Professional Documents

Culture Documents

EGP3-01.22 Transportation of Cargo by Barge or Ship

Uploaded by

Mathias OnosemuodeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

EGP3-01.22 Transportation of Cargo by Barge or Ship

Uploaded by

Mathias OnosemuodeCopyright:

Available Formats

CHEVRON NIGERIA LIMITED

ESCRAVOS GAS PROJECT – PHASE 3 DEVELOPMENT - ONSHORE

SPECIFICATION NUMBER EGP3–01.22

TRANSPORTATION OF CARGO BY BARGE OR SHIP

Rev Date Description By Appr. CNL

No. Appr.

A 3/10/04 Issued New for ITB3 CLH DAP

March 2004 Specification No. EGP3 – 01.22 Page 1 of 31

Notes

1) Revision numbers are A, B, C, etc. up to and including the issue for the EPC bid

package.

Rev Description

A Based on EGP3-1.22 Rev A dated AUGUST 2000,

incorporating revisions from first EGP3A Offshore bid cycle,

and editing for EGP3 Onshore.

March 2004 Specification No. EGP3 – 01.22 Page 2 of 31

TABLE OF CONTENTS

1 SCOPE........................................................................................................................... 4

2 APPLICABLE DOCUMENTS.........................................................................................4

3 GENERAL...................................................................................................................... 4

4 LOADOUT...................................................................................................................... 5

5 SEAFASTENING............................................................................................................6

6 CARGO LAYOUT AND WEIGHTS.................................................................................6

7 TOWING......................................................................................................................... 7

8 TOWING GEAR............................................................................................................ 10

9 BARGE STABILITY......................................................................................................14

10 EMERGENCY ANCHOR SYSTEM...........................................................................16

11 MOORING ARRANGEMENTS.................................................................................18

12 DAMAGE CONTROL................................................................................................18

13 NAVIGATION LIGHTS AND SOUND SIGNALS......................................................18

14 TOWING VESSEL....................................................................................................19

15 TRANSPORTATION FORCES.................................................................................20

16 POST TOW INSPECTION........................................................................................22

17 POLLUTION PREVENTION.....................................................................................23

18 SCRAP MATERIAL AND CLEAN-UP......................................................................23

19 DAMAGE REPAIR....................................................................................................23

20 DOCUMENTATION REQUIREMENTS.....................................................................23

21 FABRICATION AND ASSEMBLY.............................................................................24

FIGURES

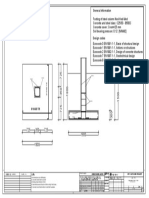

1 Main Tow Bridle (Type “A” Recovery System)

2 Main Tow Bridle (Type “B” Recovery System

3 Emergency Towing Gear

4 Billboard Emergency Anchor Mounting

APPENDIX

I Standards and Codes

II Project Documents

March 2004 Specification No. EGP3 – 01.22 Page 3 of 31

1 SCOPE

This general specification covers the minimum technical requirements for the

inland and offshore transportation of components by barge or ship. Any

exception to the requirements of this specification shall be submitted in writing to

the COMPANY for resolution. The Specification requirements apply to both

barge and ship transports, whether specifically stated or otherwise.

2 APPLICABLE DOCUMENTS

The CONTRACTOR shall consider the most recent issue of the standards and

codes listed in Appendix I as part of this specification. Any conflict between

these documents shall be submitted to the COMPANY for resolution.

3 GENERAL

The values stated in this Specification in either inch-pound units or SI units are

to be regarded separately as standard. Within the text, the SI units are shown in

brackets. The values stated in each system are not exact equivalents, therefore

each system must be used independent of the other. Combining values from

the two systems may result in nonconformance with this specification.

a. The CONTRACTOR shall furnish all labor, transportation, vessels,

supervision, materials and equipment necessary to transport the cargo to the

fabrication site(s) or to the installation site consistent with schedule. The

procedures to be used in transporting the cargo components to the

installation site shall be approved by COMPANY.

b. The CONTRACTOR shall be responsible for the structural integrity and

performance of the cargo and the marine equipment during transportation

from the fabrication site to the installation site.

c. Support and seafastening designs as well as barge strength and stability

shall be based on transportation forces and vessel behavior determined by

approved methods and procedures. These methods and procedures shall

be submitted to the COMPANY for review and approval at least 30 days

prior to any analysis being performed.

d. Results of the analyses shall be submitted to COMPANY for review,

comment and approval at least 120 days (or as agreed between COMPANY

and CONTRACTOR) prior to loadout.

e. CONTRACTOR shall provide accommodation for a COMPANY

representative on board the lead tug for the duration of tow.

f. All vessels shall be equipped with operational two-way radios. The two-way

radios shall be capable of intercommunication at all times. The COMPANY

will have the right to use the radios.

g. Barge towage shall be from the forward end via a suitable bridle as shown in

Figures 1 and 2. If two balanced tugs are being used to tow the barge, then

March 2004 Specification No. EGP3 – 01.22 Page 4 of 31

the bridle apex shall not be used and the tugs shall tow off the separate

bridle legs, via intermediate pennants.

h. The dimensions of all vessels shall be compatible with the fabrication

loadout site conditions and configured to meet the requirements for loadout,

tiedown, transport, stability and seakeeping as prescribed in this

specification.

i. Any barge provided by CONTRACTOR in accordance with this specification

shall be classed as an American Bureau of Shipping Class A1 dry cargo

barge for unrestricted ocean service or have an equal classification from a

recognized certifying agency or bureau.

j. Vessel selection is subject to COMPANY and Marine Surveyor approval.

k. CONTRACTOR shall hold the transportation spread in the installation area

until actually required onsite. If vessels are tied up at a public facility,

CONTRACTOR shall provide 24-hours per day security.

l. CONTRACTOR shall be responsible for the cleanup of the vessels after

offloading is complete.

m. The barge (or other transportation vessel) shall be suitable for transporting

the cargo over the prescribed route under the design environmental

conditions.

n. The cargo shall be packaged and positioned such that during loadout,

transportation and unloading no permanent change occurs.

o. CONTRACTOR shall create a “Security Plan for Transport” for the

transportation of materials through Nigerian waterways and other regions

known to commonly have piracy (e.g. Southeast Asia). This Security Plan

shall be in accordance with Exhibit P - Security Requirements.

4 LOADOUT

4.1 General

CONTRACTOR shall prepare and submit to COMPANY at least 90 days prior to

the scheduled date for the loadout a detailed plan including barge ballasting

requirements during loadout, method of loadout, structural force and

deformation calculations, stress analysis of the cargo and step-by-step schedule

of the loadout. CONTRACTOR shall also be responsible for providing tidal,

current and bottom condition data. Allowances for actual tidal changes and

current shall be included in the loadout plan. All critical mechanical equipment

such as pumps, sheaves, etc., shall have a backup system on standby.

4.2 Loadout Steelwork

a. Leg supported structures shall require loadout steelwork. Consideration

must be given to redundancy among the supports.

March 2004 Specification No. EGP3 – 01.22 Page 5 of 31

b. Skid beams shall be checked to have sufficient spanning capacity to

redistribute reactions when supports are deflected.

c. The support steelwork must be designed to distribute transportation forces

into the barge structure.

5 SEAFASTENING

a. CONTRACTOR shall submit to COMPANY for review and approval all

seafastening calculations and drawings at least 120 days prior to loadout.

b. Seafastening shall prevent the cargo from sliding or rolling off the barge

when subjected to motions at sea.

c. Seafastenings shall be designed to accept hog, sag and twisting of the

barge in seaway.

d. Seafastenings shall be installed after the barge has been reballasted from

the loadout condition to the tow condition.

e. For cargos that will be removed offshore, the seafastenings shall be capable

of being released in stages. The stages shall be such that the cargo is

secure for a 10 roll until the release of the final stage. The release of

seafastenings and the lift of any one item shall not disturb the seafastenings

of any other item.

f. The seafastenings shall not overstress the cargo onto which they bear. The

structure of the cargo shall be checked to ensure that it is capable of

withstanding the seafastening loads.

g. Seafastening release lines shall be clearly identified with paint marks of

distinctive color, in order that the cutting crew on a cargo barge understands

what has to be done before an item can be lifted off.

h. The seafastening removal sequence shall be planned so that seaworthiness

of the seafastening is preserved for as long as possible prior to launch or lift.

Care shall be exercised to ensure that structural elements are not gouged by

seafastenings. All attachment areas shall be inspected visually after

seafastening removal and nondestructively tested.

6 CARGO LAYOUT AND WEIGHTS

6.1 Cargo Layout

Cargo positions on the barge deck shall be selected to satisfy the following

conditions:

a. Cargo shall be supported at the strong points of the barge framing so as to

minimize the amount of support steelwork to be provided.

b. Cargo shall be located away from barge fittings such as bollards, tank vents,

access hatches and the like.

March 2004 Specification No. EGP3 – 01.22 Page 6 of 31

c. Loadout path shall be clear of barge fittings.

d. End and side overhangs shall be avoided.

e. Excessive windage on barge ends shall be avoided.

6.2 Cargo Weight

The following procedure shall be adopted when determining the weight of any

item to be transported on a cargo barge.

a. Establish the "Theoretical Weight" from an accurate weight takeoff which

shall also be used to locate the center of gravity in a three dimensional

coordinate system.

b. A 20% contingency shall be added to the theoretical weight of mechanical

equipment, and 10% contingency to the theoretical structural weight. For

items which have only an estimated weight, 25% contingency shall be

added, while for piles, only a 5% inaccuracy allowance need to be added to

the theoretical weight.

c. The weight of any pre-installed rigging must also be added to derive the

transport weight of a particular item.

7 TOWING

7.1 General

a. CONTRACTOR shall submit to COMPANY for approval a detailed document

entitled "Towage Plan" for all loadout vessels at least 120 days prior to the

respective loadout dates. This plan shall include, but not be limited to the

following:

1. Size, number, name and certification of tugs to be used for the tows.

2. Calculations for tug bollard pull and horsepower requirements.

3. Intact and damage stability calculations.

4. Detailed sketches and calculations showing proposed schedule of tank

ballasting to achieve draft and trim.

5. Cargo weight and C.G. summary.

6. Description of maneuvering plans and additional tugs, if required, to clear

the harbor or any other navigational hazards along the tow route.

7. Proposed route of the tow and contingency plans in case of equipment

failure or facility damage. This shall include identifying safe harbors

along the transit route in the event of severe weather.

8. Transit schedule to the site including bunkering plans.

March 2004 Specification No. EGP3 – 01.22 Page 7 of 31

9. Communication plans during tow, including methods of getting

information to COMPANY and identifying tow report distribution.

10. Anticipated weather data along route and the daily weather forecasting

services prior to and during tow which CONTRACTOR will provide to tug

boat captain with copy to COMPANY.

11. Description of instructions to tow masters.

12. CONTRACTOR shall create a “Security Plan for Transport” for the

transportation of materials through Nigerian waterways and other regions

known to commonly have piracy (e.g. Southeast Asia). This Security

Plan shall be in accordance with Exhibit P - Security Requirements.

13. Planned inspection of cargos during tow.

14. Post tow inspection plan.

b. Copies of COMPANY approved towage plan shall be carried at all times on

the lead tug or transportation vessel.

c. CONTRACTOR shall arrange to obtain weather forecast at least twice daily.

These forecasts shall be for 24 hours and 72 hours. CONTRACTOR shall

also provide COMPANY once a day with the 24-hour and 72-hour forecast

during the tow. These weather forecasts may be used by the tow master to

change routes to avoid storms. COMPANY shall be notified within 24 hours

of any tow route change and any resulting impact on the schedule.

d. The CONTRACTOR shall provide space aboard the lead tug and protection

from damage for tow instrumentation recording equipment, and quarters for

its operator and COMPANY representative.

e. The design for all seafastening components shall conform to API RP 2A-

WSD and this specification.

7.2 Certification

Copies of the following documents and any other documentation required by the

Marine Surveyor shall be issued to the COMPANY by a recognized and

COMPANY approved classification society or authority and shall be carried on

the barge or (lead) tug for any towage:

a. Certificate of Class

b. Certificate of Registry

c. Tonnage Certificate if not incorporated in other certification

d. Certificate/Approval of Navigation Lights and Shapes

e. Equipment Certification

f. International Load Line Certificate

g. Customs Clearance

March 2004 Specification No. EGP3 – 01.22 Page 8 of 31

h. Cargo Ship Safety Certificate

i. Deratisation Certificate

j. Certification Agent Certificate of Approval for the particular towage (issued

on sailing)

k. Stability Booklet

l. Bollard Pull Certificate

m. Certificate for all tow wires, pennants, nylons, shackles, etc.

For manned tows the following shall also be carried:

a. Life Saving Apparatus (LSA) Certificate

b. Fire Fighting Apparatus (FFA) Certificate

c. Crew List (as supernumerary tug crew or barge crew)

d. Radio Licenses (as required)

e. Permission from Certifying Authority to man barge

7.3 Pre-Tow Survey of Vessel(s)

The CONTRACTOR shall have an on hire survey of the barge prior to load out

of the cargo. Any repair found to be necessary, based on this survey, shall be

carried out to COMPANY’s satisfaction before the barge is loaded with

COMPANY’s cargo. After the cargo has been loaded out and seafastened by

the CONTRACTOR, the CONTRACTOR shall perform the following checks and

inspections in the presence of the COMPANY and Marine Surveyor.

a. Seafastening and barge ballast have been installed in accordance with the

CONTRACTOR's approved drawings.

b. Materials and equipment required for seafastening removal are checked and

inventoried. Oxygen and acetylene bottles shall be checked to ensure

required amounts for seafastening removal are available. The

CONTRACTOR may elect to load a portion of this material and equipment

on the barge after it reaches the installation site.

c. Barge navigation aids required for towing are operational.

d. Required towing shapes are installed.

e. Launch system shall be inspected to ensure good operating order. Presence

and proper storage of spare parts, hoses, rigging, and equipment for the

launch system shall be checked, inventoried and securely stowed for

transport.

f. Inventory all field installed equipment, ship loose items and other materials

and ensure that all are securely stowed and seafastened for transport.

March 2004 Specification No. EGP3 – 01.22 Page 9 of 31

7.4 Decision to Commence Tow

a. The decision to commence all tows will be made jointly by CONTRACTOR,

COMPANY and Marine Surveyor. Tow shall not commence until a three day

weather window is forecast that shows weather conditions to be less severe

than Beaufort Storm 5 (or less as required by the "Towage Plan").

b. A tow shall not commence until all cargo bracing, seafastening and barge

strengthening has been installed and welded out and CONTRACTOR has

obtained COMPANY approval for all procedures, drawings and calculations

required by the Technical Requirements.

c. After completion of the pre-tow checks and inspections the Marine Surveyor

shall issue a certificate of seaworthiness for each tow. No tow shall

commence until this certificate has been issued.

d. A pre-tow meeting shall be held between CONTRACTOR, COMPANY and

Marine Surveyor for final review of tow plan and any unresolved "punch list"

items.

8 TOWING GEAR

8.1 Strength

a. The minimum ultimate (breaking) strength of all towage connections,

fairleads and bridle shall be not less than three times the continuous static

bollard pull of the largest towing vessel plus 44 tons (40 tonnes), from any

possible direction.

b. If, for any reason, the towline breaking strength is required to be more than

three times static bollard pull, then the ultimate strength of the connections

and bridle, etc., shall all exceed the required strength of the towline.

c. The breaking load (BL) of shackles shall be at least 10% greater than the BL

of the towline to be used (or required BL of bridle if shackle is part of the

bridle).

d. If the breaking load of the shackles is not known, then the Safe Working

Load (SWL) shall exceed the continuous static bollard pull of the largest

towing vessel to be used.

8.2 Towage Connection Points

a. Towage connections to the barge shall be of an approved type. The towage

shall be able to be quickly released under adverse conditions, to allow a

fouled bridle or towline to be cleared.

b. Sufficient under-deck strength shall be provided for all towage connection

points. They shall be located at the intersection of transverse and

longitudinal bulkheads in order to transfer the load to the barge structural

framing.

March 2004 Specification No. EGP3 – 01.22 Page 10 of 31

c. COMPANY may direct the CONTRACTOR, at CONTRACTOR's expense, to

test the towage connection points using NDT methods prescribed by the

COMPANY.

8.3 Fairleads

a. Where fitted, fairleads shall be of an approved type, located close to the

deck edge. They shall be equipped with capping bars and located in line

with the tow connections.

b. Where the bridle can bear on the deck edge, the deck edge shall be suitably

faired.

8.4 Main Towing Wire and Spare

a. The main and spare tow wires shall have a breaking strength, after making

allowance for corrosion and wear, of at least two times static bollard pull

(BP). For tugs under 88 tons (80 tonnes) ton BP the breaking load (BL) of

the tug wire shall be based on the following guidelines, subject to

COMPANY approval:

BP = 22 – 33 tons (20 – 30 tonnes), BL = 2.75 x BP

BP = 44 – 66 tons (40 – 60 tonnes), BL = 2.50 x BP

BP = 88+ tons (80+ tonnes), BL = 2.00 x BP

b. The length of the main and spare tow wire shall each be at least 3000 feet

(910 meters) for unrestricted towing. For specific tows in benign weather

areas or areas of restricted space, use of shorter wires shall be subject to

COMPANY approval.

8.5 Synthetic Spring

a. Synthetic spring if used shall have a breaking load at least two times that of

the main wire. It must be in good condition and protected from wear,

solvents and sunlight.

b. The synthetic spring shall be made up as a continuous loop with a hard eye

at each end.

c. The synthetic spring shall normally be shackled between the main towing

wire and the intermediate pennant.

8.6 Shackles

a. The breaking load (BL) of any shackle in the tow shall be at least 10%

greater than the BL of the towline (or required BL of the bridle if the shackle

is part of the bridle).

b. If Safe Working Load (SWL) of the shackle is quoted instead of the Breaking

Load (BL), then SWL shall not be less than the Static Bollard Pull of the

towing vessel.

March 2004 Specification No. EGP3 – 01.22 Page 11 of 31

c. All towing vessels shall carry adequate spare shackles of sufficient size, as

well as number of smaller ones. Split pins or seizing wire for the shackle

shall also be carried.

8.7 Hard Eyes

All towlines, pennants, etc., shall have hard eyes or sockets.

8.8 Bridle Apex

The bridle apex connection shall be a towing ring or triangular shaped plate.

This is often called the "Delta," "Flounder" or "Monkey" Plate.

8.9 Bridle Legs

a. Each bridle leg shall be of stud link chain or composite chain and wire with a

minimum diameter of 2 1/2" (64 mm). If composite, the chain shall be

sufficiently long to extend beyond the deck edge, and prevent the wire

chafing.

b. The length of each leg shall be such that the angle at the apex is between

45 and 60.

c. The end link of any chain shall be a special enlarged link, not a normal link

with the stud removed. All wire shall have "hard eyes."

d. Each bridle leg shall be connected to a flounder plate and a tail chain (chain

pennant) having the same dimensions and breaking strength as the bridle

legs filled forward on the flounder plate and sufficient length to allow the tug

to gather it onto its deck without getting too close to the barge.

8.10 Intermediate Pennant

a. An intermediate wire pennant shall always be fitted between the main towline

and the bridle or chain pennant.

b. The breaking strength of the pennant shall not be less than that of the main

towline with the possible exceptions indicated item “c.” below. It shall have

"hard eyes" and be of the same lay (i.e., left or right hand) as the main

towline.

c. The use and design of a "stretcher," "fuse" or "weak link" pennant is subject

to COMPANY and Marine Surveyor approval.

d. A nylon spring shall not be connected directly to the bridle apex.

e. A spare pennant shall be carried on the towing vessel or barge.

8.11 Bridle Recovery System

8.11.1 Type A - with Winch

a. This type of bridle recovery system is shown in Figure 1. It consists of a

winch (9) and a recovery line (7) connected to the bridle apex (5), via a

suitable lead (8) which may be an "A" frame roller or bolster plate.

March 2004 Specification No. EGP3 – 01.22 Page 12 of 31

The recovery winch shall be manually operated, or have its own power

source, and have an adequate barrel capacity for the required recovery wire.

If manually operated it shall be so geared that the tow bridle apex can be

recovered by two men operating the equipment in bad weather, and shall be

equipped with ratchet gear and brake. The winch shall be capable of

handling at least 5.5 tons (5 tonnes) load, or 75% of the weight of the bridle,

plus attachments including intermediate pennant, whichever is greater. It

shall be suitably secured to the barge structure.

b. The breaking load of the recovery wire shall be at least three times the

weight of the bridle, apex and intermediate pennant. The wire shall be at

least 1 inch (25 mm) diameter.

c. The recovery wire shall be shackled onto the bridle apex. It may have its

own shackles on the rear side of the delta plate.

8.11.2 Type B - with Pennant

a. If the Type A system cannot be fitted, the Type B system shown in Figure 2

may be used. This has an additional pennant, not less than 165 feet (50 m)

in length, as strong as the intermediate pennant. It is connected into the

towing arrangement at the fore end of the bridle apex. This pennant is led

back to the barge, being soft lashed to one of the bridle legs. It shall be

secured outside of all obstructions along the deck edge with soft lashings

every 10 feet (3 m), or metal clips opening outwards.

b. The terminal eye shall be located close to the barge side to enable it to be

passed to the towing vessel. A messenger line shall be available to assist in

this operation.

8.12 Emergency Towing Gear

a. Emergency towing gear must be provided in case of bridle failure or inability

to recover the bridle. This gear shall normally be fitted at the bow of the

barge, but may be accepted at the stern. It may either be a separate bridle

and pennant, or a system as shown in Figure 3. Appropriate spare parts

should also be stored on board the tug to make repairs to the primary bridle

and connections.

The alternative system consists of the following:

Tow connection on or near the barge centerline (over a bulkhead).

Capped fairlead (if required).

Emergency pennant, minimum length 200 ft (60 m) with hard eyes and

chain from tow connection to beyond deck edge.

Extension wires (if required) long enough to prevent the float line chafing

on the barge.

Float line, to extend 150 ft (45 m) aft of stern.

Conspicuous easily handled plastic buoy trailing system.

March 2004 Specification No. EGP3 – 01.22 Page 13 of 31

b. The strength of items listed above shall be as for the main bridle and

connections. The breaking load of the handling systems shall not be less

than 33 tons (30 tonnes), which must be sufficient to break securing devices.

c. If the emergency tow gear is attached forward, it shall be led over the main

tow bridle. It shall be secured to the edge of the barge deck, outside all

obstructions, with soft lashings every 10 feet (3 m), or metal clips opening

outwards.

d. If the emergency tow gear is attached aft, the wire shall be coiled or flaked

near the stern so that it can be pulled clear. The outboard eye shall be led

over the deck edge to prevent chafe of the float line.

e. The Type B recovery system cannot be accepted as, or be connected to, the

emergency tow gear as it relies on the main bridle tow connections.

9 BARGE STABILITY

9.1 General

CONTRACTOR shall provide COMPANY with calculations and drawings

showing the barge-cargo layouts, buoyancy arrangement, and mass properties.

The CONTRACTOR shall provide a ballast condition that will meet the stability

requirement for the barge plus cargo. This includes loadout, towing and

installation procedures.

All barges shall satisfy the intact and damaged stability requirements set forth in

the United States Coast Guard "Requirements for Mobile Offshore Drilling Units"

or equivalent requirements set forth by a recognized certifying agency or bureau

such as Lloyd's, American Bureau of Shipping, or Det Norske Veritas.

The range of static stability of barge and cargo about an axis shall exceed 40

degrees. The angle of (the point where nonwatertight opening immersion

starts) shall exceed 20 degrees. For dynamic stability the wind shall correspond

to the 1 in 100 tow for the specific route planned. Unless specifically approved

otherwise by the COMPANY, the analysis shall be based on the tow taking

place during the time of the year that would cause the most severe stability

problems.

For the intact dynamic stability, factors of safety against overturning by a 100-

knot wind shall not be less than 1.4 calculated as the ratio of areas under the

righting and overturning moment curves up to the second intercept of those

curves or the angle of down flooding is less.

For the damage dynamic stability, factors of safety against overturning by a 50-

knot wind shall not be less than 1.4 calculated as the ratio of areas under the

righting and overturning moment curves up to the second intercept of those

curves or the angle of down flooding is less.

March 2004 Specification No. EGP3 – 01.22 Page 14 of 31

9.2 Draft

a. After loadout, CONTRACTOR shall reballast the barge(s) for the tow

condition. The towage draft shall be small enough to give adequate

freeboard and stability and large enough to dampen motion and reduce

slamming. Mean draft in the towage condition shall not exceed the assigned

load line.

b. Where water ballast is used, it shall, where possible, be kept in full tanks,

pressed up so as to minimize free surface sloshing. Other tanks shall be

clean and empty.

c. When selecting tanks to be filled with ballast, the side or wing tanks shall be

used to gain the greatest inertia to resist barge rolling accelerations. Ballast

shall not be concentrated amidships nor isolated at the fore and aft ends as

these arrangements will create undesirable sagging or hogging stresses

respectively within the barge structure.

d. The effect of cargo removal offshore on a barge ballast arrangement shall be

checked, particularly when more than one item is being transported on a

barge. If offshore ballast adjustments are necessary then they shall be

indicated on the arrangement drawing.

e. An approximately 12" (300 mm) wide by 4' (1200 mm) long white line shall be

painted on the port and starboard side of the barge's bow and stern draft

lines.

9.3 Trim

Trim shall be obtained, where possible, by the position of cargo. However,

positioning of the cargo to achieve the desired trim shall not result in excessively

high longitudinal and/or heave accelerations of the cargo. It shall be selected to

give good directional control and will typically be 0.3% and 1.0% of the waterline

length, by the stern. Where barges with faired sterns are fitted with directional

stabilizing skegs, it may be best to have no trim. CONTRACTOR shall discuss

this option with the COMPANY and obtain approval prior to implementation.

9.4 List

The ballast arrangement shall produce the least possible list, and must never be

such that static list exceeds 1% of the barge breadth.

9.5 Pumping and Sounding

9.5.1 Pumping System

a. All barges shall have one of the following systems, able to pump into and

from all critical tanks, in order of preference:

Two independent pump rooms or one protected pump room, as

described below.

An unprotected pump room with an independent emergency system that

can pump out the pump room.

March 2004 Specification No. EGP3 – 01.22 Page 15 of 31

A system of portable pumps.

b. Independent pump rooms shall have separate pumps, controls, and access

and each shall be able to manifold to all tanks. This may be achieved by

splitting a compartment with a watertight bulkhead.

c. A pump room area shall be protected from flooding, caused by grounding or

collision, by the construction of cofferdams or double bottoms with a

minimum depth of 6 feet (1.8 m) from the outside hull.

9.5.2 Pump Type

a. If portable pumps are used, then they shall either be portable enough to be

moved around the barge (and cargo) by two men, or enough pumping

equipment shall be carried, so that any compartment can be covered.

b. Each portable pump shall be able to pump out from the deepest tank (with

top hat installed). This requires submersible pumps for barges over about

18 feet (5.6 m) depth, due to suction head. Portable submersible pumps

shall be able to fit through tank manholes.

9.5.3 Pump Capacity

The total capacity of the fixed or portable pumps shall be such that any one wing

tank (or other critical tank or pump room) can be emptied in 4 hours. At least

two pumps shall be provided, except where there is a protected pump room.

9.5.4 Vents

All compartments connected to a pumping system shall have a 1/4 inch (6 mm)

diameter breather hold fitted in the air pipe. This will give audible warning or

reduce pressure differentials in event of mishap. This breather hole can be

drilled into the gooseneck of the vent or a metal sleeved hole in the wooden

bung used to close the vent. For short unmanned tows, the vents shall be

closed with the wooden bungs.

9.5.5 Watertight Manholes

a. If manholes to critical compartments are covered up by cargo then either

alternative manholes shall be fitted or cutting gear shall be installed and

positions marked for making access, and welding gear and materials carried

for remaking watertight.

b. Access shall always be available to pump rooms and other work areas.

c. Ladders to the tank bottom are required from each manhole position.

d. Suitable tools shall be provided for removal and refastening manhole covers

and sounding plugs. All manhole covers shall be properly secured with bolts

and gaskets, renewed as necessary.

March 2004 Specification No. EGP3 – 01.22 Page 16 of 31

9.5.6 Top Hats

a. For manholes in decks that can be covered by seas, a top hat (normally 24

inches (600 mm) high that can be bolted in place shall be provided.

b. A sounding plug shall be installed in each compartment (in manhole covers if

necessary) to avoid removing manhole covers. For tanks that will be

sounded regularly, a sounding tube and striker plate are required.

10 EMERGENCY ANCHOR SYSTEM

10.1 General

All barges shall have an emergency anchor system, always capable of holding

the barge and cargo in gale conditions. (Note that many anchors fitted to

classification society rules are only suitable for holding the barge without cargo.)

10.2 Size and Type of Anchor

a. The weight of one anchor shall be at least 1/10 of the static bollard pull

required for the tow.

b. For a barge that will be used for many tows, the anchor shall be chosen for

that with the largest bollard pull requirements.

10.3 Anchor Cable Length

a. The minimum effective length of anchor cable required is 600 feet (180 m),

preferably mounted on a winch. If the cable runs through a spurling pipe, or

other access to storage below decks, then the pipe or access shall be

capable of being made watertight.

b. If there is no winch and inadequate space to flake out a cable properly, a

minimum length of 300 feet (90 m) may be acceptable.

10.4 Anchor Cable Strength

a. For cable on a winch, or capstan, which can be paid out under control, the

minimum breaking load of the cable shall be fifteen times the weight of the

anchor, or one and one-half times holding power of the anchor if greater.

b. For cable flaked out, to allow for the extra shock load, the minimum breaking

load of the cable shall be thirty times the weight of the anchor (or three times

holding power if greater). The last few flakes of cable on deck shall have

lashings that will break and slow down the cable before it is fully paid out.

10.5 Attachment of Cable

a. The inboard end of the cable shall be led through a capped fairlead near the

barge center line and be secured fixed to the barge.

b. The breaking load of connections of the cable to the winch or padeye on the

barge structure shall be greater than that of the cable.

March 2004 Specification No. EGP3 – 01.22 Page 17 of 31

10.6 Anchor Mounting and Release

a. If there is no suitable permanent anchor housing, the anchor shall be

mounted on a billboard, as shown in Figure 4, at about 60 degrees to the

horizontal.

b. The anchor shall be held on the billboard in stops to prevent lateral and

upwards movement. It shall be secured by wire and/or chain stops that can

be easily released manually without endangering the operator.

c. The billboard shall normally be mounted on the stern. It shall be positioned

such that on release the anchor will drop clear of the barge and the cable will

pay out without fouling.

d. If the anchor is mounted at the stern, this will become the bow when

anchored. Anchor lights and shapes must be positioned accordingly.

e. For any system, it must be possible to safely release the anchor manually,

without the use of power to release pawls or dog securing devices. If the

anchor is held on a brake, an additional manually released fastening shall be

fitted.

11 MOORING ARRANGEMENTS

11.1 Position

The barge shall be provided with a minimum of at least four mooring positions

(bollards/stagehorse, etc.) on each side of the barge. If fairleads to the bollards

are not installed, then the bollards shall be provided with capping bars, horns, or

head plate to suitably retain mooring lines at high angles of pull.

11.2 Mooring Ropes

At least four mooring ropes of adequate length and strength, typically about 2 to

3 inches (50 to 75 mm) diameter polypropylene or nylon, 200 to 300 feet (60 to

90 m) long each shall be provided for a sea passage. These ropes may be

carried on the towing unit if they cannot be stored or secured on the barge.

12 DAMAGE CONTROL

When the planned duration of the tow exceeds two days, the following

equipment shall be carried on the barge in packages:

Burning Gear

Welding Equipment

Steel Plate - Various Sizes

Caulking Material

Sand

March 2004 Specification No. EGP3 – 01.22 Page 18 of 31

Cement

Nails

Wooden Plugs - Various Sizes

Wooden Wedges - Various Sizes

Hammer and Tools

13 NAVIGATION LIGHTS AND SOUND SIGNALS

13.1 General

The barge shall carry the lights and shapes required by the International

Regulations for Preventing Collisions at Sea (1972), and any local regulations.

13.2 Power Source

Navigation lights shall be independently operated (e.g., by gas burning or from

independent electrical power source). Spare mantles/bulbs shall be carried, and

power sources shall be amply adequate for the maximum anticipated duration of

the voyage.

14 TOWING VESSEL

14.1 General

a. The towing vessel(s) shall be inspected by a Marine Surveyor before the tow.

The survey will cover the vessel, its equipment, machinery and manning.

b. Upon receipt of barge dimensions, loaded draft and dimensions of cargo, the

CONTRACTOR will assess towage resistance and will submit for COMPANY

approval the details of towing vessel(s).

c. Minimum bollard pull requirements shall be computed by methods approved

by the COMPANY and submitted to the COMPANY for approval.

14.2 Towing Winch

a. The towing vessel(s) shall be equipped with towing winches.

b. If only one drum is used for towing wire, the spare wire shall be stowed on a

reel or other spooling device, and be readily accessible even in heavy

weather and in such a position that transfer to the main towing drum can be

easily effected.

c. The winch shall be adequately secured to the tug. The end of the wire shall

be made fast to the drum.

March 2004 Specification No. EGP3 – 01.22 Page 19 of 31

14.3 Tailgates/Stern Rails

Where a towing tailgate or stern rail is fitted, the radius of the upper rail shall be

more than ten times the diameter of the vessel's main towline, and adequately

faired to prevent snagging.

14.4 Additional Equipment

a. Antichafe gear shall be fitted as necessary. In particular, all wire shall be

protected at towing pods, tow bars and stern rail.

b. All towing craft shall be equipped with burning and welding gear suitable for

use by crew members during periods of emergency.

c. On any tow outside coastal limits, the towing vessel(s) shall carry a portable

pump suitably equipped with means of suction and delivery, having a

self-contained power unit with sufficient fuel for 12 hours usage at the

pump's maximum rating.

14.5 Towline Positioning and Control

a. Positioning the towline in preparation for towage shall be conducted in such

a manner so as to prevent entanglement and fouling around the propellers of

the tug.

b. Where a towing pod is fitted, its strength shall be shown to be adequate. It

shall be well faired and the inside and ends shall have a minimum radius of

ten times the towline diameter.

c. Where no pod is fitted, the after deck shall be fitted with a gog rope,

mechanically operated and capable of being adjusted from a remote station.

Where the anchor-handling wire is used as a gog rope, a spare must be

carried.

d. On square-sterned towing vessels, mechanically or hydraulically operated

tops, capable of being withdrawn or removed, shall be fitted near the aft end

of the bulwarks, to prevent the towline slipping around the vessel's quarter in

heavy weather.

e. A powered work boat shall be provided, for emergency communication with

the cargo barge while under tow, and must have adequate means for

launching in a sea way.

f. In addition to the classification requirements, the towing vessel shall carry

portable transmitter/receivers, i.e., walkie-talkies, for communication with the

barge when tug personnel are placed on board during an emergency.

Suitable spare batteries or means of recharging them shall be provided.

g. Tow vessels shall be fitted with a search light to aid night operations and for

use in illuminating the tow during periods of emergency, or malfunction of the

prescribed navigation lights.

March 2004 Specification No. EGP3 – 01.22 Page 20 of 31

14.6 Bunkers

The towing vessel(s) shall have a reserve of fuel and other consumables of at

least 5 days supply over any proposed towage duration. In the event that the

fuel reserve drops below 5 days supply during the voyage due to adverse

weather conditions, CONTRACTOR shall resupply the towing vessel at sea. If

refueling enroute is proposed, then suitable arrangements shall be made before

the tow starts.

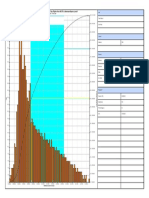

15 TRANSPORTATION FORCES

15.1 General

The cargo and seafastening shall be designed to withstand the motions and

forces resulting from the design transportation conditions. CONTRACTOR’s

procedure for performing all motion related analyses, including fatigue analysis,

shall be submitted to the COMPANY for review and approval at least 30 days

prior to starting analyses.

15.2 Motion Analysis

a. A dynamic motion analysis of the barge/cargo system shall be performed to

determine maximum barge response for a 1 in 100 tow for the specific route

planned as approved by the COMPANY. CONTRACTOR shall obtain tow

specific environmental criteria for the analysis from a recognized marine

consultant and submit it to COMPANY for approval along with the analysis

procedure. Unless specifically approved otherwise by the COMPANY, the

analyses shall assume tow to take place during that part of the year that

results in the most severe barge-cargo response. If final barge selections

have not been made, conservative assumptions shall be made regarding

barge sizes and cargo layouts. The analysis shall consider the following:

Static and dynamic loading from barge movements (head, quartering and

beam seas)

One minute sustained wind

Wave slaming, pounding and buoyancy of items on deck (for the

maximum angle of roll or pitch, assuming a level sea)

The cargo (structure) and seafastenings shall be designed for the 1 in

1000 forces resulting from the above

b. Gravity, roll and pitch acceleration forces shall be resolved into components

acting parallel and perpendicular with the barge deck. These combinations

of forces shall be tabulated for all items of cargo, and used as the basis for

design of cargo, supports and seafastenings.

c. The following roll and pitch angles and heave accelerations shall be used to

derive transportation forces on the cargo and barge if more severe than the

motion analysis response.

Single Amplitude

March 2004 Specification No. EGP3 – 01.22 Page 21 of 31

(in 10 sec period)

Type Roll Pitch Heave

Small Cargo Barge 25o(2) 15o 0.2g

(250 feet length

75 feet beam)

Larger Barges 20o(2) 10o 0.2g

Inland Tows 5o(1)(2) 5o(1) 0.1g

Notes:

(1) Use static angle corresponding to worst damage stability condition, if

greater

(2) Roll center is assumed at the waterline.

d. Under no circumstance shall the global accelerations used for transportation

design be less than:

0.65g Lateral

0.35g Longitudinal

0.50g Vertical

15.3 Allowable Stress Levels

a. The CONTRACTOR shall provide documentation and calculations to

COMPANY not later than one hundred and twenty (120) days prior to

respective loadout dates demonstrating that all barges and cargo comply

with all allowable stresses set forth by API, AISC and the barge's classifying

authority for all loading conditions encountered during loadout, transportation

and launch as applicable.

b. The following maximum stress ratio (allowable stress/AISC basic allowable)

limits shall apply:

Item Loadout Transport

Barge 1.0 1.0

Cargo 1.0 1.33 (See note 1)

Seafastening N/A 1.0

Note 1: Design of cargo structural members directly attached to the

seafastening shall be based on an allowable stress ratio of 1.0.

15.4 Fatigue Damage Prevention

CONTRACTOR shall conduct structural fatigue analyses and provide designs to

mitigate fatigue damage.

a. CONTRACTOR shall submit tow seastate criteria for COMPANY approval.

March 2004 Specification No. EGP3 – 01.22 Page 22 of 31

b. The factor of safety on the number of tows shall be 4.

c. COMPANY approval is required for SCF formula selection.

d. CONTRACTOR shall submit to COMPANY the analytical procedures for the

fatigue analysis 30 days prior to starting the analysis.

e. Seafastening shall be included in the fatigue analysis.

f. Stress concentration factors for the seafastening to structure joints are to be

limited to a maximum of 6.0.

16 POST TOW INSPECTION

a. A visual inspection witnessed by COMPANY, shall be made of all cargo

components upon arrival at destination. CONTRACTOR shall prepare for

COMPANY approval a post tow inspection plan and submit to COMPANY for

approval at least 120 days prior to loadout. The plan shall identify members

and joints to be inspected and method(s) of inspection. The post tow

inspection plan shall consider the results of the transportation analyses when

identifying the members and joints to be inspected.

b. Post-tow inspection records shall be provided to the COMPANY within

twenty-four hours of inspection and prior to lift of modules or components. If

damage is detected, the scope of the inspection shall be increased to

ascertain overall damage to the cargo. The increased scope may include

the use of NDT methods and shall be performed at CONTRACTOR's

expense.

17 POLLUTION PREVENTION

a. All operations shall be conducted in such a manner as to preclude pollution

of the waters of adjacent streams and navigable water ways.

b. The disposal of liquid waste materials into the waters shall be limited to

saltwater and other materials that have been adequately treated for the

removal of oil or other constituents that may be harmful to aquatic life or

injurious to life and property.

c. Other nonliquid waste materials that may be harmful or hazardous to life or

property, or that result in an unsightly appearance, shall not be disposed of

into the waters.

d. The CONTRACTOR shall take every precaution to prevent structural metal

debris and junk from falling into the water during loadout, transportation or

after arrival at destination.

March 2004 Specification No. EGP3 – 01.22 Page 23 of 31

18 SCRAP MATERIAL AND CLEAN-UP

All scrap material including seafastenings shall be disposed of at

CONTRACTOR's expense. CONTRACTOR shall be responsible for cleaning up

the barge(s) after delivery of the cargo.

19 DAMAGE REPAIR

The CONTRACTOR shall be responsible for repair of any damage to the cargo,

and shall submit repair proposals and procedures to the COMPANY for

approval. Repairs may be required immediately or at some future date, as

directed by the COMPANY. All repairs and related activity will be at

CONTRACTOR’s cost.

20 DOCUMENTATION REQUIREMENTS

20.1 Drawings

CONTRACTOR shall furnish COMPANY with drawings for the cargo barges, to

be used for transportation, not later than 120 days prior to loadout. Drawings

shall include the following:

General Arrangement

Outboard Profile and Main Deck Arrangement

Compartmentation Plan and Capacity Plan (including deadweight scale)

Hydrostatic Curves

Cross Curves of Stability

Midship Section and Transverse Framing Detail

Shell Plating and Framing

Bow Sections and Details

Stern Sections and Details

Longitudinal and Transverse Bulkhead Details (all Bulkheads)

Towing Bitt Details and Tow Rigging Arrangement

Ballast Schematic (including pump capacities and curves)

Skidway Arrangement and Details

20.2 Calculations

CONTRACTOR shall provide, 120 days prior to loadout, all detailed calculations

and drawings that demonstrate the adequacy of all designs.

March 2004 Specification No. EGP3 – 01.22 Page 24 of 31

20.3 Towing Progress Report and Documents

The barge position and attitude will be recorded at least twice daily and

communicated by fax or e-mail to the COMPANY at least once a day. A barge

log shall be kept current and a copy provided to the COMPANY at the

completion of the charter. This document will include:

Date and Time

Position, Speed and Heading

Wind Speed and Direction

Sea Height and Direction

Swell Height and Direction

Barge Roll Angle and Period

Any Unusual Cargo and Vessel Behavior

20.4 Incident Analysis

If an incident or injury occurs at any point in the transport of materials,

CONTRACTOR shall conduct a Root Cause Analysis, in accordance with

Exhibit F – HES Management Plan, to the satisfaction of COMPANY.

21 FABRICATION AND ASSEMBLY

CONTRACTOR shall maintain full-time quality control inspector(s) at fabrication

and assembly sites at all times when significant work is being carried out. At

least one AWS certified welding inspector shall be on duty whenever welding is

in progress.

March 2004 Specification No. EGP3 – 01.22 Page 25 of 31

March 2004 Specification No. EGP3 – 01.22 Page 26 of 31

March 2004 Specification No. EGP3 – 01.22 Page 27 of 31

March 2004 Specification No. EGP3 – 01.22 Page 28 of 31

March 2004 Specification No. EGP3 – 01.22 Page 29 of 31

APPENDIX I

STANDARDS AND CODES

American Bureau of Shipping (ABS)

Rules for Building and Classing Mobile Offshore Drilling Units

Rules for Building and Classing Steel Vessels

American Institute of Steel Construction (AISC)

Specification for Structural Steel Buildings – Allowable Stress Design and Plastic Design

American National Standards Institute (ANSI)

A58.1 Building Code Requirements for Minimum Design Loads in Buildings and

Other Structures

American Petroleum Institute (API)

RP 2A-WSD Recommended Practice for Planning, Designing and Constructing Fixed

Offshore Platforms – Working Stress Design

RP 2M Recommended Practice for Qualification Testing of Steel Anchor Designs for

Floating Structures

American Society for Non-Destructive Testing (ASNT)

SNT-TC-1A Non-Destructive Testing Qualification and Certification

American Society for Testing and Materials (ASTM)

A36/A36M Standard Specification for Carbon Structural Steel

American Society of Mechanical Engineers (ASME)

Section IX Welding and Brazing Qualifications

American Welding Society (AWS)

D1.1 Structural Welding Code – Steel

Minerals Management Service (MMS)

Requirements for Verifying the Structural Integrity of OCS Platform

United States Coast Guard (USCG)

Requirements for Mobile Offshore Drilling Units

March 2004 Specification No. EGP3 – 01.22 Page 30 of 31

United States Department of Labor - Occupational Safety and Health Administration

(OSHA)

29 CFR 1910 General Industry OSHA Safety and Health Standards

March 2004 Specification No. EGP3 – 01.22 Page 31 of 31

APPENDIX II

PROJECT DOCUMENTS

Exhibit F - Health, Environment, and Safety Management Plan

Exhibit P - Security Requirements

March 2004 Specification No. EGP3 – 01.22 Page 32 of 31

You might also like

- Bulk Material Handling: Practical Guidance for Mechanical EngineersFrom EverandBulk Material Handling: Practical Guidance for Mechanical EngineersRating: 5 out of 5 stars5/5 (1)

- Leg Penetration Analysis AD-G34-1041-R2658 - Seafox 8 LPA at Zulf 246-251Document8 pagesLeg Penetration Analysis AD-G34-1041-R2658 - Seafox 8 LPA at Zulf 246-251SinojKumarMalipronNo ratings yet

- BP Survey Vessel Technical SpecificationDocument10 pagesBP Survey Vessel Technical SpecificationKurniawan PriambodoNo ratings yet

- WR Design and Fabrication of Anodes Rev 0Document10 pagesWR Design and Fabrication of Anodes Rev 0Mathias OnosemuodeNo ratings yet

- Volvo, Doosan component guide for excavators, wheel loaders, graders and busesDocument16 pagesVolvo, Doosan component guide for excavators, wheel loaders, graders and busesHendarji Hendarji100% (1)

- R0 Procedure Cendor BridgeDocument65 pagesR0 Procedure Cendor BridgeBoyNo ratings yet

- Load - Out Plan/Procedur E: Rev. Statu S Date Revision Memo Issuer Checker ApproverDocument18 pagesLoad - Out Plan/Procedur E: Rev. Statu S Date Revision Memo Issuer Checker ApproverLai Quoc100% (1)

- Jacket Loadout Analysis SummaryDocument48 pagesJacket Loadout Analysis SummaryDhanu PadhuNo ratings yet

- PP00011 Pdi DS Cal 00007 - C03Document96 pagesPP00011 Pdi DS Cal 00007 - C03Olanrewaju Tope100% (1)

- LOCG-GEN-Guideline-006 Rev 0 - Lift-Off Transportation + Inshore Mating of TopsidesDocument26 pagesLOCG-GEN-Guideline-006 Rev 0 - Lift-Off Transportation + Inshore Mating of TopsidesTomkel VoonNo ratings yet

- MS002 ST Rep 076 00016Document78 pagesMS002 ST Rep 076 00016DavisTranNo ratings yet

- Transportation Analysis Guide for Offshore StructuresDocument25 pagesTransportation Analysis Guide for Offshore StructuresphanikrishnabNo ratings yet

- Ffs-pu-5116-A-transportation of Cargo by Barge or ShipDocument28 pagesFfs-pu-5116-A-transportation of Cargo by Barge or ShipBolarinwaNo ratings yet

- G1-VE-T-7400-C21-00051-0002 MEB Caisson Seafastening and Deck Strengthening Verification For Barges Ewan 29 & 30 - 1Document39 pagesG1-VE-T-7400-C21-00051-0002 MEB Caisson Seafastening and Deck Strengthening Verification For Barges Ewan 29 & 30 - 1SharkZ FujiwaraNo ratings yet

- Construction and WeightDocument79 pagesConstruction and Weightusman nawazNo ratings yet

- KOM Loadout InterfaceDocument49 pagesKOM Loadout InterfaceNguyen Dinh Ngoc Duy100% (1)

- UPD-GF-G8-SJ-An-4101 - Barge Hafar 238 Stability and Longitudinal Strength Analysis During WHP-C WHP-D Pile Loadout Rev. BDocument42 pagesUPD-GF-G8-SJ-An-4101 - Barge Hafar 238 Stability and Longitudinal Strength Analysis During WHP-C WHP-D Pile Loadout Rev. BriandiNo ratings yet

- Topside Loadout at Ulsan-Re.1Document28 pagesTopside Loadout at Ulsan-Re.1richardykeNo ratings yet

- FRONT END ENGINEERING DESIGN - PART II SPECIFICATIONDocument41 pagesFRONT END ENGINEERING DESIGN - PART II SPECIFICATIONMohd. Fadhil JamirinNo ratings yet

- Suction Caissons / Anchors: An Emerging Foundation Concept For Deep Water StructuresDocument25 pagesSuction Caissons / Anchors: An Emerging Foundation Concept For Deep Water Structuresgamidi67No ratings yet

- 05-1 - EPC-SV-ALE-N-CA-10006 - Rev B2 Barge Deck Strength Check PDFDocument63 pages05-1 - EPC-SV-ALE-N-CA-10006 - Rev B2 Barge Deck Strength Check PDFBill BenNo ratings yet

- LC161076 MTKF 1 12 0001 PDFDocument176 pagesLC161076 MTKF 1 12 0001 PDFAnonymous twOrHKNo ratings yet

- Guidelines For Float Over InstallationsDocument36 pagesGuidelines For Float Over InstallationsClive GouldNo ratings yet

- ADMI Move 6procedure (Rig Move4) To Mozhel PFrev3Document15 pagesADMI Move 6procedure (Rig Move4) To Mozhel PFrev3Mohamed MostafaNo ratings yet

- Riser & I-Tube Clamp Installation ProcedureDocument43 pagesRiser & I-Tube Clamp Installation ProceduremahalakshmiNo ratings yet

- Sea TransportationDocument8 pagesSea TransportationMark Samsel RohanNo ratings yet

- ELDS-DR-S-02005: Eldfisk Ii 2/7 S Jacket and Bridge SupportDocument59 pagesELDS-DR-S-02005: Eldfisk Ii 2/7 S Jacket and Bridge SupportavtsdpmNo ratings yet

- Jacket Installation GuideDocument1 pageJacket Installation GuideNath YauNo ratings yet

- Batam Vessel Load Out Training 201407Document13 pagesBatam Vessel Load Out Training 201407adventourerNo ratings yet

- Collapse Analysis 1Document13 pagesCollapse Analysis 1samiransmitaNo ratings yet

- SL-ELT-AN-WPS1-4114-C2-S1 Topside Lift Analysis & Report PDFDocument633 pagesSL-ELT-AN-WPS1-4114-C2-S1 Topside Lift Analysis & Report PDFsaeed ghafoori100% (1)

- Etame Pipeline Fabrication PlanDocument25 pagesEtame Pipeline Fabrication PlanWilliam O OkolotuNo ratings yet

- Offshore Mooring Risk AnalysisDocument109 pagesOffshore Mooring Risk Analysisbubbly_blu2No ratings yet

- Jacket AppurtenancesDocument50 pagesJacket AppurtenancesAanbualagan ChelvanathanNo ratings yet

- Calculation Note Stabbing Guide Design Design Code Check:Api RP 2A Check For Tubular Ø 323.9 X 12.70 Due To Boatlanding InstallationDocument8 pagesCalculation Note Stabbing Guide Design Design Code Check:Api RP 2A Check For Tubular Ø 323.9 X 12.70 Due To Boatlanding InstallationSai SushankNo ratings yet

- Gen S A JK S PR 0024 G02Document45 pagesGen S A JK S PR 0024 G02e100% (1)

- Guidelines for Marine Lifting OperationsDocument32 pagesGuidelines for Marine Lifting OperationsFoxg98924No ratings yet

- Appendix e (Sacs Output)Document6 pagesAppendix e (Sacs Output)Tran Van DaiNo ratings yet

- Rockwater Spool Load-Out ProcedureDocument75 pagesRockwater Spool Load-Out ProcedurePhani Kumar G SNo ratings yet

- App 10 Longitudial Shear 2 UC 283Document3 pagesApp 10 Longitudial Shear 2 UC 283yuNo ratings yet

- Ground Bearing Capacity Calculation and Jetty Bearing Capacity Calculation Load Out Topside SvneDocument6 pagesGround Bearing Capacity Calculation and Jetty Bearing Capacity Calculation Load Out Topside SvneTran Van DaiNo ratings yet

- SL-ELT-PR-WPS1-4105-C1-S1 Topside Load Out ProcedureDocument142 pagesSL-ELT-PR-WPS1-4105-C1-S1 Topside Load Out Proceduresaeed ghafooriNo ratings yet

- Fixed PlatformsDocument98 pagesFixed Platformsusman nawazNo ratings yet

- DNV-RP-H102 Marine Operations During Removal of Offshore Installations April 2004Document22 pagesDNV-RP-H102 Marine Operations During Removal of Offshore Installations April 2004TroyNo ratings yet

- 3.4 DC STRL 9WPPDocument48 pages3.4 DC STRL 9WPPkhanhpcNo ratings yet

- WAfrica Metocean Data Rev20Document55 pagesWAfrica Metocean Data Rev20Ένκινουαν Κόγκ Αδάμου100% (2)

- Installation Engineering and Execution of Offshore ProjectsDocument104 pagesInstallation Engineering and Execution of Offshore ProjectsNMHa100% (4)

- STD TOPSIDE LIFT DESIGNDocument91 pagesSTD TOPSIDE LIFT DESIGNSarva BharNo ratings yet

- 0028/ND - Guidelines For The Transportation and Installation of Steel JacketDocument38 pages0028/ND - Guidelines For The Transportation and Installation of Steel JacketIkhwan Shafiq ZainalNo ratings yet

- Breasting Dolphin Jetty PDFDocument157 pagesBreasting Dolphin Jetty PDFPriodeep ChowdhuryNo ratings yet

- Offshore Heavy-Lift Engineering PresentationDocument31 pagesOffshore Heavy-Lift Engineering Presentationmarc121080% (5)

- ALE Capabilities Brochure FVDocument64 pagesALE Capabilities Brochure FVNatree TeeNo ratings yet

- Standard Vessel SpecificationsDocument27 pagesStandard Vessel SpecificationsCora ElenaNo ratings yet

- FPSO - Technical Specification For Marine TransportationDocument11 pagesFPSO - Technical Specification For Marine Transportationdndudc100% (1)

- 9200 9L 039 - R2Document17 pages9200 9L 039 - R2Yuda SatriaNo ratings yet

- No. 110 Guideline For Scope of Damage Stability Verification On New Oil Tankers, Chemical Tankers and Gas CarriersDocument24 pagesNo. 110 Guideline For Scope of Damage Stability Verification On New Oil Tankers, Chemical Tankers and Gas CarriersSaravanakumar VaradharajanNo ratings yet

- TS of Travelling TripperDocument10 pagesTS of Travelling TripperShashank HegdeNo ratings yet

- ESP CodeDocument7 pagesESP CodeAkash KandwalNo ratings yet

- Method Statement - BackfillDocument8 pagesMethod Statement - BackfillJurie_sk3608100% (1)

- Lifting Plane Rein .CageDocument37 pagesLifting Plane Rein .Cagehossam saadNo ratings yet

- Test 2 OrganizedDocument20 pagesTest 2 OrganizedEdward CelebreNo ratings yet

- As CL Ac Rev6Document19 pagesAs CL Ac Rev6Tammam HassanNo ratings yet

- Start Date ReportDocument1 pageStart Date ReportMathias OnosemuodeNo ratings yet

- Vedra Trade Services (VTS) ProfileDocument94 pagesVedra Trade Services (VTS) ProfileMathias OnosemuodeNo ratings yet

- J08937A-A-RG-00046 Rev A1 Interface RegisterDocument3 pagesJ08937A-A-RG-00046 Rev A1 Interface RegisterMathias OnosemuodeNo ratings yet

- Vedra Trade Services (VTS) ProfileDocument94 pagesVedra Trade Services (VTS) ProfileMathias OnosemuodeNo ratings yet

- J08937A-A-RG-00018 Rev D1 Risk RegisterDocument3 pagesJ08937A-A-RG-00018 Rev D1 Risk RegisterMathias OnosemuodeNo ratings yet

- Duration REPORTDocument1 pageDuration REPORTMathias OnosemuodeNo ratings yet

- Confident Level For Base Line Schedule Targeting Q4 2023-Using PRA SoftwareDocument1 pageConfident Level For Base Line Schedule Targeting Q4 2023-Using PRA SoftwareMathias OnosemuodeNo ratings yet

- J08937A-A-RG-00012 Rev A1 Value Engineering RegisterDocument4 pagesJ08937A-A-RG-00012 Rev A1 Value Engineering RegisterMathias OnosemuodeNo ratings yet

- Schedule Model in PRA For The AG Plant & 16inch 25.5 KM Export Line To Amena EkponoDocument1 pageSchedule Model in PRA For The AG Plant & 16inch 25.5 KM Export Line To Amena EkponoMathias OnosemuodeNo ratings yet

- AG GAS PLANT, 50MMscfd & 16, 25.5 KM Export Pipline - L1Document1 pageAG GAS PLANT, 50MMscfd & 16, 25.5 KM Export Pipline - L1Mathias OnosemuodeNo ratings yet

- Activity Duration Estimates TemplateDocument1 pageActivity Duration Estimates TemplateMathias OnosemuodeNo ratings yet

- Book 1Document2 pagesBook 1Mathias OnosemuodeNo ratings yet

- Fop KC-2 - B102Document5 pagesFop KC-2 - B102Mathias OnosemuodeNo ratings yet

- DPR 18-05-2021Document18 pagesDPR 18-05-2021Mathias OnosemuodeNo ratings yet

- 149AKQDocument1 page149AKQMathias OnosemuodeNo ratings yet

- 10'' Pipeline Activity Base CostingDocument2 pages10'' Pipeline Activity Base CostingMathias OnosemuodeNo ratings yet

- City Gate Aba Project: Gredor Nigeria LimitedDocument1 pageCity Gate Aba Project: Gredor Nigeria LimitedMathias OnosemuodeNo ratings yet

- dESIGN FOR REBAR IN A CONCRETE SLABDocument1 pagedESIGN FOR REBAR IN A CONCRETE SLABMathias OnosemuodeNo ratings yet

- In-Place Strength Evaluation of Existing Fixed Offshore PlatformDocument8 pagesIn-Place Strength Evaluation of Existing Fixed Offshore PlatformMathias OnosemuodeNo ratings yet

- BGL Kakinada Metering Skids Bid Doc Material RequisitionDocument525 pagesBGL Kakinada Metering Skids Bid Doc Material RequisitionmishtinilNo ratings yet

- 11 029 - Project ScheduleDocument102 pages11 029 - Project ScheduleGoh Boon TiongNo ratings yet

- City Gate Aba Project: Gredor Nigeria LimitedDocument1 pageCity Gate Aba Project: Gredor Nigeria LimitedMathias OnosemuodeNo ratings yet

- CIGA-NG180100021-CGSA1-CX4019-000049-Steel Connection DetailsDocument1 pageCIGA-NG180100021-CGSA1-CX4019-000049-Steel Connection DetailsMathias OnosemuodeNo ratings yet

- City Gate Aba Project: Gredor Nigeria LimitedDocument1 pageCity Gate Aba Project: Gredor Nigeria LimitedMathias OnosemuodeNo ratings yet

- City Gate Aba Project: Gredor Nigeria LimitedDocument1 pageCity Gate Aba Project: Gredor Nigeria LimitedMathias OnosemuodeNo ratings yet

- CIGA-NG180100021-CGSA1-CX4019-000046-Elevated Water Tank Steel Structural Stand and Foundation Design ReportDocument37 pagesCIGA-NG180100021-CGSA1-CX4019-000046-Elevated Water Tank Steel Structural Stand and Foundation Design ReportMathias OnosemuodeNo ratings yet

- KCDP environmental data designDocument6 pagesKCDP environmental data designMathias OnosemuodeNo ratings yet

- CIGA-NG180100021-CGSA1-CX4019-000046-Elevated Water Tank Steel Structural Stand Design ReportDocument13 pagesCIGA-NG180100021-CGSA1-CX4019-000046-Elevated Water Tank Steel Structural Stand Design ReportMathias OnosemuodeNo ratings yet

- CIGA-NG180100021-CGSA1-CX4019-000047-C01 - Elevated Water Tank Steel Structural Stand Design DrawingDocument1 pageCIGA-NG180100021-CGSA1-CX4019-000047-C01 - Elevated Water Tank Steel Structural Stand Design DrawingMathias OnosemuodeNo ratings yet

- Derelict GeneratorDocument11 pagesDerelict GeneratorJazz FawkNo ratings yet

- HD205 3Document2 pagesHD205 3Naughty VongNo ratings yet

- Tb1e 077GG0Document2 pagesTb1e 077GG0danieldario33No ratings yet

- HighNote3 U4 Test BDocument3 pagesHighNote3 U4 Test BTomek KościelnyNo ratings yet

- QR149 (QTR149) Qatar Airways Flight Tracking and History - FlightAwareDocument1 pageQR149 (QTR149) Qatar Airways Flight Tracking and History - FlightAwareArham SohailNo ratings yet

- EN PT-400 Tech Specs 03-17Document2 pagesEN PT-400 Tech Specs 03-17david100% (1)

- Government of Maharashtra: Public Works Department East Division PuneDocument18 pagesGovernment of Maharashtra: Public Works Department East Division PuneAJAY BHOSALENo ratings yet

- 3 - Idt Af - BKMDocument106 pages3 - Idt Af - BKMVishnuNo ratings yet

- Câu 2 - EmiratesDocument3 pagesCâu 2 - EmiratesNguyễn Ngọc KiềuNo ratings yet

- Indiana Jones RPG - IJ1 - Temple of Doom Adv PackDocument46 pagesIndiana Jones RPG - IJ1 - Temple of Doom Adv PackShiningNo ratings yet

- Wheel Loader - Case CCE202104-821GDocument7 pagesWheel Loader - Case CCE202104-821Gchuck absulioNo ratings yet

- Transportation SystemsDocument136 pagesTransportation SystemsKaren Dela Torre100% (1)

- A Presentation ON Seventh Five Year PlanDocument8 pagesA Presentation ON Seventh Five Year PlanruchidodejaNo ratings yet

- JHA ForHitaching Movement For Raw Material StackingDocument1 pageJHA ForHitaching Movement For Raw Material StackingShahid RazaNo ratings yet

- B&L Sanitation Study 2.23.22Document12 pagesB&L Sanitation Study 2.23.22Tim KnaussNo ratings yet

- P Kge 21090640Document1 pageP Kge 21090640Ronan GilbertNo ratings yet

- Batching Plant MT - 0.5: Mixing Technology RedefinedDocument6 pagesBatching Plant MT - 0.5: Mixing Technology RedefinedGeetesh MakadiaNo ratings yet

- S200 Acifm MNT 50 RPT XXXXXXX 01080Document2 pagesS200 Acifm MNT 50 RPT XXXXXXX 01080fayasibrahimkuttyNo ratings yet

- 966h FuseDocument4 pages966h FuseIslam Abdadaim HamadNo ratings yet

- E - C Manual - R1 - 28.8.18Document86 pagesE - C Manual - R1 - 28.8.18Bruno LopezNo ratings yet

- CTS practice exam questionsDocument3 pagesCTS practice exam questionsCDEC Here to ServeNo ratings yet

- B737 MAX ATA - 00 IntroductionDocument86 pagesB737 MAX ATA - 00 IntroductionHieu LeNo ratings yet

- TCVN 4244-2005Document179 pagesTCVN 4244-2005Toàn ĐinhNo ratings yet

- PV21 Condo 3 Rooms FULLY FURNISHED Nice Unit - Apartment Condominium For Rent in Setapak, Kuala LumpurDocument1 pagePV21 Condo 3 Rooms FULLY FURNISHED Nice Unit - Apartment Condominium For Rent in Setapak, Kuala Lumpur4ddgqh22ftNo ratings yet

- Preview ANSI OPEI B71.9-2016Document11 pagesPreview ANSI OPEI B71.9-2016sroenschNo ratings yet

- MSA-11Document16 pagesMSA-11AleX 2.0No ratings yet

- LAB 2 - Running Speed (Method 1) OEL 1Document4 pagesLAB 2 - Running Speed (Method 1) OEL 1ZULFAQAR BIN MOHAMMAD NIZAMNo ratings yet

- DA42 Operating Manual Chapter SummariesDocument41 pagesDA42 Operating Manual Chapter SummariesMk SinghNo ratings yet

- Impact of Surat cable-stayed bridge on traffic patternsDocument72 pagesImpact of Surat cable-stayed bridge on traffic patternsSunnyDeolGNo ratings yet