Professional Documents

Culture Documents

Bin Building Erection

Uploaded by

Aldous EngOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bin Building Erection

Uploaded by

Aldous EngCopyright:

Available Formats

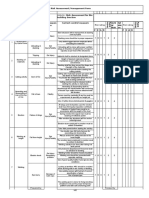

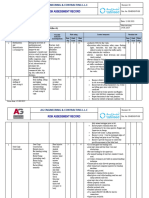

Risk Assessment/Management Form

Ref:

Section / Dept: civil Activity: Risk Assessment for Bin

Contractor :- building Erection

bility

Current control measure

Proba

bility

Sl Basic Job Potential Consequen Initi Ad

Proba

No. Steps Hazard ce Risk rating al diti Risk rating

Risk on

P E A R al P E A R

Steel structure will be transported at stacking co

zone by hydra ntr

Tripping Get Injury ol

Stacking zone should be in proper sequence 1 0 0 1 2 2 me

Transportation Only skilled riggers will be employed while asu

1

by Hydra/Crane unloading the materials re

Unloading & Get

Unloading will be done with proper certified

stacking Injury/Fatality

slings,D-Shackles & hydra/crane of required

capacity as per load of the structures

Tripping Get Injury 2 0 0 2 2 4

Material shall be stacked at designated place

Stacking of Height of stacked materials shall be

2 maintained as per safety norms & users

materials Unloading &

Get Injury convenience

stacking

Stacking shall be done as per the shape,size

& weight of the materials

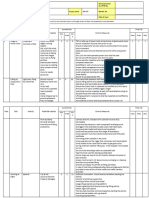

Take hot work permit before starting the

cutting activity

Cutting sets must have proper gas pipes with

Get dial watch & Flash back arrestor

3 Cutting activity Burn & Fire

Injury/Fatality To provide fire extinguisher where the hot

work is being carried out 2 0 0 1 2 4

Cutting nozzles must be cleaned before

starting the activity on daily basis

Ascending & Descending shall be

donethrough the inbuilt ladder with anchoring

of double rope safety harness attached with

Ascending and

fall arrestor

Descending of

4 Fall of man Fatality

man at the top Person must be medically fit and he must be

of Col. experienced at specially on height job

Use of safety shoes,helmet,jacket & goggles 2 0 0 1 2 4

All slings and D-shackles used for erection

shall have third party inspection certificate

Capacity of Hydra/Crane must be in

accordance with the weight of the load

Get During erection the signal man must be

5 Erection Failure of slings wearing of reflective jacket

Injury/Fatality

After erection the structures will be anchor 2 0 0 1 2 4

bolted/grouted

Erection team employed in erection must be

skilled & identified

Take Wah permit before starting the activity

Use double rope full body harness for

ascending and descending

Always anchor the safety belt above the

Working at Get

6

height

Fall from height

Injury/Fatality

head height 2 0 0 1 2 4

The erection team employed in erection must

be skilled & identified

Welding activity to be done after taking hot

work permit

Only trained & Experienced Personnel shall

be allowed for welding

Get injury Welding holder should be heavily insulated

Electric shock Respiratory Welding m/c.should be connected with 1 0 0 1 2 2

problem separate earthing

Use of good quality leather hand gloves (Dry

condition)

7 Welding Looking at welders ARC should be avoided

while working with in the vicinity of welding

Use welding screen with helmet of correct

specification of glass

Damage of

Eye injury

both eyes Use of proper ppe 1 0 0 1 2 2

The welding work is done for fixing breching

at taibeam only on the proper temporary

platform and with safe anchoring point

Prepaired by Reviwed by

1of2

Contractor Contractor

Date Date Date

2of2

You might also like

- Ref: Section / Dept: Civil Activity: Risk Assessment For BinDocument2 pagesRef: Section / Dept: Civil Activity: Risk Assessment For BinJack PNo ratings yet

- Risk Assessment - GROUNDINGDocument5 pagesRisk Assessment - GROUNDINGkarla.adamesNo ratings yet

- Risk Assessment For Shifting of Truss by Double HydraDocument1 pageRisk Assessment For Shifting of Truss by Double HydraDanang Santoso100% (2)

- 15 Piping Fabrication & Welding - Rev 3Document7 pages15 Piping Fabrication & Welding - Rev 3Rafael Restituyo LopezNo ratings yet

- JSA - Blooming Mill T-U-V Bay Axis 42 To 48Document6 pagesJSA - Blooming Mill T-U-V Bay Axis 42 To 48mohanNo ratings yet

- HIRA (Pipeline Construction Work)Document28 pagesHIRA (Pipeline Construction Work)sheerazali90% (10)

- Shifting of Materials by Double HydraDocument1 pageShifting of Materials by Double HydraShahid RazaNo ratings yet

- Scaffolding Staging Tower For Concr PumpDocument1 pageScaffolding Staging Tower For Concr Pumpasimnaqvi2008No ratings yet

- Brick WorkDocument1 pageBrick WorkGyanendra Narayan NayakNo ratings yet

- Job Safety Analysis - Cone ErectionDocument7 pagesJob Safety Analysis - Cone ErectionMohammed MinhajNo ratings yet

- Risk Assessment of Cantilever ScaffoldDocument1 pageRisk Assessment of Cantilever ScaffoldGyanendra Srivastava100% (1)

- 9 - Risk Assessment - PaintingDocument8 pages9 - Risk Assessment - Paintingmahmoud nadaNo ratings yet

- Lifting Fixing of GI SheetDocument1 pageLifting Fixing of GI SheetJack PNo ratings yet

- Risk Assessment/Management Form: Section / Dept: ActivityDocument2 pagesRisk Assessment/Management Form: Section / Dept: ActivityJack PNo ratings yet

- Risk Assessment/Management Form: Section / Dept: ActivityDocument2 pagesRisk Assessment/Management Form: Section / Dept: ActivityJack PNo ratings yet

- Lifting & Fixing of Cross BracingDocument2 pagesLifting & Fixing of Cross BracingGudduNo ratings yet

- Risk Assessment/Management FormDocument4 pagesRisk Assessment/Management FormNazriNo ratings yet

- Girder and Beam ErrectionDocument3 pagesGirder and Beam ErrectionJack PNo ratings yet

- Girder and Beam ErrectionDocument3 pagesGirder and Beam ErrectionAldous EngNo ratings yet

- Risk Assessment/Management Form: Risk Assessment-Erection of Roof Girder and BeamDocument3 pagesRisk Assessment/Management Form: Risk Assessment-Erection of Roof Girder and BeamJack PNo ratings yet

- Erection of Col - and Beam, StairDocument3 pagesErection of Col - and Beam, StairChandru100% (1)

- Risk Assessment/Management Form: Risk Assessment-Erection of Column, Stair Case and BracingDocument3 pagesRisk Assessment/Management Form: Risk Assessment-Erection of Column, Stair Case and BracingJack PNo ratings yet

- Risk Assessment/Management Form: Risk Assessment-Erection of Column, Stair Case and BracingDocument3 pagesRisk Assessment/Management Form: Risk Assessment-Erection of Column, Stair Case and BracingAhmed AbdulfatahNo ratings yet

- Attachment 7505Document11 pagesAttachment 7505Charles DoriaNo ratings yet

- JSA - LOAD TEST PILE No. 1Document6 pagesJSA - LOAD TEST PILE No. 1Sanjeet SinghNo ratings yet

- SFM-08.10-SHEM-009 Job Safety Analysis FormDocument6 pagesSFM-08.10-SHEM-009 Job Safety Analysis FormsalmankhanehsNo ratings yet

- JSA - LOAD TEST PILE No. 1Document6 pagesJSA - LOAD TEST PILE No. 1noahlungu96No ratings yet

- JSA Wall Sheeting (Rev.1) With CommentsDocument8 pagesJSA Wall Sheeting (Rev.1) With CommentsThennarasu KumarNo ratings yet

- RIGGING AND INSTALLATION OF 48 Inch REACTOR SPOOL JSA - 18.08.21Document10 pagesRIGGING AND INSTALLATION OF 48 Inch REACTOR SPOOL JSA - 18.08.21Muhammed FawazNo ratings yet

- Risk AssessmentDocument6 pagesRisk AssessmentMohammed Shiful0% (1)

- Lifting Fixing of Cross BracingDocument2 pagesLifting Fixing of Cross BracingShahid RazaNo ratings yet

- Risk Assessment HVAC DuctingDocument5 pagesRisk Assessment HVAC DuctingAsad Zakria100% (6)

- OHS - R - 4.3.1 / 01 Hazard Identification & Risk AssessmentDocument2 pagesOHS - R - 4.3.1 / 01 Hazard Identification & Risk AssessmentDevend HarinkhedeNo ratings yet

- 10 - Risk Assessment - PlumpingDocument7 pages10 - Risk Assessment - Plumpingmahmoud nada0% (1)

- Standard Activity Risk Assessment Facade Concrete Walls WF ADocument6 pagesStandard Activity Risk Assessment Facade Concrete Walls WF AChoubi ChoubacaNo ratings yet

- TRA of Lifting - TailDocument3 pagesTRA of Lifting - TailTharaka Perera100% (1)

- Paint WorkDocument1 pagePaint WorkNarender BhardwajNo ratings yet

- Risk Assessment/Management Form CivilDocument1 pageRisk Assessment/Management Form CivilGyanendra Narayan NayakNo ratings yet

- Risk Assessment/Management Form CivilDocument1 pageRisk Assessment/Management Form CivilGyanendra Narayan NayakNo ratings yet

- ELEC/RA-001 Risk Assessment CCPP, MBPL: Pipe Rack and Bottom Ash AreaDocument12 pagesELEC/RA-001 Risk Assessment CCPP, MBPL: Pipe Rack and Bottom Ash AreaYuva samaj sewa TrustNo ratings yet

- Chipping Work ManuallyDocument1 pageChipping Work ManuallyMohammed Amer PashaNo ratings yet

- Chipping Work (Manually)Document1 pageChipping Work (Manually)ChandruNo ratings yet

- Risk Assessment of Heavy LiftingDocument5 pagesRisk Assessment of Heavy Lifting채종언100% (3)

- Risk Assessment - 002 PDFDocument5 pagesRisk Assessment - 002 PDF채종언No ratings yet

- Risk Assessment - Placing of Transformer - TTSDocument6 pagesRisk Assessment - Placing of Transformer - TTSnsadnan100% (2)

- Scaffolding Risk Assessment: Rev SECL Job NoDocument5 pagesScaffolding Risk Assessment: Rev SECL Job NoSaleem AkhtarNo ratings yet

- All HiraDocument40 pagesAll Hirarameese muhammed100% (1)

- HIRA - Fabrication at ECHSDocument15 pagesHIRA - Fabrication at ECHSDhaneswar SwainNo ratings yet

- Risk Assessment Form: Project: Gem Residences Location: E. Rodriguez Ave. C5, Pasig CityDocument2 pagesRisk Assessment Form: Project: Gem Residences Location: E. Rodriguez Ave. C5, Pasig CityJhundel Factor50% (4)

- Hira - For Shot Blasting & Upto 2nd Coat of PaintingDocument15 pagesHira - For Shot Blasting & Upto 2nd Coat of PaintingDhaneswar SwainNo ratings yet

- TRA of Lifting of EquipmentsDocument3 pagesTRA of Lifting of EquipmentsandreNo ratings yet

- 89.elevator Assembly & ErectionDocument12 pages89.elevator Assembly & ErectionMohammed Mostafa El HaddadNo ratings yet

- Excavation JSA HSE ProfessionalsDocument2 pagesExcavation JSA HSE ProfessionalsSamadov 13No ratings yet

- C&C-EHS-F-002 HIRARC Working at Height (Tower and Monopole)Document5 pagesC&C-EHS-F-002 HIRARC Working at Height (Tower and Monopole)Najman HamdiNo ratings yet

- Mobile Stone Crushing JSA HSE ProfessionalsDocument1 pageMobile Stone Crushing JSA HSE ProfessionalsLebohang ChakaNo ratings yet

- Concrete Placing by Using Mobile Crane Through Concrete Bucket JSA HSE ProfessionalsDocument1 pageConcrete Placing by Using Mobile Crane Through Concrete Bucket JSA HSE ProfessionalsViron BaxhiaNo ratings yet

- Concrete ChippingDocument3 pagesConcrete ChippingAbhijit ParasharNo ratings yet

- Pile Integrity Testing RADocument12 pagesPile Integrity Testing RAmdfahad0047No ratings yet

- JSA For Annealing Project - Thirumala ConstructionDocument4 pagesJSA For Annealing Project - Thirumala ConstructionmohanNo ratings yet

- The Complete Rigger's Apprentice: Tools and Techniques for Modern and Traditional RiggingFrom EverandThe Complete Rigger's Apprentice: Tools and Techniques for Modern and Traditional RiggingNo ratings yet

- Constructionskills Tool Box Talk: No. 40 Plant and EquipmentDocument2 pagesConstructionskills Tool Box Talk: No. 40 Plant and EquipmentAldous EngNo ratings yet

- 21 Risk AssessmentsDocument2 pages21 Risk AssessmentsAldous EngNo ratings yet

- Concreting and Finishing WorkDocument1 pageConcreting and Finishing WorkAldous EngNo ratings yet

- Girder and Beam ErrectionDocument3 pagesGirder and Beam ErrectionAldous EngNo ratings yet

- Ref: Section / Dept: Civil, Contractor: Activity: Risk Assessment For BackfillingDocument2 pagesRef: Section / Dept: Civil, Contractor: Activity: Risk Assessment For BackfillingAldous EngNo ratings yet

- Cho Wa StoryDocument7 pagesCho Wa Storykshepard_182786911No ratings yet

- Philippine National Police Traininginstitute National Headquarters/National Headquarters/ National Support Units Training CenterDocument5 pagesPhilippine National Police Traininginstitute National Headquarters/National Headquarters/ National Support Units Training CenterBrian ViolaNo ratings yet

- Health PPT - Ways To Build and Keep SchoolDocument17 pagesHealth PPT - Ways To Build and Keep Schoolraymund quinnsNo ratings yet

- Indah Amalia LestariDocument2 pagesIndah Amalia Lestaribeauty asriNo ratings yet

- Resume Materi Talkshow Soedirman Student Summit 2021 "Aswa Adarma"Document2 pagesResume Materi Talkshow Soedirman Student Summit 2021 "Aswa Adarma"rahmaNo ratings yet

- Simon 雅思翻转课堂 笔记Document4 pagesSimon 雅思翻转课堂 笔记Xiaoling HeNo ratings yet

- Ophthalmological Society of Bangladesh (OSB)Document44 pagesOphthalmological Society of Bangladesh (OSB)george samNo ratings yet

- V55 High-Speed Vertical Machining Center With Makino Professional 3 Control Maintenance GuideDocument568 pagesV55 High-Speed Vertical Machining Center With Makino Professional 3 Control Maintenance GuideMax Litvin100% (1)

- Bab II Seragam PerawatDocument13 pagesBab II Seragam Perawatchaz5727xNo ratings yet

- Graduate School 3 Trimester, Academic Year 2020-2021: St. Paul University Philippines Tuguegarao City, Cagayan 3500Document3 pagesGraduate School 3 Trimester, Academic Year 2020-2021: St. Paul University Philippines Tuguegarao City, Cagayan 3500Danica Lorine Robino TaguinodNo ratings yet

- Beginning of The Year Clinic Reminders To ParentsDocument2 pagesBeginning of The Year Clinic Reminders To ParentsTuTitNo ratings yet

- Personal Statement Jomol JohnDocument2 pagesPersonal Statement Jomol Johnbiju mathewNo ratings yet

- B2 - WCET - INWOCNA 2017 by IrmaDocument37 pagesB2 - WCET - INWOCNA 2017 by Irmafajar adironiNo ratings yet

- Efektivitas Pemberian Ikan Gabus Kukus Terhadap Penyembuhan Laserasi Perineum Pada Ibu PostpartumDocument9 pagesEfektivitas Pemberian Ikan Gabus Kukus Terhadap Penyembuhan Laserasi Perineum Pada Ibu Postpartumjulimarni13No ratings yet

- Oregon Workplace Outbreaks 10-21Document6 pagesOregon Workplace Outbreaks 10-21KGW NewsNo ratings yet

- NPTE Tips Guide PlanDocument3 pagesNPTE Tips Guide Planzenab100% (1)

- Script ReportDocument3 pagesScript ReportEddie Kim CañoNo ratings yet

- Of Malaya: Design and Analysis of Wudu' (Ablution) Workstation For Elderly in MalaysiaDocument70 pagesOf Malaya: Design and Analysis of Wudu' (Ablution) Workstation For Elderly in MalaysiaArchitect01 MYConstructionNo ratings yet

- Persuasive SpeechDocument2 pagesPersuasive SpeechLinda AgmataNo ratings yet

- Invitation Letter-MDP Dec. 2017Document1 pageInvitation Letter-MDP Dec. 2017Susmit JainNo ratings yet

- TCID50 Protocol MoralesDocument2 pagesTCID50 Protocol MoralesWill Zapata BNo ratings yet

- Check in Out OutletDocument160 pagesCheck in Out Outlethrca spnNo ratings yet

- Basement DDA Car ParkingDocument1 pageBasement DDA Car Parkingrajen raghwaniNo ratings yet

- MDRRMC Resolution No. 3 2019Document3 pagesMDRRMC Resolution No. 3 2019Soriano ArmenioNo ratings yet

- 9 Choosing and Understanding Dab Pen Cartridge Costs and What Brand To BuyDocument3 pages9 Choosing and Understanding Dab Pen Cartridge Costs and What Brand To BuyMyAccntNo ratings yet

- JD of HESDocument13 pagesJD of HESDivyansh OjhaNo ratings yet

- Daftar Pekerja Yang Belum Mengerjakan Self Learning Materi: Kebijakan Human Capital Health Care Tanggal 6 Agustus 2020 Jam 9.00 WibDocument5 pagesDaftar Pekerja Yang Belum Mengerjakan Self Learning Materi: Kebijakan Human Capital Health Care Tanggal 6 Agustus 2020 Jam 9.00 WibAbditama RezaNo ratings yet

- Nasution 2019 SKRINING MAKROSKOPIS CAIRAN PLEURA DARI EFUSI PLEURA DI UNITDocument10 pagesNasution 2019 SKRINING MAKROSKOPIS CAIRAN PLEURA DARI EFUSI PLEURA DI UNITyeni rahmawatiNo ratings yet

- Canine Drug ChartDocument3 pagesCanine Drug ChartTracy MachemerNo ratings yet

- LKCMedicine Electives Programme at Imperial 2020 - Student Charter (16175) - Signed-Lei LijiaDocument1 pageLKCMedicine Electives Programme at Imperial 2020 - Student Charter (16175) - Signed-Lei LijialukesqueNo ratings yet