Professional Documents

Culture Documents

MPJ 8

Uploaded by

Aswin KrishnaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MPJ 8

Uploaded by

Aswin KrishnaCopyright:

Available Formats

IOSR Journal of Mechanical and Civil Engineering (IOSR-JMCE)

e-ISSN: 2278-1684,p-ISSN: 2320-334X, Volume 13, Issue 1 Ver. III (Jan. - Feb. 2016), PP 65-73

www.iosrjournals.org

Quarry Dust as a Partial Replacement of Coarse Aggregates

in Concrete Production

Aginam C. H1. Nwakaire, C2., Onah, B. C3.

1,2,3

Department of Civil Engineering, Nnamdi Azikiwe University, P.M.B. 5025, Awka

Abstract: This study is an attempt to investigate the suitability of quarry dust as a partial replacement of

coarse aggregates in concrete making. Samples of concrete cubes were made with varying proportions of

quarry dust replacing the coarse aggregate. It was foreseen that the utilization of quarry dusts as partial

replacement of coarse aggregates in concrete will be more beneficial due to the relative ease of inclusion that

will be achieved as opposed to batching them separately as fine aggregates. Since they are produced from the

production of coarse aggregates, they could, therefore, be better included, transported, and batched as coarse

aggregates.This promises to be a more sustainable option, preserving the global natural resource base as well

as save construction costs significantly. A total of 150 cubes were cast. Some physical properties of the concrete

constituent materials that are relevant to the experiments were determined. The mix design of 1:2:4 was adopted

and two brands of Ordinary Portland cement (OPC) were used for comparative purposes. Particle size

distribution analysis, slump test, and compressive strength test were carried out on the materials, the fresh

concrete, and the cured concrete cubes respectively. The quarry dust sample was found to be well graded and

the concrete mixes had true slumps with decreasing consistency as the quantity of quarry dust increased. The

results disclosed that replacing 10% of the required amount of gravel with quarry dust and using the Ibeto

brand of Portland cement yielded the highest amount of compressive strength of 32.3N/mm 2. It was also

observed that using the Ibeto brand of OPC, the concrete cubes made with inclusion of quarry dust up to 25%

all performed better than the zero replacement level in terms of their compressive strengths. The strengths

achieved with the Dangote brand of OPC were satisfactory up to 15% replacement level. This suggests that the

quarry dust can be utilized as a partial replacement of the coarse aggregates in concrete within the satisfactory

levels. The study further showed that variations in the properties of Portland cement brands can result in

significant differences in the performances of concretes made with them.

Keywords: concrete, quarry dust, compressive strength, coarse aggregates, partial replacement

I. Introduction

Concrete is one of the most used building materials globally. They are produced by mixing aggregates,

which are inert materials, in fixed proportions with a cementing material and water to produce concrete (Singh

2008). Aggregates are responsible for strength, hardness and durability of concrete. Aggregates are either coarse

(gravel and stones) or fine (sand). It is desirable that aggregates consist of particles with adequate strength and

resistance to exposure conditions. For a workable, durable and economical concrete mix, aggregates are

expected to be resistant to abrasion, and stable to chemical attacks. The particle size distribution and surface

texture of aggregates are also of great importance. Coarse aggregates are aggregates that are more than 4.75mm

in size (Shetty, 2005). They range from10mm to 20mm in size with a bulk density of about 1430kg/m3. Gravel

and crushed stones are some examples. For effective performance, they must be clean, hard, tough, strong,

durable, inert, free from dust and well graded (Akeem et al, 2013).

Coarse aggregate which is the strength component of the concrete have been found to be relatively high

in demand and price. In the recent past, several attempts have been made towards the replacement of natural

aggregates with other cheap materials in concrete. This quest for alternative construction materials is due to the

global sustainability concern as it relates to the preservation of the environment and non-renewable natural

resources which has been depleting in quality and quantity as a result of many human activities of which Civil

Engineering constructions are major contributors. Reuse of various industrial by-products such as flyash, silica

fume, rice husk ash, foundry waste, quarry dust, et cetera as substitutes to the conventional construction

materials in construction has been argued to be a possible way forward towards achieving an environmentally

friendly construction (Nwachukwu et al, 2012; Neville, 2002; Gambhir, 1995). Based on this, this study

attempts to study the effects of quarry dust addition on the strength characteristics of concrete and to assess the

rate of compressive strength development for replacement of coarse aggregate with quarry dust. Quarry dust, a

by-product from the crushing process during quarrying activities is one of those materials that have recent ly

gained attentions to be used as concreting aggregates, especially as fine aggregates. But the fact that the quarry

dust is a by-product of the production of coarse aggregates makes it reasonably utilized as a partial replacement

DOI: 10.9790/1684-13136573 www.iosrjournals.org 65 | Page

Quarry Dust as a Partial Replacement of Coarse Aggregates in Concrete Production

of the same, if found to be suitable. This will make for easy in-the-quarry proportioning instead of batching on

site with sand collected from a different source altogether.

Quarry dust has been used for different activities in the construction industry such as in road

construction and manufacture of building materials such as light weight aggregates, bricks, plastering material

and tiles. According to Sivakumar and Prakash (2011), quarry dust,which used to be a waste obtained during

quarry process, has very recently gained good attention to be used as an effective filler material instead of fine

aggregate. Neville (2002), Zain et al. (2000), and Gambhir (1995) also demonstrated in their studies how quarry

dust can be suitably used as concrete aggregates, especially as fine aggregates. Nwachukwu et al (2012)

explained that quarry dust is a cohesionless sandy material. He agreed that the material could be acquired either

naturally (which is rare) or artificially by the mechanical disturbance of parent rocks (blasting of rocks) for the

purpose of producing coarse aggregates used for construction. The particles of quarry dust have diameters

ranging from 0.05mm to 5.00mm. Agbode and Joel (2001) found in their study on the suitability of quarry dust

as partial replacement for sand in hollow block production, that quarry dust is cheaper than river Benue sand

even during rainy season, due to the fact that they were seen as inferior materials.

Sivakumar and Prakash (2011) investigated the mechanical properties of quarry dust addition in

conventional concrete. They concluded that the addition of the quarry dust improved the strength properties of

concrete far above the conventional concrete. Karthicket al (2014), in his study on the usage of quarry dust as a

partial replacement for sand in concrete found that the compressive strength of concrete cubes at 28 days of

curing was improved as high as 35.26% above the strength of conventional concrete when 40% of the fine

aggregate was replaced with quarry dust by weight. A similar study by Paramjeet and Singh (2014) and Ukpata

et al (2012)also reported a strength increase of 12% above conventional concrete and encourages the utilization

of quarry dust as fine aggregates.

Though no known attempt have been made in the possible replacement of coarse aggregate with quarry

dust, prior to this study, the high improvement achieved from these previous studies on fine aggregates points to

the possibility of utilizing it as coarse aggregates being that they are of the same source. Besides, quarry dust has

rough, sharp and angular particles and as such causes a gain in strength due to better interlocking. The use of

quarry dust in concrete is desirable because of its benefits such as useful disposal of by products, reduction

of coarse aggregate usage as well as increasing the strength parameters and possible increase in the

workability of concrete (Nwachukwu et al, 2012).In a developing country like Nigeria, the use of alternative

cheaper local materials or even by-products like the quarry dust as replacement of the coarse aggregate will

greatly enhance the production of concrete with desired properties at low cost. It will drastically reduce the cost

of production and consequently the cost of construction. By this, the quarry dust will be utilized effectively than

allowing it waste with consequential environmental hazard.

II. Materials And Methods

2.1; Materials

The materials used in this project include water, cement, sharp sand, quarry dust and granite. The

portable water used for the experiments was taken from the concrete laboratory water thank. Two brands of

Portland cement (Dangote and Ibeto) of grade 42.5 were used for the research. They were sourced from Local

cement dealers at Ama-achara in Enugu state. The quarry dust as well as the gravel was obtained from Isiagu

quarry, while the sharp sand used was river bed sand collected from Nyama River both in Enugu State of

Nigeria.

2.2; Methods

The Specific Gravity and the Particle Size Distribution Analysis for the samples were carried out in

accordance to BS1377. The workability test, casting, and crushing of the cubes were carried out in accordance

to BS1881 part 3 (1992). The cubes were cured in accordance with BS8110, Part 1 (1985).

The concrete mix was batched by weight and mixed manually with 1:2:4 mix proportion. Concrete

cubes of 150mm × 150mm × 150mm in size were for the casting. The proportion of the gravel was replaced by

quarry dust at 0%, 5%, 10%, 15%, 20%, and 25% replacement levels. Three cubes were cast at each

replacement level and the average compressive strength gotten at a given curing age. The curing of the concrete

was by complete immersion in water.

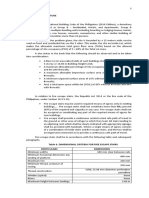

Table 1 below shows the batching of the materials at different replacement levels.

Table 1; Proportioning of the Constituent Materials.

Replacement Cement Sand Water Quarry dust

Granite (kg)

% (kg) (kg) (kg) (kg)

0 1.073 2.132 0.59 4.263 0

5 1.073 2.132 0.59 4.050 0.213

10 1.073 2.132 0.59 3.837 0.426

DOI: 10.9790/1684-13136573 www.iosrjournals.org 66 | Page

Quarry Dust as a Partial Replacement of Coarse Aggregates in Concrete Production

15 1.073 2.132 0.59 3.624 0.639

20 1.073 2.132 0.59 3.410 0.853

25 1.073 2.132 0.59 3.197 1.066

III. Results Anddiscussions

3.1; Properties of the Materials

Table 2 below is the summary of the physical properties of the sand, gravel, and quarry dust, used for

the experiment. The particle size distribution curves for the three materials are plotted as figure 1 below.

The sand used for the experiment was found to be uniformly graded with a uniformity coefficient of

3.45 while the gravel has sizes ranging between 14mm and 19mm with a uniformity coefficient of 1.35. These

are typical of the size ranges used for construction projects in Nigeria and are significantly collected from

predominant sources within Enugu State, South-East Nigeria.

Table 2; Index Properties of the Materials

Sample Designation

Property Sand Gravel Quarry dust

Specific gravity 2.56 2.71 2.57

% gravel (>4.76mm) 0 99.90 2.80

% sand (<4.76mm to 0.075mm) 99.8 0.01 98.45

% fines (<0.075mm) 2.09 2.02 1.55

Coefficient of Uniformity 3.45 1.35 45.12

Cc 1.02 1.47 1.10

The quarry dust which was the material of concern was found to be composed of varying ranges of

particle sizes but predominantly sand. This suggests that the name quarry dust does not connote a material full

of fines but points to the fact that the quarry sites have been disposing of the material as unwanted wastes. That

makes this investigation a quintessential attempt to assess the extent to which this material can suitability be

utilized in concrete works as partial replacement for coarse aggregates.

Figure 1: Particle Size Distribution for Gravel, Sand and Quarry Dust.

The specific gravity of the Sharp sand, Quarry Dust and Gravel were found to be 2.56, 2.57 and 2.74

respectively. The specific gravity value for Quarry dust is close to that of the fine aggregate, though slightly

higher. As expected, the specific gravity of the coarse aggregate was quite higher than those of sand and quarry

dust which shows how denser it is and makes it more necessary to investigate the performance of the concrete if

the quarry dust is batched into the concrete mix as coarse aggregate.

DOI: 10.9790/1684-13136573 www.iosrjournals.org 67 | Page

Quarry Dust as a Partial Replacement of Coarse Aggregates in Concrete Production

3.2; Concrete Consistency with Quarry Dust as Coarse Aggregates

The result of the workability tests carried out with 0.65 w/c ratio for the two brands of Portland cement

used, Dangote and Ibeto, have been summarized as Table 4 below. It was observed that in both cases, the

workability of the concrete decreased as the percentage of quarry dust increased. In each of the cases, a true

slump was achieved which consistently got lesser as the quantity of the quarry dust increased, strongly

suggesting that the quarry dust is more water absorbing than gravel.

Table 4: Slump Test Result for Dangote Cement and Ibeto Cement

Dangote Cement Ibeto Cement

S/n Height of Collapse (mm) Slump (mm) S/n Height of Collapse (mm) Slump (mm)

N0 190 110 M0 200.00 100

N5 220 80 M5 221.00 80

N10 235 65 M10 260.00 40

N15 270 30 M15 281.50 20

N20 285 15 M20 295.00 5

N25 300 0 M25 300.00 0

In as much as the two brands of cement used for this experiments were similar in their workability

characteristics in response to the incorporation of the quarry dust, figure 4 below shows that there is noticeable

and consistent difference between the workability of Dangote Cement and Ibeto Cement. The workability

achieved with the Dangote Cement was higher than the Ibeto cement at all replacement up till 20% where the

two are the same. It shows that the use of Dangote cement with quarry dust shows a better workability than with

Ibeto cement for w/c ratio of 0.65. From the results, the 25% percent replacement for both cement brands and

the 20% replacement for Ibeto cement were found to be inconsistent being that the slump were below 10 which

is the minimum specified by BS EN 12350-2:2009. The concrete without quarry dust had class S3 slump, the

one with 5% and Dangote 10% were of class S2 slump, while those of 10% Ibeto, 15% replacement for both, as

well as 5% replacement for Dangote were of slump class S1.

Figure 2: Workability of the Concrete mixes with the Two Portland Cement brands

3.3; Compressive Strength Result of Concrete with Different Proportions of Quarry Dust

The Compressive Strength results of the concrete cubes, at different curing ages, made with Dangote as

well as Ibeto cement are tabulated as Table 5 and Table 6 below respectively.

Table 5: Summary of Compressive Strength for Dangote Cement

S/N 7 DAYS 14 DAYS 21 DAYS 28 DAYS (N/mm²) 56 DAYS (N/mm²)

(N/mm²) (N/mm²) (N/mm²)

N0 14.12 14.30 15.26 20.88 21.31

N5 12.16 14.41 15.42 21.32 22.57

N10 10.37 11.25 13.81 14.59 20.10

N15 12.10 14.10 14.17 15.78 18.35

N20 11.58 11.79 12.10 13.78 21.57

N25 9.99 10.73 11.01 12.62 20.42

DOI: 10.9790/1684-13136573 www.iosrjournals.org 68 | Page

Quarry Dust as a Partial Replacement of Coarse Aggregates in Concrete Production

Table 6: Summary of Compressive Strength for Ibeto Cement

S/N 7 Days 14 Days 21 Days 28 Days 56 Days

(N/mm²) (N/mm²) (N/mm²) (N/mm²) (N/mm²)

M0 11.81 16.77 18.31 20.50 22.91

M5 19.77 21.76 23.91 24.46 29.73

M10 23.19 26.68 30.09 32.30 32.47

M15 18.22 20.22 21.62 24.49 26.51

M20 18.46 19.97 20.79 21.92 22.54

M25 21.26 21.79 22.79 24.04 26.99

This result is illustrated graphically in figures 3 and 4 below. Generally, the compressive strengths

increased with curing age as expected. Being that the 1:2:4 mix proportion was adopted, a concrete of grade

M15 was expected, which implies that any specimen with compressive strength of 15N/mm2 and above at 28

days of curing would be satisfactory. Therefore, all the cubes cast with the Ibeto cement were all found to be

satisfactory whereas those made with Dangote cement up to 15% replacement were also found to be

satisfactory. Besides, all the cubes achieved a compressive strength above 15N/mm2 at 56 days of curing. Which

supports the fact that concrete gains strength with age at curing.

Figure 3: Increase in Compressive Strength with Age of Curing Dangote

Figure 4: Increase in Compressive Strength with Age of Curing Ibeto

DOI: 10.9790/1684-13136573 www.iosrjournals.org 69 | Page

Quarry Dust as a Partial Replacement of Coarse Aggregates in Concrete Production

Figure 5 is the graph of the 28th day strengths achieved at different replacement levels of the coarse

aggregate with quarry dust. Concrete with Quarry dust show an increasingly compressive strength. In other

words, compressive strength of concrete made with replacement of coarse aggregate with Quarry dust ranges

from 18.35N/mm2 to 22.57N/mm2 for Dangote Cement and 22.54N/mm2 to 32.47N/mm2 for Ibeto cement.

Dangote cement is maximum at 5% replacement (N5) and the compressive strength is 22.57N/mm2. Other

replacements however showed a declining compressive strength. Looking at the various replacements: N5

showed a steadily rapidly strength gain. Other replacements however show a similar strength gain at 56 days but

are comparatively smaller. Ibeto Cement showed an early compressive strength gain with replacement of coarse

aggregate with Quarry dust for all the replacements. Its Compressive Strength ranges from 22.54 N/mm2 up to

32.47 N/mm2 after 56 days and reaches its peak value at 10% replacement (M10). At M10, the compressive

Strength is 32.47 N/mm2 (29.44% more than that of the conventional concrete of 0% replacement) for 56 days.

For 7 days, 14 days, 21 days and 28 days, the strength is also higher than the conventional concrete of 0%

replacement (49.07%, 37.14%, 39.15%, 36.53%) respectively.

The Ibeto brand of cement shows better compressive strength than Dangote Cement: from the result

and analysis, it was seen that the compressive strength of concrete made by replacing coarse aggregate with

Quarry dust is higher with the use of Ibeto cement. For 5% replacement, the compressive strength of the

concrete made with Ibeto cement is about 38.49%, 33.78%, 35.51%, 12.84%%, 24.08% for 7 days, 14 days, 21

days, 28 days and 56 days respectively more than that of Dangote, for 10% replacement, Ibeto was still higher

(about 55.28%, 57.83%, 54.10%, 54.83%, 38.10% more than Dangote for 7 days, 14 days, 21 days 28 days and

56 days respectively). For 15% it is still more than that of Dangote Cement (about 33.59%, 30.27%, 34.46%,

35.67%, 30.78% for 7 days, 14 days, 21 days 28 days and 56 days respectively). For 20% replacement, it is still

higher though at 56 days, the Strength difference is low about 4.30%, ( for other days i.e 7 days, 14 days, 21

days and 28 days, Ibeto Cement is about 37.27%, 40.96%, 41.80%, 37.14% more than that of Dangote cement).

While for 25% replacement, it is higher (about 53.01%, 50.76% 51.69%, 47.50%, 24.34% more than that of

Dangote Cement). And these show very high difference between the two for all replacement. The difference

between the two would have been as a result of the difference in the composition of the two brands of cement.

35

30

Dangote

28th day Compressive strength

Ibeto

25

20

15

10

0 5 10

% Replacement15 20 25

th

Figure 5; Variation in Compressive Strength of the Concretes at 28 Day of Curing

These results suggest that the slump test for workability and consistency of mix has no practically

significant information to give about the final strength of the concrete. It only points to the ease of placing and

smoothness of the finished product than to the strength gain. This opinion is based on the fact that the fresh

concrete mixes with the Dangote cement tended to be more workable than those made with the Ibeto cement,

but the cubes from the Ibeto cement were significantly stronger.

3.4; Relationship between Density and Compressive Strength

Figures 6 and 7 show the average observed densities of the concrete cubes before they were crushed.

The results of the average densities gotten are shown below:

DOI: 10.9790/1684-13136573 www.iosrjournals.org 70 | Page

Quarry Dust as a Partial Replacement of Coarse Aggregates in Concrete Production

2520

2500

2480

2460 N0

Density (Kg/m3)

2440

N5

2420

N10

2400

2380 N15

2360 N20

2340 N25

2320

7 14 21 28 56

Age of Curing (Days)

Figure 6: Density Result for all days of curing with Dangote Cement

2560

2540

2520

2500

Density (kg/m3)

M0

2480

M5

2460

M10

2440

2420 M15

2400 M20

2380 M25

2360

7 14 21 28 56

Age of Curing (Days)

Figure 7: Density Result for all Days of Curing with Ibeto Cement

For the Dangote cement, at 15% replacement, the density was found to be lowest (2360.49kg/m3) while

the maximum (2503.70kg/m3) was at 5% replacement at 56 days which coincidentally is the maximum

compressive strength observed.

DOI: 10.9790/1684-13136573 www.iosrjournals.org 71 | Page

Quarry Dust as a Partial Replacement of Coarse Aggregates in Concrete Production

Figure 8: Variation of Compressive Strength with Density with Dangote Cement

Figure 9: Variation of Compressive Strength with Density with Ibeto Cement

From the figure 8 and 9 above, it could be seen that the densities of the cubes increased with increase in

their compressive strength. The variation is not uniform neither are the relationships perfectly linear, by

observation of the curves, but the result of the Pearson correlation coefficients (0.9 and 0.8 for Dangote and

Ibeto respectively) suggest a positive negative correlation between density and compressive strength of

concrete. This further suggests that as the density of the concrete specimen increases, the compressive strength

of the same is also expected to increase in like manner.

IV. Conclusion And Recommendation

Based on this experimental investigation on the possible replacement of coarse aggregate with Quarry

Dust in Concrete, it could be concluded that the workability of concrete decreases with increasingly percentage

of Quarry Dust in the mix and workability test being a pointer to the consistency of the mix does not imply the

final strength characteristics of the same.

DOI: 10.9790/1684-13136573 www.iosrjournals.org 72 | Page

Quarry Dust as a Partial Replacement of Coarse Aggregates in Concrete Production

This study shows that replacing 10% of the required amount of gravel with quarry dust and using the

Ibeto brand of Portland cement yielded the highest amount of compressive strength of 32.3N/mm2. It was also

observed that using the Ibeto brand of OPC, that the concrete made with inclusion of quarry dust up to 25% all

performed better than the zero replacement level in terms of their compressive strengths. In contrast, the

concrete cubes made with the Dangote cement performed less with the inclusion of the quarry dust. Besides, the

strengths achieved were satisfactory up to 15% replacement level. This suggests that the quarry dust can be

utilized as a partial replacement of the coarse aggregates in concrete within the satisfactory levels. Hence, the

variations in the properties of Portland cement brands can result in a significant difference in the performance of

concretes made with them.

From the observed densities of the concrete made by replacing coarse aggregate with Quarry dust, the

concretes fall in category of normal weight concrete. Based on the Pearson’s correlation coefficients gotten from

the experimental data, there is a strong positive relationship between the Density and the Compressive Strength

of concrete. This suggests that as the density increases with the compressive strength.

The main foreseen benefits of the utilization of quarry dusts as partial replacement of coarse aggregates

in concrete is the relative ease of inclusion as opposed to batching them separately as fine aggregates. They are

produced from the production of coarse aggregates and could better be included, transported, and batched as

coarse aggregates. This promises to be a more sustainable option, which will preserve the global natural

resource base as well as save construction costs significantly.

It is recommended, therefore, that quarry dust be batched into concrete mixes as partial replacement of

gravel instead of fine aggregates as recommend by most researchers. Crushing of concrete test cubes before

placing such for the main structures is very necessary. This will give information about the target compressive

strength from such a mix, as the variations in Portland cement brands can affect the final performance of the

concrete members.

V. Further Studies

Investigation into the properties of different brands of Portland cement that would result in variations in

concrete strength performance is recommended for further studies.

References

[1]. Agbode, U.N. and Joel, G.K. (2001) Quarry Dust Concrete. Engineering Science and Technology: An International Journal

(ESTIJ), Vol.2, No.8; pp 67-71

[2]. Akeem, A.R., Aliu, A.S., Emenike, A.J.(2013)Effect of Curing Methods on Density and Compressive Strength of Concrete.

International Journal of Applied Science and Technology, Vol. 3 No. 4; pp 55-64

[3]. BS 1377; Part 2:1990. Methods for Test of Soils for Civil Engineering Purposes. British Standard Institute London, United

Kingdom.

[4]. BS 1881; Part 3:1992. Methods for Determination of Density of Partially Compacted Semi-dry Fresh Concrete. British Standard

Institute London, United Kingdom.

[5]. BS 8110; Part 1:1985. Methods of Curing, British Standard Institute London, United Kingdom.

[6]. Gambhir, M.L. (1995). Concrete Technology; Second Edition, Tata McGraw-Hill Publishing Company Limited, New Delhi.

[7]. Karthick, J., Rama, T., Bharathi, N.M. (2014) An Experimental Study on Usage of Quarry Rock Dust as Partial Replacement for

Sand in Concrete. International Journal of Advanced Research in Education Technology,Vol. 1, Issue 1; pp 41-45

[8]. Neville, A.M. (2002). Properties of Concrete, Fourth and Final Edition, Pearson Education Limited, Essex.

[9]. Nwachukwu, U.C., Onyebuchi, N. N., Onwuamaeze, F.C.(2012) The Use of Quarry Dust as Partial Replacement of Sharp Sand in

Optimization of Concrete using Scheffe’s Simplex Method. Project submitted to the Department of Civil Engineering, Federal

University of Technology, Owerri, Imo State.

[10]. Paramjeet, M. and Singh, A. (2014).Evaluation of Characteristics Strength of Concrete using Crushed Stone Dust as Fine

Aggregate. International Journal of Enhanced Research in Science Technology & Engineering, Vol. 3 Issue 6; pp: 119-121

[11]. Shetty, M. S. (2005) Concrete Technology.rejendraravindraprinterspvt.ltd, New Delhi.

[12]. Singh, P. (2008) Civil Engineering Materials. S. K. kataria and Sons, New Delhi.

[13]. Sivakumar, A. and Prakash, M. (2011) Characteristic Studies on the Mechanical Properties of Quarry Dust Addition in

Conventional Concrete,Journal of Civil Engineering and Construction Technology, Vol. 2(10); pp. 218-235

[14]. Ukpata, J.O.,Ephraim, M.E. and Okeke, G.A. (2012) Compressive Strength of Concrete using Lateritic Sand and Quarry Dust as

Fine Aggregates. ARPN Journal of Engineering and Applied Science,Vol.7, No.1, pp 81-92

[15]. Zain, M.E., Kelly, E.A., and Awaona, O.P. (2000) Civil Engineering Materials. Macmillan Press London.

DOI: 10.9790/1684-13136573 www.iosrjournals.org 73 | Page

You might also like

- Design Example - Deep Mass Concrete Pad BaseDocument5 pagesDesign Example - Deep Mass Concrete Pad BaseAnonymous xcFcOgMi100% (1)

- Stone Dust & RubberDocument64 pagesStone Dust & RubberSyed Mohd Mehdi100% (1)

- 18 SPJ - S18 - Soil - StabilisationDocument25 pages18 SPJ - S18 - Soil - StabilisationCarwen WongNo ratings yet

- A Study On Use of Bottom Ash and Fly Ash in Concrete Used in Pavement ConstructionDocument11 pagesA Study On Use of Bottom Ash and Fly Ash in Concrete Used in Pavement ConstructionIJRASETPublications100% (1)

- Filter PressDocument3 pagesFilter PressAbd Elrahman Hamdy0% (1)

- A Research Paper On DormitoriesDocument5 pagesA Research Paper On DormitoriesNicholas Ivy EscaloNo ratings yet

- Gantry Cranes-Design ProcedureDocument29 pagesGantry Cranes-Design ProcedurePoulami Guchhait100% (5)

- A Study On The Durability Properties of Concrete Using Coconut Shell and Quarry DustDocument32 pagesA Study On The Durability Properties of Concrete Using Coconut Shell and Quarry DustAira Joy AnyayahanNo ratings yet

- Quarry Dust As Fine Aggregate in Concrete MixturesDocument10 pagesQuarry Dust As Fine Aggregate in Concrete MixturesBrahmesh Varma100% (2)

- Effect of Quarry Dust On High Performance ConcreteDocument5 pagesEffect of Quarry Dust On High Performance ConcreteMark EliasNo ratings yet

- Sand Stone As Partial ReplacementDocument8 pagesSand Stone As Partial ReplacementAli SherNo ratings yet

- Replacing Query Dust Instead of Sand in Concrete MixDocument43 pagesReplacing Query Dust Instead of Sand in Concrete MixudayashankarNo ratings yet

- Behaviour of High Performance Blended Ternary Concrete Prepared Using Alternative MaterialsDocument9 pagesBehaviour of High Performance Blended Ternary Concrete Prepared Using Alternative MaterialsAnnals of Earth, Environment, and Infrastructure EngineeringNo ratings yet

- The Investigational The Effects of Waste Products Such As Wood Ash, Sugarcane Bagasse Ash, and Rice Husk Ash On The Durability of ConcreteDocument6 pagesThe Investigational The Effects of Waste Products Such As Wood Ash, Sugarcane Bagasse Ash, and Rice Husk Ash On The Durability of ConcreteIJRASETPublicationsNo ratings yet

- 346experimental Study On Concrete by Partial Replacement of Marble Dust Powder With Cement Quarry Dust With Fine PDFDocument5 pages346experimental Study On Concrete by Partial Replacement of Marble Dust Powder With Cement Quarry Dust With Fine PDFMichael ShioNo ratings yet

- FYP PresentationDocument21 pagesFYP PresentationalihassanNo ratings yet

- 2005 Aeeseap Conf.1Document6 pages2005 Aeeseap Conf.1Dale LacastreNo ratings yet

- Garg 2022 J. Phys. Conf. Ser. 2267 012110Document10 pagesGarg 2022 J. Phys. Conf. Ser. 2267 012110MohammedNo ratings yet

- Journal Printabs 4haug14esrDocument11 pagesJournal Printabs 4haug14esrBruno CarleteNo ratings yet

- To Investigate The Behavior of Concrete by Partial Replacement of Stone Dust With Fine Aggregates and Tobacco Waste Ash With CementDocument10 pagesTo Investigate The Behavior of Concrete by Partial Replacement of Stone Dust With Fine Aggregates and Tobacco Waste Ash With CementIJRASETPublicationsNo ratings yet

- Used of Recycled Tyre/Rubber As Course Aggregate and Stone Dust As Fine Aggregate in Cement Concrete WorksDocument7 pagesUsed of Recycled Tyre/Rubber As Course Aggregate and Stone Dust As Fine Aggregate in Cement Concrete WorksIOSRjournalNo ratings yet

- Suitability of Quarry Dust As Partial Replacement Material For Sand in ConcreteDocument5 pagesSuitability of Quarry Dust As Partial Replacement Material For Sand in ConcretebramuelNo ratings yet

- 11845-Article Text-21011-1-10-20211229Document6 pages11845-Article Text-21011-1-10-20211229shailenderkarreNo ratings yet

- Properties of Green Concrete Mix by Concurrent Use of Fly Ash and Quarry DustDocument7 pagesProperties of Green Concrete Mix by Concurrent Use of Fly Ash and Quarry DustIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalNo ratings yet

- Influence of Stone Dust On Compressive Strength and Embodied Energy of MortarDocument9 pagesInfluence of Stone Dust On Compressive Strength and Embodied Energy of MortarInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Con 2015 MksDocument7 pagesCon 2015 MksMukesh Kumar SamotaNo ratings yet

- 12.uso de Desechos Minerales de Silice Como Agregado en Un Concreto Verde de Alta Resistencia Trabajabilidad Resistencia Modo de FallaDocument8 pages12.uso de Desechos Minerales de Silice Como Agregado en Un Concreto Verde de Alta Resistencia Trabajabilidad Resistencia Modo de FallaJoel HernandezNo ratings yet

- The Utilization of Quarry Dust As Fine Aggregates in ConcreteDocument6 pagesThe Utilization of Quarry Dust As Fine Aggregates in ConcreteSuman VarmaNo ratings yet

- Director StudyDocument16 pagesDirector StudyAsif Zaffar AnsariNo ratings yet

- Evaluation of Mechanical Properties of Recycled Aggregate Concrete Manufactured With Fly Ash, Bagasse Ash and Banana FiberDocument6 pagesEvaluation of Mechanical Properties of Recycled Aggregate Concrete Manufactured With Fly Ash, Bagasse Ash and Banana FiberSaad IlyasNo ratings yet

- With ReadingsDocument44 pagesWith ReadingsGaurav JethleNo ratings yet

- Journal ReportDocument6 pagesJournal ReportmaruthiNo ratings yet

- ResearchPaperElsevier 4Document5 pagesResearchPaperElsevier 4NIEDO ADRIENNENo ratings yet

- Project Sand Repacement and Cement Replacement With Crusher DustDocument47 pagesProject Sand Repacement and Cement Replacement With Crusher DustAdusumalli Surendra BabuNo ratings yet

- MSC Thesis ApprovalDocument11 pagesMSC Thesis ApprovalJunaid WaheedNo ratings yet

- Icj 2017Document8 pagesIcj 2017Dr. M.V.Krishna RaoNo ratings yet

- TaguchiDocument9 pagesTaguchiAhmet SevinçNo ratings yet

- OJCE PaperDocument14 pagesOJCE Paperyusuf anwerNo ratings yet

- Strength Characteristics of Quarry Dust in Replacement of SandDocument8 pagesStrength Characteristics of Quarry Dust in Replacement of SandSuman VarmaNo ratings yet

- Brijesh ERL PDFDocument5 pagesBrijesh ERL PDFBrajeshNo ratings yet

- Construction and Building MaterialsDocument10 pagesConstruction and Building MaterialsharshitNo ratings yet

- Stone Dust in Concrete: Effect On Compressive Strength: Amit Kumar Singh, Vikas Srivastava, V.C. AgarwalDocument4 pagesStone Dust in Concrete: Effect On Compressive Strength: Amit Kumar Singh, Vikas Srivastava, V.C. AgarwalerpublicationNo ratings yet

- Sawdust As Partial Substitution To Cement For Concrete Floor SlabDocument26 pagesSawdust As Partial Substitution To Cement For Concrete Floor SlabCris OrtoneroNo ratings yet

- Experimental Research of Saw Dust As Partial Replacement For Fine Aggregate in Production of Sandcrete Hollow Blocks in NigeriaDocument7 pagesExperimental Research of Saw Dust As Partial Replacement For Fine Aggregate in Production of Sandcrete Hollow Blocks in NigeriaOlumide AdenaiyaNo ratings yet

- Experimental Study of Partial Replacement of Cement in Concrete With Marble Dust and Recron Fibre As AdmixtureDocument9 pagesExperimental Study of Partial Replacement of Cement in Concrete With Marble Dust and Recron Fibre As AdmixtureEditor IJTSRDNo ratings yet

- And Stone Dust PDFDocument7 pagesAnd Stone Dust PDFEmanoAceNo ratings yet

- Structural Characteristics of Concrete Produced With Coal Ash and Jute Fibre For Sustainable EngineeringDocument9 pagesStructural Characteristics of Concrete Produced With Coal Ash and Jute Fibre For Sustainable EngineeringEmmanuel OgunjioforNo ratings yet

- Venkata KeerhiDocument8 pagesVenkata Keerhishivanand hippargaNo ratings yet

- With ReadingsDocument50 pagesWith ReadingsGaurav JethleNo ratings yet

- Experimental Study On Blended Concrete in R.C.C Beam and Its Behaviour Phase-Ii Review-1Document17 pagesExperimental Study On Blended Concrete in R.C.C Beam and Its Behaviour Phase-Ii Review-1HemapriyaNo ratings yet

- Study On Strength and Durability of Cellular Cement-Fly Ash BlocksDocument6 pagesStudy On Strength and Durability of Cellular Cement-Fly Ash BlocksDaniela BaqueroNo ratings yet

- A Review of Fresh and Hardened Properties of ConcrDocument16 pagesA Review of Fresh and Hardened Properties of ConcrYitayewamlak AregaNo ratings yet

- Ijciet: International Journal of Civil Engineering and Technology (Ijciet)Document8 pagesIjciet: International Journal of Civil Engineering and Technology (Ijciet)IAEME PublicationNo ratings yet

- Ferrosand Is A Highly Versatile Form of Reinforced Mortar Made Up of Wire MeshDocument6 pagesFerrosand Is A Highly Versatile Form of Reinforced Mortar Made Up of Wire MeshhodNo ratings yet

- Mechanical Behaviour of Composite Produced With Quarry DustDocument10 pagesMechanical Behaviour of Composite Produced With Quarry DustMiggy YangNo ratings yet

- Sustainable Design of Concrete Using IndDocument6 pagesSustainable Design of Concrete Using IndMILON KUMAR HORENo ratings yet

- Journal of Cleaner Production: Lan Zong, Zhengyue Fei, Shiping ZhangDocument8 pagesJournal of Cleaner Production: Lan Zong, Zhengyue Fei, Shiping ZhangShaik Abdul RaheemNo ratings yet

- Marble Powder For Normal Concrete M20 PDFDocument12 pagesMarble Powder For Normal Concrete M20 PDFgururajNo ratings yet

- Rice - Husk - Abhishek (1) .Docx 21Document29 pagesRice - Husk - Abhishek (1) .Docx 21Abhi ShekNo ratings yet

- Natural Aggregates Used For Light Weight Concrete A Review2020IOP Conference Series Materials Science and EngineeringDocument10 pagesNatural Aggregates Used For Light Weight Concrete A Review2020IOP Conference Series Materials Science and EngineeringJoe Alcantara RomeroNo ratings yet

- Utilization of Sawdust in Concrete Masonry Blocks: A ReviewDocument8 pagesUtilization of Sawdust in Concrete Masonry Blocks: A ReviewHussain MarzooqNo ratings yet

- 3 Iec2018.16Document12 pages3 Iec2018.16eng. douaaNo ratings yet

- JETIR2205718Document8 pagesJETIR2205718Faisal manzoorNo ratings yet

- Study On Compressive Strength of Quarry Dust As Fine Aggregate in Concrete K. Shyam Prakash and Ch. Hanumantha RaoDocument1 pageStudy On Compressive Strength of Quarry Dust As Fine Aggregate in Concrete K. Shyam Prakash and Ch. Hanumantha RaoAswin KrishnaNo ratings yet

- Strength and Durability Properties of Concrete Containing Quarry Rock Dust As Fine Aggregate R. Ilangovana, N. Mahendrana and K. NagamanibDocument1 pageStrength and Durability Properties of Concrete Containing Quarry Rock Dust As Fine Aggregate R. Ilangovana, N. Mahendrana and K. NagamanibAswin KrishnaNo ratings yet

- Properties of Sustainable Concrete Containing Red MUD Krishna Singh Kanyal, Yash Agrawal and Trilok GuptaDocument1 pageProperties of Sustainable Concrete Containing Red MUD Krishna Singh Kanyal, Yash Agrawal and Trilok GuptaAswin KrishnaNo ratings yet

- Performance Evaluations of Calcium Nitrite On Steel Rebar Corrosion in Quarry Dust Concrete Dr.M. DeviDocument1 pagePerformance Evaluations of Calcium Nitrite On Steel Rebar Corrosion in Quarry Dust Concrete Dr.M. DeviAswin KrishnaNo ratings yet

- An Experimental Study On Crushed Stone Dust As Fine Aggregate in Cement Concrete Sarvesh P.S RajputDocument1 pageAn Experimental Study On Crushed Stone Dust As Fine Aggregate in Cement Concrete Sarvesh P.S RajputAswin KrishnaNo ratings yet

- Construction and Building Materials: Job Thomas, B. HarilalDocument7 pagesConstruction and Building Materials: Job Thomas, B. HarilalAswin KrishnaNo ratings yet

- Bismark K. Meisuh, Charles K. Kankam, Thomas K. Buabin: Effect of Quarry Rock Dust On The Flexural Strength of ConcreteDocument1 pageBismark K. Meisuh, Charles K. Kankam, Thomas K. Buabin: Effect of Quarry Rock Dust On The Flexural Strength of ConcreteAswin KrishnaNo ratings yet

- Project Name Team Architect Drawing by Approved by Drawing Detail ApprovedDocument1 pageProject Name Team Architect Drawing by Approved by Drawing Detail ApprovedWahyu WahyuNo ratings yet

- SAQUIB AKRAM (B.SC Civil Engineering)Document4 pagesSAQUIB AKRAM (B.SC Civil Engineering)Uzair JavedNo ratings yet

- Double-Action Western - August 1957Document100 pagesDouble-Action Western - August 1957denecsNo ratings yet

- Atlas Copco Xahs 186 36,37Document2 pagesAtlas Copco Xahs 186 36,37AkmalNo ratings yet

- The Subsidiary Temple of Nekhtnebef at Tell El-BalamunDocument18 pagesThe Subsidiary Temple of Nekhtnebef at Tell El-BalamunLudwigRossNo ratings yet

- 1 Catalogue - Doors Timber 0.5 - 1hrDocument2 pages1 Catalogue - Doors Timber 0.5 - 1hrErika BanguilanNo ratings yet

- BoQ Mock Up STD RoomDocument14 pagesBoQ Mock Up STD RoomJO CHNo ratings yet

- D01 CPO Tank 1 Sounding Report R1Document21 pagesD01 CPO Tank 1 Sounding Report R1Joko Sandi AsmoroNo ratings yet

- Shigeru Ban FinalDocument13 pagesShigeru Ban FinalZain IhsanNo ratings yet

- Daily Report DED (20210529)Document11 pagesDaily Report DED (20210529)My pouNo ratings yet

- Worksheet For Design of Concrete Mix: Type 1 Portland CementDocument1 pageWorksheet For Design of Concrete Mix: Type 1 Portland CementLuis PacquiaoNo ratings yet

- Godrej Prima: An Address That'S Home ToDocument55 pagesGodrej Prima: An Address That'S Home TorattamNo ratings yet

- ANNEXURE-FG1000: Gear Opearted Lapping Machine For Gate, Globe, Check, Safety and Control ValvesDocument7 pagesANNEXURE-FG1000: Gear Opearted Lapping Machine For Gate, Globe, Check, Safety and Control ValvesSamihutaNo ratings yet

- Progress-Report Toril 01.30.2020Document1 pageProgress-Report Toril 01.30.2020Fedilino P. FornollesNo ratings yet

- Steel Structure Connection DrawingsDocument1 pageSteel Structure Connection DrawingsKavi Arasan0% (1)

- Heavy and Light EquipmentDocument8 pagesHeavy and Light EquipmentJulienne CNo ratings yet

- Cost Planning and Management Lecture 1Document89 pagesCost Planning and Management Lecture 1Nikhil JadhavNo ratings yet

- Online Lecture - Bridge BearingsDocument1 pageOnline Lecture - Bridge BearingsAayush AggarwalNo ratings yet

- Contracting For Collaboration in ConstructionDocument11 pagesContracting For Collaboration in ConstructionJunior Zacarías Girón IsidoroNo ratings yet

- Wet-Ic L&T Construction LTD., Water & Effluent Treatment IcDocument1 pageWet-Ic L&T Construction LTD., Water & Effluent Treatment IcRahesh MNo ratings yet

- 806 A01A02 Tech Data 921 Rev 8Document3 pages806 A01A02 Tech Data 921 Rev 8JohnSerranoNo ratings yet

- Use of Concrete Road Recycled Aggregates For Roller Compacted ConcreteDocument6 pagesUse of Concrete Road Recycled Aggregates For Roller Compacted Concretemoustafa hadj-doulaNo ratings yet

- Cover LetterDocument4 pagesCover LetterMelvin QuidongNo ratings yet

- Project: Qpmo Renovation Work: Propose Package Option-01Document4 pagesProject: Qpmo Renovation Work: Propose Package Option-01Mohd HaroonNo ratings yet

- If The World Was Ending ChordsDocument2 pagesIf The World Was Ending ChordsVanetNo ratings yet