Professional Documents

Culture Documents

Chapter 1 Final A5 Edit PDF

Uploaded by

kING0 ratings0% found this document useful (0 votes)

107 views10 pagesOriginal Title

Chapter_1_final_a5_edit.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

107 views10 pagesChapter 1 Final A5 Edit PDF

Uploaded by

kINGCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 10

REFRACTOTRY INSTALLATION TECHNIQUES

1

IN CEMENT INDUSTRY

Chapter 1

Preparation procedures prior to the Kiln Shutdown Plan

Observance of proper preparation procedures prior to the

shutting down of Kiln for maintenance schedule is one of the

important procedures in ensuring the efficiency of the

shutdown process, as well as to ensure that the time span

involved and budgets are in accordance to the established

Operation and Maintenance Plan (Manual). The processes

involved prior to the shutting down of Kiln require advance

preparation of at least one month, by observing and

implementing the following tasks:

1.1 Inspection of Kiln Migration

- For the cement Kiln, both migration and ovality

values of the Kiln shall be measured and compared

with each other prior to its shutdown. The respective

values of both migration and ovality must be within

the allowable range.

- The Kiln migration values shall be monitored and

recorded weekly. The data of kiln migration shall be

used together with the kiln ovality values, which are

vital indicators prior to the shutting down of Kiln, and

during the full production capacity. The observed data

of both kiln migration values and kiln ovality values

should be at least 1 month prior to the shutting of the

Kiln. Thus, if any value deviate from the standards

(acceptable range), the refractory lining under the tyre

areas could have been affected from the excessive

external compressive stress thereby creating cracks or

spalling effect which will consequently reduce the

service life of refractory lining.

- The migration and ovality values are to be jointly

evaluated in drawing conclusion and setting a Kiln

REFRACTOTRY INSTALLATION TECHNIQUES

2

IN CEMENT INDUSTRY

Stop Plan which would set the adjustment target of

the migration value of each tyre.

1.2 Allocation of Refractory Maintenance Area

- The previous refractory maintenance records of each

zone in the Rotary Kiln, as shown in the past Kiln

maintenance schedule are important inputs in

determining the present refractory maintenance

operations.

- The current condition of the Kiln operating prior to

the implementation of maintenance schedule must be

monitored whether there has any abnormalities

occurred in the refractory. For example, the outside

shell temperature of the Rotary Kiln, Cyclone

Preheater and Clinker Cooler should be checked

whether any of their surface areas have been

experiencing raised in temperature values beyond the

normal standards. These data are necessary inputs in

determining the refractory maintenance plan of each

area.

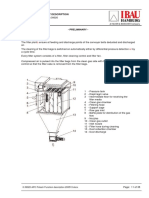

- For the outside surface wall of the Cyclone Preheater,

Hot Air Duct, Calciner and various Down Pipes,

where the damages of the refractory had been

temporarily repaired by the use of box welding (Fig.

1.1), they must be included in the present Kiln Stop

Plan by replacing its steel wall surface and the

refractory should be repaired/replaced by inside

maintenance approach, which is more appropriate.

- To enhance the efficiency of refractory installation

tasks, there must be an agreed scope of work between

the two working teams, the Cement Production Team

and the Refractory Installation Team. This will ensure

that there will be no conflicts and problems occur

during the Kiln maintenance operations, and the scope

REFRACTOTRY INSTALLATION TECHNIQUES

3

IN CEMENT INDUSTRY

of the refractory maintenance tasks have been

properly defined and planned and therefore achieving

the objective of best quality of work within the

required timeframe.

REFRACTOTRY INSTALLATION TECHNIQUES

4

IN CEMENT INDUSTRY

Fig. 1-1: Pictures of the refractory installation in Hot Air

Duct, refractory repaired by box welding [outside

maintenance approach]

1.3 Inspection of the refractory inventory, condition and

quantity

- The planner shall monitor the quantity and conditions

of all available refractory in the warehouse and

compare them with the estimated quantity required in

the schedule/plan (the quantity can be estimated based

on the previous record of the area to be replaced or

repaired) for at least 3 months in advance to give the

refractory manufacturer sufficient time to deliver the

products, based on the Kiln Stop Plan.

- The preparation or estimates of the quantity of

refractory for the Cyclone Preheater and Clinker

Cooler can be obtained from the average number of

REFRACTOTRY INSTALLATION TECHNIQUES

5

IN CEMENT INDUSTRY

refractory used during each of the previous Kiln

maintenance schedule.

- During 2-4 weeks prior to the kiln shutdown, the

quantity and conditions of the refractory shall be

again re-checked to confirm their availability in the

warehouse and readiness for use.

- In addition, the routine inspection on the conditions

and quantity of refractory shall also include inspection

of other accessory materials to be used with the

refractory; such as various grades of Anchors for each

corresponding areas, Welding Electrode, Card Board,

Plywood, Wax, and etc.

- The proactive preparation and systematically storage

of materials and establishment of efficient material

withdrawal system will contribute to the reduction of

materials loss/wastage.

1.4 Inspection of tools and equipment

- An inspection of the tools and equipment, which are

to be used for removing and installing the refractory,

in terms of their usage condition, availability,

quantity, and quality to sufficiently meet the bulk of

work should be done at least one month prior to the

scheduled Kiln shutdown. These tools and equipment

include:

o Demolishing Car

o Cavo Car

o Mult-O-Ring

o Air Breaker

o Pan Mixer; the gap/distance between the

propeller and the floor bed should not be less

than 0.5 mm. and not more than 10 mm. to the

wall. If the distance exceeds the standard, a

corresponding adjustment can be done by

REFRACTOTRY INSTALLATION TECHNIQUES

6

IN CEMENT INDUSTRY

installing steel plate (through welding) to

adjust the distance. The Pan mixer must also

be cleaned.

o Hydraulic Jack; hydraulic supports lining

during the movement of Mult-O-Ring to

install the refractory in the proceeding rings.

o Vibrator

o Refractory brick cutter and a diamond blade;

the brick cutter shall be a non-water cooling

type, since the basic bricks should not be wet

or hydrated.

Fig. 1-2: Picture of a brick cutter with the blade

o Hacksaw and Wood Saw; for preparation of

wooden forms/ moulds for castable

installation.

REFRACTOTRY INSTALLATION TECHNIQUES

7

IN CEMENT INDUSTRY

Fig. 1-3: Picture of a hacksaw

o Air Compressor; to be used during the

installation of rotary kiln refractory bricks in

the upper half portion.

- The aforementioned tools and equipment must be

inspected and certified by the safety department to

prevent any possible danger during the usage.

- The handling equipment/ machine/ vehicle such as

Lift, Folk Lift, Truck, Hand Lift, Crane, Hoist, and

Belt Conveyer are necessary to be checked and

inspected for their efficiency and capability to

effectively hold the weight of the refractory to be

handled or lifted.

- Prepare sufficient number of the personal protective

equipment, for example Safety Shoes (heat steel head,

heat resistance and heel covered safety shoes are

necessary for refractory inspection in the kiln during

immediate shutdown given that the kiln is still hot),

Dust Filler Mask, Goggle (protection of dusts and tiny

objects into the eyes), Safety Belts (for working in

high elevated areas, for instance, Cyclone Preheater),

and Safety Helmet. Also, make use of personal

REFRACTOTRY INSTALLATION TECHNIQUES

8

IN CEMENT INDUSTRY

protective equipment and install safety signs to

control and ensure safety awareness.

Fig. 1-4: Picture of the personal protective equipment

Fig. 1-5: Picture of the required personal protective

equipment and safety signs to control and ensure

safety awareness before engaging in the work

REFRACTOTRY INSTALLATION TECHNIQUES

9

IN CEMENT INDUSTRY

1.5 Preparation of workforce plan for refractory

maintenance work

- The exact timetable in the Kiln Stop Plan, including

the allowable working time and amount of work to

remove and install refractory on various areas, must

be notified to the responsible persons who are directly

in-charge of refractory works, at least 1 month in

advance, to be able to prepare adequate manpower

that correspond to the amount of work.

- A capacity building or training on refractory

knowledge for the operators; both in theory and

implementation, and by evaluating their

understanding and skills prior to the scheduled Kiln

maintenance will enhance the ability of the operators/

workers to achieve better efficiency, quality, and

accuracy.

- There must also be training provided on work

guidelines, safety in workplace, first aid procedures,

and evacuation plan in case of emergency. After the

training, workers must be evaluated for their

knowledge and understanding in order to be

documented as certified personnel and allowed to

work.

1.6 Preparation of storage areas layout for the refractory

and tools and equipment

- There must be an arrangement of the storage area for

the refractory and tools and equipment in the working

areas so as to ensure convenience and efficiency in

mobilizing the materials.

- The storage area within the working areas must be

under the shade and away from rainstorm; for

instance the area below Cyclone Preheater for

REFRACTOTRY INSTALLATION TECHNIQUES

10

IN CEMENT INDUSTRY

refractory, the area below Clinker Cooler for the

refractory to be used in the Rotary Kiln and Clinker

Cooler.

- In the absence of adequate storage area, refractory and

tools and equipment may be laid in the ground yard

but shall be fully covered with water-proof cover

sheets.

- The laying of the refractory in the storage areas shall

be systematically arranged by their quality, and

shapes or sizes and sequence of their usage, especially

in close areas.

You might also like

- NM, NP Raw Mill Semen Padang2Document272 pagesNM, NP Raw Mill Semen Padang2Emel100% (1)

- Ball Mill Inspection Procedure PDFDocument4 pagesBall Mill Inspection Procedure PDFYoya AhmedNo ratings yet

- False Air Sealing Around Vertical Raw Mill and PyroDocument5 pagesFalse Air Sealing Around Vertical Raw Mill and PyroabdulfetahNo ratings yet

- VRM Fan ..Document2 pagesVRM Fan ..harikrushnaNo ratings yet

- Optimization of A Fully Air Swept Dry Grinding Cement Raw Meal Ball Mill Closed Circuit Capacity With The Aid PDFDocument10 pagesOptimization of A Fully Air Swept Dry Grinding Cement Raw Meal Ball Mill Closed Circuit Capacity With The Aid PDFJunaid MazharNo ratings yet

- Clinker GrindingDocument7 pagesClinker Grindingdoxa mariaNo ratings yet

- Example of Cement Mill QuestionnaireDocument5 pagesExample of Cement Mill QuestionnaireIrfan AhmedNo ratings yet

- How to remove scrap from ball millDocument5 pagesHow to remove scrap from ball millsafwat hassanNo ratings yet

- MHR21924 CMC Chapter CCDocument48 pagesMHR21924 CMC Chapter CCDede KaladriNo ratings yet

- Thermowell CatalogDocument24 pagesThermowell CatalogMANTCRUZNo ratings yet

- Hammer Crusher DesignDocument45 pagesHammer Crusher DesignmubashirNo ratings yet

- List of SAP T-CodesDocument18 pagesList of SAP T-CodesastinetNo ratings yet

- Outlet Apparatus: Machine Manual En-23122.102-ADocument16 pagesOutlet Apparatus: Machine Manual En-23122.102-ARahmat YusufNo ratings yet

- Leaflet Diverter Valve WZKDocument2 pagesLeaflet Diverter Valve WZKLorenzo Antonio Vera GonzalezNo ratings yet

- Dimension Tolerance (Coal Mill)Document4 pagesDimension Tolerance (Coal Mill)nishant361No ratings yet

- Creating Purchase Requisition in SAPDocument10 pagesCreating Purchase Requisition in SAPAshok KothariNo ratings yet

- Pacific Booker - Morrison HPGR Polycom Test ReportDocument20 pagesPacific Booker - Morrison HPGR Polycom Test ReportMeghshyam Karkera100% (1)

- Raw Mill InspectionDocument20 pagesRaw Mill InspectionAtiq Ur RehmanNo ratings yet

- Introduction of Bag Filters Constructional FeaturesDocument32 pagesIntroduction of Bag Filters Constructional FeaturesTin NguyenNo ratings yet

- ATOX Raw Mill. Weekly ReportDocument7 pagesATOX Raw Mill. Weekly ReportDilnesa EjiguNo ratings yet

- Atox 20 Coal Mill Critical Interlock SheetDocument6 pagesAtox 20 Coal Mill Critical Interlock SheetValipireddy NagarjunNo ratings yet

- 15th NCB Technical PaperDocument10 pages15th NCB Technical PaperSalah RomdaniNo ratings yet

- Particle Size Distribution Analysis and Cyclone Testing ResultsDocument5 pagesParticle Size Distribution Analysis and Cyclone Testing ResultsThaigroup CementNo ratings yet

- Shree Project FinalDocument20 pagesShree Project FinalMostafa KordyNo ratings yet

- Install and Maintain Premium Helical Geared MotorsDocument8 pagesInstall and Maintain Premium Helical Geared MotorsKUNALJAYNo ratings yet

- Kiln Floating: Know The Answer To This Question? Join The Community and For A Free Guest Account To Post A ReplyDocument3 pagesKiln Floating: Know The Answer To This Question? Join The Community and For A Free Guest Account To Post A ReplySunil T V SuniNo ratings yet

- DOPOL® 90 Cyclone Stage Type B-CCDocument35 pagesDOPOL® 90 Cyclone Stage Type B-CCRahmat HidayatNo ratings yet

- FivesFCB Brochure Horomill GBDocument6 pagesFivesFCB Brochure Horomill GBpeymanNo ratings yet

- Assiut Cement PlantDocument17 pagesAssiut Cement PlantMahmoud RashadNo ratings yet

- Wear Rate Calculator MonoDocument2 pagesWear Rate Calculator MonoBùi Hắc HảiNo ratings yet

- Detect Rotor Bar Defects with Motor Current Analysis (MCADocument2 pagesDetect Rotor Bar Defects with Motor Current Analysis (MCAJaime Berry100% (1)

- ResumeDocument3 pagesResumeHari Prathap ReddyNo ratings yet

- Bypass SystemDocument9 pagesBypass SystemirfanNo ratings yet

- RABH-sugest by SatputeDocument1 pageRABH-sugest by Satputegvrr1954No ratings yet

- ATC Report on Dynamic Separator Gap IssuesDocument4 pagesATC Report on Dynamic Separator Gap IssuesDilnesa EjiguNo ratings yet

- Dokumen - Tips - Atox Raw Mill 55844e0e63329Document13 pagesDokumen - Tips - Atox Raw Mill 55844e0e63329pipit agusNo ratings yet

- Smartfill: Do You Already Have Enough Information On Your Grinding Process?Document2 pagesSmartfill: Do You Already Have Enough Information On Your Grinding Process?youssef tabetNo ratings yet

- Presep Air Separator VTP enDocument6 pagesPresep Air Separator VTP enBrunoNo ratings yet

- VB 29 - 10Document5 pagesVB 29 - 10Kenny RuizNo ratings yet

- Performance Evaluation of Vertical Roller Mill in Cement Grinding: Case Study ESCH Cement PlantDocument8 pagesPerformance Evaluation of Vertical Roller Mill in Cement Grinding: Case Study ESCH Cement PlantSohail AhmedNo ratings yet

- Questionnaire Cement Plants-01 (1) .8.04Document9 pagesQuestionnaire Cement Plants-01 (1) .8.04Debajit BurhagohainNo ratings yet

- Instruction For Filling Up The Form-Sb & Keeping Records and Information For Verification ProcessDocument57 pagesInstruction For Filling Up The Form-Sb & Keeping Records and Information For Verification ProcessBùi Hắc HảiNo ratings yet

- GS-HG Kiln Shell Scanner, Technical ManualDocument15 pagesGS-HG Kiln Shell Scanner, Technical Manualvsrikala68No ratings yet

- Schenck WebDocument4 pagesSchenck Webarief22No ratings yet

- VRM Daily Stoppage DetailsDocument7 pagesVRM Daily Stoppage DetailsValipireddy NagarjunNo ratings yet

- EAU-1,19000 CFM at 75 MM StaticDocument1 pageEAU-1,19000 CFM at 75 MM StaticdesignhvacNo ratings yet

- Cooler-2 DiagramDocument3 pagesCooler-2 DiagramPraveen Singh Chouhan100% (1)

- Ceramic Ball in Cement IndustryDocument6 pagesCeramic Ball in Cement IndustryMauricio PortillaNo ratings yet

- Bag Filter ComponentsDocument6 pagesBag Filter ComponentsAhmad Dagamseh100% (2)

- Performing A Cement Plant Operations AuditDocument6 pagesPerforming A Cement Plant Operations AuditJa Phe TiNo ratings yet

- 04-03-PODFA-Function-Roller Mill QUADROPOL-Hydraulic SystemDocument16 pages04-03-PODFA-Function-Roller Mill QUADROPOL-Hydraulic SystemДен СтаднікNo ratings yet

- Flat Slide Valve: Machine Manual En-23261.001-EDocument32 pagesFlat Slide Valve: Machine Manual En-23261.001-ERahmat YusufNo ratings yet

- Magotteaux - XLIFT PaperDocument11 pagesMagotteaux - XLIFT PaperHamed MostafaNo ratings yet

- Vibration Analysis of Rotary Cement Kiln Using Fin 2Document5 pagesVibration Analysis of Rotary Cement Kiln Using Fin 2nunchakuNo ratings yet

- The Air Circuit in A Rotary KilnDocument20 pagesThe Air Circuit in A Rotary KilnZia KhanNo ratings yet

- Ras Al Khaimmah Cement Company: Cyclone 1ADocument2 pagesRas Al Khaimmah Cement Company: Cyclone 1AVisnu SankarNo ratings yet

- Raw Mill Area-HamzaDocument21 pagesRaw Mill Area-HamzaAdnan rasoolNo ratings yet

- X X X X X X X X X X: KURVA D'rata-Rata Vs Fraksi MassaDocument3 pagesX X X X X X X X X X: KURVA D'rata-Rata Vs Fraksi MassaBùi Hắc HảiNo ratings yet

- Guide To Inspection & Maintenance of RCCDocument16 pagesGuide To Inspection & Maintenance of RCCRahul NampalliwarNo ratings yet

- Method Statement - Fueling SystemDocument9 pagesMethod Statement - Fueling SystemSanthosh Kumar100% (1)

- 004 Basic Reliability TheoryDocument19 pages004 Basic Reliability TheorykINGNo ratings yet

- 029 Systematic and Preventive Maintenance of Gear Units forDocument55 pages029 Systematic and Preventive Maintenance of Gear Units forkINGNo ratings yet

- 032 Maintenance of Pollution Control EquipmentDocument47 pages032 Maintenance of Pollution Control EquipmentkINGNo ratings yet

- 030 Wear Parts and Wear Resistant Material in MillsDocument36 pages030 Wear Parts and Wear Resistant Material in MillskINGNo ratings yet

- 018 Operation and Maintenance of Roller PressesDocument36 pages018 Operation and Maintenance of Roller PresseskINGNo ratings yet

- 028 Maintenance of CoolersDocument35 pages028 Maintenance of CoolerskINGNo ratings yet

- 003 the Reliability Engineering OverviewDocument13 pages003 the Reliability Engineering OverviewkINGNo ratings yet

- 033 Measurement of VibrationsDocument15 pages033 Measurement of VibrationskINGNo ratings yet

- 031 Upgrading of Existing PrecipitatorsDocument32 pages031 Upgrading of Existing PrecipitatorskINGNo ratings yet

- 014 Tyre and Roller Surfaces and How to Repair ThemDocument13 pages014 Tyre and Roller Surfaces and How to Repair ThemkINGNo ratings yet

- 016 Non-Destructive Testing and Crack RepairDocument23 pages016 Non-Destructive Testing and Crack RepairkINGNo ratings yet

- 015 Crack Formation in Kilns and Ball MillsDocument16 pages015 Crack Formation in Kilns and Ball MillskINGNo ratings yet

- Air Cooled Inverter ChillerDocument103 pagesAir Cooled Inverter ChillerkINGNo ratings yet

- 027 Corrosion Nder VariousDocument77 pages027 Corrosion Nder VariouskINGNo ratings yet

- 035 Expectations to Future Development of Systematic MaintenDocument12 pages035 Expectations to Future Development of Systematic MaintenkINGNo ratings yet

- Furnace Design and Operation: Pollutant FormationDocument61 pagesFurnace Design and Operation: Pollutant FormationkINGNo ratings yet

- CoalDocument146 pagesCoalneoomooon100% (1)

- 034 MAAG Survey and Diagnostic SystemDocument13 pages034 MAAG Survey and Diagnostic SystemkINGNo ratings yet

- Furnace design and operation: Fuel handling systemsDocument45 pagesFurnace design and operation: Fuel handling systemskINGNo ratings yet

- Furnace Design and Operation: Combustion AerodynamicsDocument58 pagesFurnace Design and Operation: Combustion AerodynamicskINGNo ratings yet

- Furnace Design and OperationDocument36 pagesFurnace Design and OperationkINGNo ratings yet

- Handbook On Coal QualityDocument64 pagesHandbook On Coal QualitykING100% (1)

- Furnace design and operation: Choosing fuelsDocument23 pagesFurnace design and operation: Choosing fuelskINGNo ratings yet

- CoalDocument146 pagesCoalneoomooon100% (1)

- Rotary Kilns-Section 4Document40 pagesRotary Kilns-Section 4kINGNo ratings yet

- Furnace Design and Operation Training CourseDocument22 pagesFurnace Design and Operation Training CoursekINGNo ratings yet

- Furnace Design and Operation: Heat Transfer FundamentalsDocument17 pagesFurnace Design and Operation: Heat Transfer FundamentalskINGNo ratings yet

- Rotary Kilns-Section 3Document32 pagesRotary Kilns-Section 3kING100% (1)

- Rotary Kilns-Section 5Document14 pagesRotary Kilns-Section 5kINGNo ratings yet

- Rotary Kilns-Section 2Document42 pagesRotary Kilns-Section 2kINGNo ratings yet

- Typical Materials Composition of A TireDocument3 pagesTypical Materials Composition of A TireSanjay KumarNo ratings yet

- Paints and CoatingsDocument28 pagesPaints and CoatingsMaximiliano MackeviciusNo ratings yet

- Characterization of Low Twist Yarn: Effect of Twist On Physical and Mechanical PropertiesDocument7 pagesCharacterization of Low Twist Yarn: Effect of Twist On Physical and Mechanical PropertiesMd. Humayun KabirNo ratings yet

- CLEANING PROCEDURES PDFDocument4 pagesCLEANING PROCEDURES PDFTanmoy PaulNo ratings yet

- Texroll Catalogo IngleseDocument24 pagesTexroll Catalogo IngleseDiego Fernando AVENDA¥O RODRIGUEZNo ratings yet

- Quiz P-1 MCQ on fuel propertiesDocument11 pagesQuiz P-1 MCQ on fuel propertiesJelore James CumlaNo ratings yet

- Paracetamol Tablet ObjectivesDocument7 pagesParacetamol Tablet ObjectivesezzaNo ratings yet

- Technical Requirements For Household Shelters (HSTR) 2017 - Updated 28 May 2018 PDFDocument177 pagesTechnical Requirements For Household Shelters (HSTR) 2017 - Updated 28 May 2018 PDFmeowo0oNo ratings yet

- Battery TerminalDocument9 pagesBattery TerminalW MoralesNo ratings yet

- Ork DCC Mas Id 001Document10 pagesOrk DCC Mas Id 001Phea RomNo ratings yet

- Wps For Aluminium WeldingDocument8 pagesWps For Aluminium WeldingMohammed MusaNo ratings yet

- Experimental Study On The Properties of Self-Curing ConcreteDocument7 pagesExperimental Study On The Properties of Self-Curing ConcreteSaurabh BhoyeNo ratings yet

- MSS SP 136 Ductile Iron Swing Check Valves 2007 PDFDocument14 pagesMSS SP 136 Ductile Iron Swing Check Valves 2007 PDFJavierfox98100% (1)

- A Study On Use of Rice Husk Ash in ConcreteDocument4 pagesA Study On Use of Rice Husk Ash in Concretedeepu kumarNo ratings yet

- Noritake Super Porcelain EX-3 IFU 202009 25 EU LanguagesDocument54 pagesNoritake Super Porcelain EX-3 IFU 202009 25 EU LanguagesDental OutletNo ratings yet

- Armstrong - Vinyl Pattern TypesDocument24 pagesArmstrong - Vinyl Pattern TypesAndy NgNo ratings yet

- Silo - Tips - Pier 1 Bored Pile Details PDFDocument11 pagesSilo - Tips - Pier 1 Bored Pile Details PDFJanno NietoNo ratings yet

- In Recent YearsDocument8 pagesIn Recent YearsShady HamdyNo ratings yet

- Smart Branch IPBDocument17 pagesSmart Branch IPBRozin AlhaqNo ratings yet

- Properties of Bituminous Binder Modified With Waste Polyethylene TerephthalateDocument12 pagesProperties of Bituminous Binder Modified With Waste Polyethylene Terephthalatezeidan111No ratings yet

- Recent Patents On EngineeringDocument67 pagesRecent Patents On EngineeringmarcomtnNo ratings yet

- TS-100 Lightweight Mechanical SealDocument2 pagesTS-100 Lightweight Mechanical Sealmantle_ukNo ratings yet

- BS en 15344-2007 (2008)Document18 pagesBS en 15344-2007 (2008)Ali AnsiNo ratings yet

- Mod 11 Book 4 Structures 2Document38 pagesMod 11 Book 4 Structures 2ranjit prasadNo ratings yet

- SynopsisDocument16 pagesSynopsisNiTiN dHiMaN0% (1)

- Wool FiberDocument35 pagesWool Fiberrehrifat2000No ratings yet

- A.Y. Dadabhai Technical Institute, Kosamba: A Project Report OnDocument26 pagesA.Y. Dadabhai Technical Institute, Kosamba: A Project Report OnrutvikNo ratings yet

- Door Specification PDFDocument6 pagesDoor Specification PDFM Z Hannan0% (1)

- Compositionial and Industrial Assessment of Isua-Akoko, Akure, Ayadi and Lafe (Ode Aye) Clay Deposits of Ondo State, NigeriaDocument9 pagesCompositionial and Industrial Assessment of Isua-Akoko, Akure, Ayadi and Lafe (Ode Aye) Clay Deposits of Ondo State, Nigeriaagbajelola idrisNo ratings yet

- Modelling of Copper Adsorption FinalDocument21 pagesModelling of Copper Adsorption FinalaadhyaNo ratings yet