Professional Documents

Culture Documents

Gewindebolzen m36 English Stand 130308

Uploaded by

Jiangchang QiaoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Gewindebolzen m36 English Stand 130308

Uploaded by

Jiangchang QiaoCopyright:

Available Formats

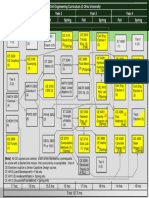

NOTES: THREADED BAR M 36 M1:5

- THREADED BARS, HEXAGON NUTS AND WASHERS

MUST BE FROM ONE SET OF THE SAME MANUFACTURER !! THREADED BAR M36 - 8.8 ISO 898-1

- ANCHOR BARS SHALL HAVE A MINIMUM LENGTH OF L > 2m WITH HEXAGON-NUT ISO 4032 - M36 - FKL 8

BETWEEN UPPER AND LOWER ANCHOR PLATE !!

- INCLINED OR HORIZONTAL ANCHOR BARS HAVE TO BE

AND WASHER ISO 7089 - 36 - 300 HV

PROTECTED FROM TRANSVERSE LOADS WITH APPROPRIATE PRE-STRESSING FORCE P = 350 KN

MEASURES (CALIBERS AND INTERMEDIATE SUPPORTS).

HOT-DIP-GALVANIZED ISO 10684

CONCRETE GRADE MIN. C30/37

EXCESS-LENGTH AND HEIGHT OF STEEL CAP HAVE

TEMPLATE T=8 SHALL BE CONNECTED TO ANCHOR-BARS

USING HEXAGON NUTS ON BOTH SIDES (AND BE CONNECTED

TO THE FORMWORK IF POSSIBLE)

INSTALL STEEL CAP AND GASKET ON ANCHOR PLATE USING

TO BE DEFINED INDIVIDUALLY.

M8 5.6 AND FILL CAP WITH CORROSION PROTECTION COMPOUND > 100 160

BOLT TENSIONING DEVICE / JACK MADE BY AS TECH

TYPE HWS16112006 (ø94 x 120mm) OR SIMILAR

25 10

85

PLEASE NOTE:

CIRCULAR ANCHOR PLATE ø160 x 45 WITH BOREHOLE ø37

105

105

CORROSION PROTECTION COMPOUND

BASE PLATE A x B x T WITH BOREHOLES ø80mm TOP OF DENSO-TAPE

45

LUBRICATED ON THE UNDERSIDE

T

ø80

AFTER INSTALLATION AND ADJUSTMENT OF STEEL

STRUCTURE FILL GAP BELOW BASEPLATE (D > 50mm) TOP OF FOUNDATION

D

WITH NON-SHRINK POURABLE MORTAR OR PAGEL

(MIN. C60/75). COMPLETE VENTING OF GAP MUST BE

ENSURED BY MEANS OF APPROPRIATE MEASURES.

SURFACE OF ANCHOR BAR SHALL BE WRAPPED WITH

2 LAYERS OF COLD PROCESSIBLE WAX-VASELINE TAPE

MADE OF ROT-RESISTANT SYNTHETIC FLEECE

(E.G. DENSO-TEC OR SIMILAR)

180

ADD. REINF.

50

50

HELICAL REINFORCEMENT 5 x ø12 BST 500S

BOTTOM OF DENSO-TAPE

50

50

LOWER ANCHOR PLATE 150 x 150 x 40 WITH BOREHOLE ø37

100

CONNECTED TO EACH OTHER WITH REBAR ø14 BST 500S

TOP OF ANCHOR PLATE

50

40

CONNECT ANCHOR PLATE TO ANCHOR-BARS USING

HEXAGON NUTS ON BOTH SIDES

> 150

BOTTOM OF FOUNDATION

> 260 > 200

1 : 10 11.03.2013

You might also like

- Gewindebolzen m16 English Stand 130308Document1 pageGewindebolzen m16 English Stand 130308Jiangchang QiaoNo ratings yet

- SPANNGLIED WR36 ENGLISCH Stand 130308Document1 pageSPANNGLIED WR36 ENGLISCH Stand 130308Jiangchang QiaoNo ratings yet

- Installation Instructions Tatsuno Dispenser Sump - Generic: 40Fc Sealant x4Document4 pagesInstallation Instructions Tatsuno Dispenser Sump - Generic: 40Fc Sealant x4Camilo CorreaNo ratings yet

- Installation Instructions EL-G-E500 Encore Dispenser: Shear Valve Arrangement in PlanDocument4 pagesInstallation Instructions EL-G-E500 Encore Dispenser: Shear Valve Arrangement in PlanCamilo CorreaNo ratings yet

- Jamesbury 3000Document4 pagesJamesbury 3000jacquesstrappe06No ratings yet

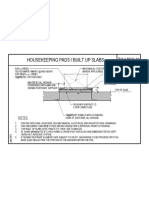

- Housekeeping Pads / Built Up Slabs TC-MISC-01: NotesDocument8 pagesHousekeeping Pads / Built Up Slabs TC-MISC-01: NoteshahaerNo ratings yet

- Industry Shed Joinery DetailsDocument1 pageIndustry Shed Joinery DetailsabhiNo ratings yet

- Sdl317a Welded Mesh FenceDocument1 pageSdl317a Welded Mesh FencekheradiradNo ratings yet

- Grounding Principle 3P-0036CDocument2 pagesGrounding Principle 3P-0036CAsif Majeed MalikNo ratings yet

- 2.l.t.protection KitDocument1 page2.l.t.protection KitsanjuNo ratings yet

- 2.l.t.protection KitDocument1 page2.l.t.protection KitSSK IndustriesNo ratings yet

- Demco Butterfly Valves BrochureDocument44 pagesDemco Butterfly Valves BrochureSai PrasathNo ratings yet

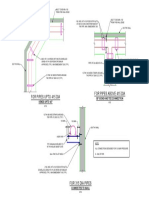

- Details Sample 4 Roof Eve PDFDocument1 pageDetails Sample 4 Roof Eve PDFNg TzewayNo ratings yet

- Ce 362 Plate 9Document1 pageCe 362 Plate 9lonyx27No ratings yet

- Hollowcore Slab End Bearing On Wall TP-HOL-01Document17 pagesHollowcore Slab End Bearing On Wall TP-HOL-01hahaerNo ratings yet

- Gate Valve Standard FeaturesDocument3 pagesGate Valve Standard Featuresعزت عبد المنعمNo ratings yet

- Catalogue K-FonikDocument1 pageCatalogue K-FonikGiang NguyễnNo ratings yet

- Válvulas Jamesbury Buterfly Valve For SteamDocument8 pagesVálvulas Jamesbury Buterfly Valve For SteamFelipe Ribeiro da CostaNo ratings yet

- Serie 600.622Document4 pagesSerie 600.622Bryan STNo ratings yet

- Irla Nala - Top PlanDocument1 pageIrla Nala - Top Plansamir bendreNo ratings yet

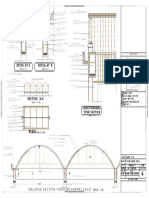

- Sheet 04 Barrel VaultDocument1 pageSheet 04 Barrel VaultSoham SatamNo ratings yet

- Pneumatic Intensifiers Bimba TRD Air To Air IntensifiersDocument2 pagesPneumatic Intensifiers Bimba TRD Air To Air Intensifiersgoen_aedyNo ratings yet

- P2 - 10c OVERDocument1 pageP2 - 10c OVERNhuVan NguyenNo ratings yet

- Poooooooooooooooooole Data SheetDocument1 pagePoooooooooooooooooole Data Sheetfathy.shehabNo ratings yet

- Raised FloorDocument3 pagesRaised FloorSama KhalidNo ratings yet

- Wall Design DavidSchwindDocument23 pagesWall Design DavidSchwindRawan ashrafNo ratings yet

- Bay Sect VillanuevaDocument2 pagesBay Sect VillanuevaRafaela VillanuevaNo ratings yet

- 3-Layer Global Transmission Sleeve: Installation GuideDocument2 pages3-Layer Global Transmission Sleeve: Installation GuideMahmoud TahaNo ratings yet

- Maintenance Stairway: Lockable Gate ForDocument1 pageMaintenance Stairway: Lockable Gate ForTsui DanielNo ratings yet

- UntitledDocument8 pagesUntitledTomas MalyNo ratings yet

- Pipe Strap Support Near Bend - V2Document1 pagePipe Strap Support Near Bend - V2krishnakumarNo ratings yet

- External Wall SecDocument1 pageExternal Wall SecSAHIL JAINNo ratings yet

- Alumina - Service - Valve - BrochureDocument6 pagesAlumina - Service - Valve - BrochureegmbrNo ratings yet

- Installation Collector Replacement Parts Conductor Bar SystemsDocument2 pagesInstallation Collector Replacement Parts Conductor Bar Systemsventas1No ratings yet

- PDF Truss DetailDocument1 pagePDF Truss DetailBikki Cyama100% (1)

- Pipe Strap Support Near Bend - V1Document1 pagePipe Strap Support Near Bend - V1krishnakumarNo ratings yet

- General Notes On Piling Material:: Long Section of PileDocument1 pageGeneral Notes On Piling Material:: Long Section of PileDesign explorer olomizanaNo ratings yet

- DA 2021 35 PATIO WITH STEEL FRAME AND STEEL ROOF 18 Burdett Retreat, MURDOCH WA 6150Document24 pagesDA 2021 35 PATIO WITH STEEL FRAME AND STEEL ROOF 18 Burdett Retreat, MURDOCH WA 6150Amin AminiNo ratings yet

- Fane Colossus 15XB DS030513Document1 pageFane Colossus 15XB DS030513Andrea PaoNo ratings yet

- ALX - 002 - Sheet - X100 - CHILLER PLANT ROOM 1 FOR SYSTEM 1 (STANDBY)Document1 pageALX - 002 - Sheet - X100 - CHILLER PLANT ROOM 1 FOR SYSTEM 1 (STANDBY)Rodhel Mark Julian PalermoNo ratings yet

- ARBUS Sapphire Parts Catalogue PDFDocument161 pagesARBUS Sapphire Parts Catalogue PDFCarlos David Gutiérrez SerranoNo ratings yet

- P - 6c OVERDocument1 pageP - 6c OVERNhuVan NguyenNo ratings yet

- Standard Drawing For Storm Water Drain & Grating Cover - 2Document1 pageStandard Drawing For Storm Water Drain & Grating Cover - 2zohaibimranNo ratings yet

- Flush Bottom ValvesDocument3 pagesFlush Bottom ValvesErkan TakNo ratings yet

- Installation Instructions Dresser Wayne Dispenser Sumps - GenericDocument5 pagesInstallation Instructions Dresser Wayne Dispenser Sumps - GenericCamilo CorreaNo ratings yet

- Ref.: Gil/cms/g3/0591 Date: 31/03/2011Document2 pagesRef.: Gil/cms/g3/0591 Date: 31/03/2011prati121No ratings yet

- Nozzles For Fixed Fire Suppression: Manual No. 104.FFDocument6 pagesNozzles For Fixed Fire Suppression: Manual No. 104.FFManuelMartinezNo ratings yet

- Curtain Wall & Crash Barrier DrawingDocument1 pageCurtain Wall & Crash Barrier DrawingSharun ShajiNo ratings yet

- Lenz 57XLDocument1 pageLenz 57XLclaudioNo ratings yet

- Car Park Shed DrawingDocument1 pageCar Park Shed DrawingNizamuddin AbdullahNo ratings yet

- Ridce de Tail: ToorseDocument4 pagesRidce de Tail: ToorseTriveni TriveniNo ratings yet

- 11 - Butterfly ValvesDocument22 pages11 - Butterfly ValvesLuisNo ratings yet

- FT - Cut List Rev02Document1 pageFT - Cut List Rev02Sergio RezendeNo ratings yet

- 00 AirwolfDocument8 pages00 AirwolfJavier MontalvoNo ratings yet

- Type PD 1 (Ecgd 3) : Cell Grill DoorDocument1 pageType PD 1 (Ecgd 3) : Cell Grill Doorblack_3289100% (1)

- Flexiable Pipe Joints For Class H2Document1 pageFlexiable Pipe Joints For Class H2Denise2512No ratings yet

- Mwangi 3 Bedroom RuaiDocument10 pagesMwangi 3 Bedroom RuaiROBINSON NDERITUNo ratings yet

- 2018-10-29 - MX-5 Spec Miata Front Damper User Manual (Issue)Document2 pages2018-10-29 - MX-5 Spec Miata Front Damper User Manual (Issue)Emanuel VidalNo ratings yet

- Coolnet Pro Data Sheet PDFDocument2 pagesCoolnet Pro Data Sheet PDFNetafim HondurasNo ratings yet

- PF1320 Impact CrusherDocument1 pagePF1320 Impact Crushermartinez gerardoNo ratings yet

- Concrete Estimate ExcelDocument35 pagesConcrete Estimate ExcelFrancis Jan DiscayaNo ratings yet

- AssignmentDocument18 pagesAssignmentBidur KhanalNo ratings yet

- Ayala Triangle Gardens: Roughing Installation (Drop-Off Landscape Lightings)Document6 pagesAyala Triangle Gardens: Roughing Installation (Drop-Off Landscape Lightings)james alfarasNo ratings yet

- Pham and Hancock - Direct Strength Design of Cold-Formed Purlins - 2009Document10 pagesPham and Hancock - Direct Strength Design of Cold-Formed Purlins - 2009Olivia OeyNo ratings yet

- Class F ContractorDocument23 pagesClass F ContractorRachel IngramNo ratings yet

- Wind Load: The IBC - 2012 and ASCE 7 - 10 Provisions: Mithun Pal Civil/Structural EngineerDocument72 pagesWind Load: The IBC - 2012 and ASCE 7 - 10 Provisions: Mithun Pal Civil/Structural EngineerjeanNo ratings yet

- Low Cost Housing (Rabindra)Document21 pagesLow Cost Housing (Rabindra)rabo KumarNo ratings yet

- The Architectural CodeDocument25 pagesThe Architectural CodeChristine Alaiza BalidNo ratings yet

- CONTACTDocument8 pagesCONTACTJhessa Dy PerezNo ratings yet

- Ejercicio 1 Curso BRBDocument2 pagesEjercicio 1 Curso BRBAlex MolinaNo ratings yet

- Industrial Training 12.09Document21 pagesIndustrial Training 12.09Emilyana ZulaikhaNo ratings yet

- Wood Joists PDFDocument27 pagesWood Joists PDFRicaRDONo ratings yet

- Profile Geogabinfra PDFDocument19 pagesProfile Geogabinfra PDFदेवराज सिंह गहरवारNo ratings yet

- Construction Job Safety AnalysisDocument10 pagesConstruction Job Safety AnalysisMata RosemarieNo ratings yet

- 4 - RC ConcreteDocument37 pages4 - RC ConcreteJulia CatherineNo ratings yet

- Methods and Structure of The Cebu CordovDocument20 pagesMethods and Structure of The Cebu CordovRichard Kate RicohermosoNo ratings yet

- CE Flowchart 2020 With Additional InfoDocument1 pageCE Flowchart 2020 With Additional InfoDamonNo ratings yet

- Terminología de Un Open PitDocument25 pagesTerminología de Un Open PitAmilcar Jairo Quiliche AraujoNo ratings yet

- Flier - IAStructE Webinar by MR R J Watson 29.01.2021Document2 pagesFlier - IAStructE Webinar by MR R J Watson 29.01.2021ceapklNo ratings yet

- Design of Flexible Pavement Using Geogrid ReinforcementDocument10 pagesDesign of Flexible Pavement Using Geogrid ReinforcementHarish GRNo ratings yet

- SECTION 07 81 00 Applied FireproofingDocument10 pagesSECTION 07 81 00 Applied FireproofingJuanPaoloYbañezNo ratings yet

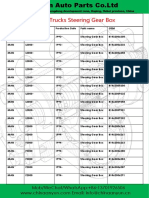

- MAN-Power Steering GearDocument15 pagesMAN-Power Steering Gear李运普No ratings yet

- Project Report: Sleek Powder Paints Address:-Plot No: - 83, MIDC Area, Satpur NashikDocument5 pagesProject Report: Sleek Powder Paints Address:-Plot No: - 83, MIDC Area, Satpur NashikRahul JadhavNo ratings yet

- คู่มือการออกแบบโครงสร้างสะพานพิเศษ (3) part2Document100 pagesคู่มือการออกแบบโครงสร้างสะพานพิเศษ (3) part2Chainun TaidamrongNo ratings yet

- Construction of 132kV Substation in Central Region (Saudi Arabia)Document78 pagesConstruction of 132kV Substation in Central Region (Saudi Arabia)danny targarianNo ratings yet

- Tiles CatalogueDocument106 pagesTiles CataloguereevaxNo ratings yet

- 52 Pac RBTDocument32 pages52 Pac RBTsoutrick BaruiNo ratings yet

- Low Cost Building Material and Techniques - Harshika - ParikshitDocument22 pagesLow Cost Building Material and Techniques - Harshika - ParikshitVinit ShahNo ratings yet

- ProposalDocument36 pagesProposalteck yuNo ratings yet