Professional Documents

Culture Documents

Soft Drinks: Perry Equipment Corporation

Uploaded by

ZackOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Soft Drinks: Perry Equipment Corporation

Uploaded by

ZackCopyright:

Available Formats

APPLICATION

Perry Equipment Corporation DATA SHEET

EL-FB-AD-02

Iso 9001 certified

APPLICATION DATA SHEET

SOFT DRINKS

SERIES SERIES

PVB PVB

WATER

SUGAR

SERIES SURGE SURGE

PVB TANK TANK

MIXING MIXING

CIP

CHEMICALS

ADDITIVES

SERIES SERIES

PL PL

CIP SERIES SERIES

WATER CARBONATION PVB PVB

SERIES SERIES

PL PL

BOTTLE WASH

BOTTLE FILL

WATER

SERIES SERIES

PL PL

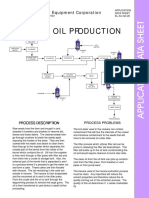

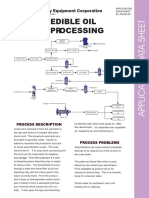

PROCESS DESCRIPTION PECO SOLUTIONS

The production of soft drinks is relatively straight- There are a number of liquid filtration applications in the

forward. Water and Sugar are mixed together soft drink process. To begin, all incoming process water

according to a predetermined formula. After must be treated to remove various contaminants. The

the primary mix, product is stored in day tanks source of the water will determine the type of contaminant

for further processing. The stored product is to be removed. For instance, surface water (lakes, rivers)

then mixed with additives that include flavorings can contain algae and other bio-organics. Well water is

and vitamins. Once this mixing is complete, the typically high in metal salts such as calcium and silica.

product is taken to packaging where it is Peco recommends UltaPure depth filter elements

bottled or canned. for the removal of deformable contaminant such as

algae. To remove minerals, which are typically

non-deformable in nature, Peco recommends the

PROCESS PROBLEMS ComPleat pleated style filter. Both of these should be

- Poor Source Water preceded by a LiquiPur Carbon filter to remove

- Incomplete Mixing organics.

-

After the initial mixing process for water and sugar, a

Peco PVB filter with UltaPure depth filter elements

will remove any agglomerations caused by improper

or incomplete mixing.

Soft drinks can be pasteurized or cold sterilized prior The caustics used are also filtered to remove

to packaging to biologically stabilize the product. impurities. Peco recommends a 1 micron

If the end productr is cold sterilized in an aseptic ComPleat pleated style filter for this application.

system, a series filtration is typically employed. In order

to meet aseptic requirements, a .45 micron membrane Bottle Washers present another filtration opportunity.

is typically employed to guarantee microbial stability. All bottles, kegs, cans, etc. Are sterile rinsed before

These membranes are typically very expensive. They filling to prevent bio-contamination growth after

preceded by one or more sets of pre-filters to extend they are filled and sealed. Once again, membrane

their on-stream life and minimize the cost per barrel type filters in the .2 micron category are utilized.

of the process. The Peco ComPleat style 0.7 And, once again, these are preceded by a pre-

micron pleated filter is an excellent choice providing filter to maximize on-stream life and system

high contaminant loading and efficiency characteristics.. economics. Peco recommends a 0.7 or 1 micron

ComPleat pleated style filter cartridge in this

There are a number of secondary operations to application.

support the filling and packaging operations. The

first operation addresses the Clean-in-Place (CIP)

procedures for filling an packaging equipment.

All of this equipment must be sterilized on a regular

basis to maintain aseptic conditions. This is

typically done with the use of various caustics in

combination with water. Water for these operations

must be clean and free from any pyrogens. This

is typically done by utilizing a .2 or .45 micron

membrane cartridge. Once again, to maximize the

on-stream life of these expensive cartridges, Peco

recommends a 0.7 micron ComPleat pleated style

filter.

Corporate Offices & Plant Perry Operation De Mexico Peco Filters, Ltd.

PERRY EQUIPMENT CORPORATION Parque Industrial Queretaro 1351 Hastings Crescent S.E.

Wolters Industrial Park Calle Cerrada La Noria #108 Calgary, Alberta

P.O. Box 640 Santa Rosa, Jaurequi Canada T2G-4C8

Mineral Wells, Texas 76068 Queretaro, Queretaro, Mexico C.P. 76220 Telephone: 403-243-6700

Telephone: 940-325-2575 Telephone: 52-442-242-12-34 Telefax: 403-287-9304

800-877-PECO Telefax: 52-422-242-12-35 e-mail: canadasales@perryequipment.com

Telefax: 940-325-4622 e-mail: Mexicosales@perryequipment.com

E-mail: e-mail: sales@perryequipment.com

sales@perryequipment.com

Perry Equipment Corporation European Offices

S.E. ASIA REGIONAL OFFICE PERRY EQUIPMENT LTD.

web site: Houston Branch Office 35-5 Jalan SP 2/1 Brunel Business Court

www.perryequipment.com 1758 West Sam Houston Parkway N. Taman Serdang Perdana, Seksyen 2 Brunel Way, Thetford

Houston, Texas 77043-3115 43300 Seri Kemgangan Norfolk IP24 IHP

Telephone: 713-973-2575 Selangor D.E. Malaysia England

Telefax: 713-467-0475 Telephone: 603-8941-2366 Telephone: 44-1-842-821000

Print Revision 1/05

e-mail: houstonsales@perryequipment.com Telefax: 603-8941-1366 Telefax: 44-1-842-821050

e-mail: asiasales@perryequipment.com e-mail: uksales@perryequipment.com

Perry Equipment Italiana S.R.L. www.perry-equipment.co.uk

Via Camozzi, 106 Middle East Sales Office

24121 Bergamo (BG) Perry Equipment Corporation

Italy P.O. Box 10895

Telephone: 3903-523-6340 Manama, Bahrain

Telefax: 3903-523-6380 Telephone: 973-1729-3309

e-mail: italysales@perryequipment.com Telefax: 973-1729-4728

e-mail: bahrainsales@perryequipment.com

You might also like

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Chapter 2 - Ecosystems Ecology A. Learning ObjectivesDocument23 pagesChapter 2 - Ecosystems Ecology A. Learning ObjectivesMarel Bonna E. QuipanesNo ratings yet

- Smaw 12 Module 1 Grade 12Document39 pagesSmaw 12 Module 1 Grade 12Francis Rico Mutia Rufon100% (14)

- Sedimentation and Sedimentation TanksDocument43 pagesSedimentation and Sedimentation TanksDevendra Sharma80% (10)

- Qualification of Purified Water Systems PDFDocument12 pagesQualification of Purified Water Systems PDFDontYou KnowMeNo ratings yet

- Filtration in Pharmaceutical Water SystemsDocument8 pagesFiltration in Pharmaceutical Water SystemsAhmad ZaidiNo ratings yet

- Design of Sour Water Stripping System: February 2009Document23 pagesDesign of Sour Water Stripping System: February 2009kishna009100% (2)

- Cleaning CalculationDocument5 pagesCleaning CalculationIlham WahyuNo ratings yet

- Containerisedmbrsystem EngDocument12 pagesContainerisedmbrsystem EngNermeen ElmelegaeNo ratings yet

- High Performance Age-Hardenable Nickel Alloys Solve Problems in Sour Oil & Gas ServiceDocument8 pagesHigh Performance Age-Hardenable Nickel Alloys Solve Problems in Sour Oil & Gas ServiceArdy PrasetyoNo ratings yet

- Chlorine Institute Manual 2000Document68 pagesChlorine Institute Manual 2000Misael RamírezNo ratings yet

- How Reverse Osmosis Works: A Look at Industrial ROFrom EverandHow Reverse Osmosis Works: A Look at Industrial RORating: 2.5 out of 5 stars2.5/5 (2)

- Hygroscopic (Osmotic) Blisters Tiny, Pin Head Size, Water Filled Blisters. Caused by Hygroscopic Salts (Iron Sulphates and Iron Chlorides)Document25 pagesHygroscopic (Osmotic) Blisters Tiny, Pin Head Size, Water Filled Blisters. Caused by Hygroscopic Salts (Iron Sulphates and Iron Chlorides)Usab GamalNo ratings yet

- Copper Sheet, Strip, Plate, and Rolled Bar: Standard Specification ForDocument7 pagesCopper Sheet, Strip, Plate, and Rolled Bar: Standard Specification ForgoggerNo ratings yet

- Centrifugal Compressor BasicsDocument45 pagesCentrifugal Compressor BasicsAnkit Gandhi100% (1)

- Material Safety Data Sheet Hdpe: Section 1 - Chemical Product and Company IdentificationDocument4 pagesMaterial Safety Data Sheet Hdpe: Section 1 - Chemical Product and Company IdentificationruksfarhanNo ratings yet

- Product Brochure With Industrial ApplicationDocument9 pagesProduct Brochure With Industrial Applicationanon_159986285No ratings yet

- ProServe - RO Training Course - Part II PDFDocument49 pagesProServe - RO Training Course - Part II PDFmohamed karemNo ratings yet

- Wine Processing: Perry Equipment CorporationDocument2 pagesWine Processing: Perry Equipment CorporationZackNo ratings yet

- Bottled Water: Perry Equipment CorporationDocument2 pagesBottled Water: Perry Equipment CorporationZackNo ratings yet

- Beer Brewing: Perry Equipment CorporationDocument2 pagesBeer Brewing: Perry Equipment CorporationZack100% (1)

- InfoCell Water Purifier v2207 FADocument22 pagesInfoCell Water Purifier v2207 FAIbnu TalibNo ratings yet

- Wine Filtration ApplicationsDocument4 pagesWine Filtration Applicationsariss_surachman_5927No ratings yet

- 60 BPMDocument8 pages60 BPMSathishNo ratings yet

- 1080 Reagent WaterDocument3 pages1080 Reagent WaterPenelope MeloNo ratings yet

- Isea Super Plus - Activated Sludge Plant - Treatment of Domestic Waste WatersDocument3 pagesIsea Super Plus - Activated Sludge Plant - Treatment of Domestic Waste WatersAG-Metal /Tretman Otpadnih Voda/Wastewater Treatment100% (1)

- Centra R 60 120 Spec Sheet Litr38761 05Document2 pagesCentra R 60 120 Spec Sheet Litr38761 05Sergio RodríguezNo ratings yet

- Water Treatment SystemDocument43 pagesWater Treatment SystemAnisa Nur WulansariNo ratings yet

- H2SO4 Alkylation - Application NoteDocument2 pagesH2SO4 Alkylation - Application NoteFaten BhsNo ratings yet

- Isea Compact Activated Sludge Plant - Treatment of Domestic Waste WatersDocument3 pagesIsea Compact Activated Sludge Plant - Treatment of Domestic Waste WatersAG-Metal /Tretman Otpadnih Voda/Wastewater Treatment100% (1)

- Polygard Trap Filters LDocument4 pagesPolygard Trap Filters LAlsultan AlsultanNo ratings yet

- GCP Sect5RB RB LineDocument25 pagesGCP Sect5RB RB Linelevanvui161No ratings yet

- C18-Andrew LiewDocument24 pagesC18-Andrew LiewCheong Wen YuanNo ratings yet

- Pharmaceutical Manufacturing: Filtration SolutionsDocument6 pagesPharmaceutical Manufacturing: Filtration SolutionsApril TejadaNo ratings yet

- FIP Water Treatment Solutions 2017 LRDocument28 pagesFIP Water Treatment Solutions 2017 LRSomaia Al-AkrasNo ratings yet

- Wastewater in The Carbon-Recycling Industry Aquatech Apr27th2021Document42 pagesWastewater in The Carbon-Recycling Industry Aquatech Apr27th2021Filippo FerrariNo ratings yet

- Owner'S Manual: Circle Reverse Osmosis Water Filtration System Model # RC100Document88 pagesOwner'S Manual: Circle Reverse Osmosis Water Filtration System Model # RC100ScottNo ratings yet

- In-Place Cleaning: M Walton, Society of Dairy Technology, Appleby in Westmorland, UKDocument3 pagesIn-Place Cleaning: M Walton, Society of Dairy Technology, Appleby in Westmorland, UKjesusbruzualNo ratings yet

- Compact UnitsDocument28 pagesCompact UnitsAhmed WagihNo ratings yet

- 24 30 FillingDocument4 pages24 30 FillingSathishNo ratings yet

- Data Sheet - Pharmed® BPT Biocompatible Peristaltic Pump Tubing PDFDocument3 pagesData Sheet - Pharmed® BPT Biocompatible Peristaltic Pump Tubing PDFildarNo ratings yet

- Esterilizacion in Situ-1Document16 pagesEsterilizacion in Situ-1juanNo ratings yet

- 1080 Reagent WaterDocument3 pages1080 Reagent WaterJV AbcedeNo ratings yet

- Vertex IsoTwistDocument1 pageVertex IsoTwistPaolo StamNo ratings yet

- Pet-Asept D enDocument17 pagesPet-Asept D enKhang TruongNo ratings yet

- 02-WTS Storage Tank PWC10111D10Document3 pages02-WTS Storage Tank PWC10111D10LuisNo ratings yet

- FBDSPAREENbDocument3 pagesFBDSPAREENbHudaFiHayyatNo ratings yet

- Sewage Treatment Plant Report For M/s Santla Devi Resorts Pvt. LTDDocument7 pagesSewage Treatment Plant Report For M/s Santla Devi Resorts Pvt. LTDSamNo ratings yet

- Product Name Generic Product NameDocument4 pagesProduct Name Generic Product Namet_i_f_anoNo ratings yet

- GreenreverseosmosisDocument2 pagesGreenreverseosmosisnermeen ahmedNo ratings yet

- Protecting Your Juice Processing Plant From: Alicyclobacillus ContaminationDocument4 pagesProtecting Your Juice Processing Plant From: Alicyclobacillus ContaminationAsif MerajNo ratings yet

- WAE Drinking Water Fountains India: Manufacturers & SuppliersDocument4 pagesWAE Drinking Water Fountains India: Manufacturers & SuppliersWae IndiaNo ratings yet

- SMWW 1080Document3 pagesSMWW 1080milagrosgvyNo ratings yet

- Kleen MCT515 - PFS-SuezDocument2 pagesKleen MCT515 - PFS-SuezMuhammad SukroniNo ratings yet

- Process Filtration Liquid Capabilities - 2Document8 pagesProcess Filtration Liquid Capabilities - 2Dodik Anang WijayaNo ratings yet

- Water Filtration PDFDocument7 pagesWater Filtration PDFDat NguyenNo ratings yet

- Econtrol Web 4 PDFDocument10 pagesEcontrol Web 4 PDFJeyaraj KLNo ratings yet

- Calgon Filtrasorb 100Document2 pagesCalgon Filtrasorb 100PT Deltapuro IndonesiaNo ratings yet

- Developments in Mud Filtration Technology in The Sugarcane IndustryDocument32 pagesDevelopments in Mud Filtration Technology in The Sugarcane IndustryvjNo ratings yet

- Article Indepth - Pall2Document7 pagesArticle Indepth - Pall2SanamNo ratings yet

- Pompa Albin Pompe Pompe Peristaltice Apa Industrie Alimentara 1Document8 pagesPompa Albin Pompe Pompe Peristaltice Apa Industrie Alimentara 1Diana GoriNo ratings yet

- Filmtec Site Information Desalination LDocument4 pagesFilmtec Site Information Desalination LNEFTALI VARGAS MANDUJANONo ratings yet

- Production of Pharmaceutical Syrups: Solid Ingredients Dosing Systems Production TanksDocument2 pagesProduction of Pharmaceutical Syrups: Solid Ingredients Dosing Systems Production Tankshenrykayode4No ratings yet

- Dehoust Greywater Brochure - 2013Document12 pagesDehoust Greywater Brochure - 2013Danyal HaiderNo ratings yet

- Process Aids Booklet ENG Print A4 AB VickersDocument8 pagesProcess Aids Booklet ENG Print A4 AB VickersFabioNo ratings yet

- PRESENTATION CcwsDocument61 pagesPRESENTATION CcwsRamkiNo ratings yet

- Bioact EC-7 Defluxer: Technical Data SheetDocument4 pagesBioact EC-7 Defluxer: Technical Data Sheetmadiahmad84No ratings yet

- ANEXURE G (Water System)Document17 pagesANEXURE G (Water System)Mohammed ZubairNo ratings yet

- EC Tech Report High Performance Polyurethanes: PDFFrom EverandEC Tech Report High Performance Polyurethanes: PDFVincentz Network GmbH & Co. KGNo ratings yet

- Vinyl Chloride Monomer: Perry Equipment CorporationDocument2 pagesVinyl Chloride Monomer: Perry Equipment CorporationZackNo ratings yet

- NYLON 6,6: Perry Equipment CorporationDocument2 pagesNYLON 6,6: Perry Equipment CorporationZackNo ratings yet

- NYLON 6 (H20) : Perry Equipment CorporationDocument2 pagesNYLON 6 (H20) : Perry Equipment CorporationZackNo ratings yet

- Distilled Liquor: Perry Equipment CorporationDocument2 pagesDistilled Liquor: Perry Equipment CorporationZackNo ratings yet

- Edible Oil Production: Perry Equipment CorporationDocument2 pagesEdible Oil Production: Perry Equipment CorporationZackNo ratings yet

- Distilled Liquor Whiskey: Perry Equipment CorporationDocument2 pagesDistilled Liquor Whiskey: Perry Equipment CorporationZackNo ratings yet

- Edible Oil Oil Processing: Perry Equipment CorporationDocument2 pagesEdible Oil Oil Processing: Perry Equipment CorporationZackNo ratings yet

- ASTM A106 GRDocument2 pagesASTM A106 GRZackNo ratings yet

- Automatic Multiple Pig Launching SystemsDocument8 pagesAutomatic Multiple Pig Launching SystemsZackNo ratings yet

- Incoclad 625 SteelDocument4 pagesIncoclad 625 SteelZackNo ratings yet

- Finding An Alternative Binder For Asphalt Using Plastic-BitumenDocument11 pagesFinding An Alternative Binder For Asphalt Using Plastic-BitumenStephen BoachieNo ratings yet

- Heat Reflecting PaintsDocument13 pagesHeat Reflecting PaintsEsau AguillónNo ratings yet

- 05 Film ProcessingDocument17 pages05 Film ProcessingChetanNo ratings yet

- Fuel Gas Conditioning-EmailDocument2 pagesFuel Gas Conditioning-Emailkelburn50% (2)

- PSPC Q&As - and - CIs - (Common - Interpretation)Document10 pagesPSPC Q&As - and - CIs - (Common - Interpretation)totoq51No ratings yet

- Recycling of Non Woven Waste: Usha Sayed, Sneha ParteDocument5 pagesRecycling of Non Woven Waste: Usha Sayed, Sneha Parteebi18750No ratings yet

- Solar Refrigeration ReportDocument21 pagesSolar Refrigeration ReportCj MoLanoNo ratings yet

- PneumaticDocument13 pagesPneumaticVikas RaoNo ratings yet

- Usp 788Document3 pagesUsp 788Wesley OliveiraNo ratings yet

- Exp. 7 Analysis of Milk For The Lipids Carbohydrates and ProteinsDocument6 pagesExp. 7 Analysis of Milk For The Lipids Carbohydrates and ProteinsClarice CatorceNo ratings yet

- Abg Analysis-1Document22 pagesAbg Analysis-1PAMNo ratings yet

- Mobil Chassis Grease LBZDocument1 pageMobil Chassis Grease LBZtribolasNo ratings yet

- Spent Fuel Pool Safety and Performance Chan Young PaikDocument23 pagesSpent Fuel Pool Safety and Performance Chan Young PaikIAEAInformationNo ratings yet

- Anaerobic Conditions Clothespin LabDocument1 pageAnaerobic Conditions Clothespin LabAlyssa ANo ratings yet

- 01 CVNG 1005 - Materials LabDocument6 pages01 CVNG 1005 - Materials LabMarly MarlNo ratings yet

- Chemical Dimension of TasteDocument31 pagesChemical Dimension of Tastemaithili joshiNo ratings yet

- SC435418MFC16Document5 pagesSC435418MFC16javierNo ratings yet

- Summer Training ProgramDocument21 pagesSummer Training ProgramAyan BorgohainNo ratings yet

- Chapter 17: Chemical Thermodynamics: 17.1 When Is A Process Spontaneous?Document4 pagesChapter 17: Chemical Thermodynamics: 17.1 When Is A Process Spontaneous?Carlos Mella-RijoNo ratings yet

- ISC 2013 Chemistry Theory Paper 1 Solved PaperDocument20 pagesISC 2013 Chemistry Theory Paper 1 Solved PaperAakash Singh100% (1)

- Kobel CoDocument4 pagesKobel CoCesar ZarateNo ratings yet