Professional Documents

Culture Documents

Method Statement For Cable Jointing

Uploaded by

Jaafar LagayanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Method Statement For Cable Jointing

Uploaded by

Jaafar LagayanCopyright:

Available Formats

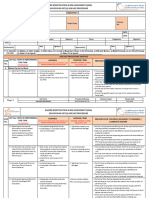

METHOD STATEMENT FOR DELTA/M/S/Cable Jointing and

PROJECT: DOC NO.:

Construction of 115/13.8kV CABLE JOINTING AND Termination-01

Al Uqair Substation A&B TERMINATION

CN#: 44000011574 REV. NO.: 00

CLIENT: NATIONAL GRID SA DATE: March 25, 2019

METHOD OF STATEMENT FOR

CABLE JOINTING AND TERMINATION

METHOD STATEMENT FOR DELTA/M/S/Cable Jointing and

PROJECT: DOC NO.:

Construction of 115/13.8kV CABLE JOINTING AND Termination-01

CN#:44000011574

Al Uqair Substation A&B TERMINATION REV. NO.: 00

CLIENT: NATIONAL GRID SA DATE: March 25, 2019

TABLE OF CONTENTS

1.0 PURPOSE ........................................................................................................................................................................ 3

2.0 SCOPE ............................................................................................................................................................................. 3

3.0 REFERENCES ................................................................................................................................................................... 3

4.0 TOOLS AND EQUIPMENT’S ............................................................................................................................................. 3

5.0 RESPONSIBILITIES OF KEY PERSONNEL .......................................................................................................................... 3

5.1. Project Manager ........................................................................................................................................................ 3

5.2. Site Manager.............................................................................................................................................................. 4

5.3. Safety Engineer .......................................................................................................................................................... 4

5.4. Safety Officer ............................................................................................................................................................. 4

5.5. QA/QC Engineer......................................................................................................................................................... 4

5.6. Site Engineer .............................................................................................................................................................. 5

5.7. Site Foreman .............................................................................................................................................................. 5

6.0 WORK PROCEDURE ........................................................................................................................................................ 5

6.1. Preparation ................................................................................................................................................................ 5

6.2. Cable Preparation ...................................................................................................................................................... 5

6.3. Cable Jointing............................................................................................................................................................. 6

6.3.1. Sliding Silicon Sleeves into Final Position ......................................................................................................... 6

6.3.2. Screen Connection and Housing ....................................................................................................................... 6

6.3.3. Fill in the compound .......................................................................................................................................... 6

7.0 SAFETY ............................................................................................................................................................................ 7

DELTA COMPANY Page 2 of 7 METHOD STATEMENT

METHOD STATEMENT FOR DELTA/M/S/Cable Jointing and

PROJECT: DOC NO.:

Construction of 115/13.8kV CABLE JOINTING AND Termination-01

CN#:44000011574

Al Uqair Substation A&B TERMINATION REV. NO.: 00

CLIENT: NATIONAL GRID SA DATE: March 25, 2019

1.0 PURPOSE

The purpose of this method statement is to make 110KV Cable jointing (1x1200sq.mm). (Inter

connecting of the single circuit)

2.0 SCOPE

This Method Statement describes the activities and performance of associated quality control

activities related to cable jointing confirming to relevant specifications, documents and local

regulations.

3.0 REFERENCES

General Specification-Cable Jointing.

4.0 TOOLS AND EQUIPMENT’S

Portable electric Hacksaw and Grinder

Hand Tool Set

Heating Mats

Alignment Rails

Propane Gas with Torch and Regulator

Adjustable jack for Cable support

Chain Block (Pulley)

Materials for jointing (Compounds, PP housing, sealing tape, shrink sleeves, cap etc...) all are

supplied from approved NG distributer (PFISTERER).

While using all equipment’s, necessary HSE plan and regulation to be adopted as per standards to

give more priority to the safety.

5.0 RESPONSIBILITIES OF KEY PERSONNEL

5.1. Project Manager

The Project manager will be responsible for the timely performance of all excavation works with

compliance with the contract drawings, project specifications and HSE plan. He must mobilize the

appropriate equipment and work force to do the job as required.

DELTA COMPANY Page 3 of 7 METHOD STATEMENT

METHOD STATEMENT FOR DELTA/M/S/Cable Jointing and

PROJECT: DOC NO.:

Construction of 115/13.8kV CABLE JOINTING AND Termination-01

CN#:44000011574

Al Uqair Substation A&B TERMINATION REV. NO.: 00

CLIENT: NATIONAL GRID SA DATE: March 25, 2019

5.2. Site Manager

The Construction will monitor the acclivities He must take note existing shortfall and problems and

discuss the same with the Project Manager. Corrective solutions must be identified and applied to

compensate for the shortfalls.

5.3. Safety Engineer

Conduct the safety induction course 10 all personnel involved in the work

monitor and supervise the risk assessment

ensure that necessary Permit lo Work is available

the method statement and risk assessment are understood and

understood, complied and applied in the worksite

ensure that all workers are provided with sufficient information regarding workplace hazards

and planned control measures

5.4. Safety Officer

Supervision of equipment handling, transportation and disposal of excavated materials

Ensure that relevant work permit is secured prior to start of work

Ensure that equipment is operational and certified

Ensure that all drivers/operators are qualified to operate the machines/ equipment

Regular inspection and maintenance of the equipment

Perform other duties as Instructed by the safety engineer

5.5. QA/QC Engineer

The QA/QC engineer will be responsible for the quality aspects of the works. He will assure that

the QA and QC plan will be implemented.

The required (RFl’s) shall be submitted to the (Client).

All required test for existing subgrade, and backfill materials must be done and that all

requirements are complied.

He will proactively coordinate with the site engineer and issue appropriate internal (Site

Instructions) when he sees that performance of works deviate from the approved.

DELTA COMPANY Page 4 of 7 METHOD STATEMENT

METHOD STATEMENT FOR DELTA/M/S/Cable Jointing and

PROJECT: DOC NO.:

Construction of 115/13.8kV CABLE JOINTING AND Termination-01

CN#: 44000011574

Al Uqair Substation A&B TERMINATION REV. NO.: 00

CLIENT: NATIONAL GRID SA DATE: March 25, 2019

5.6. Site Engineer

The Site Engineer will be in charge for the supervision and implementation of all excavation

works as required in the specifications and drawing, especially in giving orders to Site supervisors.

Site engineer is also in charge for the preparation and filing of reports.

5.7. Site Foreman

The Site Foreman will be in charge for the supervision and implementation of various excavation

works, as instructed by the Site engineer

The Site Foreman shall also keep record of all work schedules work production and daily safely

issues

6.0 WORK PROCEDURE

Work should be carried out by a certified trained and competent jointer aware of all product

requirements and safety practices.

The jointer must have learnt the correctly intended installation procedure and is responsible to

arrange the site conditions required to install.

6.1. Preparation

Check the materials are complete and suitable for the cable to be fitted on.

Check the relevant tools required for the following installation work are available on site.

Check the site conditions are adequate to provide the correct working environment for the

correct and clean fitting of the product.

6.2. Cable Preparation

Cable overlapping – Lay the cables in their final position overlapping (Using heating mats and

alignment rails, heat and straighten the cables)

Check the prepared cable insulation is not flat sided and the eccentricity is within the acceptable

limits according to the requirement.

Check the diameter of the prepared insulation is within the limits according to the appropriate

parts.

DELTA COMPANY Page 5 of 7 METHOD STATEMENT

METHOD STATEMENT FOR DELTA/M/S/Cable Jointing and

PROJECT: DOC NO.:

Construction of 115/13.8kV CABLE JOINTING AND Termination-01

CN#: 44000011574

Al Uqair Substation A&B TERMINATION REV. NO.: 00

CLIENT: NATIONAL GRID SA DATE: March 25, 2019

6.3. Cable Jointing

Marks on cables has been done according to the requirement and locate the silicone sleeve on

final positioning – Cutting and grinding should be done according to the requirement.

Using gloves apply grease inside the sleeve and over the cable and place a split bucket into the

sleeve and using mounting tool place the silicon sleeve onto cable.

Mount the (Sicon) torque control connector positioning it with a max. 2mm spacing between the

insulation shoulders on either side.

Remove carefully temporary protection and ensure associated cable and pre-molded silicone

sleeves are without damage and clean

Use cover plugs provided for (sicon) torque control connector shear bolts

6.3.1. Sliding Silicon Sleeves into Final Position

Prepare mounting equipment

Grease cable with silicon using gloves

sleeves into final position and remove tape carefully and completely

6.3.2. Screen Connection and Housing

Make the screen connection and PP Housing

Apply sealing tape in tow screen seal positions

Straighten screen wires out around circumferences of cable the silicone sleeves

Apply sealing tape on outer sheath

Bend back screen wires over shrink sleeves

Fix bonding cable connection

Ensure the incoming bonding cable are sealed against moisture at the compression sleeves as

indicated

6.3.3. Fill in the compound

Compound units Component description Level

Component A White label 1.5 KG 10 mm directly after

Component B White label 14.5 KG filling

Component A 2 Yellow stripped label 0.950 KG 10 mm directly after

Component B 2 Yellow label 9.05 KG filling

After installation sign the complete check sheet

DELTA COMPANY Page 6 of 7 METHOD STATEMENT

METHOD STATEMENT FOR DELTA/M/S/Cable Jointing and

PROJECT: DOC NO.:

Construction of 115/13.8kV CABLE JOINTING AND Termination-01

CN#: 44000011574

Al Uqair Substation A&B TERMINATION REV. NO.: 00

CLIENT: NATIONAL GRID SA DATE: March 25, 2019

7.0 SAFETY

All works shall comply with safety procedure or instruction as set in out in project Safety Plan and

Municipality rules and regulation.

Basic Personal Protective Equipment (PPE) shall be worn by all staff or labors.

All the work should be carried out under the supervision of Competent Person.

Always maintain good Housekeeping.

DELTA COMPANY Page 7 of 7 METHOD STATEMENT

You might also like

- Affidavit Waiver RightsDocument2 pagesAffidavit Waiver RightsMasa Lyn87% (47)

- Method Statement For GIS.1Document8 pagesMethod Statement For GIS.1Jaafar Lagayan100% (9)

- Method Statement For Installation of Cables, Wires & Termination - Rev02.Document27 pagesMethod Statement For Installation of Cables, Wires & Termination - Rev02.RaulSaavedra88% (8)

- Procedure For MV Cable Termination and TestingDocument8 pagesProcedure For MV Cable Termination and TestingAtlas Dammam100% (1)

- Method Statement for Protective EarthingDocument12 pagesMethod Statement for Protective EarthingPraveen Kumar50% (2)

- Cable Installation MethodDocument7 pagesCable Installation MethodAhmad Dagamseh100% (1)

- 33KV Cable Jointing and Termination MethodDocument3 pages33KV Cable Jointing and Termination Methodbutunsona60% (10)

- Electrical Method StatementDocument7 pagesElectrical Method StatementDylanNo ratings yet

- Method Statement For Light Fixtures-RevisedDocument14 pagesMethod Statement For Light Fixtures-RevisedelbaraniNo ratings yet

- Method Statement For MV Switchgear (Inspire)Document5 pagesMethod Statement For MV Switchgear (Inspire)Gajendran Sriram50% (2)

- Method Statement For Installation of Rmu: Al Naboodah Mep L.L.CDocument5 pagesMethod Statement For Installation of Rmu: Al Naboodah Mep L.L.Csujan198050% (2)

- Method of Statement and JSA For Live Line Crosssing in PXIDocument8 pagesMethod of Statement and JSA For Live Line Crosssing in PXITwin BullsNo ratings yet

- HV Cable Termination Method StatementDocument10 pagesHV Cable Termination Method StatementWalid0% (1)

- Method Statement For MDB & DB-MSBDocument10 pagesMethod Statement For MDB & DB-MSBelbaraniNo ratings yet

- Method Statement Earthing, Bonding and Lightning Protection LatestDocument11 pagesMethod Statement Earthing, Bonding and Lightning Protection Latestasombrado_jeraldNo ratings yet

- Method Statment For Earthing InstallationDocument8 pagesMethod Statment For Earthing InstallationJustin AlwarNo ratings yet

- Cable Tray InstallationDocument7 pagesCable Tray Installationareef007No ratings yet

- MOS For Electrical Conduit InstallationDocument8 pagesMOS For Electrical Conduit Installationanas BieNo ratings yet

- Testing and Commissioning Procedure For Earthing System Method StatementDocument2 pagesTesting and Commissioning Procedure For Earthing System Method StatementHumaid ShaikhNo ratings yet

- MS For Electrical InstallationDocument31 pagesMS For Electrical InstallationPatricia Jackson100% (1)

- Court Clerk Cover Letter ExamplesDocument7 pagesCourt Clerk Cover Letter Examplesafazapfjl100% (2)

- Proforma For Calculation of Income Tax For Tax DeductionDocument1 pageProforma For Calculation of Income Tax For Tax DeductionManchala Devika100% (1)

- Tri-Cities Community Bank Case Study SolutionDocument2 pagesTri-Cities Community Bank Case Study SolutionJohn Marthin ReformaNo ratings yet

- Cable Pulling and Termination Method StatementDocument8 pagesCable Pulling and Termination Method StatementMohammed NouzalNo ratings yet

- Method Statement For Installation of LV Power, Control and Low Current System Cables, Glands and AccessoriesDocument5 pagesMethod Statement For Installation of LV Power, Control and Low Current System Cables, Glands and Accessoriesmidhun muraliNo ratings yet

- Ms For MV Cable Pulling ProcedureDocument11 pagesMs For MV Cable Pulling ProcedureFaris Abandeh100% (1)

- MS For MV Cable Pulling ProcedureDocument10 pagesMS For MV Cable Pulling Procedurekbldam100% (2)

- 002-PDS-CON-007 Method Statement For FOC Installation, Splicing & TestingDocument15 pages002-PDS-CON-007 Method Statement For FOC Installation, Splicing & TestingMalik Zaman100% (1)

- Work Method Statement For Erection in Loc Start D and End CDocument8 pagesWork Method Statement For Erection in Loc Start D and End CTwin Bulls0% (1)

- Method Statement For Cable Laying 03Document8 pagesMethod Statement For Cable Laying 03paulloh64No ratings yet

- Method Statement - Earthing & Lightning ProtectionDocument9 pagesMethod Statement - Earthing & Lightning ProtectionKamal Deo Shah100% (1)

- Method statment-Underground-Cables-Laying-of-MV-LV-Street-Lighting-External-WorksDocument9 pagesMethod statment-Underground-Cables-Laying-of-MV-LV-Street-Lighting-External-WorksUET MAIN100% (1)

- Method Statement For Testing CommissioningDocument6 pagesMethod Statement For Testing CommissioningsameershahzanNo ratings yet

- Method Statement - Exterior Lighting Fixtures InstallationDocument7 pagesMethod Statement - Exterior Lighting Fixtures Installationisrar50% (2)

- Install 33KV Power Transformer MethodDocument7 pagesInstall 33KV Power Transformer MethodBabu50% (2)

- CCTV Method Statement Final Rev-01 PDFDocument33 pagesCCTV Method Statement Final Rev-01 PDFabdul wasay100% (1)

- Method Statement For Cable Conduit & Tray Installation PDFDocument5 pagesMethod Statement For Cable Conduit & Tray Installation PDFUtku Can Kılıç100% (1)

- BEW - Method Statement For Electrical Conduiting in Concealed WallDocument9 pagesBEW - Method Statement For Electrical Conduiting in Concealed WallArun UdayabhanuNo ratings yet

- Checklist For Cable Try Fabrication and EractionDocument2 pagesChecklist For Cable Try Fabrication and Eractionnayum100% (1)

- Al Karamah School LV Panel ReplacementDocument35 pagesAl Karamah School LV Panel ReplacementAnandu AshokanNo ratings yet

- Method Statement For Transmission Line Lanco PDFDocument37 pagesMethod Statement For Transmission Line Lanco PDFAmar WadoodNo ratings yet

- Statement For CCTV System Testing & CommissioningDocument9 pagesStatement For CCTV System Testing & CommissioningAnonymousNo ratings yet

- Install Wiring & LightingDocument17 pagesInstall Wiring & LightingSyed AtherNo ratings yet

- Work Method Statement For X-A T#31 To 34Document8 pagesWork Method Statement For X-A T#31 To 34Twin Bulls100% (1)

- ITP For MV Power Cables & Accessories InstallationDocument1 pageITP For MV Power Cables & Accessories InstallationAdil HasanovNo ratings yet

- KP-00+++-MQ758-V0008-Rev 1-METHOD OF STATEMENT FOR HV SUBSTATION BUSBAR INSTALLATION WORKSDocument21 pagesKP-00+++-MQ758-V0008-Rev 1-METHOD OF STATEMENT FOR HV SUBSTATION BUSBAR INSTALLATION WORKSUtku Can KılıçNo ratings yet

- Method of Statement For Conduit InstallationDocument15 pagesMethod of Statement For Conduit InstallationMohd MuksinNo ratings yet

- Earthing Method StatementDocument5 pagesEarthing Method StatementMuhammad Saqib AsifNo ratings yet

- MoS For Cable Pulling and Termination WorksDocument11 pagesMoS For Cable Pulling and Termination Worksanhtuan206No ratings yet

- QC-143 R2 Distribution Panel ChecklistDocument1 pageQC-143 R2 Distribution Panel ChecklistCamilo Jorquera100% (1)

- Ups Installation Method StatementDocument197 pagesUps Installation Method StatementehteshamNo ratings yet

- Method StatementDocument5 pagesMethod StatementRavikant Pandey100% (2)

- Method of Statement-13.8KVDocument57 pagesMethod of Statement-13.8KVzaheerNo ratings yet

- MV Cable Pulling and Installation Method StatementDocument8 pagesMV Cable Pulling and Installation Method StatementArshad Akhtar KhanNo ratings yet

- MOS ELectrical Sub StationDocument10 pagesMOS ELectrical Sub Stationecstacy7No ratings yet

- Method Statement-MV Cable (132) Laying & TerminationDocument9 pagesMethod Statement-MV Cable (132) Laying & TerminationSriram VNo ratings yet

- Method Statement For The Installation of TransformerDocument11 pagesMethod Statement For The Installation of TransformerShaikh Ahamed100% (1)

- Cable Pulling Method StatementDocument11 pagesCable Pulling Method StatementJaafar LagayanNo ratings yet

- Method Statement For Asphalt Work-1Document7 pagesMethod Statement For Asphalt Work-1Jaafar LagayanNo ratings yet

- 20SWCG00051 1 100 0000le Ie0 MS 001007 - 00aDocument14 pages20SWCG00051 1 100 0000le Ie0 MS 001007 - 00afayaz5233No ratings yet

- Wi-Trd-48 Balance Pipe ReplacementDocument13 pagesWi-Trd-48 Balance Pipe ReplacementKiana Raine VillanNo ratings yet

- Method StatementsDocument61 pagesMethod StatementssathishNo ratings yet

- SE-HIO-4AEL-MST-0014 Testing and Commissioning of Wires and Single Core CableDocument11 pagesSE-HIO-4AEL-MST-0014 Testing and Commissioning of Wires and Single Core Cablevishwas salunkheNo ratings yet

- WMS Installation of HV & MV CablesDocument8 pagesWMS Installation of HV & MV CablesLeoj Saliw-an Palaoag100% (1)

- JSP For OHTL No. 19 Excavation Works For Tower Foundation Pad and ChimneyDocument10 pagesJSP For OHTL No. 19 Excavation Works For Tower Foundation Pad and ChimneyJaafar LagayanNo ratings yet

- JSP For SS No. 5 Tower Crane InstallationDocument15 pagesJSP For SS No. 5 Tower Crane InstallationmohammedtofiqahmedNo ratings yet

- JSP For SS No. 6 Loading and Installation of Panel Board (Manual Lifting)Document16 pagesJSP For SS No. 6 Loading and Installation of Panel Board (Manual Lifting)mohammedtofiqahmedNo ratings yet

- JSP For OHTL No. 17 Underline Gantry Installation and ErectionDocument15 pagesJSP For OHTL No. 17 Underline Gantry Installation and ErectionJaafar LagayanNo ratings yet

- JSP For OHTL No. 16 Erection of Upper Body StructureDocument14 pagesJSP For OHTL No. 16 Erection of Upper Body StructureJaafar LagayanNo ratings yet

- MS Cable Tray and Conduit InstallationDocument13 pagesMS Cable Tray and Conduit InstallationJaafar LagayanNo ratings yet

- Method Statement For Asphalt Work-1Document7 pagesMethod Statement For Asphalt Work-1Jaafar LagayanNo ratings yet

- Cable Pulling Method StatementDocument11 pagesCable Pulling Method StatementJaafar LagayanNo ratings yet

- MS 110 DC Battery Charger UPSDocument10 pagesMS 110 DC Battery Charger UPSJaafar LagayanNo ratings yet

- Method Statement For Asphalt Work-1Document7 pagesMethod Statement For Asphalt Work-1Jaafar LagayanNo ratings yet

- Bank Company ActDocument16 pagesBank Company Actmd nazirul islam100% (2)

- Essay 3Document2 pagesEssay 3Rinna Trisha V. QuilinoNo ratings yet

- Epc Contracts Process Plant SectorDocument30 pagesEpc Contracts Process Plant Sectorlimpama100% (2)

- Persuasive EssayDocument4 pagesPersuasive Essayapi-338650494100% (7)

- Abc Ved 1227686577805956 8Document21 pagesAbc Ved 1227686577805956 8Sathiya Soruban ElangovanNo ratings yet

- Comparison Among Languages: C. Cappa, J. Fernando, S. GiuliviDocument62 pagesComparison Among Languages: C. Cappa, J. Fernando, S. GiuliviSaoodNo ratings yet

- (1 To 31) Details MCQDocument197 pages(1 To 31) Details MCQHidden VoicesNo ratings yet

- Chapter 02 - CONCEPTUAL FRAMEWORK: Objective of Financial ReportingDocument6 pagesChapter 02 - CONCEPTUAL FRAMEWORK: Objective of Financial ReportingKimberly Claire AtienzaNo ratings yet

- As 1085.12-2002 Railway Track Material Insulated Joint AssembliesDocument7 pagesAs 1085.12-2002 Railway Track Material Insulated Joint AssembliesSAI Global - APAC100% (1)

- Ethical Considerations: Why Is Ethics The Focus of A Lead Chapter in This Book?Document17 pagesEthical Considerations: Why Is Ethics The Focus of A Lead Chapter in This Book?ibrahim haniNo ratings yet

- MPU22012 ENTREPRENEURSHIP REPORT SLIDE (Autosaved)Document20 pagesMPU22012 ENTREPRENEURSHIP REPORT SLIDE (Autosaved)Errra UgunNo ratings yet

- KCSE History Marking SchemeDocument61 pagesKCSE History Marking SchemeDavid Musila ToywaNo ratings yet

- Jadpel PTM Ganjil 2021-22 Per 30 Agustus 2021Document9 pagesJadpel PTM Ganjil 2021-22 Per 30 Agustus 2021Siti MardyahNo ratings yet

- Ecole Barrie Wilson NewsletterDocument2 pagesEcole Barrie Wilson Newsletterapi-315249760No ratings yet

- Central Excise Vizag08022021Document35 pagesCentral Excise Vizag08022021do or dieNo ratings yet

- Chapter 6 Verification of Assets and Liabilities PM PDFDocument60 pagesChapter 6 Verification of Assets and Liabilities PM PDFVyankatrao NarwadeNo ratings yet

- All Grown Up - BareDocument9 pagesAll Grown Up - BareNiamh HawkesNo ratings yet

- Laws Affecting Nursing PracticeDocument65 pagesLaws Affecting Nursing PracticeDave MismanNo ratings yet

- Nord Pool - The Nordic Power MarketDocument30 pagesNord Pool - The Nordic Power MarketVanádio Yakovlev FaindaNo ratings yet

- ICAR IARI 2021 Technician T1 Recruitment NotificationDocument38 pagesICAR IARI 2021 Technician T1 Recruitment NotificationJonee SainiNo ratings yet

- SAP Certified FICO Consultant ResumeDocument12 pagesSAP Certified FICO Consultant Resumeஆக்ஞா கிருஷ்ணா ஷர்மாNo ratings yet

- The PARC StoryDocument59 pagesThe PARC StoryRio AlmenaNo ratings yet

- Security Valuations - Stocks EZDocument9 pagesSecurity Valuations - Stocks EZAakash RegmiNo ratings yet

- Shaking Hands With Other Peoples PainDocument19 pagesShaking Hands With Other Peoples PainGimonjoNo ratings yet

- Hospicio CaseDocument19 pagesHospicio CaseCserah Marl EnanoNo ratings yet

- How To Use The CS-MMEL Method For Passenger Reduction Calculation With One Exit Inoperative Under Mmel?Document7 pagesHow To Use The CS-MMEL Method For Passenger Reduction Calculation With One Exit Inoperative Under Mmel?Syed Zeeshan UddinNo ratings yet