank Drawing and

Details

Work Procedure Diagram

Inspection and Test Plan

Waterway Excavation Method statement for surge shaft sinking

Trung Hieu Construction Joint Stock Company

Nam Long 2 hydropower project

Method Statement

For

Surge Shaft Sinking

1. General

Part of the underground waterways of the Nam L o n g 2 Project, is the excavation of a

shaft, the Surge shaft. The surge shaft is situated on the end of the headrace tunnel. Its vertical

axis (ST) is 72.44 meters from the axis of the headrace tunnel (MT). The surge shaft will

dissipate pressure transients in the tunnel during start-up and load rejection operation of the

power station.

2. Scope of Work

The scope of work will be:

a. Rock excavation of the surge shaft.

b. Installation of necessary ground support to excavation

c. Concrete lining and grouting of the shaft excavation

d. Installation of related civil structures and mechanical equipment

e. Associated ventilation and lighting work.

3. Reference Documents

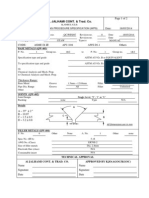

Document No : TH-NL2-DD-WW-01

Description : Detailed Design of Waterway

Document No. : TH-NL2-SM-QCP-01

Description : Quality Control Plan

Document No : TH-NL2-SM-EHS-01

Description : Construction Enviromental Health Safety Plan

Document No : TH-NL2-MS-SvC-01

Description : Method statement of Survey for construction

4. Major Materials and Supplies

Item Description Use

1 Steel Ribs HEB 200 Support from Portal

2 Rock bolt , Friction Type Rock support as applicable

3 Cement Shotcrete and concrete production

4 Sand Shotcrete and concrete production

5 Coarse Aggregate Shotcrete and concrete production

6 Steel Wire mesh Rock Support

7 Admixtures Shotcrete and concrete Admixture

8 NONEL Long Period Delay Blasting

Detonators

Waterway Excavation Method statement for surge shaft sinking

Trung Hieu Construction Joint Stock Company

Nam Long 2 hydropower project

Item Description Use

9 Emulsion dynamites 3 2 mm Ø x 300 Blasting

mm.

10 Emulsion dynamite 25 mm Ø x 200 Blasting (smooth blasting)

mm.

11 Electric Detonator Blast Initiation

12 Blasting Wire Blast Initiation

5. Major Equipment and Tools

Item Description No. Activity

1 Drill machine 2 Drilling and rock bolting

2 Air Compressor. 2 Compressed air supply

3 Generator 1 Electrical power supply

4 Breaker. 2 Scaling and Trimming

5 Hydraulic excavator 2 Mucking

6 Wheel Loader 2 Mucking

7 Dump Truck 4 Spoil Disposal

8 Shotcreting machine 2 Shotcrete application

9 Concrete Mixer Truck 4 Shotcrete/Concrete Delivery

10 Boring Machine 2 Pilot Raise Boring

11 Ventilation Fan 4 Ventilation

12 Concrete Pump 2 Concreting

13 Accelerator Dosing pump 3 Shotcrete Application

14 Friction Bolt Pump 4 Rockbolting

15 Blasting Machine 6 Blasting

16 Scaffold set 1 Various shaft works

17 Hoist and accessories 1 Hoisting and lowering

18 Pick up 4x4 1 Service car

6. Work Procedure

6.1. Preparation

Prior to starting the excavation and construction work, the necessary plant, equipment,

materials and supplies needed to start the works will be at the site. The necessary temporary

facilities will be laid out on site, proximate to the work area as possible.

Waterway Excavation Method statement for surge shaft sinking

Trung Hieu Construction Joint Stock Company

Nam Long 2 hydropower project

6.2. Survey and Setting out

The shaft location, centerline and alignment, and elevation will be established by survey, in

accordance with the design as indicated in the layout plan and typical cross sections of the

reference drawings.

6.3. Shaft Excavation and Construction

Construction of the shafts will be done in two stages. The first stage will be the drilling of a

pilot bore, and the second stage will be the widening of the pilot bore to the designed

excavation limit and casting the concrete lining. The pilot bore will have a final diameter of

1.5 meter.

Prior to pilot hole drilling starting, the open excavation will be done at elevation 684.00 m to

prepare the staging area and platform for the shaft excavation.

The first segment from 684.00m to 682.50m, the shaft is large and shadow, so an use excavator

like the open excavation methods.

The second segment from 682.50m to 673.00m, the shaft sinked in to soil, the sinking method

will like the figures bellow:

Fabriate the frame, leng 3m, radial 2.95m like bellow:

Exavation:

Waterway Excavation Method statement for surge shaft sinking

Trung Hieu Construction Joint Stock Company

Nam Long 2 hydropower project

Waterway Excavation Method statement for surge shaft sinking

Trung Hieu Construction Joint Stock Company

Nam Long 2 hydropower project

Installation of reinforcement frame:

Waterway Excavation Method statement for surge shaft sinking

Trung Hieu Construction Joint Stock Company

Nam Long 2 hydropower project

Waterway Excavation Method statement for surge shaft sinking

Trung Hieu Construction Joint Stock Company

Nam Long 2 hydropower project

Corollary to this activity, the excavation of the shaft bottom from the Headrace tunnel will be

done.

Waterway Excavation Method statement for surge shaft sinking

Trung Hieu Construction Joint Stock Company

Nam Long 2 hydropower project

6.3.1. Pilot Hole

Preparation

Work will involve the ground preparation and excavation work and the provision of

the necessary facilities for the pilot bore drlling.

The digging of headrace tunel from the position of the surge shaft bottom to the

Adit 2 will becomplete.

Waterway Excavation Method statement for surge shaft sinking

Trung Hieu Construction Joint Stock Company

Nam Long 2 hydropower project

Survey and Setting out

Survey to set out and mark location, centerline, and elevation of the pilot bore,after

which the boring machine will be set. The pilot bore will be set along the axis of

the shaft.

Survey will establish prior to drilling pilot hole.

Drilling of Pilot Hole

Drilling of the pilot hole will be done until breakthrough with the designed shaft

bottom excavation.

Cuttings from the pilot hole will be mucked out from the shaft top using manual and

hoist with bucket that will load the spoil to weel loader for transport to designated

disposal areas.

Waterway Excavation Method statement for surge shaft sinking

Trung Hieu Construction Joint Stock Company

Nam Long 2 hydropower project

6.3.2. Shaft Collaring

The s h a f t will be widened to the designed construction limits to a depth of 11

meters. After the initial excavation, collaring of the shaft will be done by applying the

designed support system. Suitable hoisting equipment, and related accessories will be

installed to transport machinery, equipment, supplies and personnel from the shaft

collar to the work area.

After advancing 11 meters, the sinking platform will be installed to facilitate the work

of the shaft construction.

The alternative access for workers, shaft elevators will also be established and

installed.

Typical Supply Arrangement for Surge Shaft Excavation

6.3.3. Excavation

The pilot hole will then be widened starting from the top and progressing downward.

Main excavation will be by drill and blast method.

The depth of each drilling round will be in the range of 1.5 m. to 2.0 m. The explosives

charge will be limited to ensure that the pilot hole is not deteriorated or damaged by

the blasting operations. Another consideration in the design of the blasting pattern,

type of explosives, and explosives charge will be the fragmentation after the blast to

avoid “choking” of the pilot hole. The pilot hole will serve as “free face” for the

blastingoperation.

Explosives charging and detonation will be carried out only by competent and

authorized personnel.

After blasting, the shaft will be defumed for at least 20 minutes before work will be

allowed to resume.

Waterway Excavation Method statement for surge shaft sinking

Trung Hieu Construction Joint Stock Company

Nam Long 2 hydropower project

6.3.4. Mucking

After each blast, broken rock is expected to drop to the shaft bottom through the pilot

hole. The remaining spoil from the blasted area will be mucked to the p i l o t using

a manual. When mucking at the shaft excavation is completed, the pilot hole will be

covered with a grizzly, and mucking at the shaft bottom will commence.

The spoil at the bottom of the shaft will then be loaded by a wheeled loader into dump

trucks that will transport the spoil to the spoil area through the access adit.

Waterway Excavation Method statement for surge shaft sinking

Trung Hieu Construction Joint Stock Company

Nam Long 2 hydropower project

Mucking by Wheel loader at Shaft Bottom

6.3.5. Trimming and Scaling

After each blast, trimming and scaling will be done by breaker to scale loose rocks

resulting from the blast, and to remove any under breaks to attain the designed

excavation limit.

6.3.6. Primary Support Installation

Shotcrete (First Layer)

Once the excavation profiles are checked, an initial layer of shotcrete will be applied

on the newly excavated walls of the shaft. The initial layer will be 3 – 5 cm. thick.

Shotcrete application will be done by a shotcrete machine. To ensure the correct

thickness of shotcrete is attained, thickness guides will be installed in a 2 m. grid

pattern.

Waterway Excavation Method statement for surge shaft sinking

Trung Hieu Construction Joint Stock Company

Nam Long 2 hydropower project

Rockbolting and Wiremesh Installation

After the first layer of shotcrete is applied, drilling for rockbolts will be done. Rockbolt

patterns and densities will be in accordance with the reference design and construction

drawings. The rockbolt patterns and density may increase or decrease according to the

actual ground conditions as determined by the geologist or geotechnical engineer.

After drilling the holes for the rockbolts, theywill be flushed to remove sludge or drill

cuttings remaining inside the hole.

When required, the wiremesh will be laid out along the shotcreted surface. The

wiremesh will be fastened to the surface by steel pins to ensure the wiremesh is flush

on the surface. Rockbolts will then be installed to further anchor the wiremesh to the

surface.

Drilling for Rockbolts

Waterway Excavation Method statement for surge shaft sinking

Trung Hieu Construction Joint Stock Company

Nam Long 2 hydropower project

Rockbolt Installation using Shaft Sinking Platform

Shotcrete (Final Layer)

Once the rockbolts and wiremesh are installed, a final layer of shotcrete will be

applied. The thickness of the final layer will be 3 – 4 cm. or as determined by the

geologist or geotechnical engineer. Again, thickness guides will be installed on a 2

meter grid pattern to ensure that the correct thickness of shotcrete is applied.

Shotcreting will be done by a robotic shotcrete machine.

The procedures will be repeated until excavation of the shaft is completed.

Waterway Excavation Method statement for surge shaft sinking

Trung Hieu Construction Joint Stock Company

Nam Long 2 hydropower project

6.4. Concrete Lining

6.5. Grouting

Once the concrete has cured adequately and attained the required strength, grouting through

cast in pipes will be done.

Contact and consolidation grouting will be done according to the predetermined patterns. If

additional locations are required for grouting, these shall immediately be done.

7. Ventilation

An adequate ventilation system will be set-up. Axial fans will be used and fresh air will be

conveyed to the working face by flexible ducting. Since mobile diesel equipment will be used in

the shaft excavation, the ventilation system will provide a minimum of 50 l/s/hp according to

the relevant ST/MT. Gasoline powered or stationary diesel equipment will not be used inside the

shaft.

Air quality determination will be done at the start of the work shift/s and after blasting, to check

the concentration of noxious gases, before starting or resuming work.

8. Illumination/Lighting

As the shaft excavation progresses, lighting will be provided at the advancing shaft bottom and

transit area as specified in the ST/MT. Mobile/movable spotlights, with minimum 40 lux

illumination, will be used in the working area, so that they can be easily positioned, transferred

or removed during blasting. In the transit area, fixed lighting with minimum of 10 lux illumination

will be installed. The lighting will be installed along the perimeter of the shaft and spacing will

be every 2 meters. Spacing between lighting rings will be maintained at 5 meters. Fixed lighting

will be maintained 20 meters away from the advancing face.

Waterway Excavation Method statement for surge shaft sinking

Trung Hieu Construction Joint Stock Company

Nam Long 2 hydropower project

9. Dewatering

Water from the shaft excavation activities will be drained thru the pilot raise bore down to the

access adit. The drainage ditches and channels at the access adit will receive the water from the

shaft and convey to the drainage system at the platform area.

The discharge water will finally be conveyed by the drainage system to a sedimentation tank, to

allow settling of silt and mud before further discharge of the water into natural drainagesystems.

The sedimentation tank will be regularly cleaned to ensure it’s functionality.

10. Quality Assurance

Before and during the execution of works, materials testing will be performed by either on-site or

off site laboratories, in Lao PDR, as approved by the Employer’s Representative. Standard

specifications and test methods will be in accordance with that described in therelevant ST or

MT. Other specifications and test methods shall be approved and accepted by the Employer’s

Representative on site before use.

To ensure that the works are done in accordance with the relevant S T and M T , an Interim

Test Plan covering the all phases or work procedures (Appendix)

11. Monitoring

The integrity of the shaft during construction will be regularly monitored on short term and

long term basis.

Short Term Monitoring Systems:

1. Geological mapping and geotechnical data collection after excavation shall be done to

ascertain and confirm the support system to be applied. The geologic data shall be

interpreted and analyzed by the geologist and geotechnical engineer to be able to

project the expected ground conditions for the next excavation round/s. or cycles.

2. During drilling for blasting and rockbolting, cuttings and sludge from drilling shall

be observed to obtain information on the geology and rock type immediately after

the face at certain length, and at the walls. If water ingress is encountered, flow rate

shall be determined, and if necessary, pilot holes shall be drilled, to probe deeper

into the rock face. Length of the pilot holes, diameter, etc. shall be determined by the

geologist or geotechnical engineer. Excavation methods and procedures may be

modified according to the results or findings of this procedure.

3. The applied shotcrete support shall be regularly checked for cracks and other abnormal

conditions. Once these are observed, the appropriate measures to reinforceor repair the

shotcrete shall be done immediately.

4. Probe holing drilling – When bad ground is expected or projected to be encountered,

the geotechnical engineer or geologist will require probe hole drilling to confirm the

geology condition and extent ahead of the advancing shaft bottom. The length and

diameter of the probe hole will be determined by the geologist or geotechnical

engineer and will be done before advancing the shaft. The results of the probe hole

drilling will dictate any changes in methodology, support system, or preparatory works

(consolidation grouting) in the shaft excavation.

5. Quality control of the works shall be done strictly following the Inspection and Test

Plan. (Appendix 13)

Waterway Excavation Method statement for surge shaft sinking

Trung Hieu Construction Joint Stock Company

Nam Long 2 hydropower project

Long Term Monitoring Systems:

Long term monitoring systems shall consist of procedures that are programmed to be

periodically done to monitor the tunnel integrity during and after the construction phase.

Convergence Monitoring

Convergence monitoring stations (5 points) will be established at intervals of 20

meters, one (1) week after excavation has passed. The monitoring stations shall be

established by Tunnel profiler, a computer aided, state of the art survey instrument.

No prisms, pins, steel rods are required for this, since the instrument has the software

and can be programmed to automatically locate the convergence points, and make

observation readings.

The frequency of the monitoring will depend on the geology of the rock that is

excavated and supported or as advised by the geologist or geotechnical engineer. If

the monitoring shows movement, all measures shall be taken to reinforce the support

systems at the particular location.

12. Health and Safety

a. Shaft Safety

Excavation

1. Excavation will be done only within the boundaries of the profiles as set out and

marked by survey in accordance with the layout, plans, and sections in the reference

design and construction drawings.

2. Effort shall be taken to minimize or eliminate over break and over-excavation.When

blasting is employed, the explosives charge schedule and powder factor shall be

strictly followed. Explosives charging shall be properly supervised and executed only

by authorized and experienced personnel. Prior to firing, the round shall be thoroughly

checked by the Blaster. During blasting, all entrances and access to the blast area shall

be barricaded or cordoned off and guarded.

3. All excavation done, either by blasting or hydraulic breaker, will be supported within

12 hours from the time of the blasting or excavation, to prevent deterioration or

weathering of the rock when exposed to air. An initial layer of shotcrete, 3 -5 cm. shall

be applied to cover the newly exposed rock resulting from blasting or mechanical

excavation.

4. The excavations shall be regularly mapped by the geologist or geotechnical engineer

to determine the type of rock, rock quality, geology, and other geotechnical

information required, to be able to assess the type of support needed.

5. Before starting any work at the shaft excavation, the raise bore shall be covered with

a removable grizzly or similar device to prevent workers, materials, or small

equipment from falling into it.

6. Electrical equipment and machinery to be used in the tunnel shall be properly

grounded, and electrical components provided with the protection required. Only

authorized personnel shall be allowed to repair or work on the electrical components.

7. Lighting will be provided at the tunnel face, the minimum illumination shall be 100

lux. These shall be properly mounted on stands that can be easily moved around and

positioned as required at the working face. The lighting fixtures shall be waterproof

and maximum voltage for the fixtures shall be 240 volts.

8. Transit areas shall likewise be provided with lighting fixtures, and minimum

illumination to be provided shall be 40 lux. The lighting fixtures shall be waterproof

Waterway Excavation Method statement for surge shaft sinking

Trung Hieu Construction Joint Stock Company

Nam Long 2 hydropower project

and shall have a maximum voltage of 240 volts.

9. An alternative access for workers (shaft elevator, manway ladder or stairway) shall

be provided.

10. When working above the shaft bottom, for repair or miscellaneous jobs, workers

shall be equipped with the necessary safety harness and safety ropes.

Hoisting Equipment and Accessories

1. The hoisting equipment capacity shall be equivalent to heaviest load to be hoisted plus

a safety factor of 20 percent. Hoisting equipment shall provided with the following

safety devices:

a. Emergency stop switch

b. Over travel tripping device

c. Upper limit and lower limit tripping device

d. Cable slack tripping device

e. Indicator for location of sinking platform along the length of the shaft

f. Signal system

g. Communication system with the hoist operator

2. Hoisting equipment shall be operated only by qualified and competent personnel.

The hoist operator shall be subjected to medical and psychometric tests every 6 months

to confirm fitness for the job. Signal men shall be provided on the sinking platform to

control the sinking platform and communicate with the hoist operator either directly

or by signals. The signal men shall also be subjected to medical and psychometric tests

to confirm fitness for the job.

3. After installation and commissioning, before the actual use of the hoisting equipment

for shaft excavation, a load test shall be performed to check and confirm the load

bearing capacity of the hoist and its accessories.

4. Cables shall be non-rotating steel wire rope, the diameter and number of strands shall

be dependent on the required load capacity of the cable.

5. Cables shall be securely fastened to hoist drum and the cable properly wrapped in

layers. No overlapping of the cable wrapping shall be tolerated. Once overlapping in

the wrapping is observed, re-wrapping of the cable shall be immediately done.

6. Hoist inspection and servicing shall be done weekly. The emergency tripping devices

of the hoist shall be checked for functionality and serviced. Controls, electrical and

hydraulic system, and the braking system of the hoist shall also be checked and

serviced.

7. Cable inspection and servicing shall also be done weekly. The cable shall be cleaned

and the wire strands of the cable wire rope inspected at regular intervals to check for

broken wire strands. If broken wire strands are observed, the corresponding course

of action to correct the situation shall be done as determined by the mechanical

engineer. Elongation of the cable shall also be checked. If re-wrapping of the cable to

the hoist drum is required due to elongation, it shall be done.

8. The hoist shall never be operated and the sinking platform or equipment for hoisting

or lowering in the shaft moved in an upward or downward motion unless the hoist

operator confirms signals and communication given by the signal man.

9. During the lowering of equipment or supplies, the appropriate lifting equipment shall

be used. Cable slings shall be of the appropriate size and number of legs shall at all

times be four (4). Mobile equipment shall be properly lifted at the lifting points

provided on the equipment. Cable slings shall be checked before each used of its

integrity. If broken wire strands on each or any of the legs are observed, the sling shall

Waterway Excavation Method statement for surge shaft sinking

Trung Hieu Construction Joint Stock Company

Nam Long 2 hydropower project

be discarded and replaced.

10. Once the sinking platform or equipment being hoisted or lowered are in motion, an

audible warning sign shall be triggered to warn workers, and to stay clear of its path

and the shaft bottom.

11. All personnel riding in the sinking platform shall be equipped with harness and lanyard

fastened to the sinking platform.

Communications

Communication from the shaft bottom or anywhere along the shaft to the surface,

(shaft collar platform, and hoist room) shall be done by suitable communication means

or equipment for the purpose. The communication equipment will be installed atstrategic

intervals so that communication from the shaft to the surface (shaft collar area and hoist

room) is maintained at all times. The communication equipment shall be laid out along

the shaft ladder or stairway, and the shaft bottom.

b. Support Systems:

1. Rock bolt pattern and density will be installed in accordance with the typical plans,

layout, and sections of the reference design and construction drawings.

2. The geologist or geotechnical shall evaluate all geologic and geotechnicalinformation

of the excavated area, and shall decide on the support system to be applied based on

actual ground conditions (either the increase or decrease in rockbolt density and

spacing between rockbolts, installation of wiremesh, use of steel ribs, increase in

shotcrete thickness). The geologist shall inform the site engineer of his evaluation and

recommendations regarding the support system. The site engineer and foremen shall

ensure that the required support measures are applied.

3. When grouted rockbolts are employed, the whole length of the bolts shall be fully

grouted. Grouting material shall be in accordance with the relevant DTS/GTS. Pre-

grouting of the rock bolts shall be the preferred method. When friction bolts (Swellex)

are used, the bolts shall be installed according to the manufacturer’sprocedure and

recommendations. The correct air and water pressure shall be appliedto ensure that the

friction bolt expands completely and creates the required anchorage of the rock.

4. All rockbolts face plates, conical washers, hemispherical nuts, lock nuts, and stick-

out, shall be covered with shotcrete.

5. Shotcrete quality shall be regularly checked by QC procedures. Application procedure

shall be in accordance with sound construction practice. Thickness guides shall be

installed to ensure that the correct thickness of shotcrete is applied. Water ingress will

be isolated and the rock surface to be sprayed, cleaned of loose rock fragments, soil,

debris, etc.

c. Power, Compressed air, and Water supply systems

Power distribution lines, compressed air and water delivery pipes shall be properly laid out

arranged in the tunnel.

Power supply and distribution system

The power lines shall be laid out separately from the air and water pipes and the necessary air

circuit breakers (ACB) provided to automatically cut off power supply when abnormalities

are detected. Electrically operated equipment and machinery shall be provided with circuit

breakers and shall be properly grounded. Only authorized personnel shall be allowed to work

on repairs or maintenance of the power lines and equipment.

Waterway Excavation Method statement for surge shaft sinking

Trung Hieu Construction Joint Stock Company

Nam Long 2 hydropower project

Power cables will be properly laid out and cable trays, hangers, racks provided and shall be

securely fastened.

Compressed air and water distribution system

Air receiver tanks will be installed after the compressors prior to distribution to regulate the

pressure in the delivery pipeline. The receiver shall be equipped with the necessary pressure

release valves, pressure gauges, and drain valves. A main valve shall be installed after the air

receiver tank to control or shut off compressed air supply in cases of repair or emergency.

Isolation gate valves shall be installed at intervals of 50 meters also for repair and emergency

purposes.

Concrete Delivery Pipes

Concrete delivery pipes will be laid out along the shaft and securely fastened to walls. The

pipes shall be cleaned after use.

d. Personnel Safety

The safety of the workers shall be guaranteed at all times.

Access to the Shaft Excavation Works

Access to the surge shaft excavation area shall be restricted to authorized personnel only. A

fence shall be constructed along the perimeter of the construction site and the area classified

as ENTRY BY PERMIT ONLY. Authorized workers and personnel shall be issued

Tunnel/Shaft Entry Pass or ID cards. Persons or workers without entry pass shall not be

allowed entry into the construction site.

Training and Information

All personnel who will be assigned in the tunnel and related work shall undergo safety

orientation before being allowed to work in the tunnel. Aside from this, tunnel workers shall

be required to undergo the Basic First Aid training course (Red Cross Standard) during the

duration of their employ. They shall also be required to attend refresher courses to be

scheduled by the Safety department.

Safety reminders in English and Lao language, shall be installed at strategic locations to

keep the workers informed and remind them of safety rules, regulations, and procedures.

Safety warning signs shall be installed whenever there is a hazard identified. All actions shall

be taken to correct and eliminate the hazard at the soonest possible time.

Personal Protective Equipment (PPE)

All personnel assigned in the tunnels shall be provided with the basic safety protective

equipment. These shall consist of but are not limited to the following:

Safety Helmet (approved for underground use) – for head protection

Dust mask or respirator – for respiratory protection

Ear plugs - for noise protection

Rubber Boots – foot protection

Safety gloves - hand protection

Safety goggles – eye protection

Safety Harness and Lanyard – fall protection

Waterway Excavation Method statement for surge shaft sinking

Trung Hieu Construction Joint Stock Company

Nam Long 2 hydropower project

When the nature of work requires additional PPE, these shall be identified and provided to

ensure worker protection and welfare.

Worker compliance in the use of the PPE shall be ensured by the Site supervisors, foremen,

in coordination with the safety personnel.

Air Quality and Ventilation

The minimum ventilation requirement of 300 l/s/m² shall be maintained at all times. Air

quality tests shall be done at the start of the work shift and after blasting.

After blasting operations, the blast area shall be defumed and air quality determination done

before allowing work to resume.

In cases where the ventilation system has stopped, work inside the tunnel shall be suspended

and the workers evacuated to the portal until such that time that the ventilation system has

been re-started and the work area ventilated for at least 20 minutes. No one shall be allowed

to work in the tunnel without proper ventilation.

e. Emergency Response Procedures

The emergency response plans and procedures as set forth in the Site Safety Plan shall be

strictly implemented. Information dissemination shall be done and incorporated in the safety

induction program.

A First aid station complete with a First Aid box containing essential medicine, equipment,

medical supplies, shall be maintained at the platform area for administering first aid in case

of accidents. The first aid station shall be regularly checked for supplies and equipment and

provision or replenishment done. A telephone or suitable communication equipment shall be

provided at the first aid station. The first aid station shall be manned by qualified and trained

first personnel.

All other safety measures as stated in the Site Safety Plan will be implemented and compliance

will be ensured.

13. Environmental Management

The Contractor’s Environmental Monitoring and Management Plan (EMMP) and the Site

Specific Environmental Plans (SSEP) will be strictly followed and complied with to ensure

mitigation of any impact the work may have on the environment.

Clearing and Grubbing

Once the open excavation and platform is completed, no additional clearing or grubbing is

necessary for the duration of the works.

Water from Tunnel Excavation

The discharge water from the tunnel shall be isolated and diverted to the drainage network at the

platform area. The discharge water from the shaft excavation shall be diverted or pumped if

necessary, to pilot raise bore. From the pilot raise bore, the water shall be conveyed to the

access adit platform drainage systems through the drainage channels in the access adit. At the

access adit platform area, a sedimentation tank shall be constructed or provided, where silt,

mud, and other impurities will be allowed to settle, before the water is discharged to natural

drainage systems.

Waterway Excavation Method statement for surge shaft sinking

Trung Hieu Construction Joint Stock Company

Nam Long 2 hydropower project

Dust Generated during Blasting and Mucking

Dust generated during blasting shall be dissipated from the tunnel by means of the ventilation

system. Broken rock resulting from the blast shall be sprayed with water to eliminate dust

generation during mucking.

Hazardous Materials (HAZMAT)

Storage and Handling

Hazardous materials (oil, fuel, lubricants, explosives etc.) shall be stored in designated areas

that are fenced out and provided with containment structures or facilities in case of accidental

spill. The storage areas shall be clearly marked out and fenced off.

The necessary spill response kits and equipment shall be made available. Handling of these

materials shall be in accordance with the manufacturer’s recommendations.

Explosives shall be stored in magazines provided with adequate ventilation and lighting to

prevent premature deterioration of the explosives and explosives accessories. Detonators shall

be stored separately from explosives. The explosives magazines shall be fenced off and

secure, with access limited to authorized personnel. Earth barricades shall be proved around

the magazines, and when necessary, lightning arresters will be installed. The necessary fire

fighting equipment shall be provided for each magazine. The magazines shall be regularly

checked and inspected. Brushing around the perimeter of the magazines shall also be done.

Disposal

Hazardous materials shall be disposed of according to the procedures stated in the EMMP.

Temporary storage for waste shall be established to accommodate these materials until a

permanent disposal area is designated. The temporary storage shall be provided with the

necessary facilities to prevent contamination of the environment.

Non- Hazardous Materials

Storage and Handling

Non-hazardous materials shall be stored according to the manufacturer’s recommendations.

Accidental spills shall be immediately treated and cleaned up according to procedures

recommended by the manufacturer. Storage areas will likewise be fenced out and clearly

marked out.

Disposal

Disposal of these materials shall be in accordance with the manufacturer’s recommendation

and procedures as set forth in the EMMP and SSEP.

Garbage Generated

All temporary facilities (workshops, offices, lunch rooms) shall be provided with garbage

receptacles to receive garbage generated from these facilities. Garbage will be collected

regularly and will be disposed in designated disposal areas and procedures as stated in the

EMMP and SSEP.

Toilets

Toilets shall be provided at strategic locations within the platform area. The toilets shall be

provided with a septic tank and continuous supply of water. The toilets shall be maintained

for cleanliness and sanitation.

Spoil Disposal Areas

Waterway Excavation Method statement for surge shaft sinking

Trung Hieu Construction Joint Stock Company

Nam Long 2 hydropower project

Slopes of spoil disposal areas shall be maintained less than the determined angle of repose

of the material to ensure stability. Coffer dams along the boundaries of the spoil disposal areas

shall be constructed to ensure that the accumulated spoil is not washed away into natural

drainage systems during heavy rains. Drainage shall be properly maintained to avoidsaturation

of the spoil material during rains and the necessary silt traps or ponds constructed along the

drainage or discharge channels into natural drainage systems. The disposal areas shall be

monitored regularly so that they are filled only to the designed capacity.

All other environmental plans and procedures as stated in the EMMP and SSEP shall be strictly

complied with to mitigate any impact of the construction activity on the environment.

Waterway Excavation Method statement for surge shaft sinking

Trung Hieu Construction Joint Stock Company

Nam Long 2 hydropower project

APPENDIX

1. Location Surge shaft

2. Reference Design Drawings

3. Typical Excavation Profiles for Surge Shaft Excavation

4. Typical Drilling Pattern

5. Typical Rockbolt Installation

6. Sedimentation Tank Drawing and Details

7. Work Procedure Diagram

8. Inspection and Test Plan

Waterway Excavation Method statement for surge shaft sinking

Trung Hieu Construction Joint Stock Company

Nam Long 2 hydropower project

Appendix 1

LOCATION OF

SURGE SHAFT

Waterway Excavation Method statement for surge shaft sinking

Trung Hieu Construction Joint Stock Company

Nam Long 2 hydropower project

LOCATION SURGE SHAFT

Waterway Excavation Method statement for surge shaft sinking

Trung Hieu Construction Joint Stock Company

Nam Long 2 hydropower project

Appendix 2

REFERENCE DESIGN DRAWINGS

Waterway Excavation Method statement for surge shaft sinking

Trung Hieu Construction Joint Stock Company

Nam Long 2 hydropower project

Appendix 3

Typical Excavation Profiles for Surge Shaft Excavation

Waterway Excavation Method statement for surge shaft sinking

Trung Hieu Construction Joint Stock Company

Nam Long 2 hydropower project

Appendix 4

TYPICAL DRILLING PATTERN

Waterway Excavation Method statement for surge shaft sinking

Trung Hieu Construction Joint Stock Company

Nam Long 2 hydropower project

Typical Drilling Pattern of pilot hole

Waterway Excavation Method statement for surge shaft sinking

Trung Hieu Construction Joint Stock Company

Nam Long 2 hydropower project

Appendix 5

TYPICAL ROCKBOLT INSTALLATION

Waterway Excavation Method statement for surge shaft sinking

Trung Hieu Construction Joint Stock Company

Nam Long 2 hydropower project

Waterway Excavation Method statement for surge shaft sinking

Trung Hieu Construction Joint Stock Company

Nam Long 2 hydropower project

Appendix 6

SEDIMENTATION TANK DRAWING AND DETAILS

Waterway Excavation Method statement for surge shaft sinking

Trung Hieu Construction Joint Stock Company

Nam Long 2 hydropower project

Appendix 7

Work Procedure Diagram

For Surge Shaft Excavation

Waterway Excavation Method statement for surge shaft sinking

Trung Hieu Construction Joint Stock Company

Nam Long 2 hydropower project

Work Procedure Diagram

Stage 1: P i l o t H o l e S i n k i n g

Survey and setting out

Defuming

Mucking

Scaling and Trimming

Temporary reinforcement by steel

frame

Widening of pilot hole

Waterway Excavation Method statement for surge shaft sinking

Trung Hieu Construction Joint Stock Company

Nam Long 2 hydropower project

Work Cycle Chart

Stage 2: Widening of Pilot Hole using the Drill and Blast Excavation

Survey and setting out

Excavation by

Drill and Blast

Defuming

Mucking

Scaling and Trimming

Shotcrete

(First Layer)

Rockbolting and Wiremesh

Installation

Shotcrete

(Final Layer)

Repeat Cycle

Concrete lining and Grouting

Waterway Excavation Method statement for surge shaft sinking

Trung Hieu Construction Joint Stock Company

Nam Long 2 hydropower project

Appendix 8

INSPECTION AND TEST PLAN

Waterway Excavation Method statement for surge shaft sinking

Trung Hieu Construction Joint Stock Company

Nam Long 2 hydropower project

Waterway Excavation Method statement for surge shaft sinking

Trung Hieu Construction Joint Stock Company

Nam Long 2 hydropower project

Waterway Excavation Method statement for surge shaft sinking

You might also like

- Multiframe AutomationDocument148 pagesMultiframe AutomationPoowadol NiyomkaNo ratings yet

- Tunnel ConstructionDocument171 pagesTunnel ConstructionBhaskar Reddy94% (16)

- Design of Tunnel Support: January 1996Document23 pagesDesign of Tunnel Support: January 1996edisNo ratings yet

- Plating Process Flow DiagramDocument4 pagesPlating Process Flow DiagramManu SharmaNo ratings yet

- Method Statement FOR Construction of Diaphragm Walls (With BAUER BC Trench Cutter System)Document24 pagesMethod Statement FOR Construction of Diaphragm Walls (With BAUER BC Trench Cutter System)sagar badheNo ratings yet

- Method Statement For GroutingDocument2 pagesMethod Statement For GroutingDEBASIS BARMAN100% (1)

- GEMINI II Operating Instructions 06-235975-001 Print 5127 2014-05-08Document120 pagesGEMINI II Operating Instructions 06-235975-001 Print 5127 2014-05-08Nattapong Natt100% (1)

- Residential Development Diaphragm Wall WorkDocument41 pagesResidential Development Diaphragm Wall Workjodemode100% (2)

- Shaft Sinking For All Ground Conditions: A World Leader in Groundbreaking Tunnelling TechnologyDocument2 pagesShaft Sinking For All Ground Conditions: A World Leader in Groundbreaking Tunnelling TechnologyasepdayatNo ratings yet

- Rock Blasting - A Practical Treatise On The Means Employed In Blasting Rocks For Industrial PurposesFrom EverandRock Blasting - A Practical Treatise On The Means Employed In Blasting Rocks For Industrial PurposesNo ratings yet

- Secant Pile Works Technical Specifications - Rev0Document16 pagesSecant Pile Works Technical Specifications - Rev0Sundar Kandasamy100% (1)

- Diaphragm Wall, Checklist For Site ConstructionDocument1 pageDiaphragm Wall, Checklist For Site ConstructionKOMAL JOSHI75% (4)

- WPS GTAW pipe welding procedureDocument2 pagesWPS GTAW pipe welding procedureRichard PeriyanayagamNo ratings yet

- Method Statement For Installation of Soil Nails With For Slope StabilizationDocument11 pagesMethod Statement For Installation of Soil Nails With For Slope StabilizationDelon Yau100% (2)

- TE2 - 11 MayDocument182 pagesTE2 - 11 MayPTchongNo ratings yet

- Rock ExcavationDocument9 pagesRock ExcavationMohammad Hadoumi SaldanNo ratings yet

- Grouting and Shaft SinkingDocument16 pagesGrouting and Shaft SinkingAnonymous ntE0hG2TPNo ratings yet

- Method Statement Geo Technical Investigation: 1. PurposeDocument7 pagesMethod Statement Geo Technical Investigation: 1. PurposeJ. Kumar Infraprojects LtdNo ratings yet

- Method Statement For Bored PilesDocument18 pagesMethod Statement For Bored PilesKaushalye Mahanama Dissanayake100% (3)

- Method Statement For 1st Construction Years Weir Foundation ExcavationDocument19 pagesMethod Statement For 1st Construction Years Weir Foundation ExcavationJoseph NguyenNo ratings yet

- Grouting Methods and Applications in Tunnel ConstructionDocument11 pagesGrouting Methods and Applications in Tunnel Constructionpurple agmjNo ratings yet

- Method Statement For Diversion Tunnel WorksDocument39 pagesMethod Statement For Diversion Tunnel WorksLutfi Geo100% (3)

- Groundwater Control For Cross PassagesDocument6 pagesGroundwater Control For Cross PassageskrainajackaNo ratings yet

- Pile Instalation Methods 2Document9 pagesPile Instalation Methods 2Bright MuzaNo ratings yet

- Tunnel ConstructionDocument32 pagesTunnel Constructionabhay100% (2)

- Hot Tap Check ListDocument4 pagesHot Tap Check Listborisortiz100% (1)

- 2013 Microtunneling ReviewDocument36 pages2013 Microtunneling ReviewEWheelerFK0% (1)

- Design of Rock Bolting Systems For Underground ExcavationsDocument275 pagesDesign of Rock Bolting Systems For Underground ExcavationsMax Tapia CastilloNo ratings yet

- Method Statement For Grouting Sonic Tubes of Bored PilesDocument16 pagesMethod Statement For Grouting Sonic Tubes of Bored PilesYay B. Gico67% (3)

- RFP Uttarkashi PDFDocument173 pagesRFP Uttarkashi PDFRayees AhmadNo ratings yet

- Tunnel Support Systems ClassificationDocument31 pagesTunnel Support Systems Classificationsarvannn100% (1)

- Shotcrete Support Load CalculationsDocument6 pagesShotcrete Support Load Calculationsanon_160157252No ratings yet

- SEM NATM Design and ContractingDocument5 pagesSEM NATM Design and Contractingapi-3714473100% (2)

- Step by Step License and Risk Management GuideDocument14 pagesStep by Step License and Risk Management GuideamjadonlineNo ratings yet

- Edited Excavation, Shoring, Dewatering & Construction MsDocument6 pagesEdited Excavation, Shoring, Dewatering & Construction MsArun Chandra Babu100% (1)

- New Austrian Method Used Design of Soft-Ground Tunnels For Washington MetroDocument4 pagesNew Austrian Method Used Design of Soft-Ground Tunnels For Washington MetroJothimanikkam SomasundaramNo ratings yet

- As Per The Work Plan and The Relevant Contract Provisions, The Deployment of Tentative Equipment Exclusively For Tunnel Work Is As Per Given BelowDocument9 pagesAs Per The Work Plan and The Relevant Contract Provisions, The Deployment of Tentative Equipment Exclusively For Tunnel Work Is As Per Given BelowjitendraNo ratings yet

- Method Statement For Tunnel ExcavationDocument26 pagesMethod Statement For Tunnel ExcavationAnshul KushwahaNo ratings yet

- IH-NTCO-X-04-252501-A0 - Method Statement For Surge Shaft ExcavationDocument49 pagesIH-NTCO-X-04-252501-A0 - Method Statement For Surge Shaft Excavationapi-3827616100% (7)

- WTC 2020 - Full Paper 1 (ACI 533) - 402 - FinalDocument6 pagesWTC 2020 - Full Paper 1 (ACI 533) - 402 - FinalMehdi BakhshiNo ratings yet

- MRT Safety Controls for Adjacent DevelopmentDocument7 pagesMRT Safety Controls for Adjacent DevelopmentTuntun TatNo ratings yet

- Method Statement - TBM SimpleDocument29 pagesMethod Statement - TBM SimpleMazhar BasaNo ratings yet

- Practical Guide To Rock Tunneling by Dean BroxDocument266 pagesPractical Guide To Rock Tunneling by Dean BroxVassilis PentheroudakisNo ratings yet

- Problem Set Mock Exam - CHE PDFDocument11 pagesProblem Set Mock Exam - CHE PDFBenzene100% (1)

- Rock Anchor MethodologyDocument9 pagesRock Anchor Methodologykaleswara_tellakulaNo ratings yet

- Pre-Excavation Grouting in Rock TunellingDocument140 pagesPre-Excavation Grouting in Rock Tunellingmandeepgeology100% (1)

- Design of Rock Bolt and Shotcrete Support of TunnelDocument10 pagesDesign of Rock Bolt and Shotcrete Support of TunnelScott DownsNo ratings yet

- GroutingDocument31 pagesGroutingranendra sarmaNo ratings yet

- NATM Siddharth PatelDocument38 pagesNATM Siddharth PatelSiddharth PatelNo ratings yet

- Doctoral Thesis - D&B in TunnelsDocument73 pagesDoctoral Thesis - D&B in TunnelskiranismNo ratings yet

- Tunneling On Soft Soils PDFDocument12 pagesTunneling On Soft Soils PDFGourab MandalNo ratings yet

- Tunnels and Suport SystemsDocument33 pagesTunnels and Suport SystemsShella Marie Nartatez-NiroNo ratings yet

- 05 Microtunneling Machines 22Document13 pages05 Microtunneling Machines 22Madalina Nitu100% (1)

- Recommendations for TBM excavationDocument4 pagesRecommendations for TBM excavationRohit SharmaNo ratings yet

- NATM Course ContentDocument7 pagesNATM Course ContentRaul PozoNo ratings yet

- NATMDocument24 pagesNATMningshaNo ratings yet

- 02 Chemical Grouting ShirlawDocument24 pages02 Chemical Grouting ShirlawTerwabe Wapagovski100% (1)

- GT9R6A1 - 1998 - Watertightness of Precast Concrete Lining Segments PDFDocument8 pagesGT9R6A1 - 1998 - Watertightness of Precast Concrete Lining Segments PDFOmar ElioNo ratings yet

- Rockbolting: Principles and ApplicationsFrom EverandRockbolting: Principles and ApplicationsRating: 5 out of 5 stars5/5 (1)

- Unit 8 TunnelsDocument11 pagesUnit 8 TunnelsEashan AdilNo ratings yet

- Ground Freezing 1980: Selected Papers from the Second International Symposium on Ground Freezing, Trondheim, Norway, 24-26 June 1980From EverandGround Freezing 1980: Selected Papers from the Second International Symposium on Ground Freezing, Trondheim, Norway, 24-26 June 1980No ratings yet

- Rock Cut Slope Design - June 2013Document22 pagesRock Cut Slope Design - June 2013latineb100% (1)

- TBM-Challenges-in-the-Himalayas Squeezing Ground Conditions (Carter, 2011) PDFDocument20 pagesTBM-Challenges-in-the-Himalayas Squeezing Ground Conditions (Carter, 2011) PDFOnur İnalNo ratings yet

- TunnelingDocument18 pagesTunnelingmihretabNo ratings yet

- New Austrian Tunneling Method (NATM) in Himalayan Geology: Emphasis On Execution Cycle MethodologyDocument14 pagesNew Austrian Tunneling Method (NATM) in Himalayan Geology: Emphasis On Execution Cycle Methodologydiana cristina arias aldana100% (1)

- MoM Meeting PSG - ADC - LJHC-TH - ETBDocument3 pagesMoM Meeting PSG - ADC - LJHC-TH - ETBJoseph NguyenNo ratings yet

- NM2-SCI-DA-3-GRO-MS-0012-A-PRL - CMS For Curtain Grouting For Main Dam Foundation - Stage 1Document16 pagesNM2-SCI-DA-3-GRO-MS-0012-A-PRL - CMS For Curtain Grouting For Main Dam Foundation - Stage 1Joseph NguyenNo ratings yet

- H K H P C P: Ouay Aouane Ydropower Roject Onstruction HaseDocument14 pagesH K H P C P: Ouay Aouane Ydropower Roject Onstruction HaseJoseph NguyenNo ratings yet

- MoM Commitment Meeting PSG - ADC - LJHC-TH - ETB - RevisedDocument6 pagesMoM Commitment Meeting PSG - ADC - LJHC-TH - ETB - RevisedJoseph NguyenNo ratings yet

- Mom Commitment Meeting PSG - Adc - LJHC-TH - EtbDocument6 pagesMom Commitment Meeting PSG - Adc - LJHC-TH - EtbJoseph NguyenNo ratings yet

- CONSTRUCTION DRAWING EXPLANATIONDocument5 pagesCONSTRUCTION DRAWING EXPLANATIONJoseph NguyenNo ratings yet

- Volume 2.2.1 Calculation Report For NL2 WeirsDocument66 pagesVolume 2.2.1 Calculation Report For NL2 WeirsJoseph NguyenNo ratings yet

- SAND DISCHARGE CULVERT EROSION ISSUEDocument7 pagesSAND DISCHARGE CULVERT EROSION ISSUEJoseph NguyenNo ratings yet

- NL2 Construction Quality Management Plan SubmissionDocument57 pagesNL2 Construction Quality Management Plan SubmissionJoseph NguyenNo ratings yet

- Shop Drawing Water Ways-Tunneling Drawing Code: TH-NL2-SD-WW-MT-DG-01Document77 pagesShop Drawing Water Ways-Tunneling Drawing Code: TH-NL2-SD-WW-MT-DG-01Joseph NguyenNo ratings yet

- Preliminary 12.03.2019: Client Global HydroDocument2 pagesPreliminary 12.03.2019: Client Global HydroJoseph NguyenNo ratings yet

- Reinforced Concrete For SpillwayDocument59 pagesReinforced Concrete For SpillwayJoseph NguyenNo ratings yet

- Execution Method For Spillway Hydraulic Surfaces of HKO Main DamDocument29 pagesExecution Method For Spillway Hydraulic Surfaces of HKO Main DamJoseph NguyenNo ratings yet

- Reinforced Concrete of Canal (Draft)Document96 pagesReinforced Concrete of Canal (Draft)Joseph NguyenNo ratings yet

- Method Statement of Tunnels DiggingDocument95 pagesMethod Statement of Tunnels DiggingJoseph NguyenNo ratings yet

- Drawings For NL2 WaterwayDocument57 pagesDrawings For NL2 WaterwayJoseph NguyenNo ratings yet

- Reinforced Concrete For IntakeDocument29 pagesReinforced Concrete For IntakeJoseph NguyenNo ratings yet

- Calculation WaterwayDocument120 pagesCalculation WaterwayJoseph NguyenNo ratings yet

- 4.reinforced Concrete of Surge Tank (Draft)Document15 pages4.reinforced Concrete of Surge Tank (Draft)Joseph NguyenNo ratings yet

- 5 Assessment of LPHPP Dam Safety and Navigation PDFDocument20 pages5 Assessment of LPHPP Dam Safety and Navigation PDFJoseph NguyenNo ratings yet

- Method Statement of HKO Sand Discharge Culvert Bottom ConcreteDocument28 pagesMethod Statement of HKO Sand Discharge Culvert Bottom ConcreteJoseph NguyenNo ratings yet

- Method Statement of Tunnels DiggingDocument95 pagesMethod Statement of Tunnels DiggingJoseph NguyenNo ratings yet

- Execution Method For Spillway Hydraulic Surfaces of HKO Main DamDocument20 pagesExecution Method For Spillway Hydraulic Surfaces of HKO Main DamJoseph NguyenNo ratings yet

- Vol-III - Sec-IV - Civil All Items ONGC Spec FenceDocument4 pagesVol-III - Sec-IV - Civil All Items ONGC Spec FenceKrm ChariNo ratings yet

- Item Description Unit QTY Rate Amount Egp. Egp. Division 2: Site Construction EarthworkDocument15 pagesItem Description Unit QTY Rate Amount Egp. Egp. Division 2: Site Construction EarthworkAmr M. AbdallahNo ratings yet

- Hexadecimal Numeral System ExplainedDocument6 pagesHexadecimal Numeral System ExplainednaufNo ratings yet

- General ISO Geometrical TolerancesDocument2 pagesGeneral ISO Geometrical TolerancesMaheshNo ratings yet

- Lecture 5: Model-Free Control: David SilverDocument43 pagesLecture 5: Model-Free Control: David SilverFawaz PartoNo ratings yet

- Indonesia Digital Landscape 2018Document36 pagesIndonesia Digital Landscape 2018Yanti GintingNo ratings yet

- Series QuestionsDocument5 pagesSeries QuestionsAnushka BijarniaNo ratings yet

- Alcohol Phenol Ether One Shot Bounce BackDocument129 pagesAlcohol Phenol Ether One Shot Bounce BackShivadeep VishwakarmaNo ratings yet

- Evil ZineDocument36 pagesEvil Zinen123v100% (1)

- FRP Technology by WeatherheadDocument20 pagesFRP Technology by WeatherheadSagarNo ratings yet

- Nagios XI Product OverviewDocument2 pagesNagios XI Product Overviewphduycanh0% (1)

- Project Engineer - Mechanical Design (CATIA - CREO) PDFDocument3 pagesProject Engineer - Mechanical Design (CATIA - CREO) PDFsubhrajit.omNo ratings yet

- Install Guideposts DelineatorsDocument4 pagesInstall Guideposts DelineatorsLWF TripNo ratings yet

- Quality in Decentralised MFGDocument15 pagesQuality in Decentralised MFGRahul ChoudhuryNo ratings yet

- Instruction Manual: Please Read Fully Before InstallationDocument16 pagesInstruction Manual: Please Read Fully Before InstallationleonormmapNo ratings yet

- SIPOCDocument7 pagesSIPOCFran JimenezNo ratings yet

- Minimal Transient Switching of CapacitorsDocument7 pagesMinimal Transient Switching of CapacitorsRuben MartinezNo ratings yet

- JVL MacComm OCX FileDocument2 pagesJVL MacComm OCX FileElectromateNo ratings yet

- Ebara Horizontal Multistage PumpDocument27 pagesEbara Horizontal Multistage PumpYohanes KrisNo ratings yet

- Introduction To Chemical Kinetics: CHEM 102 T. HughbanksDocument16 pagesIntroduction To Chemical Kinetics: CHEM 102 T. HughbanksKarthikNo ratings yet

- Vietnam - Introduce Tekla Open APIDocument34 pagesVietnam - Introduce Tekla Open API김성곤No ratings yet

- S7ConnectionTypes PDFDocument100 pagesS7ConnectionTypes PDFcarlos ortizNo ratings yet

- An Overview On Performance of Steel Slag in Highway IndustryDocument12 pagesAn Overview On Performance of Steel Slag in Highway Industrybkollarou9632No ratings yet