Professional Documents

Culture Documents

H. Lee, G. H. Yun, T. U. Yoo, S. Kim, J. K. Hwang, W. Lee and Z. Yun

Uploaded by

Nguyen AnOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

H. Lee, G. H. Yun, T. U. Yoo, S. Kim, J. K. Hwang, W. Lee and Z. Yun

Uploaded by

Nguyen AnCopyright:

Available Formats

The Strength and Weakness of 4-stage Anoxic

MBR for Biological Nutrient Removal

H. Lee*, G. H. Yun*, T. U. Yoo*, S. Kim*, J. K. Hwang**, W. Lee** and Z. Yun*

* Department of Environmental Engineering, Korea University, Anam-dong, Sungbuk-ku, Seoul, South Korea, 136-701

(E-mail: lhs1351@korea.ac.kr;rmal9292@korea.ac.kr; ub1905ub@korea.ac.kr; envzyun@korea.ac.kr)

** Dongbu Corporation, 891-10, Daechi-dong, Gangnam-gu, Seoul, South Korea, 135-523

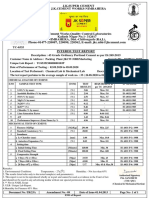

Influent sewage characteristics and operating conditions

dPAO in BNR

Phase 1 Phase 2 Phase 3 Phase 4

Parameters

Nitrified recycle*: 2Q Nitrified recycle: 2Q Nitrified recycle: 1Q Nitrified recycle: 2Q

Denitrification without carbon energy: NO3 as electron donor for

Anoxic recycle**: 1Q Anoxic recycle: 0.5Q Anoxic recycle: 0.5Q Anoxic recycle: 0.3Q

Operating days (d) 121 35 72 69

TSS (mg/L) 70~320 (135) 50~227 (108.5) 43~118 (72.2) 36~127 (91)

denitrification SS

VSS (mg/L) 68~280 (128) 53~227 (104) 35~122 (66.1) 30~108 (79.1)

The use of dPAO is advantageous to weak sewage

TCOD (mg/L) 170~390 (284) 94~454 (242) 102.3~273 (201) 145~349 (255.8)

COD SCOD (mg/L) 40~128 (92.9) 59~115 (86.3) 54~168 (111.2) 61~140.8 (98.4)

Microbial characteristics dPAO in BNR is still unclear Further N

VFA (mg/L)

TN (mg/L) 23~50 (36.1) 25~38 (31.3)

17.0~58.2 (39.8)

25.5~38 (35.9) 27.5~34 (30.8)

NH4-N (mg/L) 12.9~29.2 (22.7) 13.2~24 (19.3) 13.8~26.6 (20.4) 7.5~26.4 (19.5)

scientific investigation is needed P

TP (mg/L) 2.7~5.5 (3.9) 2.8~4.0 (3.3) 1.6~5.1 (3.4) 3.5~5.8 (3.8)

Role of dPAO in BNR-MBR modification was investigated in this PO4-P (mg/L)

SCOD/N/P ratio

1.8~4.4 (3.0)

23.8 : 9.3 : 1

1.2~3.0 (2.8)

26.2 : 9.5 : 1

0.5~3.8 (2.1)

32.7 : 10.6 : 1

1.4~4.3 (2.9)

25.9 : 8.1 : 1

research Influent flow rate (L/d)

MLSS Aerobic MBR 3,280~4,750 (3,940) 2,560~5,320 (4,050)

30

3,280~5,560 (3,870) 4,960~7,570 (5,560)

(mg TSS/L) Anoxic MBR 2,310~3,840 (3,330) 2,950~4,810 (3,850) 3,270~5,140 (4,180) 4,380~7,010 (5,784)

Aerobic MBR 8.9~37.5 (20.6) 5.2~53.8 (24.8) 15.8~32.5 (21.5) 18.5~68 (29.3)

SRT (d)

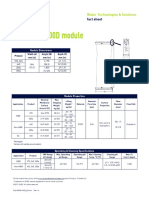

Biological Nutrient Removal (BNR) with Membrane Bio-reactor (MBR) *

Anoxic MBR

Recycle from Ox to 1st AX

9.4~37.5 (23.4) 12.5~40.8 (25.8) 10.5~35.8 (20.6) 20~56.8 (30.2)

Membrane replaces the secondary clarifier to solve the sludge

** Recycle from 2nd AX to AN

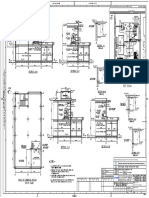

Schematic diagrams of lab reactors

settling problems Submerged

Inf. (30 L/d): Step feed (AN : 2nd AX = 8:2)

BNR-MBR is difficult to achieve high degree of N and P removal, 1.5 hr 1.5 hr 1.5 hr

membrane

3 hr

especially in weak sewage low VFA, high MLSS and long SRT OX-

AN 1st AX 2nd AX Effluent

To maximize the dPAO, examine the anoxic installation of MBR

RAS (0.3~1Q)

membrane in BNR-MBR modification RAS (1~2Q)

(a) Aerobic MBR

Inf. (30 L/d): Step feed (An : 2nd AX = 8:2)

Research Objectives P Effluent

1.5 hr 1.5 hr 1.5 hr 3 hr

Evaluate the strength and weakness of laboratory 4-stage anoxic MBR AN 1st AX 2nd AX Ox

system compared with the aerobic MBR RAS (0.3~1Q)

RAS (1~2Q)

(b) Anoxic MBR (a) Aerobic MBR (b) Anoxic MBR

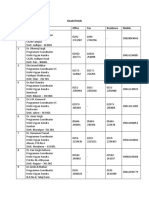

Solids removal and sludge settling characteristics Effluent water quality *Phase 1 (a), Phase 2 (b), Phase 3 (c), Phase 4 (d)

Influent VSS/TSS ratio = 0.85

Effluent TSS conc. close to almost zero because of the membrane separation

500 6 OX sludge

TSS VSS SVI

Sample in aerobic MBR

(mg/L) (mg/L) (mL/g)

OX in aerobic MBR 2,920 2,380 79

OX sludge

COD & SS Aerobic MBR ≈ Anoxic MBR

in % size

400 in anoxic MBR OX in anoxic MBR 2,850 2,300 106 2nd AX sludge

Settling surface (mL)

TN Aerobic MBR (7.1 mg/L) < Anoxic MBR (5.2 mg/L)

2nd AX in anoxic MBR 2,950 2,350 104 in anoxic MBR

of particle

4

300

Mean diameter T P Aerobic MBR (0.5 mg/L) > Anoxic MBR (0.9 mg/L)

Volume

2nd AX sludge

Sample

in anoxic MBR (μm)

Anoxic MBR could contribute to reduce DON conc. of effluent

% Volume

200 Aerobic MBR 150.8

2

The effect on the recycle ratio

Anoxic MBR 94.7 *Nitrified recycle (a) and anoxic recycle (b) in anoxic

100 MBR, and nitrified recycle (c) and anoxic recycle (d) in

OX sludge

in aerobic MBR

anoxic MBR

0 0

0 5 10 15 20 25 30 0.01 0.1 1 10 100 1000

Time (min) Particle Diameter (μm)

(a) Settling characteristics (b) Particle size distribution

Effect of sludge settling characteristics on

MBR was evaluated:

1) Sludge settleability

SVI value: Aerobic MBR (79 mL/g) > Anoxic

MBR (106 mL/g)

Initial settling velocity: OX sludge in aerobic

MBR > OX sludge in anoxic MBR

2) Particle size distribution

Anoxic sludge tend to form smaller

particles (mean ø = 94.7 µm) than the oxic

sludge (mean ø = 150.8 µm)

3) Flux

Aerobic MBR (36.9 L/m2/h) > Anoxic MBR

(29.9 L/m2/h)

Membrane in anoxic zone showed lower

For both systems:

avg. flux

Nitrified recycle ratio Effluent TN conc.

Anoxic recycle ratio Effluent TP conc.

The strengths of the anoxic MBR in BNR system

1. Lower TN concentration in effluent (The anoxic MBR: 5.2 mg/L vs. The aerobic MBR: 7.1 mg/L)

2. Effective carbon utilization (2.46 g SCOD/g N+P)

The weaknesses of the anoxic MBR in BNR system

1. Relatively higher P concentration in effluent (The anoxic MBR: 0.9 mg/L vs. The aerobic MBR: 0.5 mg/L)

2. Lower sludge settleability with lower permeability of membrane

You might also like

- Transistor Electronics: Use of Semiconductor Components in Switching OperationsFrom EverandTransistor Electronics: Use of Semiconductor Components in Switching OperationsRating: 1 out of 5 stars1/5 (1)

- ZB 1 PDFDocument1 pageZB 1 PDFputodosNo ratings yet

- Inductively Coupled Plasma-Mass Spectrometry: Practices and TechniquesFrom EverandInductively Coupled Plasma-Mass Spectrometry: Practices and TechniquesNo ratings yet

- Spectrum Report: Sample InfoDocument4 pagesSpectrum Report: Sample InfoEngineering Ked SolutionNo ratings yet

- Elastomers and Rubber Compounding MaterialsFrom EverandElastomers and Rubber Compounding MaterialsI FrantaRating: 4.5 out of 5 stars4.5/5 (3)

- Corrosion Resistant Coatings Utilizing Hydrophobic NanoparticlesDocument29 pagesCorrosion Resistant Coatings Utilizing Hydrophobic NanoparticlesSteve SandersNo ratings yet

- Opc JK Super MTC (4) 25.02.2024Document1 pageOpc JK Super MTC (4) 25.02.2024msconstu2No ratings yet

- Corrosion Resistant Coatings Utilizing Hydrophobic NanoparticlesDocument21 pagesCorrosion Resistant Coatings Utilizing Hydrophobic NanoparticlesSteve SandersNo ratings yet

- Jcb-Def Dealer Guide 2015 - FinalDocument8 pagesJcb-Def Dealer Guide 2015 - FinalIan WoodsNo ratings yet

- (W 14) JK 53 Opc MTC - 2022Document1 page(W 14) JK 53 Opc MTC - 2022Niranjan KumarNo ratings yet

- JK 43 Opc Test CertificateDocument1 pageJK 43 Opc Test CertificateRavi kumar100% (1)

- Septic Tank Data Sheet PDFDocument2 pagesSeptic Tank Data Sheet PDFAditya JainNo ratings yet

- Knerr ID Number 179 Korr HaDocument4 pagesKnerr ID Number 179 Korr HaMark Darryl Mansay DeloriaNo ratings yet

- NWMP Jan 2022Document1 pageNWMP Jan 2022Praneeth GSNo ratings yet

- General Arrangement Drawing For Radar Level Transmitter (NMR81)Document1 pageGeneral Arrangement Drawing For Radar Level Transmitter (NMR81)pankajNo ratings yet

- Fact Sheet - Moduł Ultrafiltracyjny FSpw500D-MOD - ENDocument1 pageFact Sheet - Moduł Ultrafiltracyjny FSpw500D-MOD - ENdownloads1945No ratings yet

- Materials Results SheetDocument1 pageMaterials Results SheetGolam MasudNo ratings yet

- Laboratory Tests ON Soil Samples: 1 Renuka ConsultantsDocument3 pagesLaboratory Tests ON Soil Samples: 1 Renuka Consultants8108295484No ratings yet

- Battery Recycling Datasheet: AccurecDocument1 pageBattery Recycling Datasheet: AccurecMacarena DiazNo ratings yet

- Aaqm Feb 2022Document8 pagesAaqm Feb 2022Shannu AdityaNo ratings yet

- 2.excellent Top Kraft - MM KartonDocument2 pages2.excellent Top Kraft - MM KartonMark Sebastian MitranNo ratings yet

- Pea GravelDocument1 pagePea GravelATC SurveyNo ratings yet

- Nitrogen Removal in Wastewater Stabilisation Ponds: B. Picot, T. Andrianarison, D.P. Olijnyk, F. BrissaudDocument21 pagesNitrogen Removal in Wastewater Stabilisation Ponds: B. Picot, T. Andrianarison, D.P. Olijnyk, F. BrissaudSaul LopezNo ratings yet

- Perfomance Status Cetp April 2016Document32 pagesPerfomance Status Cetp April 2016Rahul ParmarNo ratings yet

- NWMP Feb 2022Document1 pageNWMP Feb 2022Praneeth GSNo ratings yet

- Additional TestDocument10 pagesAdditional TestUmesh MishraNo ratings yet

- Naval BrassDocument1 pageNaval BrassAugusto Gabriel Flores ManzanedaNo ratings yet

- Technical Specification PTP Ennore Part2-2024-02!19!06!07!41Document239 pagesTechnical Specification PTP Ennore Part2-2024-02!19!06!07!41trilokNo ratings yet

- Licensed To Arun Kumar Das: Methodsfor Chemical An-Alysisofcastironand. Pig IronDocument6 pagesLicensed To Arun Kumar Das: Methodsfor Chemical An-Alysisofcastironand. Pig IronIndira MukherjeeNo ratings yet

- 1 Yield Strength Should Be The Lower Yield Point R. If It Is Not Distinct Then Choose The 0.2 % - Yield Strength RDocument3 pages1 Yield Strength Should Be The Lower Yield Point R. If It Is Not Distinct Then Choose The 0.2 % - Yield Strength RmusheerNo ratings yet

- Aa - Mindray BS-120 BS-200 Bs200e-Cldl PDFDocument1 pageAa - Mindray BS-120 BS-200 Bs200e-Cldl PDFFlorelia VazquezNo ratings yet

- Multifunctional Nanocoating On Synthetic Fibres Deposited by Pulsed Magnetron SputteringDocument1 pageMultifunctional Nanocoating On Synthetic Fibres Deposited by Pulsed Magnetron SputteringSemana de Engenharia '2010No ratings yet

- NEw HX Catalogue ScannedDocument6 pagesNEw HX Catalogue ScannedArun PrakashNo ratings yet

- JK White Cement Opc 53 19 2016Document1 pageJK White Cement Opc 53 19 2016Rishav MishraNo ratings yet

- Murugappa Morgan Thermal Ceramics LTD: Test CertificateDocument1 pageMurugappa Morgan Thermal Ceramics LTD: Test CertificateEngineersEDGE CoimbatoreNo ratings yet

- CLAN AF - SeriesDocument2 pagesCLAN AF - SeriesCARLOS LEONNo ratings yet

- Dokumen - Tips - Abb Motor Catalogue PDFDocument6 pagesDokumen - Tips - Abb Motor Catalogue PDFyogesh guptaNo ratings yet

- Carel Electronic Expansion Valve Catalogue 2023 06 15Document4 pagesCarel Electronic Expansion Valve Catalogue 2023 06 15Jose Ignacio Figueroa CortesNo ratings yet

- Strip Map Myc PKP - Muntok 2022 - 2023 Edit FiaDocument37 pagesStrip Map Myc PKP - Muntok 2022 - 2023 Edit FiaMuthmainnah Al-QolbiNo ratings yet

- Eetop - CN TSMCDocument3 pagesEetop - CN TSMCW.M. FNo ratings yet

- SC-400.10AQR1 Supplement 1 0Document3 pagesSC-400.10AQR1 Supplement 1 0SetyohdWNo ratings yet

- Mycom #1Document1 pageMycom #1Rifky Windya NNo ratings yet

- Corrosion Resistant CoatingsDocument21 pagesCorrosion Resistant CoatingsSteve SandersNo ratings yet

- D-Dimer - gl198dd Rev 01Document1 pageD-Dimer - gl198dd Rev 01mrashrafiNo ratings yet

- Po1 Po2 Po3 Po4 Po5 Po6 Po7 Po8 Po9 Po10 Po11 Po12Document9 pagesPo1 Po2 Po3 Po4 Po5 Po6 Po7 Po8 Po9 Po10 Po11 Po12Mr. G. Naga ChaitanyaNo ratings yet

- Raw Water Analysis ReportDocument1 pageRaw Water Analysis ReportSajib Chandra RoyNo ratings yet

- Pond AshDocument1 pagePond AshRavindra singh TanwarNo ratings yet

- 01 25284124-8230-26-104-0001 REV.02 Piping List CT1Document1 page01 25284124-8230-26-104-0001 REV.02 Piping List CT1Rajeev KumarNo ratings yet

- EJECTOR PresentationDocument24 pagesEJECTOR PresentationBARBARA BEATRIZ FERNANDEZ HIDALGONo ratings yet

- Prezentacija Telfor 2015Document29 pagesPrezentacija Telfor 2015MarijaNo ratings yet

- Jawaban Tutor SimanDocument8 pagesJawaban Tutor SimanAlves LellyNo ratings yet

- MM Sq. (2.36 Inch SQ.) : 1.8 /stepDocument5 pagesMM Sq. (2.36 Inch SQ.) : 1.8 /stepniggakingNo ratings yet

- Otavio RilemDocument6 pagesOtavio RilemJuceline BatistaNo ratings yet

- Stack-up Simulator history: 일자 Revision 개정 내용 담당자 비고Document4 pagesStack-up Simulator history: 일자 Revision 개정 내용 담당자 비고ChristianNo ratings yet

- Test Certificate For Current TransformerDocument1 pageTest Certificate For Current TransformerSuraj JadhavNo ratings yet

- 20 30 40 - R MDpowertempDocument6 pages20 30 40 - R MDpowertempbogdan darcaciuNo ratings yet

- Literature ReviewDocument13 pagesLiterature ReviewM S ReddyNo ratings yet

- UHP-M Dualband 0.6m Single&single Polarized C3 Antenna Datasheet (AXXSYYS06CC)Document4 pagesUHP-M Dualband 0.6m Single&single Polarized C3 Antenna Datasheet (AXXSYYS06CC)Nikola VuckovicNo ratings yet

- 13 NRA Binder Specifications RC380 April 2013Document9 pages13 NRA Binder Specifications RC380 April 2013johnNo ratings yet

- Verified Analog Parts - LNKDocument3 pagesVerified Analog Parts - LNKAnonymous BW9mIv22NNo ratings yet

- EZLAND's Health & Safety Executive (HSE) Regulations For The Construction SiteDocument26 pagesEZLAND's Health & Safety Executive (HSE) Regulations For The Construction SiteNguyen AnNo ratings yet

- 45 - 2013 - ND-CP - HD Luat LD Ve An Toan Lao DongDocument22 pages45 - 2013 - ND-CP - HD Luat LD Ve An Toan Lao DongNguyen AnNo ratings yet

- Effect of Hydrogen-Diesel Fuel Co-Combustion On Exhaust EmissionsDocument15 pagesEffect of Hydrogen-Diesel Fuel Co-Combustion On Exhaust EmissionsNguyen AnNo ratings yet

- 01 - 2011 - Ttlt-Blđtbxh-Byt HD To Chuc Thuc Hien Cong Tac BHLDDocument116 pages01 - 2011 - Ttlt-Blđtbxh-Byt HD To Chuc Thuc Hien Cong Tac BHLDNguyen AnNo ratings yet

- EZLAND's Health & Safety Executive (HSE) Regulations For The Construction SiteDocument26 pagesEZLAND's Health & Safety Executive (HSE) Regulations For The Construction SiteNguyen AnNo ratings yet

- GTCNCHUYENKHOA0001Document2 pagesGTCNCHUYENKHOA0001Nguyen AnNo ratings yet

- Iwa 9219Document1 pageIwa 9219Nguyen AnNo ratings yet

- Iwa 8932Document1 pageIwa 8932Nguyen AnNo ratings yet

- K-Water Institute, K-Waterter, Yuseong-Gu, Daejeon 305-730, South Korea Korea Institute of Energy Research, Yuseong-Gu, Daejeon, 305-343, South KoreaDocument1 pageK-Water Institute, K-Waterter, Yuseong-Gu, Daejeon 305-730, South Korea Korea Institute of Energy Research, Yuseong-Gu, Daejeon, 305-343, South KoreaNguyen AnNo ratings yet

- Iwa 8628Document1 pageIwa 8628Nguyen AnNo ratings yet

- A Bio-Eco Combined Process For Decentralized Wastewater TreatmentDocument1 pageA Bio-Eco Combined Process For Decentralized Wastewater TreatmentNguyen AnNo ratings yet

- Development of A Novel 3-Stage BAF System For Enhancing Nitrification Performance at Short Hydraulic Retention TimeDocument1 pageDevelopment of A Novel 3-Stage BAF System For Enhancing Nitrification Performance at Short Hydraulic Retention TimeNguyen AnNo ratings yet

- J. Cumin, Y. Hong, M. Dagnew, R. Bayly, W. ParkerDocument1 pageJ. Cumin, Y. Hong, M. Dagnew, R. Bayly, W. ParkerNguyen AnNo ratings yet

- Micropollutant 2016 ENGDocument12 pagesMicropollutant 2016 ENGNguyen AnNo ratings yet

- WABAG Image ENG 2016 WebDocument20 pagesWABAG Image ENG 2016 WebNguyen AnNo ratings yet

- Iwa 8418Document1 pageIwa 8418Nguyen AnNo ratings yet

- Wabag Biopur: Biofi Ltration For Wastewater TreatmentDocument6 pagesWabag Biopur: Biofi Ltration For Wastewater TreatmentNguyen AnNo ratings yet

- Fluopur Technology: MBBR & IfasDocument8 pagesFluopur Technology: MBBR & IfasNguyen AnNo ratings yet

- SludgeDigestion 2016 EN WEBDocument12 pagesSludgeDigestion 2016 EN WEBNguyen AnNo ratings yet

- Filtration2014 EN WebDocument6 pagesFiltration2014 EN WebNguyen AnNo ratings yet

- Wabag Bioden: Nitrate Removal Biological Denitrifi Cation of Ground WaterDocument6 pagesWabag Bioden: Nitrate Removal Biological Denitrifi Cation of Ground WaterNguyen AnNo ratings yet

- WABAG Operations: Plant Management For The Private and Public SectorDocument14 pagesWABAG Operations: Plant Management For The Private and Public SectorNguyen AnNo ratings yet

- Micropur Technology: An Innovative Fine Sieving SystemDocument8 pagesMicropur Technology: An Innovative Fine Sieving SystemNguyen AnNo ratings yet

- Marapur MBR Technology: Maximum PerformancesDocument12 pagesMarapur MBR Technology: Maximum PerformancesNguyen AnNo ratings yet

- CE 085 Wastewater Treatment III MBRDocument28 pagesCE 085 Wastewater Treatment III MBRNguyen An100% (1)

- Activated Sludge Calcs With ExcelDocument22 pagesActivated Sludge Calcs With ExcelsahatNo ratings yet

- Biological Wastewater Treatment II - MBBR Processes R1Document45 pagesBiological Wastewater Treatment II - MBBR Processes R1Nguyen An100% (1)

- Biological Wastewater Treatment Process Design Calculations: Harlan H. Bengtson, Pe, PHDDocument116 pagesBiological Wastewater Treatment Process Design Calculations: Harlan H. Bengtson, Pe, PHDEnder Gökmen100% (2)

- Crdi Community Based Technologies For Domestic Wastewater Treatment and Reuse Options For Urban Agriculture 1999Document81 pagesCrdi Community Based Technologies For Domestic Wastewater Treatment and Reuse Options For Urban Agriculture 1999Nguyen AnNo ratings yet

- Mun GuideDocument4 pagesMun GuideK57EK291 Nguyễn Hoài ThươngNo ratings yet

- Sufyan Mohammadi - DFGE Module 4 Exercise Results FormDocument2 pagesSufyan Mohammadi - DFGE Module 4 Exercise Results FormMohd Amaan SheikhNo ratings yet

- Jumpstart: Answer SheetDocument2 pagesJumpstart: Answer SheetAngel PicazoNo ratings yet

- 8b-Division Maritime AreasDocument28 pages8b-Division Maritime Areassitinadzirah matrozukiNo ratings yet

- Strategic Management 2Document46 pagesStrategic Management 2Ritz Talent HubNo ratings yet

- Environmental Science: Instructional Manual inDocument139 pagesEnvironmental Science: Instructional Manual inMark John Paul Cabling100% (1)

- LP4 Timber and LumberDocument12 pagesLP4 Timber and Lumberglenn salandananNo ratings yet

- Sustainability Reports BSDE 2021 PDFDocument61 pagesSustainability Reports BSDE 2021 PDFSatrio PrakosoNo ratings yet

- Women S Entrepreneurship For Sustainable EnergyDocument2 pagesWomen S Entrepreneurship For Sustainable EnergysaranNo ratings yet

- Unit 4 Energy ConserevationDocument8 pagesUnit 4 Energy Conserevationdhanusiya balamuruganNo ratings yet

- UltraTech AFR Presentation PDFDocument11 pagesUltraTech AFR Presentation PDFRandeep YadavNo ratings yet

- A. The Process of Making BiodieselDocument6 pagesA. The Process of Making BiodieselInayah VeraNo ratings yet

- RajasthanDocument4 pagesRajasthanShweta jainNo ratings yet

- Lead Battery RecyclersDocument72 pagesLead Battery RecyclersravishankarNo ratings yet

- 3.0 Community InteractionDocument95 pages3.0 Community InteractionAT4-11 HUMSS 2 CEDRICK ILAONo ratings yet

- Environmental LegislationDocument21 pagesEnvironmental LegislationYuseer AmanNo ratings yet

- Eavt Brochure Ecole EnglishDocument40 pagesEavt Brochure Ecole EnglishHakanBulutNo ratings yet

- Uj 40184+SOURCE1+SOURCE1.1Document169 pagesUj 40184+SOURCE1+SOURCE1.1Minenhle NonyaneNo ratings yet

- E Yantra Robotics Lab Report 1Document16 pagesE Yantra Robotics Lab Report 1Ayush RajNo ratings yet

- Material Safety Data Sheet: 1. Product and Company IdentificationDocument6 pagesMaterial Safety Data Sheet: 1. Product and Company IdentificationAditya FebriantoNo ratings yet

- COMMUNITY WASTE MANAGEMENT ReportDocument7 pagesCOMMUNITY WASTE MANAGEMENT Reportmahendra rawatNo ratings yet

- Pittsfield Pickleball CourtsDocument8 pagesPittsfield Pickleball CourtsiBerkshires.comNo ratings yet

- 02 WholeDocument331 pages02 WholeFardatul UmarohNo ratings yet

- Flower Turbines EU BrochuresDocument6 pagesFlower Turbines EU Brochurestheodore thaiNo ratings yet

- Chapter 6-1 Environmental Compliance PlanDocument8 pagesChapter 6-1 Environmental Compliance Planangelo plumosNo ratings yet

- Prime Coat (PVT.) LTD: Rev: 3-4-2020 Ketonic Resin Pk-5851Document4 pagesPrime Coat (PVT.) LTD: Rev: 3-4-2020 Ketonic Resin Pk-5851khizer iqbalNo ratings yet

- HW Online EGIS Student HandookDocument86 pagesHW Online EGIS Student HandookAnorld WalkerNo ratings yet

- G8 - B.3 - A, B, C. WF3 - Power - S20-W22 - KEYDocument6 pagesG8 - B.3 - A, B, C. WF3 - Power - S20-W22 - KEYOmer SalehNo ratings yet

- Sds b9r3 Emerald GhsDocument8 pagesSds b9r3 Emerald GhsGeovany MalignoNo ratings yet

- 1.evolution and Origin of Biodiversity Patterns of Descent With Modi CationDocument28 pages1.evolution and Origin of Biodiversity Patterns of Descent With Modi CationElizabeth AsuncionNo ratings yet