Professional Documents

Culture Documents

Ppe / Systems /standards / Procedures Required To Do The Job

Uploaded by

kallel mohamed0 ratings0% found this document useful (0 votes)

4 views1 pageThis Job Safety Analysis document summarizes the potential hazards and recommended safety precautions for accessing a work location. The sequence of basic job steps includes accessing personnel which could lead to slips, trips and falls, body injuries, loss of property, or collisions between vehicles. Recommendations are made to use qualified and inducted personnel, personal H2S detectors, survey the area prior to mobilizing onsite, and wear appropriate PPE. A list of required PPE, procedures, standards and other safety systems is also provided.

Original Description:

Original Title

-_JSA -

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis Job Safety Analysis document summarizes the potential hazards and recommended safety precautions for accessing a work location. The sequence of basic job steps includes accessing personnel which could lead to slips, trips and falls, body injuries, loss of property, or collisions between vehicles. Recommendations are made to use qualified and inducted personnel, personal H2S detectors, survey the area prior to mobilizing onsite, and wear appropriate PPE. A list of required PPE, procedures, standards and other safety systems is also provided.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

4 views1 pagePpe / Systems /standards / Procedures Required To Do The Job

Uploaded by

kallel mohamedThis Job Safety Analysis document summarizes the potential hazards and recommended safety precautions for accessing a work location. The sequence of basic job steps includes accessing personnel which could lead to slips, trips and falls, body injuries, loss of property, or collisions between vehicles. Recommendations are made to use qualified and inducted personnel, personal H2S detectors, survey the area prior to mobilizing onsite, and wear appropriate PPE. A list of required PPE, procedures, standards and other safety systems is also provided.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 1

JSA

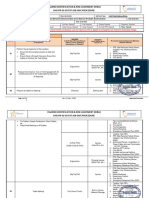

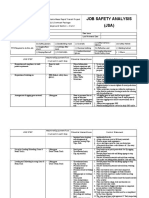

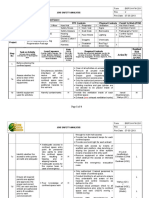

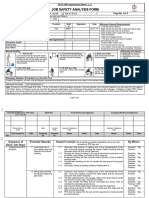

(Hazards Analysis and Risks Control Standard)

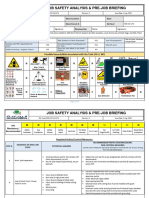

JOB SAFETY ANALYSIS (JSA)

Location: Guebiba Person in charge: PROD Crew Chief Date:

Work activity (Job): V00

Work team:

Potential accidents or hazards Recommendations to eliminate or reduce potential hazards associated

Sequence of basic job steps

associated with each step with each step

- Qualified and inducted personnel

- Personal H2S detector

- Slips, trips and falls from the same - Area survey prior to mobilize onsite

level - Wear appropriate PPE

1) Access of personnel - Body injury, loss of property -Visual check of equipment and mobile plants;

- Collision between vehicles -Respect speed limit and other safe access precautions (avoid crossing

- Security issues unauthorized zones and good segregation between vehicles and

pedestrians)

-Use of T-card system

PPE / SYSTEMS /STANDARDS / PROCEDURES REQUIRED TO DO THE JOB

Standard PPE Additional PPE Specific procedures / Standards: Other systems

Hard hat X Face shield - Confined space Permit to Work Fall protection barrier X

Safety boots /shoes X Chemical resistant apron - MSDS Warning barrier X

Coverall X Chemical resistant gloves X Warning signs X

Standard work gloves Chemical resistant boots Lockout/tag out

Safety glasses X Respiratory protection X Work permit required X

Goggles X Dielectric gloves Hot work permit

Ear plug X Body harness fall protection X Confined space permit X

Ear muffs Fire extinguisher

Others: Impervious gloves X

TPS, HSEQ

Document No: TPS-HSEQ-04-02-02

You might also like

- Site OrientationDocument2 pagesSite OrientationHitesh VaghasiyaNo ratings yet

- Loading Unloading RMU ENDocument4 pagesLoading Unloading RMU ENTilalNo ratings yet

- HIRARC Install LightingDocument2 pagesHIRARC Install LightingMohd Faizal SaharNo ratings yet

- JSA For Concrete WorkDocument6 pagesJSA For Concrete Worklê ngọc tùng0% (1)

- Electrical InstallationDocument3 pagesElectrical InstallationWalid KhelfaNo ratings yet

- JSA - 010 N2 Leak TestDocument5 pagesJSA - 010 N2 Leak TestPriharsya Adrievo DesyantoNo ratings yet

- Job Safety Analysis Risk Summary SheetDocument10 pagesJob Safety Analysis Risk Summary SheetMohammad Fazal KhanNo ratings yet

- Cable Splicing ENDocument4 pagesCable Splicing ENTilalNo ratings yet

- JSA Lifting With Equipment+Load ChartDocument13 pagesJSA Lifting With Equipment+Load ChartBoas BoetarzNo ratings yet

- JSA - Repair-Coating and Finition Work THDocument3 pagesJSA - Repair-Coating and Finition Work THKhorbi AbdeltifNo ratings yet

- Air Conditioner InstallationDocument3 pagesAir Conditioner InstallationWalid KhelfaNo ratings yet

- Workplace Hazard Assessment Form: Task Hazard(s) PPE Required Notes DepartmentDocument2 pagesWorkplace Hazard Assessment Form: Task Hazard(s) PPE Required Notes DepartmentMashur Al JunaibiNo ratings yet

- Job Hazard Analysis: Task or Step Hazards Controls Personal Protective Equipment (PPE)Document2 pagesJob Hazard Analysis: Task or Step Hazards Controls Personal Protective Equipment (PPE)Billy TalaugonNo ratings yet

- Jsa Emm 071222Document2 pagesJsa Emm 071222Mohamad Adam Mohamed NassirNo ratings yet

- Bgps H Jsa 008 Jsa Confined SpaceDocument4 pagesBgps H Jsa 008 Jsa Confined SpaceBuddy EkoNo ratings yet

- JSA - Repair-Coating and Finition WorkDocument3 pagesJSA - Repair-Coating and Finition WorkAMIN100% (1)

- Pressure Testing - 05Document5 pagesPressure Testing - 05imranrehman85No ratings yet

- Cutting ActivitiesDocument3 pagesCutting ActivitiesWalid KhelfaNo ratings yet

- Backhoe WORK PLAN JsaDocument1 pageBackhoe WORK PLAN JsaMax McguireNo ratings yet

- Job Hazard Analysis: Job/Activity: Pest Control Application Department or Location: FAC/PLANT WIDEDocument2 pagesJob Hazard Analysis: Job/Activity: Pest Control Application Department or Location: FAC/PLANT WIDEBilly TalaugonNo ratings yet

- JSA - Cor Pilecap Darat (CV-104) - (Jsa No 009-Row No 30) TGL 050713Document3 pagesJSA - Cor Pilecap Darat (CV-104) - (Jsa No 009-Row No 30) TGL 050713Ita MonoarfaNo ratings yet

- Excavation, Front Page JSA - 07Document2 pagesExcavation, Front Page JSA - 07imranrehman85No ratings yet

- Job Environmental Safety Analysis: Elimination/Substitution Engineering Administrative PPEDocument7 pagesJob Environmental Safety Analysis: Elimination/Substitution Engineering Administrative PPEJames BonitoNo ratings yet

- Hot and Acoustic Insulation - 004Document3 pagesHot and Acoustic Insulation - 004imranrehman85No ratings yet

- Position: Mechanic / Technician / Shop Personnel: Job Hazazrd AnalysisDocument3 pagesPosition: Mechanic / Technician / Shop Personnel: Job Hazazrd AnalysisKimmy LyonsNo ratings yet

- Petrochina International Jabung Ltd. Job Safety Analysis: Hse-Icg/Pcj-3075-Ca/Jsa.013Document5 pagesPetrochina International Jabung Ltd. Job Safety Analysis: Hse-Icg/Pcj-3075-Ca/Jsa.013Yosua SitumorangNo ratings yet

- Life Line ErectionDocument2 pagesLife Line Erectionimranrehman85No ratings yet

- Job Safety Analysis For Internal Corrosion Monitoring PDFDocument2 pagesJob Safety Analysis For Internal Corrosion Monitoring PDFVineet AgrawalNo ratings yet

- Risk Assess JSA Bolt Tightening 012Document7 pagesRisk Assess JSA Bolt Tightening 012Abdeldjalil Ferhati100% (2)

- Sodium Chloride PouringDocument12 pagesSodium Chloride PouringJay JocoNo ratings yet

- Lifting and Removing Using Unloading, Loading and Placing 0F Cable ReelsDocument3 pagesLifting and Removing Using Unloading, Loading and Placing 0F Cable ReelsAMINNo ratings yet

- Hiring of DozerDocument9 pagesHiring of DozerDwitikrushna RoutNo ratings yet

- Petrochina International Jabung Ltd. Job Safety Analysis: Hse-Icg/Pcj-3075-Ca/Jsa.017Document5 pagesPetrochina International Jabung Ltd. Job Safety Analysis: Hse-Icg/Pcj-3075-Ca/Jsa.017Yosua SitumorangNo ratings yet

- JSA Welding & GrindingDocument2 pagesJSA Welding & GrindingtaufikNo ratings yet

- JSA Loading & UnloadingDocument2 pagesJSA Loading & UnloadingSodikinNo ratings yet

- Job Safety Analysis: Cladding WorkDocument22 pagesJob Safety Analysis: Cladding WorkAldian MuftiNo ratings yet

- JSA-174.Confined Space EntryDocument3 pagesJSA-174.Confined Space Entryghazi4u100% (1)

- JSA 173 - CRT RIG UP - Updated 21.10.2019Document11 pagesJSA 173 - CRT RIG UP - Updated 21.10.2019tafhim rashidNo ratings yet

- Backfilling ENDocument5 pagesBackfilling ENTilalNo ratings yet

- Ppe MatrixDocument22 pagesPpe Matrixohconsultant.maiohNo ratings yet

- 8 Runs Primary Ductline Jha FormDocument2 pages8 Runs Primary Ductline Jha FormNova CastyNo ratings yet

- SAFETY TAILGATE Job Safety Analysis (JSA) - Risk Control Online PDFDocument2 pagesSAFETY TAILGATE Job Safety Analysis (JSA) - Risk Control Online PDFS A L M A NNo ratings yet

- JESA - Welding Grinding & Cutting WorksDocument7 pagesJESA - Welding Grinding & Cutting WorksLeo PascualNo ratings yet

- 12 JSA FlushingDocument5 pages12 JSA FlushingYosua SitumorangNo ratings yet

- Job Hazard Analysis: Job/Activity: Installation/ Department or Location: FACDocument2 pagesJob Hazard Analysis: Job/Activity: Installation/ Department or Location: FACBilly TalaugonNo ratings yet

- Backfilling Compaction JSADocument2 pagesBackfilling Compaction JSArashid zaman84% (25)

- Safe Work Method Statement: One World Place Manila, 32nd ST, Taguig, Metro ManilaDocument6 pagesSafe Work Method Statement: One World Place Manila, 32nd ST, Taguig, Metro Manilanani ferrerNo ratings yet

- Wall PartitionDocument1 pageWall PartitionJay SantiagoNo ratings yet

- SOP 11 - Lime Stone Circuit OprationDocument9 pagesSOP 11 - Lime Stone Circuit Oprationfaraz ahmedNo ratings yet

- Top Drive ConnectionsDocument1 pageTop Drive Connectionsghada gattouchNo ratings yet

- Petrochina International Jabung Ltd. Job Safety Analysis: Hse-Icg/Pcj-3075-Ca/Jsa.004Document7 pagesPetrochina International Jabung Ltd. Job Safety Analysis: Hse-Icg/Pcj-3075-Ca/Jsa.004Yosua SitumorangNo ratings yet

- PTW - Confined Space - ENDocument1 pagePTW - Confined Space - ENATSI HadjilaNo ratings yet

- SOP 15 - Hopper Cleaning ActivityDocument6 pagesSOP 15 - Hopper Cleaning Activityfaraz ahmed100% (2)

- Hi Tech Engineering SDN BHD Permit To Work System - Job Hazard AnalysisDocument3 pagesHi Tech Engineering SDN BHD Permit To Work System - Job Hazard AnalysisPHH9834No ratings yet

- JHA (85T Crawler Crane & Drill Rig Machine Assembling and Inspection)Document2 pagesJHA (85T Crawler Crane & Drill Rig Machine Assembling and Inspection)Armando AballeNo ratings yet

- JSA Pipe CleaningDocument2 pagesJSA Pipe CleaningDeni Noiz100% (1)

- Construction Safety Inspection ChecklistDocument5 pagesConstruction Safety Inspection ChecklistanamayitoNo ratings yet

- DPA - TemplateDocument21 pagesDPA - TemplateKayhan YasNo ratings yet

- Organization StructureDocument3 pagesOrganization StructureTahera AbbasNo ratings yet

- AECC Research PaperDocument12 pagesAECC Research PaperSiddhi LodhaNo ratings yet

- Midterm Discussion-Crimso1Document75 pagesMidterm Discussion-Crimso1Brent VelascoNo ratings yet

- English Argumentative EssayDocument4 pagesEnglish Argumentative EssayOlukoya ModesayoNo ratings yet

- Bribery and CorruptionDocument5 pagesBribery and CorruptionhanifharisNo ratings yet

- Final Thesis of Asegdech GachenaDocument84 pagesFinal Thesis of Asegdech GachenaHundeNo ratings yet

- Matrimonial Remedies - P1 - Restitution of Conjugal RightsDocument10 pagesMatrimonial Remedies - P1 - Restitution of Conjugal RightsOJASWANI DIXITNo ratings yet

- Livro 1 - 003 - Abortion Leading Cause of Death in 2018 With 41 Million KilledDocument3 pagesLivro 1 - 003 - Abortion Leading Cause of Death in 2018 With 41 Million KilledLeonardo OliveiraNo ratings yet

- DEBATEDocument10 pagesDEBATEATOLBA, Rizel D.No ratings yet

- Understanding Culture, Society, and Politics: Second QuarterDocument12 pagesUnderstanding Culture, Society, and Politics: Second QuarterRene Rey B. Sulapas85% (13)

- Award Matt Battani VS International School of Uganda 1Document20 pagesAward Matt Battani VS International School of Uganda 1Katuramu WilliamNo ratings yet

- (Lecture) Article 1-2 of The 1987 Constitution of The PhilippinesDocument18 pages(Lecture) Article 1-2 of The 1987 Constitution of The PhilippinesAcerJun ParafinaNo ratings yet

- The Historical Development of ProbationDocument80 pagesThe Historical Development of ProbationJohn Felix AndalNo ratings yet

- Petition For Writ of ProhibitionDocument16 pagesPetition For Writ of ProhibitionKSNV News3LVNo ratings yet

- Algerian Family Code and DiscriminationDocument7 pagesAlgerian Family Code and DiscriminationMarianna BuonocoreNo ratings yet

- Chapter VDocument11 pagesChapter VLeo DicaprioNo ratings yet

- Judicial Activism and The Seperation of PowersDocument14 pagesJudicial Activism and The Seperation of Powersgirish karuvelilNo ratings yet

- XU PALE Syllabus 21 22Document19 pagesXU PALE Syllabus 21 22thisfangirlingNo ratings yet

- National Law University Odisha, Cuttack: JurisprudenceDocument17 pagesNational Law University Odisha, Cuttack: Jurisprudenceparul priya nayakNo ratings yet

- Interpretation of Statutes and Principles of LegislationDocument53 pagesInterpretation of Statutes and Principles of LegislationvanigarvNo ratings yet

- Aadhar Q & ADocument13 pagesAadhar Q & Ayogaranjan nayakNo ratings yet

- Ap Reviewer q3Document3 pagesAp Reviewer q3Raph RaphNo ratings yet

- YSL IndictmentDocument95 pagesYSL IndictmentBillboardNo ratings yet

- Tamil Nadu National Law School: Plea Bargaining: Violation of Fundamental RightsDocument14 pagesTamil Nadu National Law School: Plea Bargaining: Violation of Fundamental RightsRavi shankarNo ratings yet

- BAR Application RequirementsDocument3 pagesBAR Application RequirementsJake MendozaNo ratings yet

- Central Information Commission: 2 Floor, August Kranti Bhawan, Bhikaji Cama Place, New Delhi-110066Document4 pagesCentral Information Commission: 2 Floor, August Kranti Bhawan, Bhikaji Cama Place, New Delhi-110066Jappreet SinghNo ratings yet

- Bullying, Cyberbullying and Hate SpeechDocument33 pagesBullying, Cyberbullying and Hate SpeechEve AthanasekouNo ratings yet

- Balint Jennifer Julie Evans and Nesam McMillan. Rethinking Transitional Justice, Redressing Indigenous Harm A New Conceptual Approach.Document41 pagesBalint Jennifer Julie Evans and Nesam McMillan. Rethinking Transitional Justice, Redressing Indigenous Harm A New Conceptual Approach.fperezcaravantesNo ratings yet

- Procedure For Filing Application in NGTDocument4 pagesProcedure For Filing Application in NGTSimran ChaudharyNo ratings yet