Professional Documents

Culture Documents

Platfrom HVAC

Uploaded by

aliCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Platfrom HVAC

Uploaded by

aliCopyright:

Available Formats

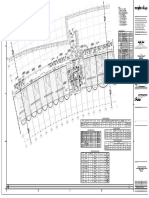

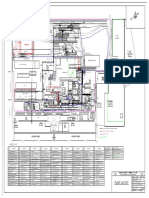

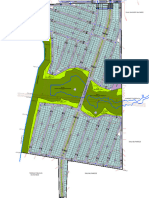

KEY PLAN

N

LINE 6 LINE 2

LINE 4

KK

AH) LINE 2

(MA LINE 6

7 8 9 LINE 1

LINE 5

3H1

LINE 3.

LINE 1

IU EL. +3.671 STATION KEY PLAN (PLATFORM LEVEL)

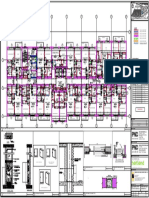

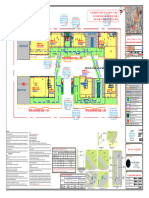

SD-300x300

SD-1220x500 IU EL. +4.412

4320 CMH

IU 780 CMH

SD-350x300 17 SD-350x300 BOD EL. +3.686

1080 CMH BOD EL. +4.344 1080 CMH

IU EL. +4.390 G34 SD-500x200 IU EL. +4.045 1 1 L

BOD EL. +4.444 5x 1 L 1 BOD EL. +4.427

864 1260 CMH

0.52

SD-350x400

1 1 L SD-500x500 IU EL. +1.550 BOD EL. +4.135

2160 CMH

0.91

S-1 864 CMH RD-900x210 N

1 1 L BOD EL. +4.427 SD-400x300

SD-400x400 BOD EL. +4.344 780 CMH

2160 CMH SD-500x200 1 1 1260 CMH

MFD L

2.00

S-1 SH37 BOD EL. +3.670 1.09

BOD EL. +4.394 S-1 D09 SD-500x500 1260 CMH IU BOD EL. +3.628 (MAKKAH)

SD-DN350 4x 05 05 M FD 2.15 S-1 1 1 L RD-400x300

SD-DN350

2.03

1080 1728 CMH BOD EL. +3.164 S-1

0.41

2.94

1 1 L PE.S IU IU EL. +2.750

1.30 BOD EL. +4.344 RK04 1260 CMH

S-1 AP02 1 1 G15 19 SH31

RD-550x500 L G78 RD-450x500 S-1 BOD EL. +3.612

IU IU 1 1 L 1260 NOTE:

1.22

1260 G05 3840 CMH

1.01

4320 CMH S-1 PE.B S-1 IU 1 1 L

1.60

0.48

12 EST04 G05 G15 1.- FLEXIBLE DUCT CONNECTORS SHALL BE INSTALLED AT THE AIR INTAKE AND

BOD EL. +4.344 12 SD-500x500 SH33 0.37 0.26 0.79 CR 08 1080 BOD EL. +4.361 G15

ST02 2x 780 1260 S-1 S-1 AIR DISCHARGE OF THE EQUIPMENTS TO REDUCE VIBRATION TRANSMISSION TO

G18 S-1 1728 CMH 1 1 780 G05

1 1 L G18 G79 G18 L

SH20

S-1 PE.B AIR DUCT STRUCTURE.

BOD EL. +4.344 S-1 S-1

1.93

4320 S-1 1260

S-1 4320 4320SH18 STF 2.- BMS SYSTEM USES MOTORIZED FIRE DAMPERS AND MOTORIZED VOLUME

S-02 SD-1220x500 RD-1220x500 S-02 1260 2.40 0.66 1.55 1.27

2.00

SD-DN350 M FD 2x 2.05 DAMPERS TO EXTRACT THE FM200 GAS IN EACH INDIVIDUAL ROOMS.

4320 CMH 4320 CMH EST02

1.66

SD-DN350 G05 MFD 3.- OTE/UPE DUCT OUT OF MINWAL SCOPE.

BOD EL. +4.344 BOD EL. +4.344 IU

1.20

SD-500x500 SH38 IU M FD 1080 27 SH19 05 4.- ELEVATION FOR BOTTOM OF SERVICES ARE REFERRED TO F.F.L.

S-1 864 CMH IU EL. +2.296 IU 05 S-1 "M-ANM-3H1SS1-CA00-EDR-200019" ELEVATION FOR BOTTOM OF SERVICES BASED

0.96 0.75 0.94 1.18 1.82 17 S-03 S-03 ON +596.21 (PLATFORM LEVEL)

1.33

BOD EL. +4.344

IU EL. +3.865 IU MFD 2.50 S-1 5.- ALL SELECTIONS OF MATERIAL AND EQUIPMENT SUBJECT TO FINAL APPROVAL.

1 1 L 08 05 6.- DX VRF INTERNAL UNITS DUCTWORK MATERIAL: GALVANIZED SHEET METAL DUCT

IU EL. +4.412

WITH 25MM FIBER GLASS 48KG, ACOUSTIC INNER LINING IN FIRST 3 METER.

IU EL. +3.613 9.- THERMOSTATS TO TO BE INSTALLED IN TECHNICAL ROOMS AND BACK OF HOUSE AREA

AND RETAILS. ELEVATION 1.5 M FROM FFL.

10.- BATTERY ROOM FRESH AIR DUCT INSIDE THE ROOM TO BE STAINLESS STEEL 316,

GAUGE 18 WITH 25mm DUCT LINER SECURED WITH PREFORATED SHEET 304.

11.- REFRIGERANT GAS SENSOR OR TRANSMITTER TO BE INSTALLED IN TECHNICAL ROOMS

AND BACK OF HOUSE AREA ACCORDING TO ASHRAE 15-2013. ELEVATION 0.5 M FROM FFL.

REFERENCE DRAWINGS

RD-790x350 SD-500x250 SD-350x400 SD-350x300

- PLATFORM LEVEL ARCHITECTURAL DRAWING.

SHEET 7

900 CMH 1260 CMH 2160 CMH 1080 CMH M-ANM-3H1SS1-CA00-EDR-200017

BOD EL. +3.839 BOD EL. +3.855 BOD EL. +4.427 BOD EL. +4.427

- PLATFORM LEVEL , HVAC DUCT AIR DIFFUSION,

1 1 L 1 1 L 1 1 L 1 1 L SEE DRAWING:

M-ANM-3H1SS1-CMAC-EDR-200016

- FOR HVAC GENERAL DETAILS

SEE DRAWING:

M-ANM-3H1SS1-CMAC-EDR-200024

- FOR HVACGENERAL SYMBOL & NOTES.

SEE DRAWING:

M-ANM-3H1SS1-CMAC-SDR-200001

RELATED DRAWINGS

- FOR HVAC SCHEMATIC MECHANICAL SERVICES VENT & AIR COND

SEE DRAWING:

M-ANM-3H1SS1-CMAC-EDR-200009-C

IU 12 (3,4) - ACCES STAIRS (ST02) IU 05 (7) - FOR BELOW PLATFORM LEVEL, HVAC EQUIPMENT LOCATION & INST DETAILS

SEE DRAWING:

M-ANM-3H1SS1-CMAC-EDR-200011-C

PE.B - FOR BELOW PLATFORM LEVEL, -HVACL DESIGN CRITERIA

PW.S SEE DRAWING:

AP02 3 CR M-ANM-3H1SS1-CMAC-EDR-200006-C

103

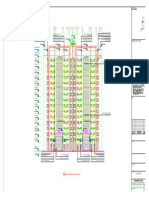

G15 ABBREVIATIONS :

IU G05

864 CMH

500x500

900 05

350x300 900 AIR OUTLET: DUCT & ACCESSORIES

350x350 350x350

Ø350 2 Ø350 1 900 CMH 0 0 900 CMH 1 SG SUPPLY GRILLE A/C AIR CONDITIONING

102 112 2 RG RETURN GRILLE FA FRESH AIR

102 EG EXHAUST GRILLE EXP EXPANSION

2160 CMH

RG

1728 CMH

400x400

DR DOOR LOUVER EXH EXHAUST

500x500

G18 IU IU DG DOOR GAP DX DIRECT EXPANSION

4320 12 12 TG TRANSFER GRILLE

550x500 500x500 500x500 VD VOLUME DAMPER

1 4320 CMH 0 0 4320 CMH D09 0 0 4320 CMH IU 08 (1,2) FAL FRESH AIR LOUVER FD FIRE DAMPER

1 4x

1080

101 EAL EXHAUST AIR LOUVER BDD BACK DRAFT DAMPER

1

1728 CMH

MVD MOTORIZE VOLUME DAMPER

2160 CMH

RG

500x500

EQUIPMENT:

400x400

G34 SA SOUND ATTENUATOR

5x

864

PE.B IU PE.B

08 FD M AHU AIR HANDLING UNIT BDD BACK DRAFT DAMPER

350x400 350x300 3

4320 CMH

IU 05(6) CR MOI 1 1080 CMH IU 19 (1) FAD FRESH AIR DUCT

4 0 IU 05 (8) SMF SMOKE EXHAUST FAN

550x500

Ø350 Ø350 2160 CMH

104 SF SUPPLY FAN AD ACCESS DOOR

103 113 450x400 MFD 350x300

EF EXHAUST FAN MFD MOTORIZE FIRE DAMPER

3 2160 CMH

0 05 1080 CMH

864 CMH

350x300 CU CONDENSING UNIT EXD EXHAUST DUCT

500x500

PE.B 450x500 FD M MFD PE.B PE.B

2 IU VRV INTERNAL UNIT SD SUPPLY DUCT

G79 PT02 1 27 2 STT

4320 CMH G18 G05 STF EU VRV EXTERNAL UNIT RD RETURN DUCT

1260 450x400 4x

RG 1 5 4320 1080 HRU HEAT RECOVERY UNIT SED SMOKE EXHAUST DUCT

105 RG IU G78 2160 CMH 2 G15 IU G05 G15 IU G05

05 1260 RG 780 19 780 1260 05 1260

500x150 0 350x400 FD M 350x300 350x300 300x300 300x300 300x300 300x300

G18 0 1260 CMH 1 0 2160 CMH 1080 CMH 1080 CMH 1 780 CMH 0 0 780 CMH 1 1 0 0 1260 CMH 1

1260 CMH

4320

MFD 1

IU 05 3 RG RG

08

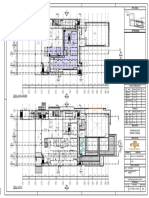

A 04.01.2018 ISSUED FOR APPROVAL (IFA)

P2 09-12-2017 INTRA AND INTER-DISCIPLINARY CHECKS (IDC)

P1 05-10-2017 INTRA AND INTER-DISCIPLINARY CHECKS (IDC)

REV. DATE DESCRIPTION APP.

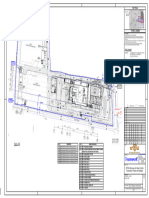

PROJECT

RIYADH METRO PROJECT

PACKAGE 2

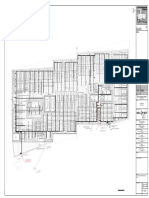

SYMBOL DUCT MATERIAL TYPE

1 Single wall galvanized steel ductwork LINE 3

2 Single wall stainless steel gauge 18, type 316 for battery room exhaust.

Double wall 304 stainless steel ductwork with SS 304 inner liner, 304 SS

3 outer Jacket and 4" ROCKWOOL insulation 150 Kg/Cu.M between

Supply & Return Duct Support Schedule shells, for the generator exhaust duct

Hilti Duct -With Lining Single fixation- one layer Solid Slab {Galvanized Duct . GA As per Construction

4 Black steel, coating with flamebar BWII fire proofing outside 2Hrs.

Sch. 4" + Fiber glass insulation 50 mm 48 kg/m3 + cladding + internal lining 25 mm 48kg/m3 + CHANGE IN DUCT ELEVATION:

T THERMOSTAT ARRIYADH NEW MOBILITY

internal proferoated sheet with same gauage of outer duct (shown sizes is internal size)}

5 GI Steel, coating with flamebar BWII fire proofing outside 2Hrs. RISE INDICATED BY "R"

R REFRIGERANT GAS SENSOR

Duct Duct Normal D SMOKE DUCT DETECTOR CHANGE IN DUCT ELEVATION:

S/N width height span

Channel used Anchor used Threaded Rod

SYMBOL DUCT INSULATION DROP INDICATED BY "D" ORIGINATOR CHECK REVIEW APPROVAL

DUCT SIZE : 1st FIGURE SIDE SHOWN,

[mm] [mm] [mm] No insulation required for Toilet Exhaust ducts and plenum boxes with 500x200

0 2nd FIGURE SIDE NOT SHOWN, DUCT WITH ACOUSTIC INTERNAL LINING Fakhr Engr.Anan Engr. Khlid MF

internal lining. SIZE IS IN mm

1 300 150 3000 MM-C-30 HKD M8 x 25 [2.0kn] AM 8 [4.7kn]

50mm thick mineral-fiber blanket/board 48kg/cu.M with foil & paper DATE SCALES ORIGINAL SIZE A1

2 300 300 3000 MM-C-30 HKD M8 x 25 [2.0kn] AM 8 [4.7kn] 1 jacket, in concealed area with vapor retarder, for Supply, Return & Ø600 ROUND DUCT SIZE DUCT ELBOW TURNING

HRU Exhaust (return) ducts TOWARD VIEWER A1= 1/100

3 350 350 3000 MM-C-36 HKD M8 x 25 [2.0kn] AM 8 [4.7kn] JANUARY 2018

FAD FRESH AIR DUCT DUCT ELBOW TURNING A3= 1/200

50mm thick mineral-fiber board 48kg/cu.M with 0.40mm aluminum 5 10m

4 400 350 3000 MM-C-36 HKD M8 x 25 [2.0kn] AM 8 [4.7kn] 2 AWAY FROM VIEWER 0

jacket, in unfinished, mechanical & electrical Indoor areas with vapor

5 500 500 3000 MQ-41 HKD M8 x 30 [2.8kn] AM 8 [4.7kn] retarder, for Supply, Return & HRU Exhaust (return) ducts. SD SUPPLY DUCT DIRECTION OF FLOW

6 550 350 3000 MQ-41 HKD M8 x 30 [2.8kn] AM 8 [4.7kn] 50mm thick 2 hours fire rated, high temperature Rockwool insulation

3 SD-500x200 DUCT ABBREVIATION - SIZE

150 kg/cu.M with FSK jacket. EXD EXHAUST DUCT DRAWING

7 550 400 3000 MQ-41 HKD M8 x 30 [2.8kn] AM 8 [4.7kn] 17000 FLOW IN CMH

25mm thick mineral fiber blanket 48 kg/cu.M with foil paper where SHALLOW UNDERGROUND STATIONS

BOD EL. +4000 BOTTOM OF DUCT

8 550 550 3000 MQ-41 HKD M8 x 30 [2.8kn] AM 8 [4.7kn] 4 concealed, Aluminum jacket 0.40mm for rectangular duct & 0.70mm RD RETURN DUCT

for round duct in exposed view & PLATFORM room without vapor --- EQUIPMENT DESIGNATION 3H1 SHOP DRAWING HVAC PLATFORM LEVEL

9 600 400 3000 MQ-41 HKD M8 x 30 [2.8kn] AM 8 [4.7kn] retarder, for fresh treated air ducts EQUIPMENT REFERENCE NUMBER

FIRE RATED DUCT

---- PLAN DUCT WORK & AIR DIFFUSION

10 600 600 3000 MQ-41 HKD M8 x 30 [2.8kn] AM 8 [4.7kn] Reference to specification: M-ANM-30000-CMAC-ESP-200012

GRILLE TAG

11 650 600 3000 MQ-41 HKD M8 x 30 [2.8kn] AM 8 [4.7kn] SYMBOL DUCT CONSTRUCTION CLASSIFICATION QTY FLOW IN CMH

OTE UPE DUCT

12 750 600 3000 MQ-52 HKD M8 x 40 [3.3kn] AM 8 [4.7kn] L 500 Pa (2" water gauge), for Fans, IU's, OU's & HRU's ducts GRILLE SIZE ANM DRAWING NUMBER REVISION SHEET

13 850 600 3000 MQ-52 HKD M10 x 40 [5KN] AM 10 [7.5kn]

H 1000 Pa (4" water gauge), for AHU's ducts M-ANM-3H1SS1-CMAC-SDR-2000016 A 8 of 20

FLEXIBLE CONNECTION ACCESS DOOR

FOR EXPANSION JOINT

Supply & Return HILTI Duct Support Schedule

ALTERNATE DOCUMENT NUMBER REVISION SHEET

M-ANM-3H1SS1-CMAC-SDR-2000016 A 8 of 20

You might also like

- Gauge Pressure SensorDocument1 pageGauge Pressure SensoraliNo ratings yet

- M-Anm-3f1ds0-Caid-Sdr-000014-01 of 02 PDFDocument1 pageM-Anm-3f1ds0-Caid-Sdr-000014-01 of 02 PDFahsan khanNo ratings yet

- Combined AC Dwgs-31Document1 pageCombined AC Dwgs-31ibrahimsirpiNo ratings yet

- 03 120000 4800000522 Amt Elv DRG 100003Document1 page03 120000 4800000522 Amt Elv DRG 100003Mosab DowaNo ratings yet

- 03 12000 48000441 Boc Inf DRG 000011 - 02Document1 page03 12000 48000441 Boc Inf DRG 000011 - 02Yasir Nisar SyedNo ratings yet

- 2019-565 Fire Protection ReviewDocument23 pages2019-565 Fire Protection ReviewMohamed AlbanaNo ratings yet

- As-Built: Approved For DesignDocument1 pageAs-Built: Approved For DesignjunNo ratings yet

- COMBINE HEAT MAP AS-BUILT (01-02-24) - CompressedDocument6 pagesCOMBINE HEAT MAP AS-BUILT (01-02-24) - CompressedDomie Neil Bucag SalasNo ratings yet

- Wa0008.Document28 pagesWa0008.Himanshu JoshiNo ratings yet

- Ad 90.0 e 02061 PDF Earthing Details B 4Document1 pageAd 90.0 e 02061 PDF Earthing Details B 4mcaslamNo ratings yet

- SHC G.PH. 2 B 03 3dr.F BW SD 005 Layout1Document1 pageSHC G.PH. 2 B 03 3dr.F BW SD 005 Layout1rajatNo ratings yet

- Hartland: LegendDocument1 pageHartland: LegendrajatNo ratings yet

- 4217-Csd-A-1a-0101-Ra Plan - Site (GSB Barat Utara 12500 MM)Document1 page4217-Csd-A-1a-0101-Ra Plan - Site (GSB Barat Utara 12500 MM)Adi PriyapurnatamaNo ratings yet

- F1 BlockDocument12 pagesF1 BlockAhmad KhaanuNo ratings yet

- 03 12000 48000441 Boc Inf DRG 000010 - 02Document1 page03 12000 48000441 Boc Inf DRG 000010 - 02Yasir Nisar SyedNo ratings yet

- Proposed Land Use 228 Sheet-1Document1 pageProposed Land Use 228 Sheet-1Shashi KumarNo ratings yet

- Tagged - QB0024-SD-DH-ACD-B1-101-MASTER PLANDocument1 pageTagged - QB0024-SD-DH-ACD-B1-101-MASTER PLANAsmir MemicNo ratings yet

- Ec2-01b Ground Floor Auxiliary LayoutDocument1 pageEc2-01b Ground Floor Auxiliary LayoutSEDFREY DELA CRUZNo ratings yet

- Ec1-01b Ground Floor Fdas LayoutDocument1 pageEc1-01b Ground Floor Fdas LayoutSEDFREY DELA CRUZNo ratings yet

- 10393565Document2 pages10393565Jackson3006No ratings yet

- Arquitectura Tipo BDocument1 pageArquitectura Tipo BMercy Carmen Pantoja RublosNo ratings yet

- Hl1Avtrm Ver.B Silkscreen TopDocument2 pagesHl1Avtrm Ver.B Silkscreen TopmillerblackNo ratings yet

- 4217-Pbg-A-1102-Rc Denah - Lantai 2 Dan 2 MezaninDocument1 page4217-Pbg-A-1102-Rc Denah - Lantai 2 Dan 2 MezaninAdi PriyapurnatamaNo ratings yet

- 4217-Pbg-A-1103-Rc Denah - Lantai 3 Dan 3 MezaninDocument1 page4217-Pbg-A-1103-Rc Denah - Lantai 3 Dan 3 MezaninAdi PriyapurnatamaNo ratings yet

- Mz-04-00001-00-05-Ar-Aed-Dg-011011 (03) - Mzfw-Overall First Floor PlanDocument1 pageMz-04-00001-00-05-Ar-Aed-Dg-011011 (03) - Mzfw-Overall First Floor PlanAMR ABDALHNo ratings yet

- 03 150000 4200000005 Ace Mec DRG 005501 - 02Document1 page03 150000 4200000005 Ace Mec DRG 005501 - 02Anas TawfiqNo ratings yet

- Roadmap ColorDocument2 pagesRoadmap Colortkhan2001No ratings yet

- Nte GR D: E-Bel2-56.2-3Document1 pageNte GR D: E-Bel2-56.2-3Prashant SanapNo ratings yet

- C23-ZG20-S-7008-1 - EMG BLDG - SHEET 2Document1 pageC23-ZG20-S-7008-1 - EMG BLDG - SHEET 2sartajNo ratings yet

- 4217-Pbg-A-1101-Rc Denah - Lantai 1 Dan 1 MezaninDocument1 page4217-Pbg-A-1101-Rc Denah - Lantai 1 Dan 1 MezaninAdi PriyapurnatamaNo ratings yet

- 10 603110 0000100201 Mah Civ SHD 000032 - 01Document1 page10 603110 0000100201 Mah Civ SHD 000032 - 01ibrahemomr9993No ratings yet

- Keyplan: See DRG S 207 - STAIRS '2/3'Document1 pageKeyplan: See DRG S 207 - STAIRS '2/3'Danrage BoodramNo ratings yet

- Gubahan ModelDocument1 pageGubahan ModelIlham Satriyo WibowoNo ratings yet

- DEWA Water Network LayoutDocument1 pageDEWA Water Network Layoutabdullah fararjehNo ratings yet

- 18 606000 1100001344 Asb Civ SHD 115152Document2 pages18 606000 1100001344 Asb Civ SHD 115152Mahmudul Alam kanakNo ratings yet

- Q17017 0100D PK4b (Ii) A TD GN MI 803 1OF1 REV00Document1 pageQ17017 0100D PK4b (Ii) A TD GN MI 803 1OF1 REV00Elektrikal InhinyeroNo ratings yet

- Esquema Excavacion A-6Document1 pageEsquema Excavacion A-6Sebastian SalazarNo ratings yet

- Mall Alec Al GF STR Abd 0055 Ab0 ADocument1 pageMall Alec Al GF STR Abd 0055 Ab0 Azubair khanNo ratings yet

- Huawei P20 BoardviewDocument2 pagesHuawei P20 Boardviewpc partnerNo ratings yet

- FLS .Mall Eltahlia 26-08-2023-RoofDocument1 pageFLS .Mall Eltahlia 26-08-2023-Roofengrabbas75No ratings yet

- QSS2 Jeg CW RF DR M 3720 D4.C02Document1 pageQSS2 Jeg CW RF DR M 3720 D4.C02Nideesh RobertNo ratings yet

- Part 01Document1 pagePart 01USMAN ARSHAD ALVINo ratings yet

- Denah STPDocument1 pageDenah STPFajri Fathur RahmanNo ratings yet

- Ruh8 2021 M-103 Second Floor Hvac-M - 1 0 3 CDocument1 pageRuh8 2021 M-103 Second Floor Hvac-M - 1 0 3 CAta AtefNo ratings yet

- 15f-Elevation 1-A-201Document1 page15f-Elevation 1-A-201Ali AltameemiNo ratings yet

- Desague (1) - Planta GeneralDocument1 pageDesague (1) - Planta Generalkristian MéndezNo ratings yet

- Ec2-02a Second Floor Auxiliary LayoutDocument1 pageEc2-02a Second Floor Auxiliary LayoutSEDFREY DELA CRUZNo ratings yet

- Master-Lokasi 25.8.2022Document1 pageMaster-Lokasi 25.8.2022naimparmal3No ratings yet

- Thomson Chassis TX807EU COMPLETE PCB DIAGRAMDocument1 pageThomson Chassis TX807EU COMPLETE PCB DIAGRAMPavel FrolovNo ratings yet

- Ed Edilberto Re Final Jajajaja1Document1 pageEd Edilberto Re Final Jajajaja1Boya comiendoNo ratings yet

- Chant Sans ParolesDocument3 pagesChant Sans ParolesDeyan DenchevNo ratings yet

- A-120 - BLVD - 1 - Roof Floor PlanDocument1 pageA-120 - BLVD - 1 - Roof Floor PlanRaghu supertechNo ratings yet

- Lighting Plan L1Document1 pageLighting Plan L1Dani WaskitoNo ratings yet

- Lighting Plan L7Document1 pageLighting Plan L7Dani WaskitoNo ratings yet

- P-1508 RU-ModelDocument1 pageP-1508 RU-ModelBhuvana EswariNo ratings yet

- P30 Lite-1 PCBDocument2 pagesP30 Lite-1 PCBSANTOSH KHANALNo ratings yet

- Arquitectura Edificios Multifamiliares - Moche 52.00 M2-OptDocument1 pageArquitectura Edificios Multifamiliares - Moche 52.00 M2-OptAugusto Obeso AlcántaraNo ratings yet

- B Side: N7Tw - Power.Pcb 1LG4B10Y04300Document2 pagesB Side: N7Tw - Power.Pcb 1LG4B10Y04300Dario EzequielNo ratings yet

- Nova Benevides II MapaDocument1 pageNova Benevides II MapaReinaldoNo ratings yet

- Work Permit S CW 08299 2022Document2 pagesWork Permit S CW 08299 2022aliNo ratings yet

- Document analysis and comparisonDocument1 pageDocument analysis and comparisonaliNo ratings yet

- Work Permit S CW 08299 2022Document2 pagesWork Permit S CW 08299 2022aliNo ratings yet

- Normal Exhaust Fans Schedule - 3H1 Design Selected: (Indoor)Document1 pageNormal Exhaust Fans Schedule - 3H1 Design Selected: (Indoor)aliNo ratings yet

- IAC ReduserDocument1 pageIAC ReduseraliNo ratings yet

- Fire Fighting Notes:: Key PlanDocument1 pageFire Fighting Notes:: Key PlanaliNo ratings yet

- IAC ReduserDocument1 pageIAC ReduseraliNo ratings yet

- 2.1 Naffco - 1566315 - 3J2Document1 page2.1 Naffco - 1566315 - 3J2aliNo ratings yet

- Behaviour of Skew Footings Resting On Clayey and Sandy SoilDocument10 pagesBehaviour of Skew Footings Resting On Clayey and Sandy SoilShahzad AnwarNo ratings yet

- Breakup RMC (13.06.2019)Document9 pagesBreakup RMC (13.06.2019)Swaraj BPNo ratings yet

- Astm A106 A106mDocument4 pagesAstm A106 A106mmahamad AziNo ratings yet

- Cantilever Wall Analysis and DesignDocument9 pagesCantilever Wall Analysis and DesignCinthya Bringas ZapatelNo ratings yet

- Butterfly Valve Chamber Design - 300 - 700mm DIDocument6 pagesButterfly Valve Chamber Design - 300 - 700mm DIRamakanth Putty100% (1)

- Pms Check List: (1) - Travelling Block and HookDocument3 pagesPms Check List: (1) - Travelling Block and HookRadhe Agri ProductsNo ratings yet

- Assignment 2-09Document2 pagesAssignment 2-09Felix HabarugiraNo ratings yet

- 2018 Waste Water Collection Systems - EugeneDocument51 pages2018 Waste Water Collection Systems - EugeneKwaku frimpongNo ratings yet

- When To Challenge Petrographic Reports - tcm45-347346Document4 pagesWhen To Challenge Petrographic Reports - tcm45-347346Dan TranNo ratings yet

- Master Spec - Reference 1Document37 pagesMaster Spec - Reference 1Jayson100% (1)

- 2017 New Eim NC IiDocument4 pages2017 New Eim NC IiThorgay AvengersNo ratings yet

- Front View Right Side View: Section Iv Details 15Document1 pageFront View Right Side View: Section Iv Details 15Darius Frane MarasiganNo ratings yet

- Syllabus of Hydraulic Engineering Section CE-213 Fluid Mechanics Course Category: DC L - T - P: 3 - 1-0 Credit: 4Document35 pagesSyllabus of Hydraulic Engineering Section CE-213 Fluid Mechanics Course Category: DC L - T - P: 3 - 1-0 Credit: 4subxaanalahNo ratings yet

- Hearst Tower Feb 06Document0 pagesHearst Tower Feb 06denis1808scribdNo ratings yet

- Elevator Chapter 6Document65 pagesElevator Chapter 6Pedro AmorsoloNo ratings yet

- Slick LineDocument10 pagesSlick LineChoochart Thongnark100% (1)

- Partsbook Lube Truck LT - R61206Document79 pagesPartsbook Lube Truck LT - R61206Muh tiadiNo ratings yet

- Lecture 04-Material Property Charts-ADocument46 pagesLecture 04-Material Property Charts-Aحبيبة امهةNo ratings yet

- Manual Compresor Hatlapa L50Document120 pagesManual Compresor Hatlapa L50ANDRES ACOSTANo ratings yet

- Syllabus For B.Arch - 2014 15 Onwards IX To X Sem PDFDocument18 pagesSyllabus For B.Arch - 2014 15 Onwards IX To X Sem PDFManish Singh RathorNo ratings yet

- Project Report RsDocument38 pagesProject Report RsVaishnavi PandeyNo ratings yet

- Ojt Weekly Log - Interior DesignDocument12 pagesOjt Weekly Log - Interior DesignDenise Ann Delos ReyesNo ratings yet

- 06 GasketSurface-Cleaning V2Document4 pages06 GasketSurface-Cleaning V2PariNo ratings yet

- Sample MTC: Material Test CertificateDocument2 pagesSample MTC: Material Test CertificateSameer KmNo ratings yet

- CCR & Simulator Room DesignDocument27 pagesCCR & Simulator Room DesignapsNo ratings yet

- Inspection and Test Plans (Itps) : Centrifugal PumpsDocument3 pagesInspection and Test Plans (Itps) : Centrifugal PumpsbahlakeNo ratings yet

- Amassadeira Basculante Ferneto ABXxxxiDocument2 pagesAmassadeira Basculante Ferneto ABXxxxiFerneto SANo ratings yet

- Oregon LNG Tank SpecDocument16 pagesOregon LNG Tank Specdr61gt100% (3)

- Proximity Sensing and Warning Technology For Heavy Construction Equipment OperationDocument10 pagesProximity Sensing and Warning Technology For Heavy Construction Equipment OperationAnand ReddyNo ratings yet

- Pega Il 0310 TD VFC HoistDocument2 pagesPega Il 0310 TD VFC HoistsalesgglsNo ratings yet