Professional Documents

Culture Documents

02 - Waste Water Treatment - Disposal For Building Premises

Uploaded by

Glyra RosalemOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

02 - Waste Water Treatment - Disposal For Building Premises

Uploaded by

Glyra RosalemCopyright:

Available Formats

Online Review Specialists – Master Plumber & Master Electrician

(Master Plumber Online Review – Sanitary, Plumbing Design & Installation)

Tributary or Contributing Sewer

Waste Water Treatment & Disposal

for Building & Premises

Public Sewers – common sewer directly controlled by public

authority.

SEWERAGE, SEWERAGE WORKS - a comprehensive term

Classification of Public Sewers: (construction, collection, transportation, pumping treatment and

a. Combination Public Sewer final disposition of sewage)

b. Separate Public Sewer

SEWAGE - the liquid wastes conducted away buildings, and with

Combination Public Sewer such ground surface, and storm water as may be present/any

wastewater containing animal or vegetable matter in suspension

and solution and may include liquids containing chemicals in

solution

SEWER - a pipe or conduit for carrying sewage and waste liquids

MAIN SEWER - (Public Sewer)

PUBLIC SEWER - a common sewer controlled by public authority

DOMESTIC SEWAGE (SANITARY SEWAGE) - liquid/water-borne

wastes free from industrial wastes

SANITARY SEWAGE - human excrement/liquid household waste

Separate Public Sewer (DOMESTIC SEWAGE)

SANITARY SEWER - with or without industrial wastes/ without

and admixture of storm water or ground water

DRAIN - a sewer, pipe or conduit (conveying ground water,

surface water, storm water, wastewater or sewage

DRAINAGE SYSTEM - the drainage pipe of a plumbing system

takes the waste water from the plumbing fixtures and deliver it to

the sewer

INDUSTRIAL WASTE - free from fecal matter

LIQUID WASTE - does not receive fecal matter

Two kinds of Sanitary Sewers

a. Intercepting or Trunk – line Sewer WASTE - (LIQUID WASTE/INDUSTRIAL WASTE)

b. Tributary or Contributing Sewer

WATER TREATMENT - conditions/treats water supply to

Intercepting or Trunk – line sewer improve water quality, remove suspended solids by filtration

Prepared by: Engr. Chrysler G. Duaso, CE, RMP

Online Review Specialists – Master Plumber & Master Electrician

(Master Plumber Online Review – Sanitary, Plumbing Design & Installation)

The household drain may flow straight into a public sewer. If a

blockage occurs anywhere in this private drain, you have sole

responsibility for cleaning any blockages or carrying out any

repairs. Most properties have some length of private drain.

Manholes shall be installed at the end of each line; at all changes

in grade, size, or alignment; at all intersections; and at distances

not greater than 120 meters for sewers 380 mm in diameter or

less and 150 meters for sewers 460 to 760 mm in diameter.

Greater spacing may be permitted in larger sewers.

(e) The minimum diameter of manholes shall be 900 mm; larger

diameters are preferable for large diameter sewers. A minimum

access diameter of 560 mm shall be provided.

Drains from two properties may join together and form a private

sewer, and then run some distance before connecting with the

public sewer. If a blockage or defect occurs at point X in the private

sewer system, the owners of the two properties would be

responsible for rectifying the problem.

This shows how all the drains from a block of houses may link up Waste Water Treatment

before running into a public sewer. In some cases, the drains from Waste Water is defined as water which carries wastes from

an entire estate may join a private sewer system before linking up homes, industries, businesses or any other sources; a mixture of

with the public system, and this could be some considerable water and dissolved or suspended solids. Treatment is necessary

distance. because in the reduction of physical, physiological, radioactive,

biological and chemical pollutants.

Present legislation dictates that the owners or occupiers of homes

above the point of the blockage or defect - whichever properties

effluent flows through that point - are responsible. Therefore, a

blockage at point Y would only involve properties four, five and

six. A blockage at point Z would involve all six properties.

Prepared by: Engr. Chrysler G. Duaso, CE, RMP

Online Review Specialists – Master Plumber & Master Electrician

(Master Plumber Online Review – Sanitary, Plumbing Design & Installation)

Types of Waste Water Treatment Plants Activated Sludge Process:

Depending on the nature of the Waste Water to be treated, Waste 1. Coarse Screen House

Water can be classified as: 2. Grit Chamber

1. Sewage Treatment Plants 3. Fine Screen House

2. Sludge Treatment Plant 4. Mixing Tank or Activated Sludge Tank

3. Industrial Waste Water Treatment 5. Aerating Tanks

4. Agricultural Waste Water Treatment Plant 6. Clarifier Tanks

5. Radioactive Waste Water Treatment Plant 7. Chemical House

6. Recycling Waste Water Treatment Plant 8. Filter House

9. Drier House

10. Warehouse

Preliminary treatment: first step in the treatment process; to

remove materials that are untreatable and separated by physical

means. Screenings and grit removal separate the sand and other

inorganic material harmful to the pumps and other equipment

Primary Treatment: simplest form of wastewater treatment;

involves filtration and settling; 45-50% of pollutants can be

removed utilizing primary techniques.

Sedimentation: process where solids and liquids are separated

by gravitational forces. The thickened solids or sludge settle to the

bottom of the clarifier

Activated Sludge Process:

Removing carbonaceous pollution arrangement

• Aeration tank: air (or oxygen) is injected in the mixed liquor

• Settling tank ("final clarifier" or "secondary settling tank"):

allow the biological flocs (the sludge blanket) to settle, thus

separating the biological sludge from the clear treated water

• Treatment of nitrogenous matter or phosphate involves

additional steps; mixed liquor is left in anoxic condition (no

residual dissolved oxygen)

Prepared by: Engr. Chrysler G. Duaso, CE, RMP

Online Review Specialists – Master Plumber & Master Electrician

(Master Plumber Online Review – Sanitary, Plumbing Design & Installation)

Secondary Treatment mainly involves biological process Advanced or Tertiary Treatment: processes that remove any

(removes 85-90% of remaining pollutants); common types of small amounts of undesirable materials remaining in the treated

secondary treatment are Trickling Filters and Activated Sludge - water. (include filtration, distillation or flocculation to remove

create conditions favorable to the growth and reproduction of suspended particles, organic material and specific chemicals

helpful microorganisms which consume most of the waste (nitrates, phosphates, heavy metals); The level of treatment

material. The microorganisms then settle out of the treated water required prior to discharge to the receiving stream depends on

in the secondary settling tank or clarifier. the quality of the body of water and the types of reuse designated

for the treated water.

Disinfection: final process/step (discharge or release of treated

water); ensures that any disease causing, or pathogenic

microorganisms are killed and that the water released into the

waterway is safe to the environment and humans

Prepared by: Engr. Chrysler G. Duaso, CE, RMP

Online Review Specialists – Master Plumber & Master Electrician

(Master Plumber Online Review – Sanitary, Plumbing Design & Installation)

1. Comminutor or Sewage Cutter

2. Primary Clarifier

3. Aeration Tanks

4. Secondary Clarifier

5. Digester Tank 6. Sludge Drying House and Bed

LEACHING CESSPOOL - a cesspool that is not watertight

PRIVY - outhouse or structure used for the deposition of

excrement

Types of Private Sewage Disposal PRIVY VAULT - a pit beneath a privy in which excrement collects

1. Cesspool

2. Privy

3. Septic Tank

CESSPOOL - a pit for the reception or detention of sewage/non-

watertight lined excavation; permitting liquid to seep through the

bottom and sides of the cesspool

Prepared by: Engr. Chrysler G. Duaso, CE, RMP

Online Review Specialists – Master Plumber & Master Electrician

(Master Plumber Online Review – Sanitary, Plumbing Design & Installation)

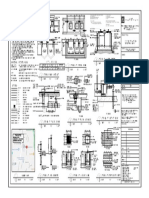

Disposal Field Trench

Sewage Treatment Plant

Septic Tank

Prepared by: Engr. Chrysler G. Duaso, CE, RMP

Online Review Specialists – Master Plumber & Master Electrician

(Master Plumber Online Review – Sanitary, Plumbing Design & Installation)

Sump Pump

❖ Wastewater from the building enters the Screen box (1). Here

coarse air bubbles are used to physically break down solid

matter in the sewage and form a mixed liquor with the water

prior to treatment.

❖ The mixed sewage liquor flows into the Aeration Chamber for

treatment (2). A bacterial culture is present in the Aeration

Chamber which digests the pollutants in the wastewater. The

bacterial culture must have a constant oxygen supply, and this

is provided by a fine bubble diffuser at the base of the tank.

❖ The mixed sewage liquor then flows into the Clarification

Chamber (3) where it can separate into clear, treated effluent

and sludge. The clear effluent can flow past the scum baffle and

out of the tank.

❖ The blower is on a plug-in timer and runs 30 minutes on and

15 minutes off, saving a lot of electricity for the treatment

process. It also allows the blower to cool down.

Sewage Treatment Plant

➢ now being used for large developments in lieu of septic tanks

or municipal sewages

➢ perform the same general function of septic tanks in

decomposing sewage

➢ However, STPs make use of mechanical equipment and usually

consist of 1 large basin

Some Typical features of an STP:

❖ An aeration system within the tank;

❖ A submersible mixer to mix the waste;

❖ A sludge waste pump that aids in clarifying;

❖ A decanter;

❖ Blowers;

❖ A fully electronic control system, etc.

Prepared by: Engr. Chrysler G. Duaso, CE, RMP

Online Review Specialists – Master Plumber & Master Electrician

(Master Plumber Online Review – Sanitary, Plumbing Design & Installation)

The Sludge Management System (SMS) 1. Grit Chamber 2. Coarse screen house

❖ In the Clarification Chamber sewage sludge accumulates at the

bottom (settled sludge) and top (floating sludge) of the 4. Incinerator

tank (1). 3. Fine screen house

❖ Air from the blower is spurred from the air regulator

valves (2) to two sludge return pipes. 5. Activated sludge tank

❖ This creates a vacuüm that sucks the sewage sludge from the

6. Aerating

bottom of the Clarification Chamber back to the Aeration 8. Power House 7. Clarifier outlet

Chamber constantly (3). basin

❖ The valve that removes the floating sludge must be opened 10. Liquid

11. Chemical

9. Drier house

once a month for this sludge to be returned. With all other ASP extractor

house

sewage treatment plants, this sludge has to be removed

manually. 12.Warehouse 13. Vacuum

power

The Trickling Filter Process

o a.k.a ‘Percolating or Sprinkling Filter System’

o Requires fewer mechanical elements and less stages

o Produces water with 95% purity

o Requires a large ground area for its building

Combination Activated Sludge and Trickling Filter System -

makes use of several chambers plus a trickling filter tank

Some STPs consist of several chambers:

➢ Primary

➢ Aeration

➢ Settling

➢ Disinfection

The Activated Sludge Process

o Involves a series of stations where the raw sewage must pass

through

o First Phase- gets rid of heavy materials with the use of three

different filter houses

o Second Phase- clarifies the effluent

o Third Phase- hardens the sludge and converts it to fertilizers

o Produces water with 99-99.5% purity

Prepared by: Engr. Chrysler G. Duaso, CE, RMP

Online Review Specialists – Master Plumber & Master Electrician

(Master Plumber Online Review – Sanitary, Plumbing Design & Installation)

Classes of Sewage Systems – Definition

Class 1- a chemical toilet, an incinerating toilet, a recirculating

toilet, a self-contained portable toilet and all forms of privy

Class 2- grey water system

Class 5- a system which requires or uses a holding tank for the

retention hauled sewage at the site where it is produced prior to

its collection by hauled sewage system

Class 3- a cesspool

Class 4- a leaching bed system including sewage systems utilizing

treatment units

Prepared by: Engr. Chrysler G. Duaso, CE, RMP

Online Review Specialists – Master Plumber & Master Electrician

(Master Plumber Online Review – Sanitary, Plumbing Design & Installation)

Clear Distances

Column 1 Column 2 Column 3 Column 4

Lake, river,

Well with a pond, stream,

Other well, or

water-tight reservoir, or a

Type of a spring used

casing to a spring not

System as a potable

depth of at used as a

water supply

least 6 metres potable water

supply

Class 1

Pit Privy 30 metres 15 metres

15 metres

Privy Vault) 15 metres 10 metres

10 metres

Pail Privy )

Class 2

10 metres 15 metres 15 metres

Leaching Pit

Prepared by: Engr. Chrysler G. Duaso, CE, RMP

You might also like

- Module 11-Private Disposal PDFDocument35 pagesModule 11-Private Disposal PDFonaaaaangNo ratings yet

- Drainage LinesDocument27 pagesDrainage LinesFritzie Sheena ZipaganNo ratings yet

- Master Plumber Refresher 2022 Part 1Document22 pagesMaster Plumber Refresher 2022 Part 1John LopezNo ratings yet

- General Plumbing NotesDocument1 pageGeneral Plumbing NotesKaizer kyle SorianoNo ratings yet

- Plumbing-Code-Refresher With Answer-KeyDocument4 pagesPlumbing-Code-Refresher With Answer-KeyEdna PurisimaNo ratings yet

- Essential Plumbing Refresher for License Exam SuccessDocument242 pagesEssential Plumbing Refresher for License Exam SuccessRoivz TriNo ratings yet

- Tolenada, Realyn A. Bsce 3A: ST NDDocument14 pagesTolenada, Realyn A. Bsce 3A: ST NDJohn Nicko Carlo Castillo100% (1)

- Plumbing ReviewerDocument21 pagesPlumbing ReviewerChica GoghNo ratings yet

- Marvelous Presentation: in Collaboration WithDocument53 pagesMarvelous Presentation: in Collaboration WithAudey PabalateNo ratings yet

- ArithmeticDocument101 pagesArithmeticJysar Reubal0% (1)

- Master Plumber Exam ReviewDocument5 pagesMaster Plumber Exam ReviewRuis Raphael HidalgoNo ratings yet

- Essential Elements of Plumbing SystemsDocument2 pagesEssential Elements of Plumbing SystemsMBA103003No ratings yet

- Feb 2023 Master Plumber Refresher Chemistry 2Document2 pagesFeb 2023 Master Plumber Refresher Chemistry 2Master Jaguar100% (1)

- Plumbing MathematicsDocument17 pagesPlumbing Mathematicsben100% (1)

- MP Coaching Module Answer Key UpdatedDocument29 pagesMP Coaching Module Answer Key Updatedhope lee oiraNo ratings yet

- Sanitary Design & Lay-OutingDocument29 pagesSanitary Design & Lay-OutingJeco BildNo ratings yet

- Jan 2023 Sanitary Engg Refresher 3Document3 pagesJan 2023 Sanitary Engg Refresher 3Master JaguarNo ratings yet

- Plumbing ReviewerDocument17 pagesPlumbing Reviewerادزسر بانديكو هادولهNo ratings yet

- PLUMBING TERMINOLOGY GUIDEDocument15 pagesPLUMBING TERMINOLOGY GUIDEGels GenovaNo ratings yet

- (Introduction) Short Course For PlumbingDocument9 pages(Introduction) Short Course For Plumbingma. rothsheld may bulacanNo ratings yet

- Module 3 Private Water Supply Sources 2Document35 pagesModule 3 Private Water Supply Sources 2ma. rothsheld may bulacanNo ratings yet

- Plumbing Code QuestionsDocument3 pagesPlumbing Code QuestionsJhay DomdomNo ratings yet

- Plumbing design analysis residential BulacanDocument4 pagesPlumbing design analysis residential BulacanZan OjedaNo ratings yet

- Final Plumbing 2Document215 pagesFinal Plumbing 2dizonabigailmaereyesNo ratings yet

- Plumbing Arithmetic Refresher SET A - ANSWER KEYDocument3 pagesPlumbing Arithmetic Refresher SET A - ANSWER KEYJan Lawrence AlbertoNo ratings yet

- Water LinesDocument34 pagesWater LinesJudy Dela PenaNo ratings yet

- Plumbing ReviewerDocument22 pagesPlumbing ReviewerMary Joy Lumacang100% (3)

- Fundamentals of Plumbing DesignDocument60 pagesFundamentals of Plumbing DesignBianca MendozaNo ratings yet

- BUILDING UTILITIES 1 Module 1 Lecture 2 Water Distribution Revised 2020Document75 pagesBUILDING UTILITIES 1 Module 1 Lecture 2 Water Distribution Revised 2020Terence GadilNo ratings yet

- PumpsDocument47 pagesPumpsnyoy yoyNo ratings yet

- Sanitary drainage system design principlesDocument6 pagesSanitary drainage system design principlesJoemarbert YapNo ratings yet

- Plumbing Arithmetic Refresher SET ADocument21 pagesPlumbing Arithmetic Refresher SET AIñigo TorresNo ratings yet

- Types of Trap Commonly Used in Residential FixturesDocument8 pagesTypes of Trap Commonly Used in Residential FixturesKhalid Ali Saif Al-ShamsiNo ratings yet

- Plumbing ReviewerDocument46 pagesPlumbing ReviewerYsabelle Marie FuentesNo ratings yet

- Plumbing Arithmetic Refresher Set B - ANSWER KEYDocument3 pagesPlumbing Arithmetic Refresher Set B - ANSWER KEYJan Lawrence AlbertoNo ratings yet

- Plumber's Exam Secrets Study GuideDocument12 pagesPlumber's Exam Secrets Study GuideDarrel YalaNo ratings yet

- Master Plumber FlashcardsDocument3 pagesMaster Plumber FlashcardsMaryel MarianoNo ratings yet

- Plumbing DetailsDocument1 pagePlumbing DetailsChristine Joyce DayangNo ratings yet

- Philippine-Architecture 4 PDFDocument3 pagesPhilippine-Architecture 4 PDFjanine domeyegNo ratings yet

- Plumbing TablesDocument3 pagesPlumbing TablesLeinad ColladoNo ratings yet

- Plumbing Fixtures PDFDocument58 pagesPlumbing Fixtures PDFNathaniel Lumpas EvangelistaNo ratings yet

- 7 - Water Waste Treatment and Disposal For Building PremisesDocument4 pages7 - Water Waste Treatment and Disposal For Building PremisesEugene MicarandayoNo ratings yet

- Electrical Drawing of School Building E-1Document1 pageElectrical Drawing of School Building E-1shafiq_05No ratings yet

- Applications & Uses of StonesDocument2 pagesApplications & Uses of StonesMuhafeez Goolab100% (1)

- Fundamentals of Water Supply SystemsDocument2 pagesFundamentals of Water Supply SystemsSey SantmoreNo ratings yet

- Plumbing General ConsiderationsDocument28 pagesPlumbing General Considerationsma. rothsheld may bulacanNo ratings yet

- Development of Sources of Water For Rural Residences-MergedDocument191 pagesDevelopment of Sources of Water For Rural Residences-MergedFebz Canutab0% (1)

- Professional PracticePart2 - 081818Document74 pagesProfessional PracticePart2 - 081818RL San100% (1)

- Question Excerpt From National Plumbing Code of The PhilippinesDocument33 pagesQuestion Excerpt From National Plumbing Code of The PhilippinesLorence GabayanNo ratings yet

- Latent Heat and Sprinkler SystemsDocument12 pagesLatent Heat and Sprinkler SystemsJohn JugarapNo ratings yet

- Equivalent Water Supply Fixture UnitsDocument1 pageEquivalent Water Supply Fixture UnitsJoey MelencionNo ratings yet

- Practical Figures (Summary)Document45 pagesPractical Figures (Summary)Jomarie AlcanoNo ratings yet

- P-trap permissible trapDocument3 pagesP-trap permissible trapMaria Elisha Mae CandelariaNo ratings yet

- Sanitary and Plumbing Systems and EquipmentDocument118 pagesSanitary and Plumbing Systems and Equipmentnadeem UddinNo ratings yet

- A Simple Guide To Your Master Plumber Licensure ExaminationDocument17 pagesA Simple Guide To Your Master Plumber Licensure ExaminationAlthara Baldago100% (1)

- MODULE 1. Basic Principles of Sanitary DesignDocument5 pagesMODULE 1. Basic Principles of Sanitary DesignKervin SangalangNo ratings yet

- Basic Principles of Sanitary DesignDocument16 pagesBasic Principles of Sanitary DesignDeniell Kahlil Kyro Gabon100% (2)

- Master Plumber Reviewer: Wastewater TreatmentDocument55 pagesMaster Plumber Reviewer: Wastewater Treatmenthermano balbonNo ratings yet

- Sanitation, Plumbing Design & Installation: B. Wastewater Treatment and Disposal For Building and PremisesDocument47 pagesSanitation, Plumbing Design & Installation: B. Wastewater Treatment and Disposal For Building and Premisesdizonabigailmaereyes100% (1)

- B. Wastewater TreatmentDocument55 pagesB. Wastewater Treatmentelynah mistiola100% (1)

- AHC - AIA Health Cover CertificateDocument1 pageAHC - AIA Health Cover CertificateGlyra RosalemNo ratings yet

- Plate #1Document2 pagesPlate #1Glyra RosalemNo ratings yet

- Design of Piles: Rosalem, Glyra BDocument41 pagesDesign of Piles: Rosalem, Glyra BGlyra RosalemNo ratings yet

- Steel Design Class Agenda - Flexural Member DesignDocument22 pagesSteel Design Class Agenda - Flexural Member DesignGlyra RosalemNo ratings yet

- CE3211 Module One: Introduction to Engineering ProfessionDocument8 pagesCE3211 Module One: Introduction to Engineering ProfessionGlyra RosalemNo ratings yet

- MECE 200 - Advance Engineering Mathematics I - Exam 02Document2 pagesMECE 200 - Advance Engineering Mathematics I - Exam 02Glyra RosalemNo ratings yet

- Loading CalculationDocument13 pagesLoading CalculationGlyra RosalemNo ratings yet

- Introduction To Steel Design: July 12, 2021Document22 pagesIntroduction To Steel Design: July 12, 2021Glyra RosalemNo ratings yet

- Mathematical Formulas GuideDocument7 pagesMathematical Formulas GuideGlyra RosalemNo ratings yet

- Training Progress Sheet: Activity Training Duration DateDocument1 pageTraining Progress Sheet: Activity Training Duration DateGlyra RosalemNo ratings yet

- Design of PilesDocument3 pagesDesign of PilesGlyra RosalemNo ratings yet

- MECE 200 - Advance Engineering Mathematics I - Exam 00Document1 pageMECE 200 - Advance Engineering Mathematics I - Exam 00Glyra RosalemNo ratings yet

- Solution Manual of Advanced Engineering Mathematics by Erwin Kreyszig 9th EditionDocument8 pagesSolution Manual of Advanced Engineering Mathematics by Erwin Kreyszig 9th EditionAnirban Pal33% (3)

- Ateneo de Davao University Civil Engineering Program Course InformationDocument3 pagesAteneo de Davao University Civil Engineering Program Course InformationGlyra RosalemNo ratings yet

- Steel/Timber Design: SY 2021-2022 First SemesterDocument2 pagesSteel/Timber Design: SY 2021-2022 First SemesterGlyra RosalemNo ratings yet

- Ale Reviewer SummaryDocument472 pagesAle Reviewer SummaryFann Menes PortentoNo ratings yet

- CE Steel Timber Design Load CombinationsDocument1 pageCE Steel Timber Design Load CombinationsGlyra RosalemNo ratings yet

- Simplified Approach For The CalculationDocument1 pageSimplified Approach For The CalculationGlyra RosalemNo ratings yet

- FoundationDocument1 pageFoundationGlyra RosalemNo ratings yet

- Simplified Approach For The Calculation PDFDocument1 pageSimplified Approach For The Calculation PDFGlyra RosalemNo ratings yet

- Structural ReferencesDocument2 pagesStructural ReferencesGlyra RosalemNo ratings yet

- Shear Strength of SoilDocument46 pagesShear Strength of SoilGlyra Rosalem100% (1)

- A Review On The Comparative Study of Steel, RCC and Composite BuildingDocument12 pagesA Review On The Comparative Study of Steel, RCC and Composite Buildingdivyashree sureshNo ratings yet

- ASBCDocument1 pageASBCGlyra RosalemNo ratings yet

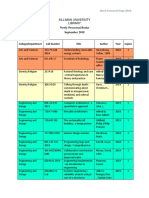

- Newly Processed Books Sept.2019 Final1Document7 pagesNewly Processed Books Sept.2019 Final1Glyra RosalemNo ratings yet

- Foundation Design Using Standard Penetration Test (SPT) N-ValueDocument39 pagesFoundation Design Using Standard Penetration Test (SPT) N-Valueneilmark undagNo ratings yet

- Guangan Bridge Initial ReportDocument9 pagesGuangan Bridge Initial ReportGlyra RosalemNo ratings yet

- Book 1Document5 pagesBook 1Glyra RosalemNo ratings yet

- Mathematical Formulas GuideDocument7 pagesMathematical Formulas GuideGlyra RosalemNo ratings yet

- Characteristics of Wastewater: Environmental Engineering Unit-IDocument124 pagesCharacteristics of Wastewater: Environmental Engineering Unit-IDragos NojeaNo ratings yet

- Amaan Alam SheetsDocument13 pagesAmaan Alam SheetsAmaan Jahangir AlamNo ratings yet

- 8.1 Food Plant Sanitation and Waste ManagementDocument2 pages8.1 Food Plant Sanitation and Waste ManagementjohnSianturi0% (1)

- PR Suez ContractDocument2 pagesPR Suez ContractChintalaRaoNo ratings yet

- Lab Report Exp 1,2,3 (Water)Document12 pagesLab Report Exp 1,2,3 (Water)Fairuz Naim ZNo ratings yet

- Updated List of EMB Recognized PCO Training Organization As of 18 September 2019 PDFDocument3 pagesUpdated List of EMB Recognized PCO Training Organization As of 18 September 2019 PDFJethro QuiritNo ratings yet

- Environmental Guidelines For The Dairy Industry PDFDocument33 pagesEnvironmental Guidelines For The Dairy Industry PDFHafiz SabriNo ratings yet

- Gómez Et Al. - 2021Document11 pagesGómez Et Al. - 2021Juan Caballero FloresNo ratings yet

- Water: Water Pollution in A Densely Populated Megapolis, DhakaDocument13 pagesWater: Water Pollution in A Densely Populated Megapolis, DhakaMd abdul karimNo ratings yet

- Evaluation of Biological Removal Efficiency in A UCT Process Treating Municipal Wastewater During Start-Up StageDocument6 pagesEvaluation of Biological Removal Efficiency in A UCT Process Treating Municipal Wastewater During Start-Up StageRose AdelineNo ratings yet

- MS For Wet TradeDocument11 pagesMS For Wet TradeGary LoNo ratings yet

- Biodiesel Plant EIA SummaryDocument13 pagesBiodiesel Plant EIA SummaryAnonymous DJrec2No ratings yet

- Report of Educational VisitDocument5 pagesReport of Educational VisitHARSHADNo ratings yet

- Wastewater Treatment - RefineryDocument16 pagesWastewater Treatment - RefineryLTE002100% (1)

- Activity 1 CODE - DeCODEhealth CotDocument15 pagesActivity 1 CODE - DeCODEhealth CotLyzl Mahinay Ejercito MontealtoNo ratings yet

- Microbial Applications Vol 1 Bioremediation and Bioenergy PDFDocument335 pagesMicrobial Applications Vol 1 Bioremediation and Bioenergy PDFFernando cisneros prietoNo ratings yet

- Cleaner Engineering and Technology: Morvarid Mohammad Mirzaee, Mehdi Zakerinia, Masoumeh FarasatiDocument10 pagesCleaner Engineering and Technology: Morvarid Mohammad Mirzaee, Mehdi Zakerinia, Masoumeh FarasatiJHONNY REYNALDO CHACALCAJE CHACALIAZANo ratings yet

- Efficiency Study of Increasing Domestic Wastewater Quality Using Zig-Zag AeratorDocument1 pageEfficiency Study of Increasing Domestic Wastewater Quality Using Zig-Zag AeratortetukoNo ratings yet

- Sewage Disposal Systems, Treatments and RecyclingDocument19 pagesSewage Disposal Systems, Treatments and RecyclingMaricel Salazar100% (1)

- Feasibility Study BioreactorDocument3 pagesFeasibility Study Bioreactorरोहित त्रिवेदीNo ratings yet

- 1 Hydro Vision Brochure e WEB QualityDocument24 pages1 Hydro Vision Brochure e WEB QualitysuinsasNo ratings yet

- 202005012116016435ranvijay Pratap Singh Environmental Pollution PDFDocument7 pages202005012116016435ranvijay Pratap Singh Environmental Pollution PDFarunkumar nayakNo ratings yet

- Burberry 2020 Chemical Management Programme UpdateDocument46 pagesBurberry 2020 Chemical Management Programme UpdateAnkita SinhaNo ratings yet

- Community Health NursingDocument25 pagesCommunity Health Nursingjhing_tajul83% (6)

- Condorchem Envidest Desalt BrochureDocument7 pagesCondorchem Envidest Desalt BrochureZobyNo ratings yet

- BS en 01253-1-2015 PDFDocument36 pagesBS en 01253-1-2015 PDFsam100% (1)

- COD Fractionation in Wastewater Characterization—The State of the ArtDocument12 pagesCOD Fractionation in Wastewater Characterization—The State of the ArtAntonio MoralesNo ratings yet

- Study settling velocity sand particles wastewater treatmentDocument6 pagesStudy settling velocity sand particles wastewater treatmentanik suciNo ratings yet

- T PAUL Uni DuE 2014-10-07Document118 pagesT PAUL Uni DuE 2014-10-07Le LuuNo ratings yet

- Role of Microorganisms in Waste Water Treatment FinalDocument12 pagesRole of Microorganisms in Waste Water Treatment FinalAhmad AhmadNo ratings yet