Professional Documents

Culture Documents

Sherq Incident Investigation Report: Site/Power Station

Uploaded by

WwOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sherq Incident Investigation Report: Site/Power Station

Uploaded by

WwCopyright:

Available Formats

Document No.

IMSP -10/03

Revision No. 00

Section INTEGRATED MANAGEMENT SYSTEM Effective Date 01/08/2017

Subject SHERQ INCIDENT INVETSIGATION REPORT Page No. Page 1 of 7

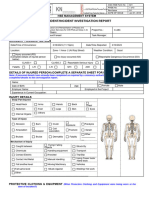

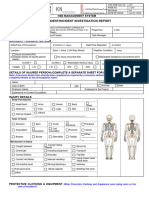

SHERQ INCIDENT INVESTIGATION REPORT

SITE/POWER STATION: MUNYATI POWER STATION

DEPARTMENT: MMD

CLASSIFICATION:

DATE OF INCIDENT: 17 JUNE 2019

DATE OF INVESTIGATION: 5 JULY 2019

Distribution List:

Managing Director

ZPC Exco

Technical Compliance Manager

Power Plant Manager

Section Heads

Departmental Forepersons

Risk and Quality Practitioners

Printed copies, unless control stamped in red on front page, is only valid on date printed. On later date, users must verify latest revision.

Revision 00 Date printed:2021/10/01 Page 1 of 7

1. INCIDENT SUMMARY

1.1 Details of Involved/Injured Persons

Name: Tinashe Manga

EC number:

Age:

Gender: Male

Dept./Sect MMD

Occupation: Attaché

Witnesses: N/A

Supervisor in Charge: Zenasi

1.2 Incident Details

Date of incident: 17 June 2019

Time of incident: 10:00

Place of incident: Boiler House

Activity Undertaken: Maintenance of the alarm chamber

Nature: Coal particles fell into his left eye

Date of Report 18 June 2019

1.3 Incident Description

T Manga was working on boiler 8 alarm chamber with artisan A Akimu. At around 10:00 Manga

was instructed to go and collect pieceas of mutton clothes for cleaning as they were working

on a dusty area. He disembarked the stairs using the right hand side of the boiler. The

employee proceeded to the firing floor and he then decided to check the readings on the final

steam pressure gauges as a routine to their work, as he looked up to check the pressures on

the gauges a coal particle fell into hi9s left eyes . Manga immediately went to the nearby tap

and splashed tap water into the eye and proceeded back to work without any difficulties and

hence he did not inform his workmates of the incident. The following morning on waking up he

felt an irritation in the eye, he then reported for duty and requested for permission to go to the

clinic from the foreperson. He went to the clinic and was assessed with the RGN. The nurse

identified a foreign body in the eye, The eye was bandaged and Manga was referred to Stanley

House Kwekwe to see the doctor. Upon arrival at Stanley House the doctor removed the

bandage and the particle was no longer in the eye but instead they spotted it on the bandage,

he was told to go back to work.

2. INVESTIGATION DETAILS

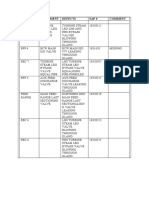

2.1 INVESTIGATION TEAM

Name Title Signature

Printed copies, unless control stamped in red on front page, is only valid on date printed. On later date, users must verify latest revision.

Revision 00 Date printed:2021/10/01 Page 1 of 7

M Kwenda SHO

J Miranzi EMD Artisan

K Mpaya GT Maintenance

A Makaza Sherqc Rep Attachee

T Chiutanyi Lab Attachee

2.2 INVESTIGATION TIME (MANHOURS): 1hr 15minutes.

2.3 STATEMENTS TAKEN BY:

Name Title

A Makaza SHERQC ATTACHEE

3. INCIDENT CLASSIFICATION

3.1. DAMAGE INCIDENT

Damage/Incident classification Major Minor X Near Miss

Nature of damage (Describe extent of damage):

Laceration and haematoma formation on the middle finger of the left hand.

3.2 ENVIRONMENTAL INCIDENT

Env Incident Classification Level 3 Level 2 Level 1 Complaint

Nature of Environmental impact (Describe ):

N/A

4. BACKGROUND TO THE INCIDENT

The injured was tasked to collect cotton waste cloth from the boiler storeroom.

Manga disembarked the stairs and as he was now walking on the firing floor he decided to check

the gauge class reading as a routine of their work

Upon checking the readings coal particles fell into his left eye..

The cotton waste was used for cleaning and dusting as they were working on a dusty area

The employee did not conduct a pre-task risk assessment as evidenced by subsequent failure to

detect the dangers of checking the gauge class without goggles.

He did not report the injury as he just splashed water in the eye and he continued with his duties

without any difficulties

Printed copies, unless control stamped in red on front page, is only valid on date printed. On later date, users must verify latest revision.

Revision 00 Date printed:2021/10/01 Page 2 of 7

He work up the following day with an irritation in the eye and he reported for duty, he then

requested to visit the clinic and was referred to Stanley House

SUMMARY OF FINDINGS

The Investigation committee went on to review the following document which correlate the purported job

1. MMD G87 for the day of the incident (attached Appendix 1)

2. Work order for the job (attached Appendix 2)

3. Pre-task risk assessment form (missing)

The G87 showed that there was work planned for boiler 8 alarm chamber but however the work delayed to

commence to the 22nd of June and yet the incident occurred on the 17 th of June.

It further shows that T Manga was not part of the work as his name does not appear on the work order.

The risk assessment form is missing. If checking of the pressure gauge was part of the job as purported ,a

risk of falling particles was supposed to be noted and a mitigation action of ensuring that one is wearing

goggles and a hard hat had to be put in place

.However from the findings it can be deduced that T Manga was not part of the job but the incident occurred

due to a coal particle falling into his eye

The actual sequence of events before the occurrence of the incident cannot br therefore established from

above

5. INCIDENT ANALYSES

6.1 INCIDENT COSTS

Medical & compensation $27.00 Generation Loss $

Labour rent/replacement $ Fines $

Investigation cost $ Others: $

Equipment Replacement/renting $ Total incident costs: $27.00

6.2 DIRECT CAUSES OF THE INCIDENT

Substandard Practices/Unsafe Act Substandard Conditions/Unsafe conditions

Inadequate Risk Assessment. Manual handling.

Lone working.

6.3 BASIC CAUSES

Personal Factors Job Factors

At risk behaviour by the injured as he did not Perforations on coal chutes which causes

follow standard procedure of pre-task risk random falling of particles.

assessment by:

o Not wearing proper gear to the tasked

job i.e. goggles

Printed copies, unless control stamped in red on front page, is only valid on date printed. On later date, users must verify latest revision.

Revision 00 Date printed:2021/10/01 Page 3 of 7

6.4 PREVENTATIVE ACTION RECOMMENDED

Addressing Personal Factors Addressing Job Factors

Employee need to be reprimanded by Providing an accessible and suitably constructed

line management for at risk behaviour. facility for checking the readings other than looking

Line supervisors need to check systems upwards..

for safety and compliance to attaches. Maintaining of coal chutes to avoid falling of coal..

Line supervisors need to be actively involved in

ensuring safe work methods are being used.

6.5 CONCLUSIONS

Immediate Cause:

Not wearing proper PPE

Basic Cause:

Failure to do pre-task risk assessment

Contributing factors:

Perforations of coal chutes which causes random falling of coal particles.

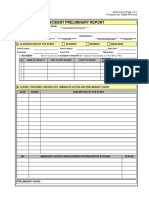

6. CORRECTIVE ACTION PLAN

No Action Responsibility Target Completion Signature

Date date at Closure

1 Maintaining of coal chutes to avoid random SEM

falling of coal

2 To establish a proper way of checking the SEM

gauge class reading and avoid looking

upwards.

7. INCIDENT REPORT APPROVAL

Shift Charge Zenasi Signature Date

Printed copies, unless control stamped in red on front page, is only valid on date printed. On later date, users must verify latest revision.

Revision 00 Date printed:2021/10/01 Page 4 of 7

SHEQ practitioner

E Ndanga Signature Date

(Risk Engineer)

Section Head F Sabvukutwa Signature Date

Power Plant Manager L K Shumba Signature Date

8. EVALUATION OF EFFECTIVENESS OF CORRECTIVE ACTIONS

9.1 Comments by the Assessor

Incident

Name Signature Date

Assessor

9.2 Closure of incident

I _______________________________ am satisfied that the corrective action plan as

(Sectional Head)

described has been fully implemented and has proven effective on controlling the associated risks,

and as far as practicable will prevent the occurrence / recurrence of undesirable events.

Signature:______________________ Date:________________

Printed copies, unless control stamped in red on front page, is only valid on date printed. On later date, users must verify latest revision.

Revision 00 Date printed:2021/10/01 Page 5 of 7

You might also like

- 01 Incident Investigation Report FORM HSE-IIPDocument2 pages01 Incident Investigation Report FORM HSE-IIPHSE S4No ratings yet

- HSE-RA-029 Straight and Cut Operation - Rev 0Document8 pagesHSE-RA-029 Straight and Cut Operation - Rev 0عمروNo ratings yet

- Investigation ReportDocument10 pagesInvestigation Reportloveson glariyansNo ratings yet

- Daily Observation Report: Health, Safety & EnvironmentDocument3 pagesDaily Observation Report: Health, Safety & EnvironmentFrancis Enriquez TanNo ratings yet

- 2021.10.2 - Ddab-Hse-Dor-Contraco - JJJDocument3 pages2021.10.2 - Ddab-Hse-Dor-Contraco - JJJFrancis Enriquez TanNo ratings yet

- Accident Incident Report (Promat)Document2 pagesAccident Incident Report (Promat)jonesNo ratings yet

- Accident Incident Report (TLS)Document2 pagesAccident Incident Report (TLS)jonesNo ratings yet

- Incident Detail Report HSE-Incident-04-2021Document6 pagesIncident Detail Report HSE-Incident-04-2021fasilNo ratings yet

- 20160323110112-Sae 1215Document1 page20160323110112-Sae 1215awesome_600No ratings yet

- KHK ACCIDENT-INCIDENT INVESTIGATION REPORT - Mr. Mohammad JawedDocument3 pagesKHK ACCIDENT-INCIDENT INVESTIGATION REPORT - Mr. Mohammad JawedAfsal KabeerNo ratings yet

- HSE-RA-008 Scaffold Erection and Dismantling - Rev 0Document20 pagesHSE-RA-008 Scaffold Erection and Dismantling - Rev 0عمرو100% (1)

- 2021-10-02 - Ddab-Hse-Dor-Contraco - RBLDocument3 pages2021-10-02 - Ddab-Hse-Dor-Contraco - RBLFrancis Enriquez TanNo ratings yet

- Incident & Accident ReportDocument7 pagesIncident & Accident ReportleganzaNo ratings yet

- Robots Part Two, The Illusion of Life (Week Three)Document34 pagesRobots Part Two, The Illusion of Life (Week Three)Vitor MacedoNo ratings yet

- Accident Incident Report (TLS)Document2 pagesAccident Incident Report (TLS)jonesNo ratings yet

- ACCIDENT INCIDENT REPORT (Al Omran)Document2 pagesACCIDENT INCIDENT REPORT (Al Omran)jonesNo ratings yet

- 14-08-2020 - 2200 Hrs - LS 4G1 - DO - Fire Fighting PVC Pipe - DraftDocument12 pages14-08-2020 - 2200 Hrs - LS 4G1 - DO - Fire Fighting PVC Pipe - DraftJohn Vincent Macatangay CleofeNo ratings yet

- CE Technical File - Medlink IIR Face MaskDocument133 pagesCE Technical File - Medlink IIR Face MaskRicha Rohilla100% (2)

- Incident / Injury Occurrence Report Part BDocument2 pagesIncident / Injury Occurrence Report Part BHamzaNoumanNo ratings yet

- Spying From Space - Constructing America's Satellite Command and Control Systems (PDFDrive)Document230 pagesSpying From Space - Constructing America's Satellite Command and Control Systems (PDFDrive)MohammadNo ratings yet

- 2021 - 10 - 04 - Ddab-Hse-Dor-Contraco - JJJDocument3 pages2021 - 10 - 04 - Ddab-Hse-Dor-Contraco - JJJFrancis Enriquez TanNo ratings yet

- Occupational Therapy Examination Review Guide 4th Edition Ebook PDFDocument57 pagesOccupational Therapy Examination Review Guide 4th Edition Ebook PDFrobert.campbell485No ratings yet

- Incident Investigation Report: For Personal Damage, Environmental Harm & Near MissesDocument10 pagesIncident Investigation Report: For Personal Damage, Environmental Harm & Near MissesMiracle DavidNo ratings yet

- HSE-RA-021 Blockwork - Rev 0Document10 pagesHSE-RA-021 Blockwork - Rev 0عمروNo ratings yet

- Philosophical Thoughts On EducationDocument30 pagesPhilosophical Thoughts On EducationCharyl Louise MonderondoNo ratings yet

- Steam TableDocument3 pagesSteam TableMUHAMAD SAUKINo ratings yet

- Near Miss 02.09.17 SCGDocument3 pagesNear Miss 02.09.17 SCGHolly SmithNo ratings yet

- Assignment 2 Grammar Lesson PlanDocument26 pagesAssignment 2 Grammar Lesson PlanKesia Kerspay100% (1)

- Centralized PurchasingDocument2 pagesCentralized PurchasingbiyyamobulreddyNo ratings yet

- FIB-AL-21 Incident Report - Crane HookDocument4 pagesFIB-AL-21 Incident Report - Crane HookaqibNo ratings yet

- FRM-SLC-001 Safety Incident ReportDocument3 pagesFRM-SLC-001 Safety Incident ReportJNo ratings yet

- IMSP 10 - 01 Flash Report-Communication of IncidentDocument2 pagesIMSP 10 - 01 Flash Report-Communication of IncidentMichael RujuwaNo ratings yet

- Incident/Accident Report: Details of Person Making This Report: Insident#EP05082019Document2 pagesIncident/Accident Report: Details of Person Making This Report: Insident#EP05082019jonesNo ratings yet

- FIB-AL-NOY-01-Damage ReportDocument5 pagesFIB-AL-NOY-01-Damage ReportAhsanNo ratings yet

- Melaksanakan InvestigasiDocument6 pagesMelaksanakan InvestigasiRishamdi HSENo ratings yet

- Accident/Incident Report: Health, Safety and Environmental PlanDocument2 pagesAccident/Incident Report: Health, Safety and Environmental PlanjonesNo ratings yet

- WENGI 2 Jun 14th 2021 Incident ReportDocument3 pagesWENGI 2 Jun 14th 2021 Incident ReportABY fernandezNo ratings yet

- Incident Investigation ReportDocument4 pagesIncident Investigation ReportZohaib TahirNo ratings yet

- Incident Investigation ReportDocument4 pagesIncident Investigation ReportZohaib TahirNo ratings yet

- ACCIDENT INCIDENT REPORT (Decagon)Document2 pagesACCIDENT INCIDENT REPORT (Decagon)jonesNo ratings yet

- Accident/Incident Report: Health, Safety and Environmental PlanDocument2 pagesAccident/Incident Report: Health, Safety and Environmental PlanjonesNo ratings yet

- CAS1969-2G00-01-124-008 Final Investigation Report FormDocument3 pagesCAS1969-2G00-01-124-008 Final Investigation Report Formlab cncNo ratings yet

- Accident/Incident Report: Health, Safety and Environmental PlanDocument2 pagesAccident/Incident Report: Health, Safety and Environmental PlanjonesNo ratings yet

- Incident Alert 001 - Incidente Operacional - Mina Islay - Ecosem HuaychaoDocument3 pagesIncident Alert 001 - Incidente Operacional - Mina Islay - Ecosem HuaychaoSEGURIDAD ECOSEM HNo ratings yet

- KAFD Programmed Abnormal Event Report FormDocument4 pagesKAFD Programmed Abnormal Event Report Formfaisal nadeemNo ratings yet

- ACCIDENT INCIDENT REPORT (Al Omran)Document2 pagesACCIDENT INCIDENT REPORT (Al Omran)jonesNo ratings yet

- ACCIDENT INCIDENT REPORT (Al Omran)Document2 pagesACCIDENT INCIDENT REPORT (Al Omran)jonesNo ratings yet

- ACCIDENT INCIDENT REPORT (Al Omran)Document2 pagesACCIDENT INCIDENT REPORT (Al Omran)jonesNo ratings yet

- Incident Notification Report - SAG3 - Personal Injury - Edi Widodo Laceration Right Pinky Finger 15 Jun 23Document3 pagesIncident Notification Report - SAG3 - Personal Injury - Edi Widodo Laceration Right Pinky Finger 15 Jun 23Muhammad Fachrizal SyarifNo ratings yet

- Capa Tarlac Files Unsafe ActDocument1 pageCapa Tarlac Files Unsafe ActJulzNo ratings yet

- UOI-F-SHE-028 Form Laporan Investigasi Insiden 12.2Document5 pagesUOI-F-SHE-028 Form Laporan Investigasi Insiden 12.2herlin cahyakusumaNo ratings yet

- Accident/Incident Report: Health, Safety and Environmental PlanDocument2 pagesAccident/Incident Report: Health, Safety and Environmental PlanjonesNo ratings yet

- INC 61251+ +Investigation+ReportDocument2 pagesINC 61251+ +Investigation+Reportvinay kumarNo ratings yet

- ACCIDENT INCIDENT REPORT (Silver Line)Document2 pagesACCIDENT INCIDENT REPORT (Silver Line)jonesNo ratings yet

- ACCIDENT INCIDENT REPORT (Silver Line)Document2 pagesACCIDENT INCIDENT REPORT (Silver Line)jonesNo ratings yet

- Rapports NMDocument7 pagesRapports NMMehdi MessNo ratings yet

- Health and Safety Solutions Accident Investigation FormDocument2 pagesHealth and Safety Solutions Accident Investigation Formhussein aliNo ratings yet

- 18-Report Preliminary Incident 27th Oct 2015 MRDocument2 pages18-Report Preliminary Incident 27th Oct 2015 MRapi-412713219No ratings yet

- Incedent ReportDocument5 pagesIncedent ReportprasadprasildaNo ratings yet

- BION-HSE-20-000-Iaccident Investigation ReportDocument16 pagesBION-HSE-20-000-Iaccident Investigation ReportSyed AhmadNo ratings yet

- 2021.10.02 - Ddab-Hse-Dor-Contraco - RFMDocument2 pages2021.10.02 - Ddab-Hse-Dor-Contraco - RFMFrancis Enriquez TanNo ratings yet

- FORM 10 - Government Safety Engineer's Accident Investigation ReportDocument1 pageFORM 10 - Government Safety Engineer's Accident Investigation ReportTomas del RosarioNo ratings yet

- Final Incident: INFORMASI KECELAKAAN: (Berilah Tanda X' Pada Jenis Kecelakaan Yang Memenuhi Kriteria Dibawah Ini)Document3 pagesFinal Incident: INFORMASI KECELAKAAN: (Berilah Tanda X' Pada Jenis Kecelakaan Yang Memenuhi Kriteria Dibawah Ini)Muhammad JayadhiNo ratings yet

- Risk Assessment For Scaffold DismentalDocument6 pagesRisk Assessment For Scaffold DismentalTayyab AliNo ratings yet

- Incident Alert - Daño Al Cobertor de Vehiculo ParticularDocument3 pagesIncident Alert - Daño Al Cobertor de Vehiculo ParticularJeff RobertNo ratings yet

- Incident Preliminary Report: Attachment 2 Page 1 of 1 Procedure No. F2820-P0019-03Document1 pageIncident Preliminary Report: Attachment 2 Page 1 of 1 Procedure No. F2820-P0019-03HSE HerygintingNo ratings yet

- Preliminary Incident Report Sudin Samsudin Senin-28 December 2015Document2 pagesPreliminary Incident Report Sudin Samsudin Senin-28 December 2015api-412713219No ratings yet

- Research Methods IME 101 SyllabusDocument1 pageResearch Methods IME 101 SyllabusWwNo ratings yet

- Mostly Asked Questions in Interview With Thermal Power PlantDocument43 pagesMostly Asked Questions in Interview With Thermal Power PlantWwNo ratings yet

- Training Program Operations 2015 2016Document8 pagesTraining Program Operations 2015 2016WwNo ratings yet

- Research Methods AssignmentsDocument1 pageResearch Methods AssignmentsWwNo ratings yet

- Innovation Mgt2Document7 pagesInnovation Mgt2WwNo ratings yet

- Boiler Assessment Questions: Munyati Power StationDocument2 pagesBoiler Assessment Questions: Munyati Power StationWwNo ratings yet

- Emotional IntelDocument1 pageEmotional IntelWwNo ratings yet

- Munyati Power Station Control RoomDocument1 pageMunyati Power Station Control RoomWwNo ratings yet

- Id No. 53-081725 B29: Curriculum Vitae For Wayne Miles MoyoDocument1 pageId No. 53-081725 B29: Curriculum Vitae For Wayne Miles MoyoWwNo ratings yet

- 49 - Improve Steam Turbine Efficiency by Use of Reheat Rankine Cycle PDFDocument8 pages49 - Improve Steam Turbine Efficiency by Use of Reheat Rankine Cycle PDFSiddhant SatpathyNo ratings yet

- ZPC Munyati Power Station Boiler Combustion As at 9:00 06/12/18Document2 pagesZPC Munyati Power Station Boiler Combustion As at 9:00 06/12/18WwNo ratings yet

- Equipment Defects Sap # CommentDocument1 pageEquipment Defects Sap # CommentWwNo ratings yet

- Assessment (CUFE 481)Document8 pagesAssessment (CUFE 481)WwNo ratings yet

- Avon December 2020 BrochureDocument219 pagesAvon December 2020 BrochureWwNo ratings yet

- Business Stats Exam 7Document11 pagesBusiness Stats Exam 7WwNo ratings yet

- Digestive Care Package AdvancedDocument22 pagesDigestive Care Package AdvancedWwNo ratings yet

- Workers EC ADDRESSDocument3 pagesWorkers EC ADDRESSWwNo ratings yet

- RegulationsDocument9 pagesRegulationsWwNo ratings yet

- To: At: Munyati Power Station: Integrated Management SystemDocument1 pageTo: At: Munyati Power Station: Integrated Management SystemWwNo ratings yet

- Hierarchy of Company MeetingsDocument3 pagesHierarchy of Company MeetingsWwNo ratings yet

- Minutes For General Meeting - CorrectedDocument13 pagesMinutes For General Meeting - CorrectedWwNo ratings yet

- Detox Care Package Advanced 20190727Document29 pagesDetox Care Package Advanced 20190727WwNo ratings yet

- Make Up Creativ-WPS OfficeDocument1 pageMake Up Creativ-WPS OfficeWwNo ratings yet

- Brain Care Package Advanced 20170904Document16 pagesBrain Care Package Advanced 20170904WwNo ratings yet

- Bone and Joint Care Package With Notes 20180131Document19 pagesBone and Joint Care Package With Notes 20180131WwNo ratings yet

- Make Up Creativ-WPS OfficeDocument1 pageMake Up Creativ-WPS OfficeWwNo ratings yet

- Ut 621024Document14 pagesUt 621024DarleiDuarteNo ratings yet

- Mech Syllabus R-2017 - 1Document110 pagesMech Syllabus R-2017 - 1goujjNo ratings yet

- SOL-Logarithm, Surds and IndicesDocument12 pagesSOL-Logarithm, Surds and Indicesdevli falduNo ratings yet

- Capital Budgeting and Capital Budgeting and Risk Analysis Risk AnalysisDocument16 pagesCapital Budgeting and Capital Budgeting and Risk Analysis Risk AnalysisHaris FendiarNo ratings yet

- Chapter 6 SBLDocument4 pagesChapter 6 SBLbrave manNo ratings yet

- Motion in One Dimension QuestionDocument6 pagesMotion in One Dimension Questionabh_omega33% (3)

- Critique of Violence - Walter BenjaminDocument14 pagesCritique of Violence - Walter BenjaminKazım AteşNo ratings yet

- World Link YolaDocument3 pagesWorld Link YolaHamilton Obando100% (1)

- 1.rle Rubrics For Case PresentationDocument2 pages1.rle Rubrics For Case PresentationKhristine EstosoNo ratings yet

- MHSS ItalyDocument9 pagesMHSS Italyromedic36No ratings yet

- IPE SakibBhaiMagicChothaDocument55 pagesIPE SakibBhaiMagicChothaTousif SadmanNo ratings yet

- LogDocument67 pagesLogRudhi Al GhaisanNo ratings yet

- Pile Capacity - An Overview - ScienceDirect TopicsDocument15 pagesPile Capacity - An Overview - ScienceDirect TopicssurNo ratings yet

- VSR Trans. PPT3Document16 pagesVSR Trans. PPT3VSR TRANSNo ratings yet

- CHAPTER 2 - ALGEBRA (Latest)Document41 pagesCHAPTER 2 - ALGEBRA (Latest)FirdausNo ratings yet

- Q1 Practical Research 2 - Module 1bDocument15 pagesQ1 Practical Research 2 - Module 1bRhea Mae MacabodbodNo ratings yet

- Evolis User ManualDocument28 pagesEvolis User ManualIonmadalin1000No ratings yet

- Systematic Literature Review SvenskaDocument6 pagesSystematic Literature Review Svenskafihum1hadej2100% (1)

- Python - Data EngineeringDocument34 pagesPython - Data EngineeringChetan PatilNo ratings yet

- Mecanica MD - AZG-UDocument29 pagesMecanica MD - AZG-UStefanoViganóNo ratings yet

- Studi Tentang Pelayanan Terhadap Kapal Perikanan Di Pelabuhan Perikanan Pantai (PPP) Tumumpa Kota ManadoDocument9 pagesStudi Tentang Pelayanan Terhadap Kapal Perikanan Di Pelabuhan Perikanan Pantai (PPP) Tumumpa Kota ManadoAri WibowoNo ratings yet

- Alignment Technique - The Steam TurbineDocument2 pagesAlignment Technique - The Steam TurbineRajeswar KulanjiNo ratings yet