Professional Documents

Culture Documents

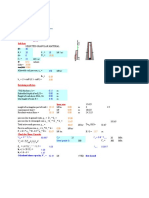

Estimation of Gravity Loads

Uploaded by

Solomon Ndugwa BalemeziOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Estimation of Gravity Loads

Uploaded by

Solomon Ndugwa BalemeziCopyright:

Available Formats

REFERENCE PARTICULARS

Estimation of Gravity loads

Characteristic Permanent Loads

Timber Trusses:

Average Density of Ugandan Hardwood = 600kg/m 3

Zziwa et al

Truss Spacing = 2.5m

Rafters:

Length: 2 x 7.26m, Size: 90 x 40mm

2× 7.26 ×0.09 ×0.04 × 600 ×9.81

G k , r= =0.31 kN

1000

Double Tie Beams:

Length: 9.25, Size: 90 x 40mm and 141 x 32mm

9.25 ×0.09 ×0.04 × 600 ×9.81

G k , t 1= =0.20 kN

1000

9.25 ×0.14 × 0.03× 600 ×9.81

G k , t 2= =0.23 kN

1000

Struts & Ties:

Total Length: 16.14, Size: 80 x 35mm

16.14 ×0.08 × 0.04 ×600 × 9.81

G k , st = =0.30 kN

1000

Total Permanent Load due to Single Truss:

G k , T =0.31+ 0.20+ 0.23+0.3=1.05 kN

REFERENCE PARTICULARS

Truss Load on Walls (Linearly Distributed Load):

1.05 kN 1

Gk , T = × =0.21 kN /m

2 2.5 m

Zziwa et al

Wall Plate:

Average Density of Ugandan Hardwood = 600kg/m 3

Size: 100 x 32mm

0.1× 0.03× 600 ×9.81

G k , ℘= =0.02 kN /m

1000

Roofings

Catalogue

Gauge 30 Corrugated Iron Sheets:

Metal Thickness = 0.315mm, Weight = 3.2kg/m2

3.2 ×9.81 kN 9.25 m

G k , S= × =0.15 kN /m

1000 m2 2

Zziwa et al

Purlins:

Average Density of Ugandan Hardwood = 600kg/m 3

Size: 80 x 35mm, 8no. on one side of truss

0.08× 0.04 ×600 × 9.81

G k , P=8× =0.15 kN /m

1000

CML Lab Report

Wall:

Average Density Bricks = 2133kg/m3

Size: 210 x 130 x 75mm, Height-to-Eaves = 3.5m

3.5× 0.21× 2133 ×9.81

Gk , W = kN / m=15.38 kN /m

BS 648 1000

Concrete Ring Beam:

Concrete Density = 2400kg/m3

Size: 210 x 230mm

REFERENCE PARTICULARS

0.23 ×0.21 ×2400 × 9.81

G k , P= kN /m=1.14 kN /m

1000

Total Permanent Loading (per m-run of wall);

Load from: DL

kN/m

1. Corrugated Iron 0.15

Sheets

2. Purlins 0.15

3. Timber Roof Trusses 0.21

4. Wall Plate 0.02

5. Ring Beams 1.14

6. Wall self-weight 15.38

Total 17.05

Characteristic variable load

Note: Since it was raining at the time of collapse, there could not have

been a live load on top of the roof. Accordingly, the variable load was

considered to be zero.

Design load at SLS

Partial factor of safety for permanent loads = 1.00

Partial factor of safety for variable loads = 1.00

Service load, = (1.0 × 17.05) + (1.0 × 0) = 17.05 kN/m

REFERENCE PARTICULARS

REFERENCE PARTICULARS

EN 19996-1-1 Vertical Resistance Check (No Wind Load Acting)

Cl. 5.5.1.2 Effective Height, he

h e= ρn × h

h=3000mm; Clear Storey Height

ρn =2; Cantilever with no stiffening walls s

Thus,

h e=2×3000=6000 mm

Cl. 5.5.1.3 Effective Thickness, teff

t e ff =ρt × t

t=210 mm ; actual wallthickness Obtained from CML report.

Cl. 5.5.1.3 (2) ρt =1.14 ; obtained ¿ table 5.1by interpolation . Pier size 350x350mm spaced

at 3400mm average.

t e ff =1.14 ×210 mm=239.4 mm

Cl. 5.5.1.4 Slenderness Ratio;

6000

S R= =25

239.4

Note: Slenderness Ratio is less than 27. This is acceptable.

Cl. 6.1.2 Philosophy of Design Check;

Cl. 6.1.2.1

Wall Vertical Resistance , N Rd ≥ Design Load at SLS , N Ed

∅ × t × b× f k

N Rd=

γm

Where;

∅=0.49; Capacity Reduction Factor in accordance with Annex G

t=210 mm; actual wall thickness

REFERENCE PARTICULARS

0.7 0.3

f k =K × f b × f m ; Characteristic Compressive Strength of Masonry

K=0.2; Table 3.3

f b=3.1MPa; average brick strength from CML report

f m=2.9 MPa; average mortar strength from CML report

f k =0.2 ×3.10.7 × 2.90.3=0.61 MPa

γ m=1 ; material partial safety factor considered equal to 1 because this is a

check of already constructed material and not a design.

Consider 1m-run of wall

Plan Area=0.21× 1=0.21 m 2> 0.1; No modification for fk required

From which

0.49 ×1000 ×210 × 0.61

F d= =62,769 N ( 62.8 kN )

1

Design Load at SLS=17.05 kN

Conclusion: Vertical Resistance of the Church walls against gravity loads

was far higher than the gravity loads at Serviceability Limit State. Thus,

the walls were stable against gravity loads.

You might also like

- B13 Outfall Structure CalculationDocument36 pagesB13 Outfall Structure Calculationxuxiangqian2018100% (1)

- A. ReferencesDocument5 pagesA. ReferencesAndy Claud MassaliNo ratings yet

- 05.08.2009 - Cable Trench SectionsDocument22 pages05.08.2009 - Cable Trench SectionsandyhrNo ratings yet

- Calculator 1Document9 pagesCalculator 1hgag selimNo ratings yet

- Transverse-Design771 TriDocument17 pagesTransverse-Design771 TriBasava SowmyaNo ratings yet

- Form Work Tie Rod Calculation 1Document3 pagesForm Work Tie Rod Calculation 1NalinNo ratings yet

- DATADocument3 pagesDATAFaiz SyazwanNo ratings yet

- Design of Culvert.Document4 pagesDesign of Culvert.Mariappan .PNo ratings yet

- Temple FACILITY Circular Slab DesignDocument1 pageTemple FACILITY Circular Slab Designselvakumar sNo ratings yet

- Duct Support CalculationDocument4 pagesDuct Support CalculationSuresh DNo ratings yet

- Masonry Design Examples To BS5628Document11 pagesMasonry Design Examples To BS5628mys85100% (3)

- Design of - ESR (200KL)Document33 pagesDesign of - ESR (200KL)sanju middya100% (1)

- Design of PurlinDocument4 pagesDesign of PurlintanguanNo ratings yet

- Design of Flash Mixer at Kurawar - 1ADocument13 pagesDesign of Flash Mixer at Kurawar - 1AAnonymous RREG0QJWNo ratings yet

- Calculation For 1.4m X 1.5m RCC Box CulvertDocument4 pagesCalculation For 1.4m X 1.5m RCC Box Culvertrupesh417No ratings yet

- SHEAR WAL DESIGN - Lift Core - CopyxDocument5 pagesSHEAR WAL DESIGN - Lift Core - CopyxLam Kah LeongNo ratings yet

- Floor Details: Tatprofiled SteelDocument14 pagesFloor Details: Tatprofiled SteelshaimenneNo ratings yet

- Floor Details: Tatprofiled SteelDocument14 pagesFloor Details: Tatprofiled SteelshaimenneNo ratings yet

- Revised Pad Footing Rev.1 (10.7.2018)Document4 pagesRevised Pad Footing Rev.1 (10.7.2018)Ally Khoo100% (1)

- Revised Pad Footing Rev.1 (10.7.2018)Document4 pagesRevised Pad Footing Rev.1 (10.7.2018)Ally KhooNo ratings yet

- Maxspan Slab WordDocument3 pagesMaxspan Slab WordJames Aswa100% (1)

- 1.10 Beam Design To BS 8110 and ACI 318: 95 1.20 General Parameters 1.2.1 Design Illustration Design DecsriptionDocument4 pages1.10 Beam Design To BS 8110 and ACI 318: 95 1.20 General Parameters 1.2.1 Design Illustration Design DecsriptionMICHAEL MWONGANo ratings yet

- PE Design at 111 Koon SengDocument2 pagesPE Design at 111 Koon SengJason LeoNo ratings yet

- Design of HCL FRP Storage TANKDocument21 pagesDesign of HCL FRP Storage TANKHaries Bugarin GarciaNo ratings yet

- As Per Indian Standard Code of Practice: Input ParametersDocument17 pagesAs Per Indian Standard Code of Practice: Input ParametersAmit Tiwari100% (1)

- 1901 Tri 44 RPT 004Document7 pages1901 Tri 44 RPT 004civilceejiNo ratings yet

- RC Tank Design CalculationDocument8 pagesRC Tank Design CalculationNicholas ThompsonNo ratings yet

- 1.1 Column Design: Step 1: Calculation of LoadDocument6 pages1.1 Column Design: Step 1: Calculation of LoadSunidhi rathoreNo ratings yet

- Alone Wellingborough TrainShed Design of Repairs To Timber RoofDocument4 pagesAlone Wellingborough TrainShed Design of Repairs To Timber RoofKelvin bongNo ratings yet

- RC Retaining Wall by CDSCODocument7 pagesRC Retaining Wall by CDSCOnazrawiNo ratings yet

- Ug Tank PreviewDocument2 pagesUg Tank Previewaaditya chopadeNo ratings yet

- 2.2 Simply Supported Beam V.2Document7 pages2.2 Simply Supported Beam V.2Hafiz95 ReactsNo ratings yet

- Design of Elastomeric BearingsDocument6 pagesDesign of Elastomeric BearingsHarshitha GaneshNo ratings yet

- Design Calculation of Falsework For Construction of 1800mm Thick Slab - r3Document14 pagesDesign Calculation of Falsework For Construction of 1800mm Thick Slab - r3Chan Kin Cheung100% (1)

- 02 Simply Suppported Beam AnalysisDocument7 pages02 Simply Suppported Beam AnalysisbasitNo ratings yet

- Design of Flash Mixer at Aron - 4DDocument10 pagesDesign of Flash Mixer at Aron - 4DSougata MondalNo ratings yet

- Null 4Document5 pagesNull 4emranahmed056studentNo ratings yet

- Design Considerations For Mounted Store Room (Grass Godown) at Chhani-VadodaraDocument3 pagesDesign Considerations For Mounted Store Room (Grass Godown) at Chhani-Vadodaratarang patelNo ratings yet

- Residential Building Design Using Excel Program FinalDocument22 pagesResidential Building Design Using Excel Program FinalManohar VangaNo ratings yet

- Book 1Document71 pagesBook 1Yosa Citra AditamaNo ratings yet

- Jutpani SS20Document23 pagesJutpani SS20Suman NakarmiNo ratings yet

- Example On Design of Timber Structure Part2Document21 pagesExample On Design of Timber Structure Part2Nur Syazana88% (8)

- Water Tank Wal Foundation EXTERNAL WALL - Equalisation TankDocument12 pagesWater Tank Wal Foundation EXTERNAL WALL - Equalisation TankDenishmakvanaNo ratings yet

- University of Dar Es SalaamDocument10 pagesUniversity of Dar Es SalaamChris AdaminovicNo ratings yet

- Explanatory Notes For RC Concrete ProjectDocument32 pagesExplanatory Notes For RC Concrete ProjectJean pierre ManriqueNo ratings yet

- Inde. ScaffDocument12 pagesInde. ScaffPriya G67% (3)

- Lintel DesignDocument3 pagesLintel DesignPrashant HuddarNo ratings yet

- 1901 - TRI - W44 - Dome Design Sheet - Rev6.1Document5 pages1901 - TRI - W44 - Dome Design Sheet - Rev6.1civilceejiNo ratings yet

- Purlin Design Astino ProjectDocument1 pagePurlin Design Astino ProjectSalvatore ShwNo ratings yet

- Design of PurlinsDocument10 pagesDesign of PurlinsFranklyn GenoveNo ratings yet

- Referenc e Calculation RemarksDocument13 pagesReferenc e Calculation RemarksJin ChuanNo ratings yet

- Slab DesignDocument1 pageSlab DesignMadhu SudhanNo ratings yet

- Slab and StaircaseDocument8 pagesSlab and StaircaseSamikshya ShahNo ratings yet

- Example 3.3 - Simply Supported One Way Slab PDFDocument6 pagesExample 3.3 - Simply Supported One Way Slab PDFFarhana HussinNo ratings yet

- Design of Flash Mixer at Kurawar - 1ADocument4 pagesDesign of Flash Mixer at Kurawar - 1AAnonymous RREG0QJWNo ratings yet

- Composite BeamDocument2 pagesComposite BeamJustin MusopoleNo ratings yet

- Strength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresFrom EverandStrength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresRating: 4 out of 5 stars4/5 (1)

- Weekly ReportDocument17 pagesWeekly ReportSolomon Ndugwa BalemeziNo ratings yet

- Slab BeamDocument17 pagesSlab BeamSolomon Ndugwa BalemeziNo ratings yet

- AV Office - SeptDocument1 pageAV Office - SeptSolomon Ndugwa BalemeziNo ratings yet

- Paving Brick and Concrete BeamDocument2 pagesPaving Brick and Concrete BeamSolomon Ndugwa BalemeziNo ratings yet

- AV Office - Elevations 1Document1 pageAV Office - Elevations 1Solomon Ndugwa BalemeziNo ratings yet

- UB 406x178x85: Cross-Section PropertiesDocument2 pagesUB 406x178x85: Cross-Section PropertiesSolomon Ndugwa BalemeziNo ratings yet

- 01 - Foundation LayoutDocument1 page01 - Foundation LayoutSolomon Ndugwa BalemeziNo ratings yet

- Extract From NBCDocument4 pagesExtract From NBCSolomon Ndugwa BalemeziNo ratings yet

- Estimation of Wind LoadsDocument4 pagesEstimation of Wind LoadsSolomon Ndugwa BalemeziNo ratings yet

- Wind Loading On Portal Frames2Document4 pagesWind Loading On Portal Frames2Solomon Ndugwa BalemeziNo ratings yet

- A Arjun C: + Arjunc8@h +971 56 121 4376Document3 pagesA Arjun C: + Arjunc8@h +971 56 121 4376Solomon Ndugwa BalemeziNo ratings yet

- Analysis ReportDocument30 pagesAnalysis ReportSolomon Ndugwa BalemeziNo ratings yet

- JUNE, 2020: Building Inspection BookletDocument44 pagesJUNE, 2020: Building Inspection BookletSolomon Ndugwa BalemeziNo ratings yet

- Реngauge:: Actual Size!Document2 pagesРеngauge:: Actual Size!Solomon Ndugwa BalemeziNo ratings yet

- Description Unit Rate (Ugx) Quantity Architectural DesignDocument2 pagesDescription Unit Rate (Ugx) Quantity Architectural DesignSolomon Ndugwa BalemeziNo ratings yet

- Wind Design To Cp3 - 1972: Namulemu Catholic Church General Wind Input TablesDocument3 pagesWind Design To Cp3 - 1972: Namulemu Catholic Church General Wind Input TablesSolomon Ndugwa BalemeziNo ratings yet

- Variation of Elongation Against Plate Thickness: Dimensions and Mechanical Strength of Metal AnchorsDocument6 pagesVariation of Elongation Against Plate Thickness: Dimensions and Mechanical Strength of Metal AnchorsSolomon Ndugwa BalemeziNo ratings yet

- FRAM Geolab LTD ProfileDocument25 pagesFRAM Geolab LTD ProfileSolomon Ndugwa BalemeziNo ratings yet

- Catalog PDFDocument92 pagesCatalog PDFSolomon Ndugwa BalemeziNo ratings yet

- Renovation of Kisenyi Health Center Iv: Sign BoardDocument1 pageRenovation of Kisenyi Health Center Iv: Sign BoardSolomon Ndugwa BalemeziNo ratings yet

- Letter of Transmittal: Engr. Anacleto M. Cortez JRDocument6 pagesLetter of Transmittal: Engr. Anacleto M. Cortez JRJames VincentNo ratings yet

- Curtain Wall SystemDocument27 pagesCurtain Wall SystemDiksha MagidwarNo ratings yet

- Factors Affecting Selection of Foundation For BuildingsDocument4 pagesFactors Affecting Selection of Foundation For BuildingskamalNo ratings yet

- Construction Materials: Assignment ReportDocument7 pagesConstruction Materials: Assignment ReportKiệt ĐỗNo ratings yet

- Analysis of Shear Walls For Multi-Storey Timber BuildingsDocument54 pagesAnalysis of Shear Walls For Multi-Storey Timber BuildingsrahimmullaNo ratings yet

- NSCPDocument3 pagesNSCPJulius Christian PerezNo ratings yet

- ASTM C133 Test Methods For Cold Crushing Strength and Modulus of Rupture of RefractoriesDocument1 pageASTM C133 Test Methods For Cold Crushing Strength and Modulus of Rupture of RefractoriesIkramul Fajri YasmanNo ratings yet

- How To Properly Size Unitary EquipmentDocument3 pagesHow To Properly Size Unitary EquipmentDavid O. AlmeidaNo ratings yet

- Modular ConstrctnDocument4 pagesModular ConstrctnParvez Saif100% (1)

- Pressurization CalculationDocument6 pagesPressurization CalculationAbdul HakkimNo ratings yet

- Types of Bonds in Brick Masonry: Stretcher BondDocument4 pagesTypes of Bonds in Brick Masonry: Stretcher Bondshahbaz anwerNo ratings yet

- RCC51 Column Load Take-Down DesignDocument11 pagesRCC51 Column Load Take-Down DesignAnonymous BOlFHmjkNo ratings yet

- Building Roof and Its Functions (Psychological, Climatic and Structural) - Flat Roof and Pitched RoofDocument15 pagesBuilding Roof and Its Functions (Psychological, Climatic and Structural) - Flat Roof and Pitched RoofAnqa Parvez100% (1)

- Passivhaus DetailDocument18 pagesPassivhaus Detailsofronije2005No ratings yet

- Heating PumpsDocument31 pagesHeating Pumpspejki100% (2)

- Testing For Exterior WallsDocument32 pagesTesting For Exterior WallsSK DograNo ratings yet

- Grasses Their Use in BuildingDocument8 pagesGrasses Their Use in BuildingpitufitoNo ratings yet

- Challenges of Urban Housing Quality Insights A - 2016 - Procedia - Social and BDocument9 pagesChallenges of Urban Housing Quality Insights A - 2016 - Procedia - Social and BKATE NATALEY CASTILLONo ratings yet

- Lay Out I. ExcavationDocument53 pagesLay Out I. ExcavationTaki TachibanaNo ratings yet

- Steel Construction BCSATata Steel SCI - DesignDocument51 pagesSteel Construction BCSATata Steel SCI - Designmys85100% (1)

- Concrete Channel Drain: Type B1 To B3Document18 pagesConcrete Channel Drain: Type B1 To B3Lim Lion YeeNo ratings yet

- High Strength Concrete Columna With Intervening Normal Strength One Way Slabs and Beams FloorsDocument39 pagesHigh Strength Concrete Columna With Intervening Normal Strength One Way Slabs and Beams FloorsGan Chin PhangNo ratings yet

- Bearing Piles and GroupsDocument36 pagesBearing Piles and Groupsjologscresencia100% (1)

- Unit 5Document42 pagesUnit 5ashok Pradhan0% (1)

- Load Calculation of RCCDocument2 pagesLoad Calculation of RCCmohan babuNo ratings yet

- Codes For HomeownersDocument521 pagesCodes For HomeownersNitsugaNo ratings yet

- DuraGal DCM Lintels Sep01Document30 pagesDuraGal DCM Lintels Sep01Denise2512No ratings yet

- LongspanstructuresDocument77 pagesLongspanstructuresKartik Saini100% (1)

- Storage Raised Floor: Cooling Raised FloorDocument10 pagesStorage Raised Floor: Cooling Raised Floormona.k.mNo ratings yet

- NEOM-NEN-TGD-304 - 01.00 - Wind Design Requirements For Building StructuresDocument11 pagesNEOM-NEN-TGD-304 - 01.00 - Wind Design Requirements For Building Structuresmahmudulalam konokNo ratings yet