Professional Documents

Culture Documents

kx80 Página 111

Uploaded by

Pablo0 ratings0% found this document useful (0 votes)

26 views1 pageOriginal Title

kx80_Página_111

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

26 views1 pagekx80 Página 111

Uploaded by

PabloCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 1

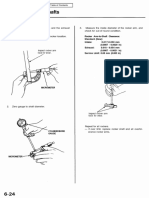

7-10 ENGINE BOTTOM ENDITRANSMISSION

Crankshaft Assembly Notes Connecting Rod Big End Side Clearance

Since the assembly of the crankshaft demands O Measure the side clearance of the connecting rod

exacting tolerances, the disassembly and

with a thickness gauge.

reassembly of the

crankshaft can only be done by the clearance exceeds the service timit, replace the

a shop having the crankshaft.

necessary tools and equipment.

O Reassemble the crankshaft according to the

standard tolerances in Specifications. Standard:Rod Big End Side Clearance

O Connecting Rod Bendr Twist 0.35 - 0.45 mm

O Connecting rod big end radial clearance. Service Limit: 0.7 mm

0 Coid-fitting tolerance between crankpin and flywheels.

OSide clearance between the connecting rod big end and Side Clearance

one of the flywheets.

Side Clearance

O Crankshaft runout.

Connecting Rod Big End Radial Clearance

oset the crankshaft in a flywheel alignment jig or on V

blocks, and place a dial gauge against the

connecting rod big end.

OPush the connecting rod first towards the gauge and

then in the opposite direction. The difference between

the two gauge readings is the radial clearance.

the radial clearance exceeds the service limit, the

crankshaft should be either replaced or disassembied

and the crankpin, needle bearing, and connecting rod

big end examined for wear.

Rod Big End Radial Crankshaft Runout

Standard: oset the crankshaft on V blocks, and place a dial

KX60 gauge against the points indicated.

o.om - 0.033 mm OTurn the crankshaft slowiy. The maximum difference

KX80, KDX80 0.023 - 0.035 mm

in gauge readings is the crankshaft runout.

Service Limit: 0.08 mm

Crankshaft Runout

Standard: Not more than OE mm

Limit:

0.10 mm

mm

O

Big EndSeizure

case of serious seizure with damaged flywheels, the

crankshaft must be

case of less serious damage, disassa•nble the

crankshaft and replace- the crankpinr needte bearing,

side washers, and connecting rod.

You might also like

- Engine Valve Lash - Inspect - Adjust c9Document3 pagesEngine Valve Lash - Inspect - Adjust c9Antonio78% (9)

- Mercruiser Service Manual GM V6 4.3 CompleteDocument895 pagesMercruiser Service Manual GM V6 4.3 CompletePaul Chuon94% (16)

- Nissan Y61 Engine MechanicalDocument65 pagesNissan Y61 Engine Mechanicalblumng100% (2)

- Isuzu Engine 6ve1 35l Workshop Manual PDFDocument582 pagesIsuzu Engine 6ve1 35l Workshop Manual PDFCristian100% (1)

- Universal Tool and Cutter Grinder Manual Low ResDocument16 pagesUniversal Tool and Cutter Grinder Manual Low ResDale Wade100% (1)

- Band Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsFrom EverandBand Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsRating: 5 out of 5 stars5/5 (1)

- Nissan Engine MR20DE Repair Manual DownloadDocument218 pagesNissan Engine MR20DE Repair Manual DownloadMohammed Elkuni100% (8)

- How to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheFrom EverandHow to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheRating: 4.5 out of 5 stars4.5/5 (2)

- Overhauling a Differential Step-by-StepDocument14 pagesOverhauling a Differential Step-by-StepHaris100% (2)

- Lovol - Fl936-Dhbo6g0131Document140 pagesLovol - Fl936-Dhbo6g0131LuzioNetoNo ratings yet

- H.N. Gupta - Fundamentals of Internal Combustion Engines-PHI Learning Private Limited (2013)Document675 pagesH.N. Gupta - Fundamentals of Internal Combustion Engines-PHI Learning Private Limited (2013)suspiria100% (3)

- Crank Shaft PresentationgnsDocument42 pagesCrank Shaft Presentationgnskr_abhijeet72356587100% (1)

- 2005 Seadoo Rotax 1503 4 Tech Shop Manual - 101 EndDocument24 pages2005 Seadoo Rotax 1503 4 Tech Shop Manual - 101 EndOscar Eduardo GomezNo ratings yet

- Cylinderipiston: System Components 10-2 Cylinderipiston Removal 10-4 10-3 Cylinderipiston Installation....... 10-9Document118 pagesCylinderipiston: System Components 10-2 Cylinderipiston Removal 10-4 10-3 Cylinderipiston Installation....... 10-9poiufdsapuroiqNo ratings yet

- Eaton Fuller Heavy Duty Transmissions: Illustrated Parts List RTLO-16918B March 2003Document42 pagesEaton Fuller Heavy Duty Transmissions: Illustrated Parts List RTLO-16918B March 2003Oscar MarquezNo ratings yet

- Series-90 250cc Service 520l0898 Rev Aa 2012-03Document64 pagesSeries-90 250cc Service 520l0898 Rev Aa 2012-03anon_757712831No ratings yet

- Motor Doosan DV11Document220 pagesMotor Doosan DV11David Catari100% (4)

- Tool and Cutter PDFDocument15 pagesTool and Cutter PDFKiwishooter50% (4)

- Work Shop Manual - BUKH DV 20 ME PDFDocument306 pagesWork Shop Manual - BUKH DV 20 ME PDFTom KooleNo ratings yet

- Alignment StandardsDocument6 pagesAlignment StandardsFidelFornolles100% (2)

- 950H - Ajuste de Luz de VálvulasDocument4 pages950H - Ajuste de Luz de VálvulasRenato Assis da Silva100% (2)

- Traction Alternator Type Ta10106cyDocument64 pagesTraction Alternator Type Ta10106cyTirthankar DasNo ratings yet

- Suzuki GSX R 400 GK73A 1988 1989 Manual de Reparatie WWW - Manualedereparatie.infoDocument248 pagesSuzuki GSX R 400 GK73A 1988 1989 Manual de Reparatie WWW - Manualedereparatie.infoJesus Morales67% (3)

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Mitsubishi Engine 4DQ3 4DQ30 Service Manual 99609-50000Document61 pagesMitsubishi Engine 4DQ3 4DQ30 Service Manual 99609-50000Miroslav TabakovskiNo ratings yet

- Calibracion de Valvulas John Deere 6090Document3 pagesCalibracion de Valvulas John Deere 6090青春只是一张黑白画。100% (1)

- Must Change Item in PohDocument23 pagesMust Change Item in Pohmailbkrao100% (1)

- Cummins Onan MDKDS DT DU Parts ManualDocument94 pagesCummins Onan MDKDS DT DU Parts ManualAsep Shaifurrahman0% (1)

- C12+ Crusher Parts ManualDocument115 pagesC12+ Crusher Parts ManualAndrey StrukovNo ratings yet

- KTA50 - Connecting RodDocument8 pagesKTA50 - Connecting RodSebastian Nicușor PărăoanuNo ratings yet

- Bucyrus: Technical ManualDocument7 pagesBucyrus: Technical ManualJohn GrayNo ratings yet

- Etk en Es 062224 LTM 1090 4 1 PDFDocument1,287 pagesEtk en Es 062224 LTM 1090 4 1 PDFGilvan JuniorNo ratings yet

- Installation of piston rings step-by-stepDocument3 pagesInstallation of piston rings step-by-stepEdimilson RodriguesNo ratings yet

- Gears in Drive Shaft: S. No. Fastener, Size, Tool Usage, Precautions, Photos Aggregate To Assemble / InstructionsDocument20 pagesGears in Drive Shaft: S. No. Fastener, Size, Tool Usage, Precautions, Photos Aggregate To Assemble / InstructionsJulian GallegoNo ratings yet

- Gears in Drive Shaft: S. No. Fastener, Size, Tool Usage, Precautions, Photos Aggregate To Assemble / InstructionsDocument20 pagesGears in Drive Shaft: S. No. Fastener, Size, Tool Usage, Precautions, Photos Aggregate To Assemble / InstructionsJulian GallegoNo ratings yet

- Gears in Drive Shaft: S. No. Fastener, Size, Tool Usage, Precautions, Photos Aggregate To Assemble / InstructionsDocument20 pagesGears in Drive Shaft: S. No. Fastener, Size, Tool Usage, Precautions, Photos Aggregate To Assemble / InstructionsJulian GallegoNo ratings yet

- Crankcase Overhaul LimitsDocument36 pagesCrankcase Overhaul LimitsLUISA FERNANDA TORRES MANOSALVANo ratings yet

- 001-054 Piston and Connecting Rod AssemblyDocument8 pages001-054 Piston and Connecting Rod AssemblyYè WințNo ratings yet

- P250-250S Cap 07 (CYLINDER PISTON)Document9 pagesP250-250S Cap 07 (CYLINDER PISTON)Minh ChuNo ratings yet

- Einbau Gleitlager en PDFDocument4 pagesEinbau Gleitlager en PDFMohammed SaberNo ratings yet

- D200 Cap 07 (Cilindro-Pistone)Document9 pagesD200 Cap 07 (Cilindro-Pistone)Wylk BeserraNo ratings yet

- Chapter 8Document13 pagesChapter 8igorNo ratings yet

- Deb58tis 4Document11 pagesDeb58tis 4CHEMA BASANNo ratings yet

- Arranque de Patada CBFDocument23 pagesArranque de Patada CBFlau cv 97No ratings yet

- Cylinder Piston Removal Installation GuideDocument10 pagesCylinder Piston Removal Installation Guideorly pocoateNo ratings yet

- AGILITY50 Cap 08 (Cilindro Pistone)Document8 pagesAGILITY50 Cap 08 (Cilindro Pistone)api-3759317100% (1)

- 61SNC01 - 07 - Engine Mechanical - BlockDocument30 pages61SNC01 - 07 - Engine Mechanical - BlockangelvalladaresNo ratings yet

- Section 6-2Document80 pagesSection 6-2Raidul WafiNo ratings yet

- Crankcase and Crankshaft Service Procedures for YUP 50 ScooterDocument9 pagesCrankcase and Crankshaft Service Procedures for YUP 50 Scootertutifruti649No ratings yet

- Rocker Arms and Shafts: Clearance InspectionDocument1 pageRocker Arms and Shafts: Clearance InspectionsoftallNo ratings yet

- Catalogo Foton - Bj3319dmpkc-Abza02Document5 pagesCatalogo Foton - Bj3319dmpkc-Abza02Jhean PhierNo ratings yet

- Motor3 Suzuki VL800Document20 pagesMotor3 Suzuki VL800Crisan SorinNo ratings yet

- Euronorm Slewing Rings Manual (ENG)Document8 pagesEuronorm Slewing Rings Manual (ENG)Gladwin JesNo ratings yet

- A86&A88-chapter 22 (REAR CONSTANT VELOCITY JOINTS AND FINAL DRIVE GEAR)Document19 pagesA86&A88-chapter 22 (REAR CONSTANT VELOCITY JOINTS AND FINAL DRIVE GEAR)Stojanov MarjanNo ratings yet

- 11 Crankcase CrankshaftDocument7 pages11 Crankcase CrankshaftSaraNo ratings yet

- 2006 2008 Cbf1000 A 13 Crankshaft Balancer Piston CylinderDocument34 pages2006 2008 Cbf1000 A 13 Crankshaft Balancer Piston CylinderMurariu IonutNo ratings yet

- 1A-108 Engine Mechanical (4Hk1, 6Hk1) : CautionDocument1 page1A-108 Engine Mechanical (4Hk1, 6Hk1) : CautionВладимир Швед100% (1)

- KXR50 Cap 11 (Albero Motore)Document13 pagesKXR50 Cap 11 (Albero Motore)tutifruti649No ratings yet

- BW125 - 150 Cap 07 (Cilindro Pistone)Document9 pagesBW125 - 150 Cap 07 (Cilindro Pistone)Franckie HyacintheNo ratings yet

- EAGLE 3.3L V6 Timing Chain Replacement GuideDocument4 pagesEAGLE 3.3L V6 Timing Chain Replacement GuideAlfredo SalasNo ratings yet

- SM 7Document32 pagesSM 7WSMengine WSMengineNo ratings yet

- Bearing Water PumpDocument17 pagesBearing Water PumpHenni TanNo ratings yet

- 324D-CALIBRACION VALVULASsis - Cat.com Sisweb Sisweb Techdoc Techdoc Print Page - JsDocument5 pages324D-CALIBRACION VALVULASsis - Cat.com Sisweb Sisweb Techdoc Techdoc Print Page - JsjhonNo ratings yet

- Pneumatic Actuators Firesafe: Type and Design The Principle and Application of The Scotch Yoke ConstructionDocument4 pagesPneumatic Actuators Firesafe: Type and Design The Principle and Application of The Scotch Yoke ConstructionreliableplacementNo ratings yet

- Group 2 operational checks and troubleshooting for forkliftsDocument3 pagesGroup 2 operational checks and troubleshooting for forkliftsstefan corjucNo ratings yet

- Is Rod Drop Measurement Right For My CompressorDocument4 pagesIs Rod Drop Measurement Right For My CompressorMadhana GopalNo ratings yet

- Gear CouplingDocument17 pagesGear CouplingSuresh KavaliNo ratings yet

- KXR50 Cap 08 (Cilindro Pistone)Document18 pagesKXR50 Cap 08 (Cilindro Pistone)tutifruti649No ratings yet

- KXR50 Cap 07 (Testa Cilindro Valvole)Document13 pagesKXR50 Cap 07 (Testa Cilindro Valvole)tutifruti649No ratings yet

- Manual de Taller Honda PCX150Document185 pagesManual de Taller Honda PCX150Bruno De CarloNo ratings yet

- Crankshaft Grinding GuidelinesDocument2 pagesCrankshaft Grinding Guidelinesиван ТрояновNo ratings yet

- CR Valve Lash AdjustmentDocument2 pagesCR Valve Lash Adjustmenthusan shahNo ratings yet

- Deethanizer Reflux Pump InfoDocument5 pagesDeethanizer Reflux Pump InfoarasNo ratings yet

- Preparatory Steps: Note: The Following Procedure Is Only To Be Used ForDocument9 pagesPreparatory Steps: Note: The Following Procedure Is Only To Be Used FordeedNo ratings yet

- Ch. CT - Capella Tech DataDocument7 pagesCh. CT - Capella Tech DataPabloNo ratings yet

- Ch. 13 - SuspensionDocument12 pagesCh. 13 - SuspensionPabloNo ratings yet

- Ch. 0 - Cover and TOCDocument3 pagesCh. 0 - Cover and TOCPabloNo ratings yet

- Ch. 8 - DriveshaftDocument4 pagesCh. 8 - DriveshaftPabloNo ratings yet

- Ch. 9 - Rear AxleDocument10 pagesCh. 9 - Rear AxlePabloNo ratings yet

- kx80 Página 039Document2 pageskx80 Página 039PabloNo ratings yet

- Ch. T - RX-2 Tech DataDocument7 pagesCh. T - RX-2 Tech DataPabloNo ratings yet

- Ch. 11 - BrakesDocument12 pagesCh. 11 - BrakesPabloNo ratings yet

- Ch. 10 - SteeringDocument8 pagesCh. 10 - SteeringPabloNo ratings yet

- Carburetor Idle Speed AdjustmentDocument2 pagesCarburetor Idle Speed AdjustmentPabloNo ratings yet

- Fuel System Cleaning and Float Height MeasurementDocument1 pageFuel System Cleaning and Float Height MeasurementPabloNo ratings yet

- 'Remove The Choke Knob/starter Plunger Assembiy From The CarburetorDocument1 page'Remove The Choke Knob/starter Plunger Assembiy From The CarburetorPabloNo ratings yet

- Fuel System 2-17: Air Cleaner Element Cleaning and InspectionDocument1 pageFuel System 2-17: Air Cleaner Element Cleaning and InspectionPabloNo ratings yet

- kx80 Página 041Document1 pagekx80 Página 041PabloNo ratings yet

- kx80 Página 045Document1 pagekx80 Página 045PabloNo ratings yet

- Fuel System 2-15: The Needle Is Worn As Shown in FigureDocument1 pageFuel System 2-15: The Needle Is Worn As Shown in FigurePabloNo ratings yet

- kx80 Página 043Document1 pagekx80 Página 043PabloNo ratings yet

- 7-8 Engine Bottom Enditransmission: Crankcase AssemblyDocument1 page7-8 Engine Bottom Enditransmission: Crankcase AssemblyPabloNo ratings yet

- Fuel System 2-15: The Needle Is Worn As Shown in FigureDocument1 pageFuel System 2-15: The Needle Is Worn As Shown in FigurePabloNo ratings yet

- 7-2 Engine Bottom Enditransmission: Exploded ViewDocument1 page7-2 Engine Bottom Enditransmission: Exploded ViewPabloNo ratings yet

- kx80 Página 102Document1 pagekx80 Página 102PabloNo ratings yet

- KX80XDX80: SE Class Sae Iow 30 or Iow 40 0.6 L 0.7 LDocument1 pageKX80XDX80: SE Class Sae Iow 30 or Iow 40 0.6 L 0.7 LPabloNo ratings yet

- 7-6 Engine Bottom Enditransmission: Transmission OilDocument1 page7-6 Engine Bottom Enditransmission: Transmission OilPabloNo ratings yet

- Special Tools: Shift Shaft Oíl Seal Guide: 57001-264Document1 pageSpecial Tools: Shift Shaft Oíl Seal Guide: 57001-264PabloNo ratings yet

- Crankcase Splitting: Engine Bottom Enditransmission 7-7Document1 pageCrankcase Splitting: Engine Bottom Enditransmission 7-7PabloNo ratings yet

- Engine Bottom Enditransmission 7-3: Locking Agent To TheDocument1 pageEngine Bottom Enditransmission 7-3: Locking Agent To ThePabloNo ratings yet

- Engine Bottom Enditransmission 7-13 KX60, KDX80:: 3. 3rd/4th Gear (18T/20T Larger Gear Faces Right)Document1 pageEngine Bottom Enditransmission 7-13 KX60, KDX80:: 3. 3rd/4th Gear (18T/20T Larger Gear Faces Right)PabloNo ratings yet

- Crankshaft, Connecting Rod: Engine Bottom Enditransmission 7-9Document1 pageCrankshaft, Connecting Rod: Engine Bottom Enditransmission 7-9PabloNo ratings yet

- kx80 Página 115Document1 pagekx80 Página 115PabloNo ratings yet

- Tap X-Files 3Document185 pagesTap X-Files 3sa eedNo ratings yet

- Assignment 1Document15 pagesAssignment 1Ikhwan TeeNo ratings yet

- February2024 INCALDVD CoverLetterDocument4 pagesFebruary2024 INCALDVD CoverLetterSuministros MantenimientoNo ratings yet

- HELIX Precision Miniature Lead Screw Assemblies Catalog PDFDocument36 pagesHELIX Precision Miniature Lead Screw Assemblies Catalog PDFkaniappan sakthivelNo ratings yet

- RUKO Thread TabelDocument1 pageRUKO Thread TabelhadiNo ratings yet

- Fiberstrong Wavistrong: Flange GuideDocument1 pageFiberstrong Wavistrong: Flange Guidesiva8000No ratings yet

- General Information: Rigging Screws & TurnbucklesDocument2 pagesGeneral Information: Rigging Screws & TurnbucklespersonNo ratings yet

- ms40 383Document5 pagesms40 383zio.jean01No ratings yet

- Genuens Cable BAJAJ-HERO-HONDA-TVSDocument15 pagesGenuens Cable BAJAJ-HERO-HONDA-TVSKirti KrushnaNo ratings yet

- RV 10 DigitalDocument11 pagesRV 10 DigitalAce TisuyNo ratings yet

- Machine Design MD by S K Mondal T&Q PDFDocument263 pagesMachine Design MD by S K Mondal T&Q PDFAbhijeet SahuNo ratings yet

- SIS optimized air conditioner lines document titleDocument3 pagesSIS optimized air conditioner lines document titleAnderson Oliveira SilvaNo ratings yet

- Electronic Parts Catalog - Option Detail Option Group Graphic Film Card DateDocument2 pagesElectronic Parts Catalog - Option Detail Option Group Graphic Film Card DatenurdinzaiNo ratings yet

- Point WiringDocument4 pagesPoint Wiring8085ro100% (7)

- End Fittings, Turnbuckles and Compensation Devices, Pulleys and Cable System ComponentsDocument11 pagesEnd Fittings, Turnbuckles and Compensation Devices, Pulleys and Cable System ComponentsHafiy SiddqiNo ratings yet

- CCA Proiect - Fancsali - Clutch - AE1791Document16 pagesCCA Proiect - Fancsali - Clutch - AE1791Fancsali IstvánNo ratings yet