Professional Documents

Culture Documents

PE Design at 111 Koon Seng

Uploaded by

Jason LeoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PE Design at 111 Koon Seng

Uploaded by

Jason LeoCopyright:

Available Formats

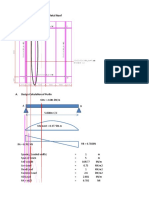

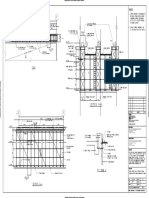

DESIGN OF STEEL BRACKET FOR THE STEEL SCAFFOLDING

Project at : 111 KOON SENG

300 S = 1000 mm

Bracket Detail

A B

2 M16 bolts

Angle 65 mm x 65 mm x 5 mm thk

10mm thk Base Plate

All welding at joints are 6mm full fillet weld

Existing Wall 200mm thick

1700 mm

Tie Back

TECHNICAL DATA: BS 5950-2000 Bolt at Every 3

Bays 2 Lifts

Allowable stress of steel fs = 165 N/mm2

Lever Arm of the supports la = 0.30 M

H = 22.0M

Dist. Of point load from the support A k =S/2+0.3= 0.80M 11 Lifts

Length of horizontal member of bracket L = 1.70M

LOADING CONSIDERATION: Height of Roof Level H= 22.0M

Dead Load:

Standards 2 x 29.00 Kg/No. = 58.00 Kg

Transions 12 x 42.00 Kg/No. = 504.00 Kg

Base Jack 2 x 3.60 Kg/No. = 7.20 Kg Cantilever

Joint Pin 2 x 0.53 Kg/No. = 1.06 Kg Bracket

G. I. Pipe 4 x 10.00 Kg/No. = 40.00 Kg

Laying at

Clamps 4 x 0.60 Kg/No. = 2.40 Kg

Traead Board 60 x 6.50 Kg/No. = 390.00 Kg

2nd storey

Bracket Detail 1 x 20.00 Kg/No. = 20.00 Kg

Wall Tie 1 x 1.00 Kg/No. = 1.00 Kg

Dead Load DL = 1023.66 Kg

Live Load: LL = 150 Kg

Sketch of the Scaffolds Arrangement

Superimposed Load = 1.4DL + 1.6LL = 1673.12 Kg= 1.67 ton

Therefore System Load 16.73 KN

Check the Force on the Wall Tie

Pulling Force Due to Vertical Load on the Wall Tie

Wall ties to be provided at every 5M Summation of Moments about C =0 H = 5M

c/c Vertically.

The pulling force on Wall Tie P = Ps*L/H = 10.20 KN

Note : Because sufficient wall tie is

Used cross bracing is not necessary Allowable force on the wall tie Fa = 13 KN

To be provided to the face of the

Scaffold Since P is less than the allowable pull Fa OK

Each steel bracket has to withstand the vertical Load W = 16.73 KN

Moment about A : Mu = W x k/4 = 3.35 KN-M without torsion cable provided

There fore Ra = Mu / la = 11.15 KN

There arc two fastening bolts each bolt is to lake the pull of 5.58 KN

Recommendation : 2 * M 16 Cast in bolts have he allowable tension of 70.00 KN

Since Ra = 11.15 KN which is less than 36.00 KN for 2 x 16 mm dia. Anchor bolts OK

The tie back torsion cable is not needed in this case

Check on the Bracket Steel Section Members Sizes

a. Without Tie Back Torsion Cable Mxx = W*L = 11.15 KN-M

Therefore Zxx = 67600.4 mm3 = 67.600353 cm3

Sizes used are 50 mm * 50 mm * 5mm thk angles to fabricate the bracket

lxx = 25.3 cm4 Cx = Cy = 1.77 cm Axx = 6.367 cm2 y"= 4.48 cm

Section Modulus for thr frame Zc = (2* lxx + 2 * Axx*y'^2)/y" = = 68 cm3

Compressive force on the member Pc = 53.52 KN Lc = 1.035 M iy = 2.3 cm

Therefore compressive stress fsc = 84.05 N/mm2 Le/iy = 45 From Handbook

Allowable compressive stress fc = 190 N/mm2 Since the allowable compression stress is greater than fsc OK

You might also like

- Chequer Platform-Flat Bar Design - L 1.112m - SDL 10kpaDocument1 pageChequer Platform-Flat Bar Design - L 1.112m - SDL 10kpaGOHNo ratings yet

- Pedestal and Foundation For Piping Support ACI 318 (American Code)Document21 pagesPedestal and Foundation For Piping Support ACI 318 (American Code)Nikhil Tawade100% (1)

- Pavement Slab Design For RTGDocument2 pagesPavement Slab Design For RTGBishal karki100% (1)

- Gable BaseplateDocument2 pagesGable BaseplateSURIYANo ratings yet

- As Per Indian Standard Code of Practice: Input ParametersDocument17 pagesAs Per Indian Standard Code of Practice: Input ParametersAmit Tiwari100% (1)

- Design of Concrete PadDocument3 pagesDesign of Concrete PadBeveh G SupSupNo ratings yet

- Pedestal Design 3, 4,5 & 6Document2 pagesPedestal Design 3, 4,5 & 6munishant10% (1)

- Element Location: Subject: Made by Design Code: Loading On Slab Value Units JamesDocument5 pagesElement Location: Subject: Made by Design Code: Loading On Slab Value Units JamesJames AswaNo ratings yet

- 1.2 ประมาณราคาศูนย์เด็ก ใส่ ประตู หน้าต่าง อิฐแก้ว แล้วDocument18 pages1.2 ประมาณราคาศูนย์เด็ก ใส่ ประตู หน้าต่าง อิฐแก้ว แล้วsarafan leewan0% (1)

- Stub Design (ASCE)Document10 pagesStub Design (ASCE)Saurabh TiwariNo ratings yet

- Retaining WallDocument8 pagesRetaining Wallমাসুম বিল্লাহNo ratings yet

- Design Calculation of Formwork and Falsework of Column - r2Document14 pagesDesign Calculation of Formwork and Falsework of Column - r2Chan Kin Cheung100% (1)

- Asmita SchoolDocument19 pagesAsmita Schoolformwork companyNo ratings yet

- Steel Rafter Section For Eave Roof Section ReductionsDocument25 pagesSteel Rafter Section For Eave Roof Section ReductionsJanaka KarunarathnaNo ratings yet

- Ref Drawing 2. Ref Code: 3. Design DatasDocument3 pagesRef Drawing 2. Ref Code: 3. Design DatasJoe Nadakkalan100% (3)

- Staging and Scaffolding of Bridge Deck SlabDocument3 pagesStaging and Scaffolding of Bridge Deck SlabPhanindra Nath100% (1)

- Design Calculation of Falsework For Construction of 1800mm Thick Slab - r3Document14 pagesDesign Calculation of Falsework For Construction of 1800mm Thick Slab - r3Chan Kin Cheung100% (1)

- Structural Design of JackwellDocument10 pagesStructural Design of JackwellParas HarsheNo ratings yet

- SdasdasdDocument18 pagesSdasdasddheeraj SureshNo ratings yet

- Bearing DesignDocument5 pagesBearing DesignAnde BhanuNo ratings yet

- Design Document of 24m Guyed MastDocument26 pagesDesign Document of 24m Guyed Mastdheeraj SureshNo ratings yet

- Densing (CVE162 Midterm Exam Problem 4)Document7 pagesDensing (CVE162 Midterm Exam Problem 4)Angela Christine DensingNo ratings yet

- STC Structural Calculation: GeneralDocument26 pagesSTC Structural Calculation: GeneralSurya FahmiNo ratings yet

- Deep BeamDocument20 pagesDeep BeamakhilaNo ratings yet

- Aeration & Settlement Tank CalculationDocument35 pagesAeration & Settlement Tank Calculationdadz mingiNo ratings yet

- Duct Support CalculationDocument4 pagesDuct Support CalculationSuresh DNo ratings yet

- New Microsoft Excel WorksheetDocument10 pagesNew Microsoft Excel WorksheetSantosh ReddyNo ratings yet

- Calculation For 1.4m X 1.5m RCC Box CulvertDocument4 pagesCalculation For 1.4m X 1.5m RCC Box CulvertManish BhatkarNo ratings yet

- Coba JembatanDocument28 pagesCoba JembatanAbdi Septia PutraNo ratings yet

- Revised Pad Footing Rev.1 (10.7.2018)Document4 pagesRevised Pad Footing Rev.1 (10.7.2018)Ally Khoo100% (1)

- Revised Pad Footing Rev.1 (10.7.2018)Document4 pagesRevised Pad Footing Rev.1 (10.7.2018)Ally KhooNo ratings yet

- T0516-Eco Sanctuary CPL 23-Feb-16 LYJ RC 250 850 3000: Design Calculation For Pilecap 4Rc250Document2 pagesT0516-Eco Sanctuary CPL 23-Feb-16 LYJ RC 250 850 3000: Design Calculation For Pilecap 4Rc250Tj TanNo ratings yet

- Appendix C-Working Platform。Document22 pagesAppendix C-Working Platform。黃嘉傑No ratings yet

- Inverted Beam DesignDocument11 pagesInverted Beam DesignNikhilNo ratings yet

- Calculation - Pierhead - Jembatan KIT BatangDocument9 pagesCalculation - Pierhead - Jembatan KIT Batanghanif ahmadNo ratings yet

- Fillet Weld Strength (AISC)Document8 pagesFillet Weld Strength (AISC)shadab521No ratings yet

- Design of Stem To Find Maximum Bending Moment at The JunctionDocument5 pagesDesign of Stem To Find Maximum Bending Moment at The JunctionKarthik NadigNo ratings yet

- PurlinDocument2 pagesPurlinSURIYANo ratings yet

- Size of Base Plate and Anchor Connection: 1 Material PropertiesDocument2 pagesSize of Base Plate and Anchor Connection: 1 Material PropertiesPrayush RajbhandariNo ratings yet

- References Calculations Bridge Abutment Curtain Wall Analysis and Design (Bs 5400)Document10 pagesReferences Calculations Bridge Abutment Curtain Wall Analysis and Design (Bs 5400)WycliffeNo ratings yet

- SC-S14006-PK02-FTCO-EXT-11 Rev. 01Document6 pagesSC-S14006-PK02-FTCO-EXT-11 Rev. 01Alaa Al-habashNo ratings yet

- Design of Open Well StaircaseDocument2 pagesDesign of Open Well StaircaseAnish Neupane100% (1)

- 4.beam Design Singly and DoublyDocument10 pages4.beam Design Singly and DoublyReuben James BangaoilNo ratings yet

- Steel Composite 1 VERY GOOD MahfuzDocument5 pagesSteel Composite 1 VERY GOOD MahfuzEdson NhabetseNo ratings yet

- Idn - 4Document5 pagesIdn - 4Anh KyNo ratings yet

- Slab DesignDocument1 pageSlab DesignMadhu SudhanNo ratings yet

- Design Analysis 1Document13 pagesDesign Analysis 1Katy PerryNo ratings yet

- Column K PDFDocument27 pagesColumn K PDFAngelika Caguioa BiayNo ratings yet

- AISC2005-Anchor BoltDocument9 pagesAISC2005-Anchor Boltnmtam.sdh20No ratings yet

- Cross GirderDocument1 pageCross Girderkarthikmr85No ratings yet

- Estimation of Gravity LoadsDocument7 pagesEstimation of Gravity LoadsSolomon Ndugwa BalemeziNo ratings yet

- Design of Steel Truss MembersDocument6 pagesDesign of Steel Truss MembersSaim WaqarNo ratings yet

- 1 Design Calculation For Metal RoofDocument29 pages1 Design Calculation For Metal RoofAlishaNo ratings yet

- Residential Building Design Using Excel Program FinalDocument22 pagesResidential Building Design Using Excel Program FinalManohar VangaNo ratings yet

- Design of RC Pad With Single Column Footing: Dead Imposed WindDocument22 pagesDesign of RC Pad With Single Column Footing: Dead Imposed Windsvrao4u100% (2)

- Transverse-Design771 TriDocument17 pagesTransverse-Design771 TriBasava SowmyaNo ratings yet

- Design of Connection:: 1. Connection Between Beam and Column PostDocument3 pagesDesign of Connection:: 1. Connection Between Beam and Column PostSaugat ThapaNo ratings yet

- Annexure-2 (Section Design Calcs)Document107 pagesAnnexure-2 (Section Design Calcs)blisscutest beagleNo ratings yet

- Design of A R.C.C Mountable Drain Slab CoverDocument4 pagesDesign of A R.C.C Mountable Drain Slab CoverBilal Ahmed Barbhuiya100% (8)

- 953ADocument1 page953AJason LeoNo ratings yet

- TSB - WLS - TSF - 01-05 (WELLTECH) - (NEW) - W-InternalDocument1 pageTSB - WLS - TSF - 01-05 (WELLTECH) - (NEW) - W-InternalJason LeoNo ratings yet

- PE Design at 111 Koon SengDocument2 pagesPE Design at 111 Koon SengJason LeoNo ratings yet

- Rentalworks Mobile Working Laptop Program-1Document1 pageRentalworks Mobile Working Laptop Program-1Jason LeoNo ratings yet

- 26599Document6 pages26599Jason LeoNo ratings yet

- Spider Cat 2013 FINALDocument280 pagesSpider Cat 2013 FINALJason LeoNo ratings yet

- PE Design at Jalan Toa PayohDocument2 pagesPE Design at Jalan Toa PayohJason LeoNo ratings yet

- Suspended ScaffoldsDocument29 pagesSuspended ScaffoldsJason Leo100% (1)

- FINAL - Hanging Scaffold StandarDocument3 pagesFINAL - Hanging Scaffold StandarJason LeoNo ratings yet

- Solution Past Paper Higher-Series4-08singaborepdfDocument16 pagesSolution Past Paper Higher-Series4-08singaborepdfSharenyaa SivapragasamNo ratings yet

- LCCI Accounting Level 3 Model Answers Series 3 2010 (3012)Document12 pagesLCCI Accounting Level 3 Model Answers Series 3 2010 (3012)Jason Leo80% (5)

- Steel Erection Safety Program One ManualDocument82 pagesSteel Erection Safety Program One ManualHardeep SinghNo ratings yet

- NASC Scaffold SpecificationDocument15 pagesNASC Scaffold Specificationstephen155100% (2)

- Edge Protection System XP: User InformationDocument72 pagesEdge Protection System XP: User InformationyuyulsukNo ratings yet

- Appointment Letter Temporary WorksDocument3 pagesAppointment Letter Temporary Worksjamie100% (2)

- AACE 2002 Measured Mile1 PDFDocument7 pagesAACE 2002 Measured Mile1 PDFMohammed Abdul MuqeemNo ratings yet

- BTW Sor (Fy10)Document236 pagesBTW Sor (Fy10)Tan AnthonyNo ratings yet

- Safety Questions and AnswersDocument30 pagesSafety Questions and Answersmiaicarba86% (50)

- Hazard Risk Assessment of Roof of The Mazanine Floor..Document15 pagesHazard Risk Assessment of Roof of The Mazanine Floor..Akhtar BahramNo ratings yet

- As 1576.4 Scaffolding Suspended Scaf PDFDocument17 pagesAs 1576.4 Scaffolding Suspended Scaf PDFtheNo ratings yet

- 17 NewDocument1 page17 NewFadi M. AyoubNo ratings yet

- Anutone For SOR CGDocument27 pagesAnutone For SOR CGPradeep ParvateNo ratings yet

- Ms - For Roofing and CladdingDocument13 pagesMs - For Roofing and CladdingElezer BatchoNo ratings yet

- Technology and Livelihood Education: CarpentryDocument25 pagesTechnology and Livelihood Education: CarpentryJymaer Geromo0% (1)

- 60-1 Mobile ScaffoldsDocument3 pages60-1 Mobile ScaffoldsAkhilNo ratings yet

- Scaffolding BrochureDocument24 pagesScaffolding BrochurenetatrainingNo ratings yet

- Maintop 2013 ReDocument20 pagesMaintop 2013 Reم.حسين العامريNo ratings yet

- TR 1a Glycol Overhead Piping East SideDocument11 pagesTR 1a Glycol Overhead Piping East SideShamsul AffendiNo ratings yet

- Job Safety Analysis PlumbersDocument5 pagesJob Safety Analysis Plumbersallen2912100% (1)

- Structure Edge: User InformationDocument44 pagesStructure Edge: User InformationJose GilNo ratings yet

- 5th Floor - Main Office CeilingDocument12 pages5th Floor - Main Office CeilingErick GearNo ratings yet

- CEC110 TheoryDocument100 pagesCEC110 TheoryAbdulrahMan muhammmed65% (17)

- LWS - Cont-Vol-2 - George PDFDocument802 pagesLWS - Cont-Vol-2 - George PDF陳育瑜No ratings yet

- Health & Safety ManagementDocument34 pagesHealth & Safety ManagementGovind Kumar SinghNo ratings yet

- ACR CRISP 2W1.05L2H Drg.V1Document5 pagesACR CRISP 2W1.05L2H Drg.V1Suresh DNo ratings yet

- Urea Stripper ProcedureDocument6 pagesUrea Stripper ProcedureSoumitra GuptaNo ratings yet

- Cis22 2021Document47 pagesCis22 2021Astray NoirNo ratings yet

- IMIA - WGP 80 13 Formwork and Scaffolding Collapses 21 7 13Document31 pagesIMIA - WGP 80 13 Formwork and Scaffolding Collapses 21 7 13Abdulhadi Nasser100% (1)

- Ewrc SHP Gen Hse Jsa 00040Document12 pagesEwrc SHP Gen Hse Jsa 00040Rickz CabaloNo ratings yet

- Jsa ExcavationDocument33 pagesJsa Excavationlal5012002390782% (17)

- JV ScaffoldingDocument2 pagesJV ScaffoldingKasarachi AmadiNo ratings yet