Professional Documents

Culture Documents

Preheater Inspection Report 23 12 10

Preheater Inspection Report 23 12 10

Uploaded by

Visnu Sankar0 ratings0% found this document useful (0 votes)

11 views2 pagesCopyright

© © All Rights Reserved

Available Formats

XLSX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

11 views2 pagesPreheater Inspection Report 23 12 10

Preheater Inspection Report 23 12 10

Uploaded by

Visnu SankarCopyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

You are on page 1of 2

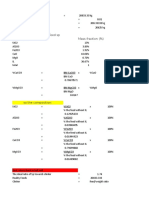

RAS AL KHAIMMAH CEMENT COMPANY

PREHEATER INSPECTION REPORT 23/12/2010

SPECIFIC AREA OF INSPECTION OBSERVATIONS

CYCLONE 1A:

1 Cylindrical portion O.K.

2 Conical portion O.K.

3 Roof condition O.K.

4 Coating condition NO

5 Coating cleaning requirements NO

6 Immersion tube condition O.K.

CYCLONE 1B:

1 Cylindrical portion O.K.

2 Conical portion O.K.

3 Roof condition O.K.

4 Coating condition NO

5 Coating cleaning requirements NO

6 Immersion tube condition O.K.

CYCLONE II:

1 Cylindrical portion O.K.

2 Conical portion O.K.

3 Roof condition O.K.

4 Coating condition NO

5 Coating cleaning requirements NO

6 Immersion tube condition O.K.

CYCLONE III:

1 Cylindrical portion O.K.

2 Conical portion O.K. All three blaster nozzles are O.K.

3 Roof condition O.K.

4 Coating condition NO

5 Coating cleaning requirements NO

6 Immersion tube condition O.K.

CYCLONE IV:

1 Cylindrical portion O.K.

2 Conical portion Upper cone at three place approx. 3M² patch required.

3 Roof condition O.K.

4 Coating condition NO COATING

5 Coating cleaning requirements NO

6 Immersion tube condition O.K.

CYCLONE V:

1 Cylindrical portion O.K.

2 Conical portion O.K.

3 Roof condition O.K.

4 Coating condition Abnormally there was no coating inside the cyclone, it is just like Cyclone -1

5 Coating cleaning requirements NO

6 Immersion tube condition Immersion tube is not there into cyclone - V

DUCT CY.II TO CY. I A AND I B

1 Duct Walls O.K.

2 Bull nose of Cyclone IA and IB O.K.

3 Duct Roof O.K.

4 Coating conditions NO COATING

5 Coating cleaning requirements NO

6 Splash box of feed chute O.K.

DUCT CYCLONE III TO CYCLONE II

1 Duct Walls O.K.

2 Bull nose of Cyclone II O.K.

3 Duct Roof O.K.

4 Coating conditions NO COATING

5 Coating cleaning requirements NO

6 Splash box of cyclone IA and IB O.K.

DUCT CYCLONE IV TO CYCLONE III

1 Duct Walls O.K.

2 Bull nose of Cyclone III O.K.

3 Duct Roof O.K.

4 Coating conditions NO COATING

5 Coating cleaning requirements NO

6 Splash box conditions of cyclone II O.K.

DUCT CYCLONE V TO CYCLONE IV

1 Duct Walls O.K.

2 Bull nose of Cyclone IV O.K.

3 Duct Roof O.K.

4 Coating conditions NO COATING

5 Coating cleaning requirements NO COATING

6 Splash box conditions of cyclone III O.K.

GOOSE NECK TO CYCLONE V

1 Duct Walls O.K.

2 Bull nose of Cyclone V O.K.

3 Duct Roof O.K.

4 Coating conditions NO COATING

5 Coating cleaning requirements O.K.

GOOSE NECK

1 Duct Walls O.K.

2 Duct Roof O.K.

3 Coating conditions 200 TO 250 MM THICK COATING FOUND

4 Coating cleaning requirements Yes

MIXING CHAMBER TO GOOSE NECK

1 Duct Walls O.K.

2 Coating conditions 100 MM AT BEND POSITION

3 Coating cleaning requirements YES

MIXING CHAMBER

1 Duct Walls O.K.

2 Coating conditions NO COATING

3 Coating cleaning requirements NO COATING

4 Horizantal and Vertical beams Good

PRECALCINER

1 Side walls O.K.

2 Roof Replaced with new.

3 Coating conditions NO COATING

4 Tertiary air inlet duct O.K.

PRECALCINER TO MIXING CHAMBER DUCT

1 Side walls O.K.

2 Slope wall below calciner O.K.

3 Coating conditions NO COATING

4 Vertical wall below calciner O.K.

KILN INLET

1 Side Walls O.K.

2 Orifice plate area O.K.

3 Orifice plate O.K.

4 Kiln inlet cyclone V meal chute guide O.K.

5 Kiln inlet arch O.K.

TERTIARY AIR DUCT

1 Vertical duct O.K.

2 Horizantal duct O.K.

3 Dust settling chamber Cleaned

4 Tertiary air damper One CCR side flap removed, castable damage in second flap.

COOLER (INLET THROAT UP TO PARTITION WALL)

1 C.C.R.Side wall O.K.

2 G.C.C. Side wall O.K. Both bull nose castable replaced. ( Found in damaged condition )

3 Partition wall O.K.

4 Kiln discharge wall O.K.

5 Cooler roof At two position top, near expansion joint ( Chance fo red spot ) damage.

COOLER (FROM PARTIONWALL UP TO CLINKER BREAKER)

1 C.C.R.Side wall O.K.

2 G.C.C. Side wall O.K.

3 Clinker breaker wall O.K.

4 Cooler roof Some portion 5M² damage.

You might also like

- Bar BendingDocument142 pagesBar Bendingjaffna100% (4)

- P-752 Unit4Document505 pagesP-752 Unit4sysyphus01100% (1)

- Ansi GPTC z380 1 - 2018 Addendum 2 02 - 19 - 19Document212 pagesAnsi GPTC z380 1 - 2018 Addendum 2 02 - 19 - 19Melele MuNo ratings yet

- Solid Wall HDPE Pipe: NRCS NEH 636 Chap. 52 Buried Pipeline Design CalculationsDocument13 pagesSolid Wall HDPE Pipe: NRCS NEH 636 Chap. 52 Buried Pipeline Design CalculationsBalaji HariNo ratings yet

- Test For Properties of Cement: Physical & ChemicalDocument4 pagesTest For Properties of Cement: Physical & ChemicalmuqeetNo ratings yet

- Pile DesignDocument3 pagesPile Designalinawaz91100% (9)

- Perimeter and Area Practice WorksheetDocument4 pagesPerimeter and Area Practice WorksheetVisnu SankarNo ratings yet

- Architectural Detailing NOTESDocument12 pagesArchitectural Detailing NOTESakhil rajNo ratings yet

- 7 Quality Management and Control of Cement Production - Ó+ Í - + - +ÝËÙ+ÏÍãDocument88 pages7 Quality Management and Control of Cement Production - Ó+ Í - + - +ÝËÙ+ÏÍãNova HeriNo ratings yet

- Floating The KilnDocument1 pageFloating The KilnsreeganeshrNo ratings yet

- Energy Consumption Norms For Cement Sector Under Energy Conservation Act - 2001Document28 pagesEnergy Consumption Norms For Cement Sector Under Energy Conservation Act - 2001Sarah FrazierNo ratings yet

- Dust - and - Meal Presentation PDFDocument27 pagesDust - and - Meal Presentation PDFawwadNo ratings yet

- MMBC - 6: Topic - Acp Cladding Presented by - Manish.J SandhyaDocument25 pagesMMBC - 6: Topic - Acp Cladding Presented by - Manish.J SandhyaSneha DineshNo ratings yet

- Mayor ShutdownDocument121 pagesMayor ShutdownIrshad HussainNo ratings yet

- ACC WadiDocument62 pagesACC WadiMohamed ArifNo ratings yet

- Document List: The Document List Contains Links To All Files of The Manual. Click On The Green Text To Open A FileDocument4 pagesDocument List: The Document List Contains Links To All Files of The Manual. Click On The Green Text To Open A FilemkpqNo ratings yet

- The Purpose of A Cooler Is, Obviously To Cool The Clinker - This Is Important For A Several ReasonsDocument31 pagesThe Purpose of A Cooler Is, Obviously To Cool The Clinker - This Is Important For A Several ReasonsZegera MgendiNo ratings yet

- Failure and Repair of The Liner of A High Pressure Carbamate CondenserDocument10 pagesFailure and Repair of The Liner of A High Pressure Carbamate CondenserGrootNo ratings yet

- The Air Circuit in A Rotary KilnDocument20 pagesThe Air Circuit in A Rotary KilnZia KhanNo ratings yet

- Solid Fuels: 朱信 Hsin Chu Professor Dept. of Environmental Engineering National Cheng Kung UniversityDocument36 pagesSolid Fuels: 朱信 Hsin Chu Professor Dept. of Environmental Engineering National Cheng Kung UniversitysreeNo ratings yet

- Cement Plant VIPDocument51 pagesCement Plant VIPengr kazamNo ratings yet

- Cleaning Preheater Cyclone Choke WIDocument5 pagesCleaning Preheater Cyclone Choke WIErmiyas MistreNo ratings yet

- Unit 2 - CementDocument55 pagesUnit 2 - CementSaharsha GadariNo ratings yet

- Textbook 3 Cementproduction v31Document8 pagesTextbook 3 Cementproduction v31Mohammad Awais NazirNo ratings yet

- Infinity For Cement EquipmentDocument128 pagesInfinity For Cement EquipmentLe Hoang100% (1)

- 3 Strategies For Reducing Cement KilnDocument14 pages3 Strategies For Reducing Cement Kilnorientanjali7066100% (1)

- Tips On Kiln OperationDocument1 pageTips On Kiln OperationVipan Kumar DograNo ratings yet

- Pyroprocessing: Dr. Ari Diana SusantiDocument27 pagesPyroprocessing: Dr. Ari Diana SusantiTitan Titanovsky KoraagNo ratings yet

- CoriolisDocument17 pagesCoriolisJuan AlzateNo ratings yet

- Process Operation Manual For Clinker Burning SystemDocument109 pagesProcess Operation Manual For Clinker Burning SystemGebrehiwot Esayas100% (1)

- Department of Chemical Engineering: Analysis & Comparison of Cheaper Binder For Coal FinesDocument26 pagesDepartment of Chemical Engineering: Analysis & Comparison of Cheaper Binder For Coal FinesVijaya GosuNo ratings yet

- Example of Cement Mill QuestionnaireDocument5 pagesExample of Cement Mill QuestionnaireIrfan AhmedNo ratings yet

- Chapter 6 Final A5 EditDocument16 pagesChapter 6 Final A5 EditkINGNo ratings yet

- Refrateck SolutionsDocument8 pagesRefrateck SolutionsMagesh Kumar0% (1)

- Quality and Formulae 4Document1 pageQuality and Formulae 4zane truesdaleNo ratings yet

- Lecture Cement IndustryDocument65 pagesLecture Cement IndustryUsman AliNo ratings yet

- Lab Report BGN 254 Group 1 (2022)Document48 pagesLab Report BGN 254 Group 1 (2022)amirul syafiqNo ratings yet

- Modeling Kiln OperationDocument36 pagesModeling Kiln OperationKiarash NiroumandNo ratings yet

- Clinker Coolers: By: Oliver Christian D. DeyparineDocument26 pagesClinker Coolers: By: Oliver Christian D. Deyparinemoonbright27No ratings yet

- Duoflex PDFDocument8 pagesDuoflex PDFTinTunNaingNo ratings yet

- Cement Kiln Co-ProcessingDocument11 pagesCement Kiln Co-ProcessingflukemonsterNo ratings yet

- Dry Feed: Feed Entered SP H2O Content in SP H2O Content in SPDocument20 pagesDry Feed: Feed Entered SP H2O Content in SP H2O Content in SPIrfan Ahmed100% (1)

- Combustion in Cement KilnDocument20 pagesCombustion in Cement KilnLe HoangNo ratings yet

- RA SiC T CM EC PDFDocument2 pagesRA SiC T CM EC PDFDaniel RicartNo ratings yet

- MHR21924 CMC Chapter CCDocument48 pagesMHR21924 CMC Chapter CCDede KaladriNo ratings yet

- Process Control of LURM MillDocument6 pagesProcess Control of LURM Millimam janiNo ratings yet

- Clinker GrindingDocument7 pagesClinker Grindingdoxa mariaNo ratings yet

- False Air Sealing Around Vertical Raw Mill and PyroDocument5 pagesFalse Air Sealing Around Vertical Raw Mill and PyroabdulfetahNo ratings yet

- Department of Chemical EngineeringDocument19 pagesDepartment of Chemical EngineeringPandia RajanNo ratings yet

- 3.4 - Burning in A KilnDocument4 pages3.4 - Burning in A KilnIrshad Hussain100% (1)

- Shree Project FinalDocument20 pagesShree Project FinalMostafa KordyNo ratings yet

- FA Fineness - Comparing Residue On 45 and Blaine PDFDocument5 pagesFA Fineness - Comparing Residue On 45 and Blaine PDFTran Huynh NamNo ratings yet

- 03mill SlidesDocument21 pages03mill SlidesNael El SayyadNo ratings yet

- Explosões em Plantas de CimentoDocument20 pagesExplosões em Plantas de CimentoDenivaldo NascimentoNo ratings yet

- Review No.145: Keystone S Cross-OverDocument7 pagesReview No.145: Keystone S Cross-Overbasavaraju535No ratings yet

- ABC Cooler Inlet PDFDocument4 pagesABC Cooler Inlet PDFSushant GuptaNo ratings yet

- Application Procedure ROCKHARD-90Document4 pagesApplication Procedure ROCKHARD-90JCSNo ratings yet

- Kiln OptimizationDocument7 pagesKiln Optimizationneo 87No ratings yet

- Chapter 1 Final A5 Edit PDFDocument10 pagesChapter 1 Final A5 Edit PDFkINGNo ratings yet

- Is There A Problem There ? Hint:: Kiln Mechanics Basics: Specific Problems D.WilleDocument3 pagesIs There A Problem There ? Hint:: Kiln Mechanics Basics: Specific Problems D.WilleDiego AlejandroNo ratings yet

- Section Clinker Et Broyage Ciment: Contrat 119 Mecanique ProcessDocument27 pagesSection Clinker Et Broyage Ciment: Contrat 119 Mecanique ProcessYhaneNo ratings yet

- VRM Daily Stoppage DetailsDocument7 pagesVRM Daily Stoppage DetailsValipireddy NagarjunNo ratings yet

- Clinker Cooler OperationDocument5 pagesClinker Cooler OperationJCSNo ratings yet

- Calderys Refractory Solutions For Cement PlantsDocument14 pagesCalderys Refractory Solutions For Cement PlantsMagesh KumarNo ratings yet

- Helical Gearbox InstallationDocument8 pagesHelical Gearbox InstallationKUNALJAYNo ratings yet

- GE Energy: Advancements in Particulate Emissions Control Technology For Industrial SourcesDocument43 pagesGE Energy: Advancements in Particulate Emissions Control Technology For Industrial Sourceszane truesdaleNo ratings yet

- Some Questions and Answers of CEMENT Rotary KilnDocument4 pagesSome Questions and Answers of CEMENT Rotary KilnSalud Y SucesosNo ratings yet

- Government Engineering College, GandhinagarDocument28 pagesGovernment Engineering College, GandhinagarJaynish IdhariyaNo ratings yet

- Quenched Cupola Part 1Document12 pagesQuenched Cupola Part 1Diego MoralesNo ratings yet

- Revision English Worksheet: Periodic Tes - Feb / March 2019Document2 pagesRevision English Worksheet: Periodic Tes - Feb / March 2019Visnu SankarNo ratings yet

- Tax Invoice / Credit Note: Simply Set Up Autopay To Effortlessly Pay For Your BillsDocument4 pagesTax Invoice / Credit Note: Simply Set Up Autopay To Effortlessly Pay For Your BillsVisnu SankarNo ratings yet

- Revision Shapes and PatternsDocument2 pagesRevision Shapes and PatternsVisnu SankarNo ratings yet

- Informal Letter Writing Class 4Document4 pagesInformal Letter Writing Class 4Visnu SankarNo ratings yet

- PERIODIC TEST 1 (2021-2022) Time Table and Portion - Class IvDocument2 pagesPERIODIC TEST 1 (2021-2022) Time Table and Portion - Class IvVisnu SankarNo ratings yet

- Evs Written Sept. 2021 Model PaperDocument8 pagesEvs Written Sept. 2021 Model PaperVisnu SankarNo ratings yet

- KG2 A-First Term Written Evaluation - Sept. 2021Document1 pageKG2 A-First Term Written Evaluation - Sept. 2021Visnu SankarNo ratings yet

- Revision 1 and Revision 2 AnswersDocument8 pagesRevision 1 and Revision 2 AnswersVisnu SankarNo ratings yet

- Informal Letter Writing Class 4Document4 pagesInformal Letter Writing Class 4Visnu SankarNo ratings yet

- Look at The Tally Graph and Answer The Questions That Follow (Home Work)Document7 pagesLook at The Tally Graph and Answer The Questions That Follow (Home Work)Visnu SankarNo ratings yet

- KG 2 Date Sheet & Portion Sheet - First Term Evaluation September 2021Document2 pagesKG 2 Date Sheet & Portion Sheet - First Term Evaluation September 2021Visnu SankarNo ratings yet

- Story Comprehension - The Little Red HenDocument1 pageStory Comprehension - The Little Red HenVisnu SankarNo ratings yet

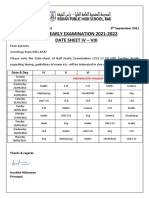

- Half Yearly Examination 2021-2022 Date Sheet Iv - ViiiDocument1 pageHalf Yearly Examination 2021-2022 Date Sheet Iv - ViiiVisnu SankarNo ratings yet

- Datesheet & Portion For Half Yearly Examination 2021 - Class IVDocument3 pagesDatesheet & Portion For Half Yearly Examination 2021 - Class IVVisnu SankarNo ratings yet

- Screenshot 2023-09-12 at 11.24.30 AMDocument17 pagesScreenshot 2023-09-12 at 11.24.30 AMVikram Mathew NinanNo ratings yet

- Data Sheet For HDPEDocument1 pageData Sheet For HDPEShowkath AliNo ratings yet

- Hydrology With Schematic Diagram ResearchDocument8 pagesHydrology With Schematic Diagram ResearchGleizel AutorNo ratings yet

- Question Paper CodeDocument3 pagesQuestion Paper CodeKeesanth Geetha ChandrasekaranNo ratings yet

- TECAPEI Natural (Sabic Ultem 1000 Series) 14Document1 pageTECAPEI Natural (Sabic Ultem 1000 Series) 14kgrier8966No ratings yet

- B. Split FlapDocument6 pagesB. Split FlapIpsita DasNo ratings yet

- Effects of Approach Flow ConditionsDocument6 pagesEffects of Approach Flow ConditionsBharath kumarNo ratings yet

- Scib Industrialised Building System SDN BHD: COMPANY NO 554894-ADocument60 pagesScib Industrialised Building System SDN BHD: COMPANY NO 554894-AHariman SallehNo ratings yet

- Nenmong HNTTHAIDocument106 pagesNenmong HNTTHAIHà Nguyễn Thành TháiNo ratings yet

- Cross Drainage WorksDocument22 pagesCross Drainage Workslalithkumar145100% (1)

- Atul N. Srinivasa Parthasarathy: Contact Information Permanent AddressDocument3 pagesAtul N. Srinivasa Parthasarathy: Contact Information Permanent AddressAmit Rajendra PhadatareNo ratings yet

- Rock Mechanics Report 05Document8 pagesRock Mechanics Report 05Bernardo Baqueiro RiosNo ratings yet

- Windows Best Practice Guide - Window TerminologyDocument19 pagesWindows Best Practice Guide - Window TerminologyKarn SandhuNo ratings yet

- Journal of Building Engineering: Jian Li, Feng Li, Caiwei Liu, Jijun MiaoDocument13 pagesJournal of Building Engineering: Jian Li, Feng Li, Caiwei Liu, Jijun MiaoSeban ACNo ratings yet

- PBA. Modul 7 BendungDocument61 pagesPBA. Modul 7 BendungYeskiel Anagh BonexNo ratings yet

- Electrical Specifications - UnlockedDocument8 pagesElectrical Specifications - UnlockedSaad AkramNo ratings yet

- Thousand Tower & Sendai MTDocument7 pagesThousand Tower & Sendai MTAnastasia YesicaNo ratings yet

- Underwater Repairs: 18.1 GeneralDocument11 pagesUnderwater Repairs: 18.1 GeneralmigescuNo ratings yet

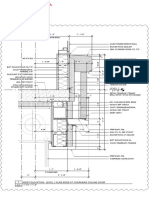

- 2020 0827 - Overhead Door Head DetailDocument1 page2020 0827 - Overhead Door Head Detaildata copyNo ratings yet

- TP Gestein-Stb: Technical Testing Regulations For Aggregates in Road ConstructionDocument14 pagesTP Gestein-Stb: Technical Testing Regulations For Aggregates in Road ConstructionChakir KasdarliNo ratings yet

- DOBFvDocument16 pagesDOBFvISHAN VERMANo ratings yet

- BOQ of Mid Day Meal ShedDocument11 pagesBOQ of Mid Day Meal Shedamit singh100% (1)