Professional Documents

Culture Documents

General Construction Notes:: Rehabilitation and Expansion of Puntales Feeder Port

Uploaded by

alezandro del rossiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

General Construction Notes:: Rehabilitation and Expansion of Puntales Feeder Port

Uploaded by

alezandro del rossiCopyright:

Available Formats

1.

UNLESS OTHERWISE SHOWN IN PLANS ALL CONCRETE HOLLOW BLOCKS AND CERAMIC BLOCKS

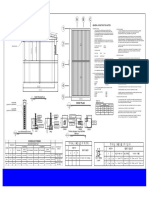

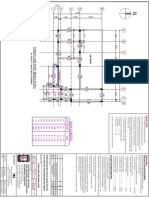

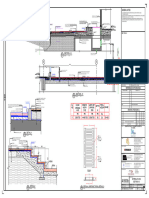

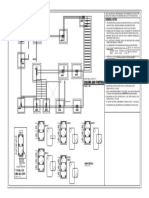

GENERAL CONSTRUCTION NOTES:

1. IN THE INTERPRETATION OF THE DRAWING, INDICATED DIMENSIONS SHALL GOVERN AND

DISTANCES OF SIZES SHALL NOT BE SCALED FOR CONSTRUCTION PURPOSES. 1. UNLESS OTHERWISE NOTED IN PLANS, THE YIELD STRENGTH OF REINFORCING BARS SHALL BE: SHALL BE REINFORCED AS SHOWN IN THE SCHEDULE OF CONCRETE HOLLOW BLOCKS AND CERAMIC

A. FOOTINGS, FOOTING BEAMS AND GIRDERS ------ fy = 275 MPa ( 40,000 psi ) BLOCK REINFORCEMENT.

2. IN REFERENCE TO OTHER DRAWINGS, SEE ARCHITECTURAL DRAWINGS FOR DEPRESSIONS

B. COLUMNS AND SHEAR WALLS -------------- fy = 275 MPa ( 40,000 psi )

IN FLOOR SLABS, OPENINGS IN THE WALLS AND SLABS, INTERIOR PARTIONS, LOCATION 2. PROVIDE 150mm x 300mm STIFFENER COLUMN REIFORCED WITH 4-12mm WITH 6mmØ TIES AT

OF DRAINS ETC. C. BEAMS AND GIRDER ------------------- fy = 275 MPa ( 40,000 psi ) 150mm ON CENTER WHERE CONCRETE HOLLOW BLOCK TERMINATES AND AT EVERY 3.0M LENGTH

3. IN CASE OF DISCREPANCIES AS TO THE LAYOUT, DIMENSIONS, AND ELEVATIONS BETWEEN D. NON-LOAD BEARING WALL PARTITIONS, BEDDED SLABS, FLOOR & ROOF SLABS, OF CONCRETE HOLLOW BLOCK WALLS UNLESS NOTED IN STRUCTURAL PLANS.

PARAPETS, CATCH BASIN, SIDE WALK. --------- fy = 227 MPa ( 33,000 psi ) 1. ALL WALLS SHALL BE REINFORCED ACCORDING TO THE FOLLOWING SCHEDULE OF WALL 1. UNLESS , OTHERWISE NOTED IN PLANS, CAMBER ALL

THE STRUCTURAL PLANS, AND ARCHITECTURAL DRAWINGS, THE COTRACTOR SHALL NOTIFY 1. PROVIDE EXTRA SETS OF TIES AT 100mm O.C. FOR TIED COLUMN REINFORCEMENT

REINFORCEMENT UNLESS OTHERWISE INDICATED IN THE PLANS. BEAMS AND GIDER AT LEAST 6mm.S

BOTH THE STRUCTURAL ENGINEERS AND THE ARCHITECT. 2. ALL REINFORCING BARS SIZE 10mm OR BIGGER SHALL BE DEFORMED IN ACCORDANCE WITH SCHEDULE OF CONCRETE HOLLOW BLOCK AND CERAMIC BLOCK REINFORCEMENT ABOVE AND BELOW BEAM-COLUMN CONNECTIONS FOR A DISTANCE FROM FACE FOR EVERY 4.50M OF SPAN , EXCEPT CANTILEVERS

ASTM A 706. BARS. BLOCK OF CONNECTION EQUAL TO THE GREATER OF THE OVERALL THICKNESS OF COLUMN,

4. ALL CONCRETE WORKS SHALL BE DONE IN ACCORDANCE WITH THE ACI.318 95 BUILDING THICKNESS REINFORCEMENT NOTES FOR WHICH THE CAMBER SHALL BE

3. SPLICES SHALL BE SECURELY WIRED TOGETHER & SHALL LAP OR EXTEND IN ACCORDANCE 1/6 THE CLEAR HEIGHT OF COLUMN OR 450mm. WALL VERTICAL AS NOTED IN PLANS OR AS ORDERED BY THE ENGINEER

CODE REQUIREMENTS FOR REINFORCED CONCRETE AND ALL STRUCTURAL STEEL WORK HORIZONTAL VERTICAL A. MINIMUM LAPS AT SPLICE = 0.25M

THICKNESS

W/ TABLE A & TABLE B (TABLE OF LAP SPLICE & ANCHORAGE LENGTH) UNLESS OTHERWISE 2. COLUMN TIES SHALL BE PROTECTED EVERYWHERE BY A COVERING OF CONCRETE CAST SECTION BUT IN NO CASE LESS THAN

ACCORDING WITH ASCI SPECIFICATION (9th EDITION) IN SO FAR AS THEY DO NOT CONFLICT B. PROVIdE RIGHT ANGLED REINFORCEMENT HORIZONTAL VERTICAL REMARKS

SHOWN ON DRAWINGS, SPLICES SHALL BE STAGGERED WHENEVER POSSIBLE. 75 mm 10mmØ @ 600mm O.C. 10mmØ @ 600mm O.C. 20mm FOR EVERY 3.0M OF FREE SPAN.

WITH THE LOCAL BUILDING CODE REQUIREMENT. AT CORNERS 0.92M LONG MONOLITHICALLY WITH THE CORE WITH THE MINIMUM THICKNESS OF 40mm AND NOT

100mm Ø10mm @ 250mm O.C. Ø10mm @ 300mm O.C. HORIZONTAL BARS VERT.

C. WHERE CHB OR CER. BLK. WALL DOWELS LESS THAN 40 TIMES THE MAXIMUM SIZE OF COARSE AGGREGATE IN MILLIMETERS. 20 BAR DIA.

5. ACI REFERS TO AMERICAN CONCRETE INSTITUTE, ASCI TO AMERICAN INSTITUTE OF STEEL 125 mm 10mmØ @ 600mm O.C. 10mmØ @ 600mm O.C. 125mm Ø10mm @ 200mm O.C. Ø10mm @ 250mm O.C. AT CENTERS VERTICAL BARS

JOIN COL. R.C. BEAMS AND WALL DOWELS

LAPPED SPLICE

3. WHERE COLUMNS CHANGE IN SIZE , VERTICAL REINFORCEMENTS SHALL SHALL BE OFFSET HORIZ. 2. TYPICAL BARS BENDING AND CUTTING DETAILS FOR ON COMPRESSION

CONSTRUCTION AND ASTM TO AMERICAN SOCIETY FOR TESTING MATERIALS. 150 mm 10mmØ @ 600mm O.C. 10mmØ @ 600mm O.C. 150mm Ø12mm @ 250mm O.C. Ø12mm @ 300mm O.C. BARS STAGGERED OUT

WITH THE SAME SIZE AS VERT. OR HOR. BARS SHALL BE AS SHOWN IN FIG. B-1. BARS

AT A SLOPE OF NOT MORE THAN 1 IN 6 AND EXTRA 10mm TIES AT 100mm SHALL THREE-FOURTH

6. CONSTRUCTION NOTES AND TYPICAL DETAILS APPLY TO ALL DRAWINGS UNLESS OTHERWISE 1. ALL SLAB REINFORCEMENTS SHALL BE 20mm CLEAR MINIMUM FROM BOTTOM AND FROM REINFORCEMENTS SHALL BE PROVIDED THE ENBEDMENT

200 mm 12mmØ @ 600mm O.C. 12mmØ @ 600mm O.C. BE PROVIDED THRU OUT THE OFFSET REGION. REINFORCING BARS SHALL HAVE 25mm CLEAR CONCRETE COVER FROM FACE OF WALL EXCEPT L1 L2 L1

SHOWN OR NOTED MODIFY TYPICAL DETAILS AS DIRECTED TO MEET SPECIAL CONDITIONS. THE TOP OF SLAB. LENGTHS IN

FOR WALLS IN CONTACT WITH THE GROUND WHERE A MINIMUM OF 60mm SHALL BE PROVIDED,

4. UNLESS OTHERWISE INDICATED IN THE PLANS, LAP SPLICES FOR COLUMN REINFORCE- SEE TABLE "A" TABLE 'A'

7. SHOP DRAWINGS WITH ERECTION AND PLACING DIAGRAMS OF ALL STRUCTURAL STEELS, 2. UNLESS OTHERWISE DETAILED IN CONTINUOUS SLAB HAVING SAME REINFORCEMENT RUNNING AND FOR EXPOSED FACES OF FORMED WALLS WHERE THE MINIMUM SHALL BE 50mm CLEAR. L1/5 L1/3 L1/4 L1/4 L1/3 L1/5

MENT SHALL BE MADE WITHIN THE CENTER HALF OF COLUMN HEIGHT, AND THE SPLICE FOR LENGTH OF

MISCELLANEOUS IRON, PRE-CAST CONCRETE ETC. SHALL BE SUBMITTED FOR ENGINEERS IN ONE DIRECTION, REINFORCING BARS SHALL BE BENT UP, OR CUT AS FOLLOWS 2. CARRY VERTICAL BARS AT LEAST 60mm ABOVE FLOOR LEVEL TO PROVIDE FOR SPLICES WHEN EMBEDMENT

APPROVAL BEFORE FABRICATION. LENGTH SHALL NOT BE LESS THAN 40 BAR DIAMETERS. WELDING OR APPROVED NECESSARY STOP AT 50mm BELOW TOP SLAB OR SOLID BAND WHERE THE WALL ENDS VERTICAL

MECHANICAL DEVICES MAY BE USED PROVIDED THAT NOT MORE THAN ALTERNATE BARS AND HORIZONTAL BARS SHALL BE SPLICED BY LAPPING A DISTANCE EQUAL TO 30 DIAMETERS

8. CONTRACTOR SHALL NOTE AND PROVIDE ALL MISCELLANEOUS CURBS, SILLS, STOOLS, ARE WELDED OR MECHANICALLY SPLICED AT ANY LEVEL AND THE VERTICAL DISTANCES AND WIRED SECURELY WITH 16 G.I. WIRE PROVIDED THAT SPLICES IN ADJACENT BARS ARE

EQUIPMENT'S AND MECHANICAL BASES THAT ARE REQUIRED BY THE ARCHITECTURAL, BETWEEN THESE WELDS OR SPLICES OF ADJACENT BARS IS NOT LESS THAN 600mm. STAGGERED AT LEAST 1.50M.O.C.

CLEAR TOTAL MIN. HEIGHT OF REINFORCEMENT

ELECTRICAL, AND MECHANICAL DRAWINGS. L /3 L2 /4 L2 /4

L /4 2 L3 2 2L/3 SPAN LENGTH fc' LINTEL 3. UNLESS OTHERWISE NOTED IN THE PLANS, ALL OPENINGS IN WALLS 250mm OR THICKER SHALL SEE TABLE "A"

H SEE TABLE "A" 15 MIN. (WHENE COUNTED

9. ALL RESULTS OF MATERIAL TESTING FOR CONCRETE, REINFORCING BARS, & STRUCTURAL ("L") (L+0.40M) (MPa) (MM) BOTTOM TOP STIRRUPS BE REINFORCED AROUND WITH 2-20mmØ BARS FOR 225mm, 200mm, 175mm, 150mm, USE FOR LENGTH OF FOR COMPRESSION

FOR LENGTH OF

2-16mmØ. FOR 125mm AND 100mm WALLS, USE 2-12mmØ BARS. ALL WALLS SPANNING EMBEDMENT EXTEND 20 DIA. 15 MIN.

STEEL MUST BE NOTED & APPROVED BY THE STRUCTURAL DESIGNER. CROSS-TIE LAPPED SPLICE

1.20M 1.60M 200 1-Ø10 1-Ø10 Ø6mm @ 200mm SHALL HAVE VERTICAL REINFORCEMENT BENT TO A U-FORM LIKE STIRRUPS AND SPACED BEYONG OPPOSITE FACE

0.20 MIN. 0.15M MIN. 0.15M MIN. EDGE BARS 150M 1.90M 14.0 200 1-Ø10 1-Ø10 Ø6mm @ 200mm SUPPORT

350mm. MAX.

ACCORDING TO THE SCHEDULE UNLESS OTHERWISE NOTED (SEE FIG.1)

2 BARS 1.80M 2.20M 200 1-Ø12 1-Ø10 Ø6mm @ 200mm

10 EXTERIOR COLUMN INTERIOR COLUMN INTERIOR COLUMN EXTERIOR COLUMN

1. ALL CONCRETE SHALL DEVELOP A MIN. COMPRESSIVE STRENGTH AT THE END OF TWENTY 2.10M 2.50M 250 1-Ø12 1-Ø10 Ø6mm @ 200mm d 4-Ø16 VERT. BARS SUPPORT SUPPORT SUPPORT SUPPORT

L2 /5 L2 /5 L3 /5 L3 /3 m

H

EIGHT (28) DAYS W/ CORRESPONDING MAXIMUM SIZE AGGREGATE & SLUMPS AS FOLLOWS. L1/3 L /5

2.40M 2.90M 17.0 250 1-Ø12 1-Ø10 Ø6mm @ 200mm in

2.70M 3.10M 250 1-Ø16 1-Ø12 Ø10mm @ 200mm . 4-Ø16 VERT. BARS

550

L

1 L

2 L

3 L

3

LOCATION 28 DAYS STRENGTH MAX. SIZE OF MAX. SLUMP TABLE 'A' TABLE 'B'

550

AGGREGATE EXTERIOR SPAN INTERIOR SPAN CANTILEVER SPAN 3.00 3.40M 300 1-Ø16 1-Ø12 Ø10mm @ 200mm

TENSION BARS COMPRESSION BARS

3.30 3.70M 20.0 300 1-Ø16 1-Ø12 Ø10mm @ 200mm

ALL OTHERS, INCLUDING 3.60 4.00 300 1-Ø20 1-Ø12 Ø10mm @ 200mm EMBEDMENT LENGTHS AND EMBEDMENT LENGTHS AND

3,000 PSI (20.70 MPa) 20mm 100mm JOINT HOOP SPACE @ "2Sh" WHEN

SUSPENDED SLABS, LAPPED SPLICED IN MILLIMETERS LAPPED SPLICED IN MILLIMETERS

CONF. REINF.

THERE ARE BEAMS HAVING WIDTH OF

COLUMNS 3.000 PSI (20.70 MPa) 20mm 100mm 12 THK. EXPANSION JOINT

AT LEAST ONE-HALF THE COLUMN BAR SIZE fc'= 20.7MPa(3000psi) fc'= 27.6MPa(4000psi) BAR SIZE fc'= 20.7MPa(3000psi) fc'= 27.6MPa(4000psi)

WITH MASTIC FILLER 1-Ø16 VERT. BARS

WIDTH & DEPTHS NOT LESS THAN 550 550 (DEFORMED) (DEFORMED)

BEAMS, SLABS 3,000 PSI (20.70 MPa) 20mm 100mm EMBEDMENT LAPPED EMBEDMENT LAPPED EMBEDMENT LAPPED EMBEDMENT LAPPED

3. IF SLABS ARE REINFORCED BOTHWAYS BARS ALONG THE SHORTER SPAN SHALL BE PLACED CHB WALL THREE QUARTERS OF THE DEEPEST

10mm Ø 300 300 300 300 10mm Ø 225 300 200 300

SLAB ON GRADE 2,500 PSI (17.24 MPa) 20mm 100mm BELOW THOSE ALONG THE LONG SPAN AT THE CENTER AND OVER THE LONGER SPAN BEAM THAT FRAME INTO FOUR TYPICAL CONNECTION DETAIL

(DOWEL)

FOR SIZE AND SPACING 12mm Ø 300 300 300 300 12mm Ø 275 300 250 300

FOR REINFOCING BARS NEAR THE SUPPORTS. THE SPACING OF THE BARS AT THE COLUMN SIDES OF THE COLUMN. ALL OTHER

OF R.C. WALL AT CORNERS

400

OF HOR. & VERT. BARS

2. MAINTAIN MINIMUM CONCRETE COVER FOR REINFORCING STEEL AS FOLLOWS. STRIPS SHALL BE APPOXIMATELY ONE AND A HALF (1 1/2) SLAB THICKNESS 1-Ø16 VERT. BARS CONDITIONS USE HOOPS @ "Sh" CENTERS. 16mm Ø 300 400 300 400 16mm Ø 350 400 325 400

OR 45 CENTIMETERS CHB WALL SEE CONSTRUCTION NOTES.

CONF. REINF.

SUSPENDED SLABS -------------------------------------- 20mm FLR. SLAB OR BEAM DOWEL BARS TO 20mm Ø 400 550 350 500 20mm Ø 450 500 475 500

SLAB ON GRADE ---------------------------------------- 40mm 4. TEMPERATURE BARS FOR SLAB SHALL BE GENERALLY PLACED NEAR THE FACE IN TENSION FOR SIZE AND SPACING MATCH VERT. BARS

Sh

SEE CONSTRUCTION NOTES 25mm Ø 600 800 550 750 25mm Ø 550 625 550 625

WALLS ABOVE GRADE ------------------------------------- 25mm AND SHALL NOT BE LESS THAN 0.0025 BT. (SEE SCHEDULE BELOW) OF HOR. & VERT. BARS

(DOWEL)

SEE CONSTRUCTION NOTES. FOR MASONRY WALL REIN- 28mm Ø 750 1000 650 850 28mm Ø 625 675 625 675

BEAM STIRRUPS AND COLUMN TIES ---------------------------- 40mm

SCHEDULE OF MINIMUM SLAB REINFORCEMENT FORCEMENTS (TYPICAL)

400

WHERE CONCRETE IS EXPOSED TO CORNER WALL OPENING OR END WALL FIN. FLR. LVL.

PER SCHEDULE

32mm Ø 950 1300 850 1100 32mm Ø 700 775 700 775

FOR COL. BAR SPLICES SEE TABLE 1. ALL JOINTS AND CELLS

EARTH BUT POURED AGAINST FORMS --------------------------- 50mm THICKNESS MINIMUM TEMPERATURE BARS

OF MIN. LAP SPLICE LENGTH OF CONTAINING REINFORCING NOTE : TOP PLAIN BARS , MULTIPLY VALUE BY 2 NOTE : TOP PLAIN BARS , MULTIPLY VALUE BY 2

WHERE CONCRETE IS DEPOSITED

100 mm 10 mm Ø @ 400mm EACH WAY 1-Ø16 VERT. BARS R.C. COLUMN OR WALL COLUMN REINFORCEMENT BARS SHALL BE FILLED NAT. GRD. LVL. VALUES GIVEN ABOVE CAN ALSO BE USED

DIRECTLY AGAINST EARTH ---------------------------------- 75mm

(SPACING OF TIES ALONG THIS REGION DOWEL BARS TO MATCH FOR COLUMNS.

125 mm 10 mm Ø @ 400mm EACH WAY DOWEL BARS TO MATCH WITH CONCRETE GROUT.

3. CONCTRETE SHALL BE DEPOSITED IN ITS FINAL POSITION WITHOUT SEGREGATION. RE-HAND 12 THK. EXPANSION JOINT SHALL NOT BE LESS THAN 100mm) CHB VERTICAL BARS 3. IF THE BEAM REINFORCING BARS END IN A WALL THE CLEAR DISTANCE FROM THE BAR TO

CHB HOR. BARS 2. FOR REINFORCEMENTS SEE

LING OR FLOWING PLACING SHALL BE DONE PREFERABLY WITH BUGGIES, BUCKETS OR 150 mm 10 mm Ø @ 250mm EACH WAY WITH MASTIC FILLER THE FARTHER FACE OF THE WALL NOT BE LESS THAN 25mm. EMBEDMENT LENGTH SHALL

Ø10 BOTT. BARS

CONF. REINF.

CONSTRUCTION NOTES.

WHEELBARROWS, NO CHUTES WILL BE ALLOWED EXCEPT TO TRANSFER CONCRETE FROM CHB WALL 12 THK. EXPANSION JOINT @ 300 O.C. BE AS SHOWN IN A TABLE 'A' FOR TENSION BARS AND TABLE 'B' FOR COMPRESSION BARS

Sh

175 mm 10 mm Ø @ 225mm EACH WAY

(DOWEL)

HOPPERS TO BUGGIES, WHEELBARROWS OR BUCKETS IN WHICH CASE THEY SHALL NOT WITH MASTIC FILLER UNLESS SPECIFIED IN PLAN S. TOP BAR SHALL NOT BE SPLICED WITHIN THE COLUMN OR

3-Ø10 BOTT. BARS

400

WITHIN A DISTANCE TWICE THE MEMBER DEPTH FROM THE FACE OF THE COLUMN. AT LEAST

EXCEED SIX (6) METERS IN AGGREGATE LENGTH. 200 mm 10 mm Ø @ 150mm EACH WAY NOTE: 1-Ø16 CONT. HOR. BARS TWO STIRRUPS SHALL BE PROVIDED AT ALL SPLICES.

(DOWEL)

4. NO DEPOSITING OF CONCRETE SHALL BE ALLOWED WITHOUT THE USE OF VIBRATORS ALL CONCRETE REINF. DETAIL SHOULD FOR FLOOR SLAB ONLY

4. IF THERE ARE TWO OR MORE LAYERS OF REINFORCING BARS, USE 25mmØ BAR SEPARATORS

400

UNLESS AUTORIZED IN WRITING BY THE DESIGNERS AND ONLY FOR UNUSUAL CONDITIONS 5. UNLESS OTHERWISE NOTED IN THE PLANS ALL BEDDED SLABS SHALL BE REINFORCED BE DONE IN ACCORDANCE WITH ACI

WITH 10mm Ø AT 250mm O.C EACH WAY TO CENTER OF SLAB AND CONSTRUCTION FOR SIZE AND SPACING SPACED AT 1.0M ON CENTER. IN NO CASE SHALL THERE BE LESS THAN TWO (2) SEPARATORS

WHERE VIBRATIONS IS EXTREMELY DIFFICULT TO ACCOMPLISH. DETAILING MANUAL LATEST EDITION

JOINTS FOR SAME SHALL NOT BE LESS THAN 3.65 METER APART OF HOR. & VERT. BARS DOWEL TO MATCH BETWEEN TWO LAYERS OF BARS.

5. ALL ANCHOR BOLTS, DOWELS, AND OTHER INSERTS, SHALL BE PROPERLY POSITIONED & SEE CONSTRUCTION NOTES. 400

CONF. REINF.

CHB VERT. BARS 5. MINIMUM CONCRETE PROTECTION FOR REINFORCING BARS OR STEEL SHAPES SHALL BE AS

SECURED IN PLACE PRIOR TO PLACING OF CONCRETE. 6. PROVIDE EXTRA REINFORCEMENTS FOR CORNER SLAB (TWO ADJACENT DISCONTINUOUS (DOWEL) TYP. SECTION OF MASONRY

EDGES) AS SHOWN BELOW. WHERE DEPRESSED SHOWN IN FIG. B-2 UNLESS SPECIFIED ELSEWHERE.

6. ALL CONCRETE SHALL BE KEPT MOIST FOR A MINIMUM OF SEVEN CONSECUTIVE DAYS INTERSECTION WALL INTERSECTING R.C. COL. OR WALL

PARTITION REINFORCEMENTS SLAB OCCURS

b

7. CONCRETE SLAB REINFORCEMENTS SHALL BE PROPERLY SUPPORTED WITH 10mmØ STEEL MAIN REINFORCEMENT

IMMEDIATELY AFTER POURING BY THE USE OF WET BURLAP FOG SPRAYING, CURING

CHAIR OR APPROVED EQUIVALENT SPACED AT 1.0 METER ON CENTER BOTHWAYS DOWEL TO MATCH

COMPOUNDS OR OTHER APPROVED METHODS.

t

TYPICAL CONNECTION DETAIL OF MASONRY WALL TYPICAL COLUMN ELEV. SHOWING CHB VERT. BARS

t OR 1/4 D

7. STRIPPING OF FORMS AND SHORES:

FOUNDATION -----------------------------------------

DOWELS AND TIES SPACING WEB BARS

t

24 HRS. SLEEVES FOR UTILITY

ht

SEE NOTE

SUSPENDED SLAB EXCEPT WHEN PIPES MAX. 1/5 D

200 (MIN) 200 (MIN)

D

LAP SPLICE LENGTH: SEE NOTE

ADDITIONAL LOADS ARE IMPOSED ----------------------------- 8 DAYS Ø12x1000 LONG AT

DOWN INTO EDGE BEAM. EXTENDED AT ANY LEVEL NO MORE THAN

WALLS --------------------------------------------- 21 DAYS MID-DEPTH OF SLAB 3-Ø10 BARS (AS SHOWN)

4-Ø 12@ 1800 LONG TOP BARS BEND FOR SIZE AND SPACING ALTERNATE BARS SHOULD BE FIN. FLR. LVL.

BEAMS --------------------------------------------- 14 DAYS BARS MIN. OF 1,200 (4'-0") INTO BARS. AT EACH CORNER Ø10 STIRRUPS OF HOR. & VERT. BARS Ø10 BOTT. BARS @ 300 O.C. PROVIDE 3-Ø10 EXTRA STIRR.

SPLICED. MIN. DISTANCE BET. 0.025M Ø

COLUMNS -------------------------------------------- 21 DAYS @ 150 O.C. SEE CONSTRUCTION NOTES EACH SIDE OF SLEEVES

1-Ø12 TOP & TWO ADJACENT BARS SPLICES SEE NOTE SEPARATOR

4-Ø12 BOTT. BARS

WITHIN CENTER

BOTT. BARS

(DOWEL)

SHALL BE 600mm.

8. THE CONTRACTOR SHALL SUBMIT THE SCHEDULE OF POURING AND THE LOCATION OF THE 20 mm CLEAR FOR JOIST TYP. DET. FOR SLEEVES

DOWEL BARS TO MATCH 3-Ø10 BARS (AS SHOWN) TYPICAL CHB FOOTING DETAILS

HALF OF "H"

400

CONSTRUCTION JOINTS TO THE STRUCTURAL ENGINEER AT LEAST (4) DAYS PRIOR TO THE NOTE 1 40 mm CLEAR FOR BEAMS

CHB WALL L/4 THRU CONCRETE BEAM

400

CHB VERT. BARS Ø10 BOTT. BARS @ 300 O.C. AND GIRDERS

POURING FOR APPROVAL. 2 BARS

( WHERE APPLICABLE )

9. THE CONTRACTOR SHALL FURNISH AND MAINTAIN ADEQUATE FORMS SHORINGS UNTIL THE 2-Ø12 TOP BARS TOP BARS @ SUPPORT (CONT.) FIG. B-2 FIG. B-3

0

60

OPENING 6. WHEN A BEAM CROSSES A GIRDER, REST BEAM ON TOP OF GIRDER BARS, BEAM REINF-

200

CONCRETE MEMBERS HAVE ATTAINED THEIR WORKING CONDITION AND STRENGTH. 1-Ø16 VERT. REQ'D. BOTT. BARS @ SUPPORT (min.) (min.)

SLAB 38mm

CLEAR BARS TYPICAL 2-Ø12 BOTT. BARS FORCING BAR SHALL BE SYMMETRICAL ABOUT CENTER LINE WHENEVER POSSIBLE.

0

OPENING

60

t=FOR SLAB

7. GENERALLY NO SPLICES SHALL BE PERMITTED AT POINTS WHERE CRITICAL BENDING STRESSES

JT. REINF.

OCCUR, SPLICES WHERE SO PERMITTED SHALL BE INDICATED IN THE TABLE 'A' AND 'B'.

1. FOOTINGS ARE DESIGNED FOR AN ALLOWABLE SOIL BEARING PRESSURE OF 112.00 WELDED SPLICES SHALL DEVELOP IN TENSION AT LEAST 125 % OF THE SPECIFIED YIELD

2 BARS

SECTION

400

STRENGTH OF THE BAR. NOT MORE THAN 50% OF THE BARS AT ANY ONE SECTION IS

FIN. FLR. LVL.

ALLOWED TO BE SPLICED THEREIN.

CONDITIONS, UNCOVERED AND CONFIRM ACTUAL BEARING CAPACITY OF SOIL BEFORE

DEPOSITING CONCRETE. IN TWO WAY SLAB EXTEND BOTTOM BARS

BARS UP TO BEAM SUPPORT ELEVATION 20 SPLICE

AT MID SPAN 2t=FOR SLAB

60

2. FOOTING SHALL REST AT LEAST 1500mm BELOW NATURAL GRADE LINE UNLESS OTHERWISE

0

OMIT TRIMMER BARS WHERE 1. USE E70xx ELECTRODES FOR ALL MEMBERS WELDED.

INDICATED IN PLANS. NO FOOTING SHALL REST ON FILL. EXTRA TOP BARS

OPENING IS FRAMED BY BEAM

3. MINIMUM CONCRETE PROTECTION FOR REINFORCEMENTS SHALL BE 75mm CLEAR

TYP. DET. OF LINTEL BEAM AT CHB WALL OPENING @ SUPPORT (min.) 2. WELDS SHALL DEVELOP THE FULL STRENGTH OF MEMBERS JOINED UNLESS OTHERWISE

FOR CONCRETE DEPOSITED THE GROUND AND 50mm FOR CONCRETE TYPICAL CORNER SLAB DETAIL TYPICAL SLAB TYP. DETAIL OF COL. LAP SPLICE TYPICAL DETAIL FOR BEAM SHOWN OR DETAILED IN THE DRAWINGS.

DEPOSITED AGAINST A FORMWORK. OPENING DET. OR SLAB CHANGE SOFFIT

& EXT. GIRDER TO COL. CONNECT.

1. STRUCTURAL STEEL TO BE USED FOR FABRICATION AND ERECTION OF THIS STRUCTURE SHALL

COMPLY WITH ALL THE PERTINENT PROVISION OF AISC SPECIFICATION FOR THE DESIGN,

1. ALL REINFORCEMENT SHALL BE BENT COLD UNLESS OTHERWISE PERMITTED BY THE FABRICATION AND ERECTION OF STRUCTURAL STEEL FOR BUILDING LATEST EDITION.

db

STRUCTURAL ENGINEER. MAIN BAR END HOOKS STIRRUP AND TIE HOOKS 2. ALL STRUCTURAL STEEL SHAPES SHALL BE ASTM A 36 STRUCTURAL STEEL UNLESS

1. WHERE A CONSTRUCTION JOINT IS TO BE MADE, MAIN REINFORCEMENTS

NOTE: 2. REINFORCEMENT PARCIALLY EMBEDED IN CONCRETE SHALL NOT BE FILLED BENT, EXCEPT (ALL GRADES) (ALL GRADES) OTHERWISE INDICATED.

TO BE CONTINUOUS PROVIDE THESE ADDITIONAL BARS FOR

AS SHOWN IN THE DESIGN DRAWINGS OR PERMITTED BY THE STRUCTURAL ENGINEER. 3. ALL WELDED CONNECTIONS SHALL DEVELOP THE FULL STRENGTH OF THE MEMBERS CONNECTED.

L

THE SURFACE OF CONCRETE SHALL BE 38mm

ALL OPENINGS PLUS BARS (NOT BAR SIZE DIAMETER BAR SIZE DIAMETER

CLEANED AND ALL LAITANCE AND CLEAR WINDOW 3. TIES & CLOSE STIRRUPS MUST BE BENT AT 135°. 180° HOOK 90° HOOK 180° HOOK 90° HOOK 4. ALL BOLTS USED UNLESS OTHERWISE SPECIFIED SHALL BE ASTM A 307 BOLTS.

Ø10x1000 LONG SHOWN) PARALLEL TO SIDE OF OPENING

STANDING WATER REMOVED. @ 300 O.C. OPENING (DEFORMED) (mm) (DEFORMED) (mm)

EQUAL TO THE NUMBER OF TERMINATED L D+2db L L D+2db L L

MAIN REINFORCEMENTS TO BE

D db

D+2db

CONTINUOUS (TOP & BOTT. BARS) 40 BARS AT OPENING A. ALL EMBEDED PIPES FOR UTILITIES, ETC. THAT PASS THRU BEAMS SHALL BE MAXIMUM 100mm

D

10mm Ø 60 75 125 150 10mm Ø 40 125 85 100

6d

DOOR

b

OR D/3 WHICHEVER IS LESS DIAMETER SINGLE RIGID GALVANIZED IRON PIPE UNLESS OTHERWISE

t/3

SEE ARCHITECTURAL & MECHANICAL

OPENING 4db or 65mm 12mm Ø 75 100 150 200 12mm Ø 50 165 115 115

WHERE JOINTS IS AT POINT OF OR APPROVED IN WRITING BY THE STRUCTURAL ENGINEER.

t/3

PLANS FOR SLAB OPENING LOCATION.

t

STRESS, PROVIDE SHEAR RODS

t/3

WITH ENGINEERS APPROVAL 16mm Ø 95 125 175 250 16mm Ø 65 200 140 150 B. NO PIPES SHALL BE ALLOWED TO PASS THRU BEAMS VERTICALLY.

SLAB C. NO PIPES SHALL BE EMBEDED TO COLUMNS.

30 BAR DIA. 30 BAR DIA.

db

50

(MIN.) (MIN.)

TYPICAL SLAB & BEAM CONSTRUCTION JOINT DET. 1. PROVIDE TEMPORARY REMOVAL OF WATER FROM ANY SOURCE DURING CONSTRUCTION. DEWATERING

D/3

12db

L

L SHALL BE CAREFULLY AND PROPERLY PERFORMED TO AVOID DISTURBING THE FOUNDATIONS AND

TYP. EXTERIOR WINDOW & DOOR OPENING

D/3

L1 SLAB BEARING SURFACES.

D

D

D/3

2. CONTRACTOR SHALL DESIGN, INSTALL AND MONITOR EXCAVATIONS RETENTION SYSTEMS, AS REQUIRED FOR

PROTECTION OF ADJACENT PROPERTIES AND PROVIDE ALL MEASURES AND PRECAUTIONS NECESSARY TO

BEAM MINIMIZE SETTLEMENT AND PREVENT DAMAGE TO ADJACENT EXISTING OR NEW CONSTRUCTION.

PROJECT TITLE: CERTIFIED BY : PRC NO. : PREPARED BY : CHECKED & REVIEWED BY : RECOMMENDING APPROVAL : APPROVED BY : SHEET CONTENTS : SHEET NO. :

REPUBLIC OF THE PHILIPPINES VALIDITY : GENERAL NOTES

REPUBLIC OF THE PHILIPPINES

DEPARTMENT OF AGRICULTURE

REGION VI-WESTERN VISAYAS

PROVINCE OF ILOILO

BONIFACIO DRIVE , ILOILO CITY 5000

REHABILITATION AND EXPANSION

OF PUNTALES FEEDER PORT

P T R NO. :

DATE ISSUED :

GENERAL CONSTRUCTION NOTES

S-01

PHILIPPINE RURAL DEVELOPMENT PROJECT PROJECT SP ID NP.:

EVA MAE V. PARRENAS ROMEO ANDIG RAUL N. BANIAS M.D.,MPA ATTY. SUZETTE A. MAMON ARTHUR R. DEFENSOR JR.

PRDP-IB-R006-ILO-010-000-000-2019-AF

PROJECT LOCATION: BRGY. NIPA , CONCEPCION , ILOILO

PLACE ISSUED :

T I N:

M U N I C I P A L E N G I N E E R ACTING PROVINCIAL ENGINEER MUNICIPAL MAYOR , MUNICIPALITY OF CONCEPCION PROVINCIAL ADMINISTRATOR P R O V I N C I A L G O V E R N O R 44-84

You might also like

- Irr of R.A. No.8981Document13 pagesIrr of R.A. No.8981Patrice Bernabe75% (4)

- Irr of R.A. No.8981Document13 pagesIrr of R.A. No.8981Patrice Bernabe75% (4)

- Construction of Multi-Level ParkingDocument13 pagesConstruction of Multi-Level Parkingdunknown15No ratings yet

- Details - WF Wall Footing Masonry Details: CHB To Slab-On-Grade End DetailsDocument1 pageDetails - WF Wall Footing Masonry Details: CHB To Slab-On-Grade End Detailsacurvz2005No ratings yet

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- MIVAN SeminarDocument57 pagesMIVAN Seminarrsandye67% (3)

- Earthing in Industrial and Pharmaceutical PlantsDocument28 pagesEarthing in Industrial and Pharmaceutical PlantsBrayden Chetty100% (1)

- General Construction Notes:: Rehabilitation and Expansion of Puntales Feeder Port S-01 24-59Document1 pageGeneral Construction Notes:: Rehabilitation and Expansion of Puntales Feeder Port S-01 24-59alezandro del rossiNo ratings yet

- General Construction Notes: Schedule of Minimum Slab ReinforcementDocument1 pageGeneral Construction Notes: Schedule of Minimum Slab ReinforcementDominic Robiso DatuinNo ratings yet

- General Construction Notes: Schedule of Minimum Slab ReinforcementDocument2 pagesGeneral Construction Notes: Schedule of Minimum Slab ReinforcementDominic Robiso DatuinNo ratings yet

- GennotesDocument1 pageGennotesNeil ArmstrongNo ratings yet

- Construction Notes: 30 BAR. DIA. 30 BAR. DIA. 40Document1 pageConstruction Notes: 30 BAR. DIA. 30 BAR. DIA. 40MARKCHRISTMASNo ratings yet

- PlanDocument8 pagesPlanMark Christian EsguerraNo ratings yet

- Design: Construction NotesDocument1 pageDesign: Construction NotesLhea May Paz SarguetNo ratings yet

- QAHD Office Building 30 M Structural Plans-S102.0Document1 pageQAHD Office Building 30 M Structural Plans-S102.0Adrian PachecoNo ratings yet

- For Construction Drawing - FCD: General Structural Notes & SpecificationsDocument1 pageFor Construction Drawing - FCD: General Structural Notes & SpecificationsJossell De AlaNo ratings yet

- General: Schedule of CHB & Ceramic Block ReinforcementDocument1 pageGeneral: Schedule of CHB & Ceramic Block Reinforcementbobmarley20161934No ratings yet

- S-001-General Notes-1Document1 pageS-001-General Notes-1JohnIsaacNo ratings yet

- QAHD Office Building 30 M Structural Plans-S100.0Document1 pageQAHD Office Building 30 M Structural Plans-S100.0Adrian PachecoNo ratings yet

- Att-06 Drawing MarkupsDocument13 pagesAtt-06 Drawing MarkupsabdullahNo ratings yet

- Typical Truss Detail Construction Notes S-5: Not To Scale Not To Scale Sheet Content: M G Tambalque Design & ConstructionDocument1 pageTypical Truss Detail Construction Notes S-5: Not To Scale Not To Scale Sheet Content: M G Tambalque Design & ConstructionCedrixe MadridNo ratings yet

- Produced by An Autodesk Student Version: Sheet Content: Cad By: Sheet No: Project TitleDocument1 pageProduced by An Autodesk Student Version: Sheet Content: Cad By: Sheet No: Project TitleRachelle AtienzaNo ratings yet

- Structural Notes 1Document1 pageStructural Notes 1missiklein3No ratings yet

- Structural - AOBDocument21 pagesStructural - AOBMr. Mark B.No ratings yet

- Structual Plan 2-Storey ResidentialDocument9 pagesStructual Plan 2-Storey ResidentialMark Christian EsguerraNo ratings yet

- Design Criteria: Reinforcing SteelDocument12 pagesDesign Criteria: Reinforcing SteelALL-ROUNDER CIVIL ENGINEERS ENGLISHNo ratings yet

- Design of 33 SQM HousingDocument1 pageDesign of 33 SQM HousingDJNo ratings yet

- Anabu S 2Document1 pageAnabu S 2rexurctor21No ratings yet

- A. General Notes: B. Notes and Concrete Mixes and PlacingDocument1 pageA. General Notes: B. Notes and Concrete Mixes and Placingdomin domNo ratings yet

- General Concrete Slab Concrete Hollow Block Structural SteelDocument1 pageGeneral Concrete Slab Concrete Hollow Block Structural Steelparkrocky0No ratings yet

- E:/1. Hai Phat/Nh19/1. Detail Design/99. Xuat Ho So/General Notes/General Notes - DWG - Date: Thu, 22 Oct 2020 - 1:58Pm Pc:LamntDocument2 pagesE:/1. Hai Phat/Nh19/1. Detail Design/99. Xuat Ho So/General Notes/General Notes - DWG - Date: Thu, 22 Oct 2020 - 1:58Pm Pc:LamntHoang Nguyen HuyNo ratings yet

- Jayamangal Dining BlockDocument4 pagesJayamangal Dining BlockShiwani SahNo ratings yet

- Civil / Structural Construction Notes: Nearest Faultline Site Location FromDocument1 pageCivil / Structural Construction Notes: Nearest Faultline Site Location FromVince Bagsit PolicarpioNo ratings yet

- Engr Micheal STRDocument12 pagesEngr Micheal STRUmar SaiduNo ratings yet

- Plot - 1 - TERRACE ROOF BEAM LAYOUTDocument1 pagePlot - 1 - TERRACE ROOF BEAM LAYOUTMõhâmméd WassimNo ratings yet

- Construction Notes-AaDocument2 pagesConstruction Notes-AaRieo VillaNo ratings yet

- General Structural Notes Structural Steel Framing Notes:: Site Prep For CT ScannerDocument14 pagesGeneral Structural Notes Structural Steel Framing Notes:: Site Prep For CT ScannerMark JangadNo ratings yet

- 20171003-Beam & Slab Schedule-01Document1 page20171003-Beam & Slab Schedule-01Atul ShrivastavaNo ratings yet

- 006 STRCT1Document1 page006 STRCT1kingjam dimacaling2019No ratings yet

- STR - 1Document1 pageSTR - 1shankar9841469226No ratings yet

- General Construction Notes:: Two Story Residential Building Jerg Sunogan S-1Document6 pagesGeneral Construction Notes:: Two Story Residential Building Jerg Sunogan S-1clemennikki29No ratings yet

- Typ 1Document1 pageTyp 1aedlk.cpwdNo ratings yet

- Design Details Canopy Ground FloorDocument1 pageDesign Details Canopy Ground FloorAditya K100% (1)

- NotesDocument1 pageNotesMohammad AlkahteebNo ratings yet

- General Notes: Structural DetailsDocument1 pageGeneral Notes: Structural DetailsMohammad AlkahteebNo ratings yet

- Gen Notes StrucDocument1 pageGen Notes StrucorderNo ratings yet

- NoteDocument1 pageNotePom tancoNo ratings yet

- Drawing Sheet 4Document1 pageDrawing Sheet 4Kunal SharmaNo ratings yet

- General: Structural SteelDocument1 pageGeneral: Structural SteelDerf Jayson AdanteNo ratings yet

- General Structural Specifications: 1.0 Notes On Concrete Mixes and Placing 6.0 Notes On Concrete SlabsDocument1 pageGeneral Structural Specifications: 1.0 Notes On Concrete Mixes and Placing 6.0 Notes On Concrete SlabsAlfred T. Infante IIINo ratings yet

- General Notes BridgeDocument6 pagesGeneral Notes BridgeEnglish for KidsNo ratings yet

- General Construction Notes: Codes and Standards General Notes Reinforcing Steel Beams and GirdersDocument1 pageGeneral Construction Notes: Codes and Standards General Notes Reinforcing Steel Beams and GirdersByen VillanuevaNo ratings yet

- Proposed Three-Storey Building: General Structural / Construction Notes and SpecificationsDocument1 pageProposed Three-Storey Building: General Structural / Construction Notes and SpecificationsAngelo AmarNo ratings yet

- DR - 1.majid Albana Structural 13 Floor BUILDING 23Document1 pageDR - 1.majid Albana Structural 13 Floor BUILDING 23Mohamad RammelNo ratings yet

- MR - Rasul - Set - 2 - Structural - Drawing-12.RCC NOTES PDFDocument1 pageMR - Rasul - Set - 2 - Structural - Drawing-12.RCC NOTES PDFMr. SinghNo ratings yet

- A-1803b - Landscape Sections & Details - 03Document1 pageA-1803b - Landscape Sections & Details - 03karthikeyan dhanasekaranNo ratings yet

- Treehouse, Waiheke Island: Structural Steelwork NotesDocument12 pagesTreehouse, Waiheke Island: Structural Steelwork NotesKesavan DhuraiNo ratings yet

- General NotesDocument1 pageGeneral NotesMark Christian EsguerraNo ratings yet

- Dpw-1 Retaining Wall 1028' RFTDocument1 pageDpw-1 Retaining Wall 1028' RFTM JAVEDNo ratings yet

- 1 Footing Plan PDFDocument1 page1 Footing Plan PDF114 Gopal jagtapNo ratings yet

- Structural Specifications and Standard DetailsDocument1 pageStructural Specifications and Standard Detailsdomin domNo ratings yet

- Reinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionFrom EverandReinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionNo ratings yet

- Coded RA9266 (For All Philippine Architects)Document18 pagesCoded RA9266 (For All Philippine Architects)adolfblitzkriegNo ratings yet

- Rule Viii - Light & VentilationDocument44 pagesRule Viii - Light & VentilationReigneth VillenaNo ratings yet

- The Implementing Rules and Regulations (Irr) of Republic Act No. 9266Document39 pagesThe Implementing Rules and Regulations (Irr) of Republic Act No. 9266Gen Lamsis AlmoraNo ratings yet

- RA 9266 Architecture Act of 2004Document10 pagesRA 9266 Architecture Act of 2004Botenes Mallorca RhonNo ratings yet

- Architects Code of EthicsDocument9 pagesArchitects Code of EthicsMark Gella Delfin100% (1)

- Rule 7c - Classification & General Requirements of All Bldgs by Use or Occupancy - Part 3 - Revised2Document39 pagesRule 7c - Classification & General Requirements of All Bldgs by Use or Occupancy - Part 3 - Revised2Thea AbelardoNo ratings yet

- RA 9266 Architecture Act of 2004Document10 pagesRA 9266 Architecture Act of 2004Botenes Mallorca RhonNo ratings yet

- RA 1378 - Master Plumber LawDocument5 pagesRA 1378 - Master Plumber LawFzoe YambaoNo ratings yet

- Rule Vii - Classification & General Requirements - Part 1Document3 pagesRule Vii - Classification & General Requirements - Part 1alezandro del rossiNo ratings yet

- Rule Viii - Light & VentilationDocument44 pagesRule Viii - Light & VentilationReigneth VillenaNo ratings yet

- Structural DesignDocument34 pagesStructural Designdave4359No ratings yet

- Rev 207 Matrix Excel FileDocument4 pagesRev 207 Matrix Excel FileJessie Obnamia CentilloNo ratings yet

- Rule 7c - Classification & General Requirements of All Bldgs by Use or Occupancy - Part 3 - Revised2Document39 pagesRule 7c - Classification & General Requirements of All Bldgs by Use or Occupancy - Part 3 - Revised2Thea AbelardoNo ratings yet

- Architects Code of EthicsDocument9 pagesArchitects Code of EthicsMark Gella Delfin100% (1)

- RULE VII - Table VII - Schedule of Principal Accessory ConditiDocument31 pagesRULE VII - Table VII - Schedule of Principal Accessory Conditialezandro del rossiNo ratings yet

- Coded RA9266 (For All Philippine Architects)Document18 pagesCoded RA9266 (For All Philippine Architects)adolfblitzkriegNo ratings yet

- Rev 207 Matrix Excel FileDocument4 pagesRev 207 Matrix Excel FileJessie Obnamia CentilloNo ratings yet

- Rule VIIa - Class&GenReqtsBldgsPart1 PDFDocument3 pagesRule VIIa - Class&GenReqtsBldgsPart1 PDFOllyn FelipeNo ratings yet

- Board Exam SyllabusDocument7 pagesBoard Exam Syllabusalezandro del rossiNo ratings yet

- Structural DesignDocument34 pagesStructural Designdave4359No ratings yet

- Structural DesignDocument34 pagesStructural Designdave4359No ratings yet

- The Implementing Rules and Regulations (Irr) of Republic Act No. 9266Document39 pagesThe Implementing Rules and Regulations (Irr) of Republic Act No. 9266Gen Lamsis AlmoraNo ratings yet

- RA 1378 - Master Plumber LawDocument5 pagesRA 1378 - Master Plumber LawFzoe YambaoNo ratings yet

- 1998jun UtilDocument6 pages1998jun UtilGail VoirNo ratings yet

- Accommodation EstablishmentsDocument30 pagesAccommodation EstablishmentsGelyn MacasiebNo ratings yet

- 96 RTC decisionCPDDocument10 pages96 RTC decisionCPDalezandro del rossiNo ratings yet

- January 1998 Board Examination Structural DesignDocument4 pagesJanuary 1998 Board Examination Structural Designalezandro del rossiNo ratings yet

- 1997jan Util and StruclDocument4 pages1997jan Util and Struclcin26No ratings yet

- Nepal Telecom History Book 1973-2072Document409 pagesNepal Telecom History Book 1973-2072mkg_just4u8932No ratings yet

- CPWD, SDG, Chennai Approval 4Document4 pagesCPWD, SDG, Chennai Approval 4Guru Prasath100% (1)

- Monopole 30 M (Tubular)Document9 pagesMonopole 30 M (Tubular)jonni pangaribuanNo ratings yet

- Architecture As NarrativeDocument5 pagesArchitecture As NarrativeAli AhmedNo ratings yet

- Hoysala ArchitectureDocument13 pagesHoysala Architecturenemo3045100% (1)

- City Center Design GuidelinesDocument61 pagesCity Center Design GuidelinesLefteris SpirouNo ratings yet

- WoW64 Bypassing EMET PDFDocument19 pagesWoW64 Bypassing EMET PDFSatria Ady PradanaNo ratings yet

- Apricot IPv6 Transition Kashimura Rev3Document43 pagesApricot IPv6 Transition Kashimura Rev3معتصم عبدالغفار محمد علىNo ratings yet

- Draft Openconfig Netmod Model StructureDocument8 pagesDraft Openconfig Netmod Model Structuresafyh2005No ratings yet

- Vent Size & Max. Distance From Fixture PDFDocument1 pageVent Size & Max. Distance From Fixture PDFbilal almelegyNo ratings yet

- Unit 41 Electrical Installation Design in Building Services EngineeringDocument13 pagesUnit 41 Electrical Installation Design in Building Services EngineeringHenok H.100% (2)

- MNFSTDocument11 pagesMNFSTVincentiuz RobertoNo ratings yet

- DDN 832052 APL Bluelog en PDFDocument96 pagesDDN 832052 APL Bluelog en PDFArianit ZeqiriNo ratings yet

- Famous Works/Projects and Their ArchitectsDocument4 pagesFamous Works/Projects and Their ArchitectsRoi KimssiNo ratings yet

- IBM Whitepaper OSIMMDocument22 pagesIBM Whitepaper OSIMMKlaus DoernerNo ratings yet

- TCP Optimization Through FEC, ARQ and Transmission Power TradeoffsDocument12 pagesTCP Optimization Through FEC, ARQ and Transmission Power TradeoffshelbakouryNo ratings yet

- FB-MultiPier Advanced Examples ManualDocument65 pagesFB-MultiPier Advanced Examples ManualsemageciffoNo ratings yet

- SystemVerilog Switch Lab FinalDocument6 pagesSystemVerilog Switch Lab FinalmanchuricoNo ratings yet

- Spare Parts, Instruction and Maintenance Manual For Spanco Model 301 Jib CranesDocument20 pagesSpare Parts, Instruction and Maintenance Manual For Spanco Model 301 Jib Cranesabhi aroteNo ratings yet

- Pannaipatty - Compound WallDocument38 pagesPannaipatty - Compound WallrkpragadeeshNo ratings yet

- Sample Solar Permit Plan - Structual DetailDocument1 pageSample Solar Permit Plan - Structual DetailSAEL SOLARNo ratings yet

- Rain Water Harvesting (RWH) : Anand DubeyDocument28 pagesRain Water Harvesting (RWH) : Anand DubeyAnand DubeyNo ratings yet

- Antenna Tilt - Mechanical Vs Electrical - TechplayonDocument4 pagesAntenna Tilt - Mechanical Vs Electrical - TechplayonGffrNo ratings yet

- SecurOS VMSDocument2 pagesSecurOS VMSJuan Carlos Govea TellezNo ratings yet

- RoRo Offshore Doors, Platforms and Cargo Lifts Datasheet (Screen) 2013 - Original - 43210Document4 pagesRoRo Offshore Doors, Platforms and Cargo Lifts Datasheet (Screen) 2013 - Original - 43210ronny-suNo ratings yet

- BNBC HandbookDocument49 pagesBNBC Handbookarpondev80% (5)

- PowerShell Essentials For The Busy AdminDocument16 pagesPowerShell Essentials For The Busy AdminAndres BabativaNo ratings yet

- Passenger Vehicle Air ConditioningDocument19 pagesPassenger Vehicle Air ConditioningAkshay ChandelNo ratings yet