Professional Documents

Culture Documents

Fault Isolation Manual: Print Date: 2021-05-27

Uploaded by

Mahbub RahmanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fault Isolation Manual: Print Date: 2021-05-27

Uploaded by

Mahbub RahmanCopyright:

Available Formats

D FAULT ISOLATION MANUAL

**ON A/C ALL

TASK 21−60−00−810−882

Low Air Flow from Cabin and/or Flight Deck ECS System − Fault Isolation

1. General

A. This fault isolation procedure is for when the flight crew reports the cabin or flight compartment air

flow is too low.

B. Refer to the fault tree for the overview of the task.

Refer to FIG 201

2. Job Set−Up Information

Subtask 21−60−00−946−101

A. Reference Information

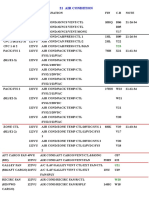

REFERENCE DESIGNATION

AMM 21−51−01−000−801 Removal of the Dual Heat Exchanger

AMM 21−51−01−400−801 Installation of the Dual Heat Exchanger

AMM 21−51−21−000−801 Removal of the Air Cycle Machine

AMM 21−51−21−400−801 Installation of the Air Cycle Machine

AMM 21−51−41−000−801 Removal of the Turbine Shutoff Valve

AMM 21−51−41−000−802 Removal of the Turbine Shutoff Valve Filter

AMM 21−51−41−400−801 Installation of the Turbine Shutoff Valve

AMM 21−51−41−400−802 Installation of the Turbine Shutoff Valve Filter

Removal of the Pack Flow Control and Shut−off

AMM 21−52−01−000−801

Valve

Removal of the Pack Flow Control and Shut−off

AMM 21−52−01−000−802

Valve Filter

Installation of the Pack Flow Control and Shut−off

AMM 21−52−01−400−801

Valve

Installation of the Pack Flow Control and Shut−off

AMM 21−52−01−400−802

Valve Filter

AMM 21−61−00−710−803 Operational Test of the ECS Temperature Control

AMM 24−00−00−910−801 Electrical/Electronic Safety Precautions

AMM 36−11−09−000−801 Removal of the High Pressure Shutoff Valve

AMM 36−11−09−400−801 Installation of the High Pressure Shutoff Valve

AMM 36−11−19−000−801 Removal of the Nacelle Shutoff Valve

AMM 36−11−19−400−801 Installation of the Nacelle Shutoff Valve

Retrieval of Data from the Central Diagnostic System

AMM 45−00−21−742−801

(CDS) − Environmental Control System (ECS)

PSM 1−84−23 − MASTER

EFFECTIVITY:

Page 299.57

See First Effectivity on Page 299.57 of 21−60−00 21−60−00 Sep 05/2020

Print Date: 2021-05-27

D FAULT ISOLATION MANUAL

REFERENCE DESIGNATION

Erase Data from the Central Diagnostic System

AMM 45−00−21−743−801

(CDS) − Environmental Control System (ECS)

AMM 49−00−00−869−801 Start Procedure of the APU

AMM 71−00−00−868−801 Engine Start

AMM 71−00−00−868−802 Engine Shutdown

FIM 21−60−00 Temperature Control

FIM 21−60−00−810−809 PACK FCV (Status) − Fault Isolation

FIM 21−60−00−810−841 FD ACM (Status) − Fault Isolation

FIM 21−60−00−810−842 CAB ACM (Status) − Fault Isolation

FIM 21−60−00−810−846 SEC HX PERF (Status) − Fault Isolation

WM 21−11−00 Bleed Air Control and Indication

WM 21−61−00 Temperature Control and Indication

3. Job Set−Up

Subtask 21−60−00−910−007

A. Obey all the electrical/electronic safety precautions (Refer to AMM 24−00−00−910−801).

B. Before you do the fault confirmation ensure the following circuit breakers are engaged

(1) ECS/BA CONT L AUTO B7 LEFT MAIN

(2) ECS/BA CONT L MAN Q6 RIGHT MAIN

(3) ECS/BA CONT R AUTO R6 RIGHT MAIN

(4) ECS/BA CONT R MAN C7 LEFT MAIN

4. Fault Confirmation

Subtask 21−60−00−810−186

A. Confirm the fault as follows:

(1) Do the retrieval of the Central Diagnostic System (CDS) fault indications and the

Environmental Control System (ECS) Flight Data page 6/7 (Refer to AMM

45−00−21−742−801).

(2) Record the present and historical faults in the applicable maintenance log book. Include the

elapse time hours for historical faults.

(3) If the fault code in the present faults or fault history is 3001 − PACK FCV, do the fault

isolation for PACK FCV (Refer to FIM 21−60−00−810−809).

(4) If the fault code in the present faults or fault history is 3004 − PACK FCV, do the fault

isolation for PACK FCV (Refer to FIM 21−60−00−810−809).

PSM 1−84−23 − MASTER

EFFECTIVITY:

Page 299.58

See First Effectivity on Page 299.57 of 21−60−00 21−60−00 Sep 05/2020

Print Date: 2021-05-27

D FAULT ISOLATION MANUAL

(5) If the fault code in the present faults or fault history is 3502 SEC HX PERF, do the fault

isolation for the SEC HX PERF (Refer to FIM 21−60−00−810−846).

(6) If the fault code in the present faults or fault history is 3F01 FD ACM, do the fault isolation

for the FD ACM (Refer to FIM 21−60−00−810−841).

(7) If the fault code in the present faults or fault history is 3F02 CAB ACM, do the fault isolation

for the CAB ACM (Refer to FIM 21−60−00−810−842).

(8) If the CDS does not show the fault codes in the present faults or fault history, do the fault

isolation.

(9) Erase the data from the CDS (Refer to AMM 45−00−21−743−801).

5. Fault Isolation

Subtask 21−60−00−810−187

NOTE: Refer to FIG 202 and FIG 203 .

A. Isolate the fault as follows:

(1) On the AIR CONDITIONING control panel, set the RECIRC fan on. Is there air flow from all

the flight compartment and all the cabin gaspers?

(a) If no, look for a duct that has separated either below the cabin floor or in the ECS bay.

(b) If yes, continue the troubleshooting.

(2) Start the Auxiliary Power Unit (APU) (Refer to AMM 49−00−00−869−801).

(3) On the APU control panel, set BL AIR on.

(4) On the AIR CONDITIONING control panel, set the controls to the positions that follow:

(a) Set the left and right PACK switches to the AUTO position.

(b) Set the FLT COMP and CABIN temperature selectors to the 12 o’clock position.

(5) Do a check for air leaks in the ECS bay area.

(a) If there are leaks, repair the leaks. Do the Close Out.

(6) Get access to the CDS ECS flight data page 6/7.

(7) Record the four−digit hexagonal code adjacent to the T4S parameter label in the left column

of the ECS flight data page 6/7.

(8) If the four−digit hexagonal code is not 6400, do the Close−Out.

(9) Use a mirror to do a visual inspection of the Pack Flow Control and Shut Off Valve

(PFCSOV). Make sure that the PFCSOV is fully open. See FIG 202.

(10) If PFCSOV is not fully open, do as follows:

(a) Replace the PFCSOV filter (Refer to AMM 21−52−01−000−802 and AMM

21−52−01−400−802).

(b) Make sure that the packs are on with the APU bleed pressure.

PSM 1−84−23 − MASTER

EFFECTIVITY:

Page 299.59

See First Effectivity on Page 299.57 of 21−60−00 21−60−00 Sep 05/2020

Print Date: 2021-05-27

D FAULT ISOLATION MANUAL

(c) Record the four−digit hexagonal code adjacent to the T4S parameter label in the left

column of the ECS flight data page 6/7.

(d) If the four−digit hexagonal code is not 6400, do the Close−Out.

(e) If the four−digit hexagonal code is 6400 and the PFCSOV is not fully open, replace the

PFCSOV (Refer to AMM 21−52−01−000−801 and AMM 21−52−01−400−801).

(f) If the PFCSOV still does not function, do a check of the wiring between the PFCSOV

and the ECS Electronic Control Unit (ECU) (Refer to WM 21−61−00).

2100−P23 2100−P3

(PFCSOV) (ECS ECU)

A 41

B 40

2100−P23 2100−P5

(PFCSOV) (ECS ECU)

C 59

(g) If the wiring is unserviceable, repair the wiring. Do the Close Out.

WARNING: EXHAUST FROM THE PACKS WILL BE HOT. MAKE SURE YOU WEAR

PROTECTIVE EQUIPMENT (GLOVES, SAFETY GLASSES, HEARING

PROTECTION). BE CAREFUL WHEN YOU ARE ON THE LADDER. THIS WILL

PREVENT INJURY TO THE MAINTENANCE PERSONNEL AND/OR DAMAGE

TO THE EQUIPMENT.

(11) If the fault continues, feel for the Air Cycle Machine (ACM) exhaust flow from the external

exhaust vents at the top left and right empennage. If necessary, use the ladder.

(12) If there is air flow from both the packs, continue to step 5.A.11.

(13) If there is no air flow from one or both the packs, make sure that the turbine shutoff valve is

open on the pack without flow: See fig 203.

(a) If the turbine shutoff valve is closed, replace the turbine shutoff valve filter (Refer to

AMM 21−51−41−000−802 and AMM 21−51−41−400−802).

(b) If the turbine shutoff valve stays closed, replace the turbine shutoff valve (Refer to

AMM 21−51−41−000−801 and AMM 21−51−41−400−801).

(c) If the turbine shutoff valve stays closed, do a check of the wiring between the left

turbine shutoff valve and the ECS ECU (Refer to WM 21−61−00):

2100−P15 2100−P2

(Left Turbine Shutoff Valve) (ECS ECU)

A 31

B 3

PSM 1−84−23 − MASTER

EFFECTIVITY:

Page 299.60

See First Effectivity on Page 299.57 of 21−60−00 21−60−00 Sep 05/2020

Print Date: 2021-05-27

D FAULT ISOLATION MANUAL

(d) If the wiring is unserviceable, repair the wiring. Do the Close Out.

(e) If the turbine shutoff valve still stays closed, do a check of the wiring between the right

turbine shutoff valve and the ECS ECU (Refer to WM 21−61−00):

2100−P17 2100−P5

(Right Turbine Shutoff Valve) (ECS ECU)

A 66

B 49

(f) If the wiring is unserviceable, repair the wiring. Do the Close Out.

(g) If the turbine shutoff valve is open, replace the ACM (Refer to AMM

21−51−21−000−801 and AMM 21−51−21−400−801).

(14) Is the low flow condition apparent with the APU bleed air?

(a) If yes, continue to step 5.A.20.

(b) If no, repeat the steps 5.A.6 to 5.A.10 with the engine bleed air (Refer to AMM

71−00−00−868−801).

NOTE: APU bleed air supplies considerable more flow and pressure than engine bleed

air. This additional pressure will mask the marginal valve performance.

(15) If the fault continues, start the #2 engine only (Refer to AMM 71−00−00−868−801). Set the

controls to the positions that follow:

(a) On the centre console, set the #2 Power Lever Angle (PLA) to DISC and #2 Condition

Lever Angle (CLA) to MIN.

(b) On the AIR CONDITIONING control panel, do as follows:

1 Set the #2 BLEED control switch to on position.

2 Set the BLEED flow control selector to NORM position.

3 Set the RECIRC fan to off position.

4 Set the #1 and #2 PACK switches to the AUTO position.

5 Set the FLT COMP and CABIN temperature selectors to the 12 o’clock position.

(16) Is there bleed air flow from the flight compartment and cabin gaspers?

(a) If yes, continue the troubleshooting.

(b) If no, replace the #2 nacelle shutoff valve (Refer to AMM 36−11−19−000−801 and

AMM 36−11−19−400−801).

(c) If there is no air flow, do a check of the wiring between the #2 nacelle shutoff valve and

ECS ECU (Refer to WM 21−11−00):

2121−P29 2100−P5

(#2 Nacelle Shutoff Valve) (ECS ECU)

A 47

PSM 1−84−23 − MASTER

EFFECTIVITY:

Page 299.61

See First Effectivity on Page 299.57 of 21−60−00 21−60−00 Sep 05/2020

Print Date: 2021-05-27

D FAULT ISOLATION MANUAL

2121−P29 2100−P5

(#2 Nacelle Shutoff Valve) (ECS ECU)

B 64

C 58

D 72

(d) If the wiring is unserviceable, repair the wiring. Do the Close Out.

(17) Look for the Inter Turbine Temperature (ITT) increase, when the #2 BLEED is set to on and

off. Does the ITT increase more than 30 °C (86 °F)?

(a) If yes, continue the troubleshooting.

(b) If no, do a check for the P2.7 to P3 pressure switch over with the #2 PLA set at 86%

Nh, #2 CLA to the MAX position, #2 BLEED to on and BLEED flow to the NORM

position. Wait for two minutes to let the system become stable. Then put the #2 PLA to

the FLIGHT IDLE position. The deice pressure gauge must decrease to approximately

10 psi (68.95 kPa), then return to 18 psi (124.11 kPa).

NOTE: P3 to P2.7 switch over will occur before the engine gets to 25% torque on

an advancing PLA. On a retarding PLA, P2.7 air must return to P3 at

approximately 35% torque.

1 If the deice pressure returns to 18 psi (124.11 kPa), continue the troubleshooting.

2 If the deice pressure does not return to 18 psi (124.11 kPa), replace the #2 High

Pressure Shut Off Valve (HPSOV) (Refer to AMM 36−11−09−000−801 and AMM

36−11−09−400−801).

3 If the deice pressure still does not return to 18 psi (124.11 kPa), do a check of the

wiring between the #2 HPSOV and the ECS ECU (Refer to WM 21−11−00):

2121−P28 2100−P5

(#2 HPSOV) (ECS ECU)

A 24

B 23

C 12

D 38

4 If the wiring is unserviceable, repair the wiring. Do the Close Out.

(18) Shut down the #2 engine (Refer to AMM 71−00−00−868−802).

(19) Start the #1 engine (Refer to AMM 71−00−00−868−801). Set the controls to the positions

that follow:

(a) On the centre console, set the #1 PLA to DISC and #1 CLA to MIN.

(b) On the AIR CONDITIONING control panel, do as follows:

PSM 1−84−23 − MASTER

EFFECTIVITY:

Page 299.62

See First Effectivity on Page 299.57 of 21−60−00 21−60−00 Sep 05/2020

Print Date: 2021-05-27

D FAULT ISOLATION MANUAL

1 Set the #1 BLEED control switch to on position.

2 Set the BLEED flow control selector to NORM position.

3 Set the RECIRC fan to off position.

4 Set the #1 and #2 PACK switches to the AUTO position.

5 Set the FLT COMP and CABIN temperature selectors to the 12 o’clock position.

(20) Is there bleed air flow from the flight compartment and cabin gaspers?

(a) If yes, continue the troubleshooting.

(b) If no, replace the #1 nacelle shutoff valve (Refer to AMM 36−11−19−000−801 and

AMM 36−11−19−400−801).

(c) If there is still no air flow, do a check of the wiring between the #1 nacelle shutoff valve

and ECS ECU (Refer to WM 21−11−00):

2121−P11 2100−P2

(#1 Nacelle Shutoff Valve) (ECS ECU)

A 53

B 54

C 14

D 39

(d) If the wiring is unserviceable, repair the wiring. Do the Close Out.

(21) Look for the ITT increase, when the #1 BLEED is set to on and off. Does the ITT increase

more than 30 °C (86 °F)?

(a) If yes, continue the troubleshooting.

(b) If no, do a check for the P2.7 to P3 pressure switch over with the #1 PLA set at 86%

Nh, #1 CLA to the MAX position, #1 BLEED to on and BLEED flow to the NORM

position. Wait for two minutes to let the system become stable. Then put the #2 PLA to

the FLIGHT IDLE position. The deice pressure gauge must decrease to approximately

10 psi (68.95 kPa), then return to 18 psi (124.11 kPa).

NOTE: P3 to P2.7 switch over will occur before the engine gets to 25% torque on

an advancing PLA. On a retarding PLA, P2.7 air must return to P3 at

approximately 35% torque.

1 If the deice pressure returns to 18 psi (124.11 kPa), continue the troubleshooting.

2 If the deice pressure does not return to 18 psi (124.11 kPa), replace the #1

HPSOV (Refer to AMM 36−11−09−000−801 and AMM 36−11−09−400−801).

3 If the deice pressure still does not return to 18 psi (124.11 kPa), do a check of the

wiring between the #1 HPSOV and the ECS ECU (Refer to WM 21−11−00):

PSM 1−84−23 − MASTER

EFFECTIVITY:

Page 299.63

See First Effectivity on Page 299.57 of 21−60−00 21−60−00 Sep 05/2020

Print Date: 2021-05-27

D FAULT ISOLATION MANUAL

2121−P10 2100−P2

(#1 HPSOV) (ECS ECU)

A 33

B 5

C 72

D 73

4 If the wiring is unserviceable, repair the wiring. Do the Close Out.

(22) Shut down the #1 engine (Refer to AMM 71−00−00−868−802).

(23) If the fault continues, get access to the heat exchanger top surface.

(24) If there are holes, leak or contamination in the heat exchanger, replace the heat exchanger

(Refer to AMM 21−51−01−000−801 and AMM 21−51−01−400−801).

6. Close Out

Subtask 21−60−00−710−003

A. Do the operational test of the ECS temperature control (Refer to AMM 21−61−00−710−803)

Subtask 21−60−00−941−098

B. Do the CDS fault message retrieval for the ECS (Refer to AMM 45−00−21−742−801).

C. Make sure that the ECS fault codes retrieved in step 4.A. are not displayed in the ECS present

fault page.

D. Do the fault isolation for the CDS present fault codes (Refer to FIM 21−60−00).

PSM 1−84−23 − MASTER

EFFECTIVITY:

Page 299.64

See First Effectivity on Page 299.57 of 21−60−00 21−60−00 Sep 05/2020

Print Date: 2021-05-27

D FAULT ISOLATION MANUAL

Do the retrieval of the Central Diagnostic

System (CDS) fault indications for the

Environmental Control System (ECS) (Refer

to AMM 45−00−21−742−801).

Record the present and historical fault codes.

If the fault code is 3502−SEC HX PERF, do the

fault isolation for the SEC HX PERF (Refer to

FIM 21−60−00−810−846).

Are Fault Codes YES If the fault code is 3F01−FD ACM, do the fault

3502, 3F01 and 3F02 isolation for the FD ACM (Refer to FIM

present? 21−60−00−810−841).

If the fault code is 3F02−CAB ACM, do the fault

isolation for the CAB ACM (Refer to FIM

21−60−00−810−842).

NO

Erase the data from the CDS (Refer to

AMM 45−00−21−743−801).

On the AIR CONDITIONING control

panel, set the RECIRC fan on.

Is there air flow Rectify the duct that has separated,

NO

from all the flight either below the cabin floor or the A

compartment and

the cabin gaspers? ECS bay.

YES

Start the Auxiliary Power Unit (APU) (Refer to AMM 49−00−00−869−801). On the

APU control panel, set the BL AIR on. On the AIR CONDITIONING control panel,

set the left and right PACK switches to the AUTO postion. Set the FLT COMP and

CABIN temperature selectors to the 12 o’clock position.

Are there air leaks YES

in the ECS bay? Repair the leaks. A

cg3231a01.dg, sg, may16/2014

NO

LOW FLOW FROM CABIN AND /OR FLIGHT DECK ECS SYSTEM − FAULT ISOLATION

Figure 211 (Sheet 1 of 10)

PSM 1−84−23 − MASTER

EFFECTIVITY:

Page 299.65

See First Effectivity on Page 299.57 of 21−60−00

21−60−00 Sep 05/2020

Print Date: 2021-05-27

D FAULT ISOLATION MANUAL

Use a mirror to do a visual inspection of the Pack

Flow Control and Shut−Off Valve (PFCSOV). Make

sure that the PFCSOV is open (approximately 50%

or more).

YES Replace the PFCSOV filter (Refer to

Is the PFCSOV closed? AMM 21−52−01−000−802 and

AMM 21−52−01−400−802).

NO

NO

Does the PFCSOV stay

closed?

YES

Replace the PFCSOV (Refer to

AMM 21−52−01−000−801 and

AMM 21−52−01−400−801).

NO Does the PFCSOV stay

closed?

YES

Do a check of the wiring between

the PFCSOV and the ECS Electronic

cg3231a02.dg, sg, may19/2014

Control Unit (ECU) (Refer to

WM 21−61−00).

C D

LOW FLOW FROM CABIN AND /OR FLIGHT DECK ECS SYSTEM − FAULT ISOLATION

Figure 211 (Sheet 2 of 10)

PSM 1−84−23 − MASTER

EFFECTIVITY:

Page 299.66

See First Effectivity on Page 299.57 of 21−60−00

21−60−00 Sep 05/2020

Print Date: 2021-05-27

D FAULT ISOLATION MANUAL

C D

YES

Is the wiring seviceable?

Feel for the Air Cycle Machine (ACM) exhaust

flow from the external exhaust vents at the

top left and right empennage. If necessary,

use the ladder. NO

Caution: Hot Air Blast.

Repair the wiring. A

YES

Is hot air exiting from the E

exhaust vents?

NO

YES Replace the applicable turbine shutoff valve

Is the applicable turbine filter (Refer to AMM 21−51−41−000−802

shutoff valve and AMM 21−51−41−400−802).

closed?

NO

NO Does the turbine

shutoff valve stay

closed?

YES

cg3231a03.dg, sg, may16/2014

Replace the applicable turbine shutoff valve

(Refer to AMM 21−51−41−000−801 and

AMM 21−51−41−400−801).

F G

LOW FLOW FROM CABIN AND /OR FLIGHT DECK ECS SYSTEM − FAULT ISOLATION

Figure 211 (Sheet 3 of 10)

PSM 1−84−23 − MASTER

EFFECTIVITY:

Page 299.67

See First Effectivity on Page 299.57 of 21−60−00

21−60−00 Sep 05/2020

Print Date: 2021-05-27

D FAULT ISOLATION MANUAL

F G

NO Does the turbine

shutoff valve stay closed?

YES

Do a check of the wiring between the turbine

shutoff valve and the ECS ECU (Refer to

WM 21−61−00).

YES

Is the wiring seviceable?

Replace the ACM (Refer to AMM

21−51−21−000−801 and AMM

21−51−21−400−801). NO

Repair the wiring. A

Does low flow YES

condition still exist H

when using APU?

cg3231a04.dg, sg, may16/2014

NO

LOW FLOW FROM CABIN AND /OR FLIGHT DECK ECS SYSTEM − FAULT ISOLATION

Figure 211 (Sheet 4 of 10)

PSM 1−84−23 − MASTER

EFFECTIVITY:

Page 299.68

See First Effectivity on Page 299.57 of 21−60−00

21−60−00 Sep 05/2020

Print Date: 2021-05-27

D FAULT ISOLATION MANUAL

Repeat the procedure using the engine bleed air air (Refer to AMM 71−00−00−868−801).

NOTE: APU bleed air supplies considerable more flow and pressure than the engine bleed air.

This additional flow and pressure will mask the marginal valve performance.

NO

Does the fault still continue? A

YES

Start the #2 engine (Refer to AMM 71−00−00−868−801). Set the #2 Power Lever Angle (PLA) to

DISC and #2 Condition Lever Angle (CLA) to MIN. Set the #2 BLEED on, BLEED flow to NORM,

RECIRC fan off, #1 and #2 PACK switches to AUTO. Set the FLT COMP and CABIN temperature

selectors to the 12 o’clock position.

Is there bleed air

NO Replace the #2 nacelle shutoff valve

flow from the filght

compartment and cabin (Refer to AMM 36−11−19−000−801

gaspers? and AMM 36−11−19−400−801).

YES

YES

Is there bleed air flow?

NO

cg3231a05.dg, sg, may16/2014

Do a check of the wiring between the

#2 nacelle shutoff valve and the ECS

ECU (Refer to WM 21−11−00).

K L

LOW FLOW FROM CABIN AND /OR FLIGHT DECK ECS SYSTEM − FAULT ISOLATION

Figure 211 (Sheet 5 of 10)

PSM 1−84−23 − MASTER

EFFECTIVITY:

Page 299.69

See First Effectivity on Page 299.57 of 21−60−00

21−60−00 Sep 05/2020

Print Date: 2021-05-27

D FAULT ISOLATION MANUAL

K L

YES

Is the wiring serviceable?

Look for the Inter Turbine Temperature NO

(ITT) increase, when the #2 BLEED is set

to on and off. Repair the wiring. A

Do a check for the P2.7 to P3 pressure switch over

NO with the #2 PLA set to 86% Nh, #2 CLA to MAX,

Did the ITT increase more #2 Bleed on and BLEED flow to NORM position.

o o

than 30 C (86 F)? Wait for two minutes to let the system become stable.

Pull the #2 PLA to the FLIGHT IDLE position. Do a

check of the deice pressure gauge. (Refer NOTE 1).

YES NOTE 1: P3 to P2.7 switch over will occur before

the engine gets to 25% torque on an advancing

PLA. On a retarding PLA, P2.7 air must return to

P3 at approximately 35% torque.

YES Did the deice pressure

gauge drop to 10 psi

and then return to

to 18 psi?

NO

Replace the #2 High Pressure Shut

Off Valve (HPSOV) (Refer to AMM

cg3231a06.dg, sg, may16/2014

36−11−09−000−801 and

36−11−09−400−801).

M N

LOW FLOW FROM CABIN AND /OR FLIGHT DECK ECS SYSTEM − FAULT ISOLATION

Figure 211 (Sheet 6 of 10)

PSM 1−84−23 − MASTER

EFFECTIVITY:

Page 299.70

See First Effectivity on Page 299.57 of 21−60−00

21−60−00 Sep 05/2020

Print Date: 2021-05-27

D FAULT ISOLATION MANUAL

M N

YES Did the deice pressure

gauge return to 18 psi?

NO

Do a check of the wiring between

the #2 HPSOV and the ECS ECU

(Refer to WM 21−11−00).

YES

Is the wiring seviceable?

NO

Shut down the #2 engine (Refer

to AMM 71−00−00−868−802). Repair the wiring. A

Start the #1 engine (Refer to AMM 71−00−00−868−801). Set the #1 PLA to DISC and #1 CLA to MIN.

Set the #1 BLEED on, BLEED flow to NORM, RECIRC fan off, #1 and #2 PACK switches to AUTO.

Set the FLT COMP and CABIN temperature selectors to the 12 o’clock position.

Is there bleed air

NO Replace the #1 nacelle shutoff valve

flow from the filght

compartment and cabin (Refer to AMM 36−11−19−000−801

gaspers? and AMM 36−11−19−400−801).

cg3231a07.dg, sg, may19/2014

YES

P R

LOW FLOW FROM CABIN AND /OR FLIGHT DECK ECS SYSTEM − FAULT ISOLATION

Figure 211 (Sheet 7 of 10)

PSM 1−84−23 − MASTER

EFFECTIVITY:

Page 299.71

See First Effectivity on Page 299.57 of 21−60−00

21−60−00 Sep 05/2020

Print Date: 2021-05-27

D FAULT ISOLATION MANUAL

P R

YES

Is there bleed air flow?

NO

Do a check of the wiring between the

#1 nacelle shutoff valve and the ECS

ECU (Refer to WM 21−11−00).

YES

Is the wiring serviceable?

NO

Look for the ITT increase, when

Repair the wiring. A

the #1 BLEED is set to on and off.

Do a check for the P2.7 to P3 pressure switch over

with the #1 PLA set to 86% Nh, #1 CLA to MAX,

NO

Did the ITT increase more #1 Bleed on and BLEED flow to NORM position.

o o Wait for two minutes to let the system become stable.

than 30 C (86 F)?

Pull the #1 PLA to the FLIGHT IDLE position. Do a

check of the deice pressure gauge. (Refer NOTE 1).

YES NOTE 2: P3 to P2.7 switch over will occur

before the engine gets to 25% torque on an

cg3231a08.dg, sg, may19/2014

advancing PLA. On a retarding PLA, P2.7 air

must revert to P3 at approximately 35% torque.

S T

LOW FLOW FROM CABIN AND /OR FLIGHT DECK ECS SYSTEM − FAULT ISOLATION

Figure 211 (Sheet 8 of 10)

PSM 1−84−23 − MASTER

EFFECTIVITY:

Page 299.72

See First Effectivity on Page 299.57 of 21−60−00

21−60−00 Sep 05/2020

Print Date: 2021-05-27

D FAULT ISOLATION MANUAL

S T

YES Did the deice pressure

gauge drop to 10 psi

and then return to

to 18 psi?

NO

Replace the #1 HPSOV (Refer to

AMM 36−11−09−000−801 and

AMM 36−11−09−400−801).

YES Did the deice pressure

gauge return to 18 psi?

NO

Do a check of the wiring between

the #1 HPSOV and the ECS ECU

(Refer to WM 21−11−00).

YES

Is the wiring seviceable?

NO

cg3231a09.dg, sg, may19/2014

Shut down the #1 engine (Refer Repair the wiring. A

to AMM 71−00−00−868−802).

LOW FLOW FROM CABIN AND /OR FLIGHT DECK ECS SYSTEM − FAULT ISOLATION

Figure 211 (Sheet 9 of 10)

PSM 1−84−23 − MASTER

EFFECTIVITY:

Page 299.73

See First Effectivity on Page 299.57 of 21−60−00

21−60−00 Sep 05/2020

Print Date: 2021-05-27

D FAULT ISOLATION MANUAL

NO

Does the fault continue? A

YES

Get access to the heat

exchanger top surface.

Does the heat YES Replace the heat exchanger (Refer to

exchanger show signs of AMM 21−51−01−000−801 and A

cracking, holes, leaks or AMM 21−51−01−400−801).

contamination?

NO

Do the operational test of the ECS

temperature control (Refer to AMM

21−61−00−710−803).

Do the CDS fault message retrieval

for the ECS (Refer to AMM

45−00−21−742−801).

YES

Do the fault isolation for the

Are fault codes present?

CDS present fault codes (Refer

cg3231a10.dg, sg, may19/2014

to FIM 21−60−00).

NO

Close Out

LOW FLOW FROM CABIN AND /OR FLIGHT DECK ECS SYSTEM − FAULT ISOLATION

Figure 211 (Sheet 10 of 10)

PSM 1−84−23 − MASTER

EFFECTIVITY:

Page 299.74

See First Effectivity on Page 299.57 of 21−60−00

21−60−00 Sep 05/2020

Print Date: 2021-05-27

D FAULT ISOLATION MANUAL

LOCKOUT ARM

SHOWN IN OPEN

POSITION. ROTATE

CCW TO CLOSE

CLOSED

POSITION

cg3244a01.dg, rc, apr22/2014

SWITCH

Pack Flow Control and Shut Off Valve

Figure 212

PSM 1−84−23 − MASTER

EFFECTIVITY:

Page 299.75

See First Effectivity on Page 299.57 of 21−60−00

21−60−00 Sep 05/2020

Print Date: 2021-05-27

D FAULT ISOLATION MANUAL

LOCKOUT ARM

cg3262a01.dg, rc, apr22/2014

SHOWN IN CLOSED

POSITION. ROTATE

CCW TO OPEN

Turbine Shutoff Valve

Figure 213

PSM 1−84−23 − MASTER

EFFECTIVITY:

Page 299.76

See First Effectivity on Page 299.57 of 21−60−00

21−60−00 Sep 05/2020

Print Date: 2021-05-27

You might also like

- Fault Isolation Manual: Print Date: 2021-05-27Document16 pagesFault Isolation Manual: Print Date: 2021-05-27Mahbub RahmanNo ratings yet

- Fault Isolation Manual: Print Date: 2021-05-27Document13 pagesFault Isolation Manual: Print Date: 2021-05-27Mahbub RahmanNo ratings yet

- Fault Isolation Manual: Print Date: 2021-05-27Document12 pagesFault Isolation Manual: Print Date: 2021-05-27Mahbub RahmanNo ratings yet

- Temporary Revision 21 043: Filing InstructionsDocument16 pagesTemporary Revision 21 043: Filing Instructionsnishat529No ratings yet

- Fault Isolation ManualDocument4 pagesFault Isolation Manualom prakash patelNo ratings yet

- Fault Isolation ManualDocument10 pagesFault Isolation Manualmuchammad faruroziNo ratings yet

- Fault Isolation ManualDocument11 pagesFault Isolation Manualmuchammad faruroziNo ratings yet

- Fuel System - Inspection/Check: Reference DesignationDocument4 pagesFuel System - Inspection/Check: Reference DesignationNilgun YetisNo ratings yet

- V2500 TSDocument18 pagesV2500 TSalex100% (3)

- Fault Isolation ManualDocument7 pagesFault Isolation Manualmuchammad faruroziNo ratings yet

- On A/C All: Zone/Access Zone DescriptionDocument4 pagesOn A/C All: Zone/Access Zone DescriptionbillyNo ratings yet

- 10N - A318 _ A319 _ A320 _ A321 - TSM - FSN_ 252 - 01-Feb-2023 - 28-21-00-810-823-A - Center Tank Autofeed System (Sequence_Distribution) Fault - The Fuel Has Not Been Used In The Correct Sequence During An Aircraft FlightDocument11 pages10N - A318 _ A319 _ A320 _ A321 - TSM - FSN_ 252 - 01-Feb-2023 - 28-21-00-810-823-A - Center Tank Autofeed System (Sequence_Distribution) Fault - The Fuel Has Not Been Used In The Correct Sequence During An Aircraft FlightКирилл АндриенкоNo ratings yet

- Chapter 21 PDFDocument1,909 pagesChapter 21 PDFAmjad Salam100% (2)

- api/resources/file/CH604MM/ATA 100/CH604/AMM/49/AMM49 10 00 04.fullDocument40 pagesapi/resources/file/CH604MM/ATA 100/CH604/AMM/49/AMM49 10 00 04.fullRahul VaishnavNo ratings yet

- On A/C All: Reference Qty DesignationDocument6 pagesOn A/C All: Reference Qty DesignationMak OrNo ratings yet

- AMM32 51 31 04.fullDocument6 pagesAMM32 51 31 04.fullTarek ElghazzalyNo ratings yet

- Amm Task Perf Each FlightDocument5 pagesAmm Task Perf Each Flightbilly100% (1)

- EfcsDocument4 pagesEfcsJai DeepNo ratings yet

- SteerDocument53 pagesSteerKuldeep SinghNo ratings yet

- AMM - 01-Aug-2023 - 22-63-00-710-001-A - Operational Test of The Yaw Damper FunctionDocument4 pagesAMM - 01-Aug-2023 - 22-63-00-710-001-A - Operational Test of The Yaw Damper Functionayan acharjeeNo ratings yet

- Operational Check of RAT Manual Deployment and Functional Check of RAT Using PDFDocument20 pagesOperational Check of RAT Manual Deployment and Functional Check of RAT Using PDFVladimir AmayaNo ratings yet

- AMM - IGO - A318/A319/A320/A321 REV DATE: Aug 01/2021 Tail Number - MSN - FSN: VT-ILN - 10151 - 431Document5 pagesAMM - IGO - A318/A319/A320/A321 REV DATE: Aug 01/2021 Tail Number - MSN - FSN: VT-ILN - 10151 - 431Rameswar PradhanNo ratings yet

- Fault Isolation ManualDocument7 pagesFault Isolation Manualmuchammad faruroziNo ratings yet

- MPP4223 - 72 21 00 05 1 PDFDocument24 pagesMPP4223 - 72 21 00 05 1 PDFkamentdNo ratings yet

- Valve - Pressure Regulating - Removal & InstallationDocument8 pagesValve - Pressure Regulating - Removal & Installationjoby619No ratings yet

- Biblia A320 - 1 PDFDocument134 pagesBiblia A320 - 1 PDFCarlos Andrés Escamilla González100% (1)

- Borescope Inspection of The Inner Cowl Bolts of The Combustion ChamberDocument3 pagesBorescope Inspection of The Inner Cowl Bolts of The Combustion Chamber尹兴旺No ratings yet

- Leap FMUDocument10 pagesLeap FMURameswar PradhanNo ratings yet

- Task 46!21!00-740-001-A Bite Test of The AtimsDocument4 pagesTask 46!21!00-740-001-A Bite Test of The AtimsSatishReddy100% (1)

- AMM - IGO - A318/A319/A320/A321 REV DATE: Aug 01/2021 Tail Number - MSN - FSN: VT-ILN - 10151 - 431Document6 pagesAMM - IGO - A318/A319/A320/A321 REV DATE: Aug 01/2021 Tail Number - MSN - FSN: VT-ILN - 10151 - 431Rameswar PradhanNo ratings yet

- Task 804Document4 pagesTask 804Buncha MatNo ratings yet

- GVI Brake Units - 32-40-00-210-801-A PDFDocument4 pagesGVI Brake Units - 32-40-00-210-801-A PDFpannNo ratings yet

- Trim TankDocument4 pagesTrim TankEnrique Rodriguez NavaNo ratings yet

- 2009-07!28!045630 Remove Install Electrohydraulic Control Module Transmission InstalledDocument3 pages2009-07!28!045630 Remove Install Electrohydraulic Control Module Transmission InstalledfulltransmissionNo ratings yet

- Task 46!21!00-710-002-A VHF 3 Link Test of The AtsuDocument8 pagesTask 46!21!00-710-002-A VHF 3 Link Test of The AtsuSatishReddyNo ratings yet

- Amm Tasks Airbus A 319 320 321Document6 pagesAmm Tasks Airbus A 319 320 321Jose HomoNo ratings yet

- AMM Tasks Airbus A-319 / 320 / 321Document6 pagesAMM Tasks Airbus A-319 / 320 / 321xjrsommsi90% (10)

- Aircraft Maintenance ManualDocument4 pagesAircraft Maintenance ManualBambang Agus RiadiNo ratings yet

- 49-90-00-810-812-A - Lube Pump Filter SW P9/GEN SCAV Filter SW P5 Fault (131-9 (A) )Document4 pages49-90-00-810-812-A - Lube Pump Filter SW P9/GEN SCAV Filter SW P5 Fault (131-9 (A) )Rahul SharmaNo ratings yet

- TSM - FHM - A318/A319/A320/A321 REV DATE: Aug 01/2021 Tail Number - MSN - FSN: 9H-FHB - 03025 - 001Document2 pagesTSM - FHM - A318/A319/A320/A321 REV DATE: Aug 01/2021 Tail Number - MSN - FSN: 9H-FHB - 03025 - 001özkanNeşeliNo ratings yet

- Chapter 27 PDFDocument3,861 pagesChapter 27 PDFAmjad SalamNo ratings yet

- A320 AMM Chapter 21Document1,563 pagesA320 AMM Chapter 21Edcil Esblaca100% (1)

- Mercedes CLK w320 Wis ContentsDocument234 pagesMercedes CLK w320 Wis ContentsȘtefan Bulgaru100% (1)

- 01Document7 pages01Jai DeepNo ratings yet

- AMM Task May 20Document1,657 pagesAMM Task May 20sreejithNo ratings yet

- TAP - A330 Removal of The Forward (FWD) Plug AssemblyDocument5 pagesTAP - A330 Removal of The Forward (FWD) Plug AssemblyEdson CarvalhoNo ratings yet

- AMM 36-11-00-710-826-A - Operational Test of The Bleed Air SystemDocument9 pagesAMM 36-11-00-710-826-A - Operational Test of The Bleed Air SystemEdson CarvalhoNo ratings yet

- A319 - A321 - LAA - and - LUS - A321NX - (Trouble Shooting Manual)Document23 pagesA319 - A321 - LAA - and - LUS - A321NX - (Trouble Shooting Manual)A WongNo ratings yet

- Job Card: 21-26-00-040-002-A - Deactivation of The Skin Air Outlet Valve in The Closed Position With The Inter..Document10 pagesJob Card: 21-26-00-040-002-A - Deactivation of The Skin Air Outlet Valve in The Closed Position With The Inter..billyNo ratings yet

- A321 Transit InspDocument37 pagesA321 Transit InspDebasis RoyNo ratings yet

- All Atas A320 Ecam Warnings ResetsDocument243 pagesAll Atas A320 Ecam Warnings ResetsLuis Gallegos100% (4)

- Electrical Power Ac Generation Cabin 115 Vac Inverter System Maintenance PracticesDocument8 pagesElectrical Power Ac Generation Cabin 115 Vac Inverter System Maintenance Practicessarvesh_ame2011No ratings yet

- A320 NE0 Fuel or Hydraulic or Oil Leakage LimitsDocument19 pagesA320 NE0 Fuel or Hydraulic or Oil Leakage LimitsArjuna SamaranayakeNo ratings yet

- EXT Eva Air: Job CardDocument19 pagesEXT Eva Air: Job CardLê Viết DũngNo ratings yet

- TAP - A330 Removal of The Exhaust Nozzle AssemblyDocument7 pagesTAP - A330 Removal of The Exhaust Nozzle AssemblyEdson CarvalhoNo ratings yet

- AMM 24-21-00-710-814-A - Operational Check of Integrated Drive Generator Disconnect FunctionDocument7 pagesAMM 24-21-00-710-814-A - Operational Check of Integrated Drive Generator Disconnect FunctionEdson CarvalhoNo ratings yet

- @A318/A319/A320/A321: Chapter 38 - Water/WasteDocument80 pages@A318/A319/A320/A321: Chapter 38 - Water/WastehengwahchungNo ratings yet

- Ecam ResetDocument36 pagesEcam ResetLeonard Komon100% (1)

- Marine Electrical Practice: Marine Engineering SeriesFrom EverandMarine Electrical Practice: Marine Engineering SeriesRating: 4 out of 5 stars4/5 (8)

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesFrom EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNo ratings yet

- Access Panel AIPC57!21!00-01Document1 pageAccess Panel AIPC57!21!00-01Mahbub RahmanNo ratings yet

- Anoopsb 8Document2 pagesAnoopsb 8Mahbub RahmanNo ratings yet

- Time Limited Dispatch AircraftDocument1 pageTime Limited Dispatch AircraftMahbub RahmanNo ratings yet

- No Dispatch Long Term: Powerplant Main MenuDocument13 pagesNo Dispatch Long Term: Powerplant Main MenuMahbub RahmanNo ratings yet

- Message List: Status: Status Message (Level) Description Fault Code Fim Task Ref (Refspl)Document168 pagesMessage List: Status: Status Message (Level) Description Fault Code Fim Task Ref (Refspl)Mahbub RahmanNo ratings yet

- Cur-037-2 Summative Assessment #1 - Week 1Document3 pagesCur-037-2 Summative Assessment #1 - Week 1Dame YooheeNo ratings yet

- D 6815 - 02 Rdy4mtu - PDFDocument11 pagesD 6815 - 02 Rdy4mtu - PDFRufo CascoNo ratings yet

- 3 - Development of An Inspection Robot ForDocument7 pages3 - Development of An Inspection Robot ForZaida AsyfaNo ratings yet

- CHANGES in AISC's SEISMIC PROVISIONS: AISC 341-05 To AISC 341-10Document68 pagesCHANGES in AISC's SEISMIC PROVISIONS: AISC 341-05 To AISC 341-10Anonymous 7MdZQn167% (3)

- Mechanical WIP Test Forms - Air Balancing - Randys Donut - Okada - With Temp - SignedDocument1 pageMechanical WIP Test Forms - Air Balancing - Randys Donut - Okada - With Temp - SignedJovani G. BallonNo ratings yet

- Laterally Loaded Pile With Plaxis 3dDocument5 pagesLaterally Loaded Pile With Plaxis 3dteomalancuNo ratings yet

- On Shrink Fit Analysis and DesignDocument10 pagesOn Shrink Fit Analysis and DesignParag NaikNo ratings yet

- A Duplex Stainless Steel 2205Document8 pagesA Duplex Stainless Steel 2205AboMuhmadSr.No ratings yet

- A320 - 70 Powerplant (CFM56) - GFC-1Document33 pagesA320 - 70 Powerplant (CFM56) - GFC-1belinda koyaiyeNo ratings yet

- Method Statement Mechanical SystemDocument181 pagesMethod Statement Mechanical SystemOsama Ali100% (1)

- Combined Use of NDT-SDT Methods For The Assessment of Structural Timber MembersDocument239 pagesCombined Use of NDT-SDT Methods For The Assessment of Structural Timber MembersSabrina PhilippeNo ratings yet

- 7 +brakesDocument143 pages7 +brakesLuis Daniel RodriguezNo ratings yet

- Mindray Wato EX-65 Anaesthesia Machine - Service Manual-6Document50 pagesMindray Wato EX-65 Anaesthesia Machine - Service Manual-6Rene GonzalesNo ratings yet

- A Technique To Determine Lift and Drag Polars in FlightDocument7 pagesA Technique To Determine Lift and Drag Polars in Flightmykingboody2156No ratings yet

- Hoop StressDocument3 pagesHoop Stresskarthikraja21No ratings yet

- Pages From Two - Stage - Booster PDFDocument16 pagesPages From Two - Stage - Booster PDFVRV.RELATORIO.AVARIA RELATORIO.AVARIA100% (1)

- AQA AS Physics A Chapter 11 Textbook AnswersDocument3 pagesAQA AS Physics A Chapter 11 Textbook AnswerscathylisterNo ratings yet

- With Aerzen Turbos, Blowers and Compressors: Heat RecoveryDocument8 pagesWith Aerzen Turbos, Blowers and Compressors: Heat RecoveryBülent BulutNo ratings yet

- Parts List: Denim Pro Model BL 18Document19 pagesParts List: Denim Pro Model BL 18David GarnerNo ratings yet

- Centrifuges, Sediment IngDocument6 pagesCentrifuges, Sediment IngLatif Hasan Çite100% (2)

- API Sealing Ability PDFDocument11 pagesAPI Sealing Ability PDFBandanos SontolNo ratings yet

- ASME - Wake Frequency CalculationDocument7 pagesASME - Wake Frequency CalculationpsaayoNo ratings yet

- ANGLEDocument3 pagesANGLEskorut100% (2)

- +DE710-03 - A01 - Manual Actualizado A Julio 2018Document74 pages+DE710-03 - A01 - Manual Actualizado A Julio 2018Juan RafaelNo ratings yet

- Shut-Down Maintenance and Pending Job List: (For Raw Mil Section-Month: April-2017)Document5 pagesShut-Down Maintenance and Pending Job List: (For Raw Mil Section-Month: April-2017)vinodsnNo ratings yet

- 2009-2010 APRILIA RSV4 FactoryDocument81 pages2009-2010 APRILIA RSV4 FactoryMade ChristianNo ratings yet

- JR - Fluid Controls Brochure - SPM0838-FOR-WEBDocument16 pagesJR - Fluid Controls Brochure - SPM0838-FOR-WEBMai Tuan AnhNo ratings yet

- Sea Saw Gen FinalDocument27 pagesSea Saw Gen FinalSanjay Jadhav67% (3)

- 4sthead Insight PDFDocument4 pages4sthead Insight PDFGuilherme PfeilstickerNo ratings yet

- A - Case Method Introduction - OK35Document48 pagesA - Case Method Introduction - OK35Adeel AhmadNo ratings yet