Professional Documents

Culture Documents

Column Design-Unaixial Bending (Task)

Column Design-Unaixial Bending (Task)

Uploaded by

ruchita jadhavOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Column Design-Unaixial Bending (Task)

Column Design-Unaixial Bending (Task)

Uploaded by

ruchita jadhavCopyright:

Available Formats

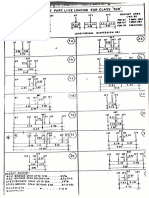

Design Of Column Subjected to Uniaxial Bending

y

B = 4000 mm

D = 5000 mm

Axial Force = 1000 kN

Moment in One Direction = 500 kNm

Area = 20000000 mm^2

Dia of Steel in Compression = 25 5m

Number of bars in Compression 25

Dia of Steel in Tension = 20

Number of bars in Tension = 25

Ast C = 12271.8463

Ast T = 7853.98163

Ast = 20125.8 mm^2 x

Ac = 19979874 mm^2

Grade of Concrete = 40 Mpa

Grade of Steel = 500 Mpa

4m

Es = 2.00E+05 Mpa

Ec = 3.30E+04 Mpa

Modular Ratio m = 6.06E+00

Trail Xu Assumed = 2500 mm

Clear Cover 50 mm

d' 62.5 mm

Effective Depth 4937.5 mm

H/2 2500

Calculation of Effective Area

Aeff = Area of Concrete in com + Area of Steel in Comp + Area of Steel in Tension

= 10000000 + 6.21E+04 + 4.76E+04

= 10109702.87 mm^2

Calculation of Effective CG

Distance of CG eff from physical centroid

e' = 1.33E+03 mm

e-e' = 4.99E+05 mm

Calculation of Effective Moment of Inertia

Ieff = 5.98982E+12 mm^4

Calculation of Depth of NA below Effective CG

y = 1.19E+00 < 1.26E+03 OK

Moment capacity of Column subjected to Uniaxial Bending

Axial Force = 1000 kN

Moment in One Direction = 900 kNm y

B = 1000 mm

D = 900 mm

Area = 900000 mm^2

Ast = 4151.61 mm^2 0.9 m x

Ac = 895848.39 mm^2

Grade of Concrete = 35 Mpa

Grade of Steel = 500 Mpa

Es = 2.00E+05 Mpa 1m

Ec = 3.30E+04 Mpa

εc = 0.0035

Material Safety Factor for steel = 1.15

Material Safety Factor for Concrete = 1.5

α = 0.67

β1 = 0.80952

Trail Xu Assumed = 206.89 mm

Yield Strain of Steel εyd = 0.002175

Clear Cover 75

d' 83

Effective Depth 817

Depth 900

Number of bars in Direct. of Depth 2

Distance between the bars 734.00

H/2 450

For this location of Xu the strain and corresponding stresses at different level of steel are

Now, Axial and moment resistance from the steel can be calculated as follows

Y d' (m) Strain ϵyd Stress Comp./ φ mm Number Area φ Number Area Nrd L.A @c.g Mrd

Tens.

1 83.000 0.002096 0.002175 419.18 Comp 16 6 1206.37 0 0 0.00 5.06E+05 3.67E+02 1.86E+08

2 817.000 0.010321 0.002175 434.78 Tension 25 6 2945.24 25 6 2945.24 -2.56E+06 -3.67E+02 -9.40E+08

No.of bars 12 4151.61 6

Total -2.06E+06 -7.54E+08

Axial Load carrying Capacity given by,

Nrd = β1xfcdxbxXu +Sfs' As' + Sfs As

fcd = α fck /γc

fcd 15.63333333333

Nrd = 2618346.756941 + -2.1E+06

= 562952.5 N

= 562.953 KN > 1000 KN Not OK

Mrd = 950733493.0579 + -7.54E+08

= 196403817.0104 N-m

= 196.4038170104 KN-m > 900.00 KN-m Not OK

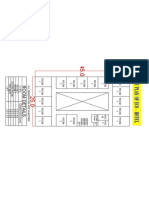

Check for stress

1000 mm

d'

Asc

900 mm

Ast

d''

Design Data

Moment = 900.00 KN-m

Axial Load = 1000.00 KN

Asc = 1206.371579 mm2

Ast = 5890.4862255 mm2

B = 1000 mm

D = 900 mm

Max. Dia at top = 16 mm

Max. Dia at bottop = 25 mm

Clear cover = 75 mm

d' Comp = 83 mm

d'' Tension = 87.5 mm

m = 6.06E+00

X = 206.894 mm

A eff = 206894.044844 + 6104.9713239 + 35699.916518

= 248698.932685 mm2

Step 4

Distance of CG eff from physical centroid

e' = 71699747.2837 + 2240524.4759 - 12941219.738

248698.93269

= 245.27267312 mm

e-e' = 1111.11111111 - 245.27267312

= 865.838437991 mm

I eff. = 738010812.747 + 2122257058.5 + 90460669.669 + 17257485657

= 20208214198 mm4

Distance of neutral axis below CG eff

The stress is zero at neural axis

y = I eff / ( Aeff. x ( e - e' ))

y = 93.8462996588 mm

Assumed is = 2.16671796327 mm Not ok

Max. compressive Stress in Concrete

= 3.61883338333 + 7.894547656

= 11.5133810393 N/mm2 < 16.8 Mpa

Max. tensile Stress in steel

= 21.9323235353 - 142.03934467

= -120.10702113 N/mm2 < 400 Mpa

You might also like

- Design Calculation For ScaffoldingDocument12 pagesDesign Calculation For Scaffoldinganwar50% (2)

- Modified RCL Design InputDocument21 pagesModified RCL Design Inputyasaswini veeramalluNo ratings yet

- DDDDDD DD DDDD DDDD DDD DDDDDocument11 pagesDDDDDD DD DDDD DDDD DDD DDDDkitti kothapalliNo ratings yet

- Abutment Program VarshneyDocument7 pagesAbutment Program VarshneyRaju Ranjan SinghNo ratings yet

- Column DesignDocument6 pagesColumn DesignDEBASIS BARMANNo ratings yet

- PROJECT: Package-4: Spur To Barwasini By-Pass (From UER II-PKG 1 (KM 7+750) To Barwasini By-Pass (NH 352-A) ) (KM 0+000 To KM 29+600)Document11 pagesPROJECT: Package-4: Spur To Barwasini By-Pass (From UER II-PKG 1 (KM 7+750) To Barwasini By-Pass (NH 352-A) ) (KM 0+000 To KM 29+600)Manupriya KapleshNo ratings yet

- Design of Pier Well FoundationDocument35 pagesDesign of Pier Well FoundationPraveen Kumar KattamuriNo ratings yet

- IndexDocument93 pagesIndexrohit singhNo ratings yet

- Analysis and Design of Reinforced Concrete Solid Slab BridgeDocument6 pagesAnalysis and Design of Reinforced Concrete Solid Slab BridgeEditor IJTSRDNo ratings yet

- Illustrative Worked Examples: Commentary of Irc: 6-2017Document2 pagesIllustrative Worked Examples: Commentary of Irc: 6-2017jatin singlaNo ratings yet

- Aditya Joshi CVDocument23 pagesAditya Joshi CVAditya JoshiNo ratings yet

- Name of The Work Nabard Construction FoDocument48 pagesName of The Work Nabard Construction FodiablopapanatasNo ratings yet

- Case Study Tech AbutmentDocument7 pagesCase Study Tech AbutmentGajendra BishtNo ratings yet

- Design of Balanced Cantilever BridgeDocument37 pagesDesign of Balanced Cantilever BridgeArafat RahmanNo ratings yet

- Loads: Dead Load of SuperstructureDocument4 pagesLoads: Dead Load of SuperstructureMuhammad HasanNo ratings yet

- Design of Water Tank (At Ground)Document5 pagesDesign of Water Tank (At Ground)archanaNo ratings yet

- (Min. of 0.33qc or 30kg/cm ) : Calculation of Rock Socketing LengthDocument1 page(Min. of 0.33qc or 30kg/cm ) : Calculation of Rock Socketing LengthvivekNo ratings yet

- Neutral AxisDocument2 pagesNeutral AxispandianNo ratings yet

- Longitudinal 16-9-15Document40 pagesLongitudinal 16-9-15P Allen Samuel Ignatius100% (1)

- Design of 24.0m PSC GirderDocument56 pagesDesign of 24.0m PSC GirderVishal SharmaNo ratings yet

- Design of Abutment-24+680Document27 pagesDesign of Abutment-24+680ajayNo ratings yet

- B1 MergedDocument74 pagesB1 MergedAA DESIGN CUNSULTANCYNo ratings yet

- IRC 24 (SteelRdBrdge) Amendment 01 IRC 24 2010, JAN 2014Document2 pagesIRC 24 (SteelRdBrdge) Amendment 01 IRC 24 2010, JAN 2014msn722005No ratings yet

- Box Culvert (1 X 6 X 2.5)Document34 pagesBox Culvert (1 X 6 X 2.5)Er Mukesh KumarNo ratings yet

- Estimation of Design Discharge in Respect of Bridge 21 (At Ch:9437.565 M)Document4 pagesEstimation of Design Discharge in Respect of Bridge 21 (At Ch:9437.565 M)Vinod MohiteNo ratings yet

- Design Document - Abutment Well - Ranipokhari - 280m - R1Document114 pagesDesign Document - Abutment Well - Ranipokhari - 280m - R1rachanaNo ratings yet

- Mankhud RE Wall Comments On DesignsDocument62 pagesMankhud RE Wall Comments On DesignsprathmeshNo ratings yet

- Temprorary Structure Design 30-07-2020Document15 pagesTemprorary Structure Design 30-07-2020Ankush SharmaNo ratings yet

- Bearing Design For ROB at Chainage 145+368 (47m CC of E.J.)Document11 pagesBearing Design For ROB at Chainage 145+368 (47m CC of E.J.)amitkuknaNo ratings yet

- 8-Bearing PedestalDocument2 pages8-Bearing Pedestalsanjay vermaNo ratings yet

- Design of Chapala Nala Bridge AbutmentsDocument14 pagesDesign of Chapala Nala Bridge AbutmentsHem ShahiNo ratings yet

- The World Bank: Uttarakhand Disaster Recovery ProjectDocument14 pagesThe World Bank: Uttarakhand Disaster Recovery Projectvicky rawatNo ratings yet

- 1x2x2-2m Fill - 250mm THKDocument40 pages1x2x2-2m Fill - 250mm THKPraveen Kumar KattamuriNo ratings yet

- Solusi Tugas Asistensi PSB #5Document10 pagesSolusi Tugas Asistensi PSB #5adhityamspNo ratings yet

- Pile Design-1Document57 pagesPile Design-1voilNo ratings yet

- Pier Sheet Hollow r0Document1 pagePier Sheet Hollow r0Varun VermaNo ratings yet

- RCC Box Culvert CH.17+481Document3 pagesRCC Box Culvert CH.17+481Suyog JungareNo ratings yet

- Segment Design FinalDocument54 pagesSegment Design FinalDEBASIS BARMAN100% (1)

- L.lii: Parl Li Loaoini ClassDocument4 pagesL.lii: Parl Li Loaoini ClassStructural SpreadsheetsNo ratings yet

- TH - 2 (Floor Slab) : Wall 68.00 500.00 1000.0 50.00 12.00 150.00 2E+5 2E+5 10.98Document2 pagesTH - 2 (Floor Slab) : Wall 68.00 500.00 1000.0 50.00 12.00 150.00 2E+5 2E+5 10.98UjwalaNo ratings yet

- Design Basis Report Bearing Replacement Scheme UpDocument14 pagesDesign Basis Report Bearing Replacement Scheme UpShivendra KumarNo ratings yet

- Design of Superstructre 16.12.2020Document54 pagesDesign of Superstructre 16.12.2020Ankush SharmaNo ratings yet

- Counterfort Retaining WallDocument7 pagesCounterfort Retaining WallMohammedNo ratings yet

- Shore Pile DesignDocument38 pagesShore Pile DesignShazid-ul Alam ShishirNo ratings yet

- Date Rev. No. Description 21-Aug-2019 R0 First Submission MLP ANS TRB RevisionsDocument1 pageDate Rev. No. Description 21-Aug-2019 R0 First Submission MLP ANS TRB Revisionsnaveen srinivasNo ratings yet

- Rub NewDocument72 pagesRub New906rahulNo ratings yet

- MJB 16+785 DC 301 PierDocument79 pagesMJB 16+785 DC 301 PierChandra BabuNo ratings yet

- Basohli Cable Stayed Bridge - IndiaDocument7 pagesBasohli Cable Stayed Bridge - IndiajnshreyNo ratings yet

- TSR NIRMAN Bow String Girder Launching Design Note-06.05.2022Document1 pageTSR NIRMAN Bow String Girder Launching Design Note-06.05.2022sups madiNo ratings yet

- Design ReportDocument62 pagesDesign Reportsubhankar biswasNo ratings yet

- RT Wall Drawing FinalDocument604 pagesRT Wall Drawing FinalYazer ArafathNo ratings yet

- Abutment Design 13+820Document61 pagesAbutment Design 13+820sanjay vermaNo ratings yet

- Design of Straight Retaining Wall For Height 5.5m FROM G.L & NBC 100 KN/SQMDocument24 pagesDesign of Straight Retaining Wall For Height 5.5m FROM G.L & NBC 100 KN/SQMShivam SharmaNo ratings yet

- Illustrative Worked ExamplesDocument2 pagesIllustrative Worked Examplesjatin singlaNo ratings yet

- 1.design ConditionDocument22 pages1.design Conditionakshay magarNo ratings yet

- Calculations of Pile Capacity of Pile: K EI TDocument5 pagesCalculations of Pile Capacity of Pile: K EI Tgaurav sharmaNo ratings yet

- Free POT/PTFE BearingDocument25 pagesFree POT/PTFE BearingZakee MohamedNo ratings yet

- Project: Date: Location: Designed By: Title: Checked By:: C C C R T C BDocument6 pagesProject: Date: Location: Designed By: Title: Checked By:: C C C R T C BDev LamichhaneNo ratings yet

- Composite Column DesignDocument4 pagesComposite Column DesignalexanderNo ratings yet

- Pile RectifyingDocument2 pagesPile RectifyingAnonymous O404LiV4CNo ratings yet

- Design of Slab: Slab Unit S1 S2 S3Document3 pagesDesign of Slab: Slab Unit S1 S2 S3jyoti bhilaweNo ratings yet

- DasfDocument1 pageDasfruchita jadhavNo ratings yet

- Stability of Stepped Retaining Wall: No of Blocks ConsideredDocument4 pagesStability of Stepped Retaining Wall: No of Blocks Consideredruchita jadhavNo ratings yet

- Environmentally-Friendly Practices in Hotels: March 2016Document9 pagesEnvironmentally-Friendly Practices in Hotels: March 2016ruchita jadhavNo ratings yet

- E-Ticket - Neeta Tours and Travels - ONLINE BUS TICKET BOOKINGS & TRAVEL SERVICESDocument4 pagesE-Ticket - Neeta Tours and Travels - ONLINE BUS TICKET BOOKINGS & TRAVEL SERVICESruchita jadhavNo ratings yet

- Confirmation of Registration: Date: Nov 9, 2018Document1 pageConfirmation of Registration: Date: Nov 9, 2018ruchita jadhavNo ratings yet

- Sustainable Strategies For Green Hotel DesignDocument64 pagesSustainable Strategies For Green Hotel DesignsundareNo ratings yet

- IBPS Static Capsule PDFDocument86 pagesIBPS Static Capsule PDFruchita jadhavNo ratings yet

- 4 Functional Element of MSW ManagementDocument6 pages4 Functional Element of MSW Managementruchita jadhavNo ratings yet

- Melissa M Fontanese Spring2010 3Document123 pagesMelissa M Fontanese Spring2010 3ruchita jadhavNo ratings yet

- ThermalFS Therminol66Document2 pagesThermalFS Therminol66Yelvia SunartiNo ratings yet

- Strength 1 Practice Problems - 240119 - 231420Document7 pagesStrength 1 Practice Problems - 240119 - 231420john patrick punsalanNo ratings yet

- DB 01.01.11.01 Pump G10Document3 pagesDB 01.01.11.01 Pump G10Pramod KumarNo ratings yet

- Thermal Properties of MaterialsDocument21 pagesThermal Properties of MaterialsBhaagi SirdNo ratings yet

- A Method To Estimate The Performance of Reciprocating CompressorDocument9 pagesA Method To Estimate The Performance of Reciprocating CompressordanielNo ratings yet

- 3 Asprion, 2010Document8 pages3 Asprion, 2010Eládio R Moura AraujoNo ratings yet

- What Is The Relation Between Elastic Constant E, C and K. - Sarthaks Econnect - Largest Online Education CommunityDocument4 pagesWhat Is The Relation Between Elastic Constant E, C and K. - Sarthaks Econnect - Largest Online Education CommunityraghuNo ratings yet

- Chapter14 ThermodynamicsDocument30 pagesChapter14 ThermodynamicsArvind RaveeNo ratings yet

- Free Convection: Name: Karzan Muhammed Salih Lecture: Unit Operation Practical Group: B Date: 11/4/2020Document5 pagesFree Convection: Name: Karzan Muhammed Salih Lecture: Unit Operation Practical Group: B Date: 11/4/2020Safwan BakrmanyNo ratings yet

- 2nd LawDocument53 pages2nd LawAbdelazim MohamedNo ratings yet

- Types of Flexural FailureDocument13 pagesTypes of Flexural FailureMohsan ali ChhajroNo ratings yet

- Surface Vehicle Recommended PracticeDocument6 pagesSurface Vehicle Recommended PracticeRanjit RajendranNo ratings yet

- An Visco - Hyperelastic Dielectric Elastomer With The Confined Compressible Fluid or Air MassDocument17 pagesAn Visco - Hyperelastic Dielectric Elastomer With The Confined Compressible Fluid or Air Massss133No ratings yet

- Theory of Archimedes: BouyancyDocument4 pagesTheory of Archimedes: BouyancyAmmar MddeniNo ratings yet

- Software LabDocument13 pagesSoftware LabLikith Gowda MNo ratings yet

- The Effect of Reinforcement On Early-Age Cracking Due To Autogenous Shrinkage and Thermal EffectsDocument7 pagesThe Effect of Reinforcement On Early-Age Cracking Due To Autogenous Shrinkage and Thermal EffectsChu Hean OonNo ratings yet

- Piles Bearing Capacity - Calculations - 2Document1 pagePiles Bearing Capacity - Calculations - 2Buliga MarianNo ratings yet

- Mechanism of Spray DryingDocument10 pagesMechanism of Spray Dryinggerpo123No ratings yet

- Heat Transfer and Exergy Analysis of A Spiral Heat ExchangerDocument16 pagesHeat Transfer and Exergy Analysis of A Spiral Heat ExchangerManuela AguirreNo ratings yet

- Yoshitake Steam Trap PDFDocument40 pagesYoshitake Steam Trap PDFDeni SuryaNo ratings yet

- ALA 1 Chapter 9 - Fluid DynamicsDocument9 pagesALA 1 Chapter 9 - Fluid Dynamicsphoenix eastwoodNo ratings yet

- Internal Incompressible Viscous Flow: BITS PilaniDocument72 pagesInternal Incompressible Viscous Flow: BITS PilaniPranav GhawatNo ratings yet

- CRD - c89 (1) Longitudenal Shear StrengthDocument2 pagesCRD - c89 (1) Longitudenal Shear StrengthKothiyal MukeshNo ratings yet

- Duct Design SlidesDocument108 pagesDuct Design SlidesJugmohunNo ratings yet

- Thermodynamic Potentials Unit3Document19 pagesThermodynamic Potentials Unit3Anonymous odl3MBNo ratings yet

- EnergeticsDocument12 pagesEnergeticsAliyah HamiltonNo ratings yet

- SM Lab (Tension Test)Document15 pagesSM Lab (Tension Test)sushilkumar100% (1)

- Line Sizing Using HysysDocument4 pagesLine Sizing Using HysysRandomNo ratings yet