Professional Documents

Culture Documents

General Structural Specifications: 1.0 Notes On Concrete Mixes and Placing 6.0 Notes On Concrete Slabs

Uploaded by

Alfred T. Infante IIIOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

General Structural Specifications: 1.0 Notes On Concrete Mixes and Placing 6.0 Notes On Concrete Slabs

Uploaded by

Alfred T. Infante IIICopyright:

Available Formats

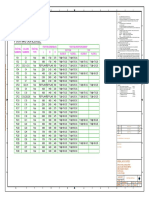

GENERAL STRUCTURAL SPECIFICATIONS

1.0 NOTES ON CONCRETE MIXES AND PLACING I. ALL TRUSSES MUST BE PROVIDED WITH A CAMBER AT THE RATE OF 3MM FOR EVERY 3000MM (UNLESS OTHERWISE SPECIFIED) 6.0 NOTES ON CONCRETE SLABS

EFFECTED BY MEANS OF A PARABOLIC LAYOUT.

A. UNLESS OTHERWIS INDICATED IN THE PLANS OR NOTED IN THE SPECIFICATIONS, THE MINIMUM 28-DAY CYLINDER COMPRESSIVE A. ALL SLAB REINFORCEMENTS SHALL HAVE A MINIMUM CONCRETE COVER OF 20MM FROM BOTTOM AND FROM THE TOP OF SLAB.

STRENGTH OF CONCRETE SHALL BE AS FOLLOWS: 4.0 NOTES ON BEAMS AND GIRDERS

B. UNLESS OTHERWISE DETAILED IN CONTINUOUS SLAB HAVING SAME REINFORCEMENT RUNNING IN ONE DIRECTION, REINFORCING

1. FOOTINGS, FOOTING BEAMS AND GIRDERS, AND BASEMENT WALLS. 20.7 MPA (3000 PSI) A. UNLESS OTHERWISE NOTED IN PLANS OR SPECIFICATIONS, CAMBER ALL BEAMS AND GIRDERS AT LEAST 6MM FOR EVERY 4.50M BARS SHALL BE BENT UP, EXTENDED OR CUT AS FOLLOWS:

2. COLUMNS AND SHEAR WALL. 20.7 MPA (3000 PSI) OF SPAN, EXCEPT CANTILEVERS FOR WHICH THE CAMBER SHALL BE AS ORDERED BY THE DESIGNER BUT IN NO CASE LESS THAN

L* L* L* L* L* 2L 4/3 EDGE BARS

3. FLOOR AND ROOF SLABS, BEAMS AND GIRDERS (OTHERWISE SPECIFIED) 20.7 MPA (3000 PSI) 20MM FOR EVERY 3.0M OF FREE SPAN. 2 BARS

4. NON-LOAD BEARING WALLS, PARTITIONS, BEDDED SLABS, PARAPETS,

0.26M MIN. HT.

CATCH BASINS, SIDEWALKS 20.7 MPA (3000 PSI) B. TYPICAL BAR BENDING AND CUTTING DETAILS FOR BEAMS AND GIRDERS SHALL BE AS SHOWN IN FIG. 4. EXTRA BARS

B. 1. CONCRETE SHALL BE DEPOSITED IN ITS FINAL POSITION WITHOUT SEGREGATION, REHANDLING, OR FLOWING PLACING SHALL 20MMØ

BE DONE, PREFERABLY WITH BUGGIES, BUCKETS, WHEELBARROWS OR BUCKETS, IN WHICH CASE THEY SHALL NOT EXCEED LAPPED SPLICE ON

SIX (6) METERS IN AGGREGATE LENGTH. COMPRESSION BARS

SEE TABLE "B"

FOR LENGTH OF L/1 L/2 L/2

2. NO DEPOSITING OF CONCRETE SHALL BE ALLOWED WITHOUT THE USE OF VIBRATORS UNLESS AUTHORIZED IN WRITING BY EMBEDMENT 0.15 MIN.

THE DESIGNERS AND ONLY FOR UNUSUAL CONDITION IS EXTREMELY DIFFICULT TO ACCOMPLISH. SEE TABLE "A" L 1/5 L* L* L* L* L 3/5

0.20 MIN. 0.15 MIN.

FOR LENGTH OF

EMBEDMENT THREE-FOURTH L 1/6 L* L* L* L* L 3/3

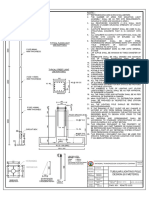

2.0 NOTES ON CONCRETE WALLS

THE EMBEDMENT L1 L2 L3 L4

LENGTHS IN

A. ALL WALLS SHALL BE REINFORCED ACCORDING TO THE FOLLOWING SCHEDULE OF WALL UNLESS TABLE "A" EXTERIOR INTERIOR CANTILEVER

OTHERWISE INDICATED IN THE PLANS. REINFORCING BARS SHALL HAVE 25MM CLEAR CONCRETE COVER FROM FACE OF WALL SPAN SPAN SPAN

EXCEPT FOR WALLS IN CONTACT WITH THE GROUND WHERE A MINIMUM OF 63MM SHALL BE PROVIDED, AND FOR EXPOSED FACES FIG. 4

OF FORMED WALLS WHERE THE MINIMUM SHALL BE 50M CLEAR. 20 MIN (WHEN COUNTED L* THE GREATER C. IF SLABS ARE REINFORCED BOTHWAYS BARS ALONG THE SHORTER SPAN SHALL BE PLACED BELOW THOSE ALONG THE LONG

FOR COMPRESSION OF THE ADJACENT SPAN AT THE CENTER AND OVER THE LONGER SPAN FOR REINFORCING BARS NEAR THE SUPPORTS. THE SPACING OF THE BARS

SEE TABLE "B" EXTENDED 20Ø BEYOND 20MM SPAN

AT THE COLUMN STRIPS SHALL BE APPROXIMATELY ONE AND ONE-HALF (1-1/2) THAT IN THE MIDDLE STRIPS BUT IN NO CASE

FOR LENGTH OF OPPOSITE SUPPORT)

REINFORCEMENTS GREATER THAN TWO AND ONE-HALF (2-1/2) THAT IN THE MIDDLE STRIPS BUT IN NO CASE GREATER THAN TWO AND ONE-HALF

WALL VERTICAL LAPPED SPLICE

THICKNESS

REMARKS

SECTION

(2-1/2) SLAB THICKNESS OR 45CM UNLESS OTHERWISE INDICATED IN THE PLANS.

HORIZONTAL VERTICAL EXTERIOR COLUMN INTERIOR COLUMN INTERIOR GIRDER EXTERIOR GIRDER 6

SUPPORT SUPPORT SUPPORT SUPPORT 6 D. TEMPERATURE BARS FOR SLABS SHALL BE GENERALLY PLACED NEAR THE FACE IN TENSION AND SHALL NOT BE LESS THAN

100 MM 10MMØ AT 250MM O.C. 10MMØ AT 300MM O.C.

HORIZONTAL BARS VERT. BARS 0.0025 BT. (SEE SCHEDULE BELOW).

AT CENTERS EXTRA TIES FOR UNLEVELED BEAM 10MM ADDT'L. TIES

125 MM 10MMØ AT 200MM O.C. 10MMØ AT 250MM O.C. (TYP. TO 150MM @ LOWER DROP ONLY)

VERTICAL BARS @ 150MM O.C.

HOR. BARS C. IF BEAM REINFORCING BARS END IN A WALL, THE CLEAR DISTANCE FROM THE BAR TO THE FARTHER FACE OF THE WALL SHALL

STAGGERED OUTSIDE

150 MM 12MMØ AT 225MM O.C. 12MMØ AT 250MM O.C. NOT BE LESS THAN 50MM. EMBEDMENT LENGTH SHALL BE AS SHOWN IN TABLE "B" FOR COMPRESSION BARS UNLESS SPECIFIED IN 150 4-10MM DROP

PLANS. TOP BARS SHALL NOT BE SPLICED WITHIN THE COLUMN OR WITHIN A DISTANCE OF TWICE THE MEMBER DEPTH FROM THE MIN. OF SLAB

SCHEDULE OF CONCRETE MIN. SLAB REINFORCEMENT

175 MM 12MMØ AT 250MM O.C.E.F. 12MMØ AT 300MM O.C.E.F. FACE OF THE COLUMN AT LEAST TWO (2) STIRRUPS SHALL BE PROVIDED AT ALL SPLICES.

THICKNESS MINIMUM TEMPERATURE BARS

T

200 MM 10MMØ AT 225MM O.C.E.F. 10MMØ AT 250MM O.C.E.F. BOTH FACES VERT. BARS

D. IF THERE ARE TWO OR MORE LAYERS OF REINFORCING BARS, USE 25MMØ BAR SEPARATORS SPACED AT 1.00M O.C. IN NO CASE 100MM 10MMØ AT 300MM EACH WAY

HORIZONTAL BARS

HOR. BARS SHALL THERE BE LESS THAN TWO (2) SEPARATORS BETWEEN LAYERS OF BARS. 125MM 10MMØ AT 250MM EACH WAY

225 MM 10MMØ AT 200MM O.C.E.F. 10MMØ AT 225MM O.C.E.F. SHALL BE OUTSIDE

150MM 10MMØ AT 200MM EACH WAY

T 300

250 MM 12MMØ AT 225MM O.C.E.F. 12MMØ AT 300MM O.C.E.F. E. MINIMUM CONCRETE PROTECTION FOR REINFORCING BARS OR STEEL SHAPES SHALL BE AS SHOWN IN FIG. 5, UNLESS SPECIFIED. 175MM 10MMØ AT 175MM EACH WAY

200MM 10MMØ AT 150MM EACH WAY

L/5 L/5

FIG. 1 L

WEB BARS FULL 2.0MM LINTEL BEAM AT

b SQUARE SQUARE 30MM O.C. TYP. TO DROP SLAB

B. CARRY VERTICAL BARS AT LEAST 600MM ABOVE FLOOR LEVEL TO PROVIDE FOR SPLICES WHEN NECESSARY. STOP AT 50MM 25MMØ PENETRATION

BUTT WELDS CUT END CUT END CONCRETE HOLLOW

BELOW TO SLAB OR SOLID BAND WHERE THE WALL ENDS VERTICAL AND HORIZONTAL BARS SHALL BE SPLICED BY LAPPING A SEPARATOR 2-16MM

BLOCKS WALL STR. BARS

DISTANCE EQUAL TO 40Ø AND WIRED SECURELY WITH NO. 16 G.I. WIRE PROVIDED THAT SPLICES IN ADJACENT BARS ARE STAGG E. UNLESS OTHERWISE NOTED IN THE PLANS, ALL BEDDED SLABS SHALL BE REINFORCED WITH 10MMØ AT 250MM O.C. EACH WAY AT

AT LEAST 1.52M (SEE FIG. 2). WELDING OF 10MM TIES CENTER OF SLAB AND CONSTRUCTION JOINTS FOR SAME SHALL NOT BE LESS THAN 3.00M APART.

REINFORCING TO @ 300MM O.C.

BE IN ACCORDANCE 2-12MMØ

C. UNLESS OTHERWISE NOTED IN THE PLANS, ALL OPENINGS IN WALLS 250MM OR THICKER SHALL BE REINFORCED AROUND WITH F. PROVIDE EXTRA REINFORCEMENTS FOR CORNER SLAB (TWO ADJACENT DISCONTINUOUS EDGES) AS SHOWN BELOW.

HT.

SEE NOTE W/ SPECIFICATION HOR. STR. BARS

400

2 - 20MMØ BARS. FOR 225MM, 200MM, 175MM, 150MM, USE 2 - 16MMØ. FOR 125MM AND 100MM WALLS, USE 2 - 12MMØ BARS AWS - D 12 W/ 6MM TIES

(SEE FIG. 3). ALL WALLS SPANNING SHALL HAVE VERTICAL REINFORCEMENT BENT TO A U - FORM LIKE STIRRUPS AND SPACED 1 - 16 @ 300MM O.C. G. CONCRETE SLAB REINFORCEMENTS SHALL BE PROPERLY SUPPORTED WITH 10MMØ STEEL CHAIR OR APPROVED EQUIVALENT

ACCORDING TO THE SCHEDULE UNLESS OTHERWISE NOTED (SEE FIG. 3). ALL CONCRETE WORK SHALL BE REINFORCED WITH SPACED AT 1.00M ON CENTER BOTHWAYS.

BARS OF AREA AT LEAST EQUAL TO THAT SPECIFIED IN ACI 318 - 89 BUILDING CODE.

3.18 MIN

SEE NOTE MAX BEAM BLOCK BEAM

NOTE 1 AT 800MM O.C.

VERTICAL BARS 12MM

20MM CLEAR FOR JOIST

1520MM BENT IN A U-FORM

40MM CLEAR FOR BEAMS THRU 28MM

LIKE STIRRUPS

MIN. AND GIRDERS

SEE SCHED. 5-10MM BARS

40d TYP. WELDED SPLICE DET.

UNDER NOTE C CHB WALL AT@ 200MM O.C.

2 BARS EACH FIG. 5 FOR BARS 12MM & 28MM

TOP & BOTTOM BARS

40d

DETAIL OF BLOCK

F. WHEN A BEAM CROSSES A GIRDER, REST BEAM BARS, BEAM REINFORCING BARS SHALL BE SYMMETRICAL ABOUT CENTER LIN AND LINTEL BEAM CORNER SLAB

SEE SCHED. WHENEVER POSSIBLE. 7.0 NOTES ON COLUMNS

1520MM

UNDER NOTE C

MIN.

G. GENERALLY, NO SPLICE SHALL BE PERMITTED ON BEAMS AT POINTS WHERE CRITICAL BENDING STRESSES OCCUR, SPLICES

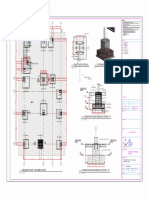

A. PROVIDE EXTRA SETS OF TIES AT 100MM O.C. FOR TIED COLUMN REINFORCEMENT ABOVE AND BELOW BEAM-COLUMN

SPLICE

WHERE SO PERMITTED SHALL BE AS INDICATED IN TABLES "A" AND "B". WELDED SPLICES SHALL DEVELOP IN TENSION AT LEAST

40 CONNECTIONS FOR A DISTANCE FROM FACE OF CONNECTION EQUAL TO THE GREATER OF ALL OVERALL THICKNESS, 61THE CLEAR

40d

VERT. BARS 6-12MMØ

d 125% OF THE SPECIFIED YIELD STRENGTH OF THE BAR NOT MORE THAN 50% OF THE BARS AT ANY ONE SECTION SHALL BE

40d VERT. BARS HEIGHT OF COLUMN OR 450MM.

A ALLOWED TO BE SPLICED THEREIN.

MIN.

40

600

W/ 10MM TIES

FLOOR LEVEL d @ 400MM O.C. CHB WALL B. COLUMN TIES AND SPIRALS SHALL BE PROTECTED EVERYWHERE BY A COVERING OF CONCRETE CAST MONOLITHICALLY WITH

FIG. 2 OPENINGS IN R.C. WALL SECTION "A" 5.0 NOTES ON FOUNDATION 400

THE CORE WITH THE MINIMUM THICKNESS OF 40MM AND NOT LESS THAN 1-1/2 TIMES MAXIMUM SIZE OF COARSE AGGREGATE IN

FIG. 3 MILLIMETER.

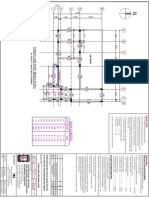

3.0 NOTES ON STRUCTURAL STEEL A. FOOTINGS ARE DESIGNED FOR AN ALLOWABLE SOIL BEARING PRESSURE OF 240 KPa (ASSUMED). THE CONTRACTOR SHALL

REPORT IN WRITING TO THE ENGINEER THE ACTUAL SOIL CONDITIONS UNCOVERED AND CONFIRM ACTUAL BEARING CAPACITY OF C. WHERE COLUMNS CHANGE IN SIZE, VERTICAL REINFORCEMENTS SHALL BE OFFSET AT A SLOPE OF NOT MORE THAN 1 IN 6 AND

A. STRUCTURAL STEEL TO BE USED FOR FABRICATION AND ERECTION OF THIS STRUCTURE SHALL COMPLY WITH ALL THE SOIL BEFORE DEPOSITING CONCRETE. EXTRA 10MM TIES AT 100MM O.C. SHALL BE PROVIDED THROUGHOUT THE OFFSET REGION.

DETAIL OF POST

PERTINENT PROVISION OF AISC SPECIFICATION FOR THE DESIGN, FABRICATION AND ERECTION OF STRUCTURAL STEEL FOR

BUILDING 1980, 8TH EDITION. B. FOOTING SHALL REST AT LEAST 600MM BELOW NATURAL GRADE LINE UNLESS OTHERWISE INDICATED IN PLANS. NO FOOTING D. UNLESS OTHERWISE INDICATED IN PLANS, LAP SPLICES FOR COLUMN REINFORCEMENT SHALL BE MADE WITHIN THE CENTER HALF

SHALL REST ON UNCOMPACTED FILL. OF COLUMN HEIGHT, AND THE SPLICES LENGTH SHALL NOT BE LESS THAN 30 BAR DIAMETER. WELDING OR APPROVED MECH'L.

B. ALL STRUCTURAL STEEL MEMBERS SHALL CONFORM TO ASTM SPECIFICATIONS FOR A - 36 STEEL. DEVICES MAY BE USED PROVIDED THAT NOT MORE THAN ALTERNATE BARS ARE WELDED OR MECHANICALLY SPLICED AT ANY

C. MINIMUM CONCRETE PROTECTION FOR REINFORCEMENTS SHALL BE 75MM CLEAR FOR CONCRETE DEPOSITED AGAINST THE LEVEL AND VERTICAL DISTANCES BETWEEN THESE WELDS OR SPLICES OF ADJACENT BARS IS NOT LESS THAN 600MM.

C. ALL WELDED AND BOLTED CONNECTIONS SHALL DEVELOP THE FULL STRENGTH OF THE MEMBERS. USE A325 BOLTS AND E70XX GROUND AND 50MM FOR CONCRETE DEPOSITED AGAINST A FORM WORK.

ELECTRODES FOR WELDING. E. IN REFERENCE TO OTHER DRAWINGS, SEE ARCHT'L. DRAWINGS FOR DEPRESSIONS IN FLOOR SLABS, OPENINGS IN WALLS AND

SLABS, INTERIOR PARTITIONS, LOCATION OF DRAINS, ETC.

D. FABRICATION AND WELDING SHALL BE GOVERNED BY APPLICABLE PROVISIONS OF THE LATEST AISC AND AWS STANDARDS. SCHEDULE OF CONCRETE HOLLOW BLOCK REINFORCEMENT

F. IN CASE OF DISCREPANCIES AS TO THE LAYOUT, DIMENSIONS, AND ELEVATIONS BETWEEN THE STRUCTURAL PLANS AND ARCHT'L.

E. THE CONTRACTOR SHALL PREPARE FABRICATION (SHOP) DRAWING OF ALL STRUCTURAL STEEL MEMBERS BASED ON DESIGNS REINFORCEMENTS

BLOCK DRAWINGS, THE CONTRACTOR SHALL NOTIFY BOTH THE STRUCTURAL ENGINEERS AND THE ARCHITECT.

REMARKS

FOR THE APPROVAL OF THE STRUCTURAL ENGINEER PRIOR TO FABRICATION. THICKNESS

HORIZONTAL VERTICAL

G. THE CONTRACTOR SHALL SUBMIT THE SCHEDULE OF POURING AND LOCATIONS OF CONSTRUCTION JOINTS TO THE STRUCTURAL

F. ALL DOUBLE ANGLE STRUCTURAL MEMBERS MUST BE PROVIDED WITH FILLER PLATES AT 300MM ON CENTERS MAXIMUM SPACING. A. MINIMUM LAP AT SPLICES = 250MM

75 MM 10MMØ AT 600MM O.C. 10MMØ AT 600MM O.C. ENGINEER AT LEAST FOUR (4) DAYS PRIOR TO THE POURING FOR APPROVAL. CURING OF CONCRETE SHALL BE CONTINUOUS FOR

B. PROVIDE RIGHT ANGLED REINFORCEMENT AT

CORNERS 900MM LONG. A MINIMUM PERIOD OF SEVEN (7)DAYS IMMEDIATELY AFTER POURING.

G. ALL STRUCTURAL STEEL WORKS SHALL BE IN ACCORDANCE WITH THE NATIONAL STRUCTURAL CODE OF THE PHILIPPINES VOL. 1 100 MM 10MMØ AT 600MM O.C. 10MMØ AT 600MM O.C. C. WHERE CHB WALLS ADJOIN COLUMNS R.C.

1992, 4TH EDITION. UNLESS OTHERWISE DETAILED IN THE PLANS, ALL STEEL SHAPES AND SECTIONS SHALL CONFORM TO ASEP BEAMS & WALLS DOWELS W/ THE SAME SIZE AS H. THE CONTRACTOR SHALL FURNISH AND MAINTAIN ADEQUATE FORMS AND SHORINGS UNTIL THE CONCRETE MEMBERS HAVE

HANDBOOK OF STRUCTURAL STEEL SHAPES AND SECTION, 1987 FIRST EDITION. 150 MM 12MMØ AT 400MM O.C. 12MMØ AT 600MM O.C. VERTICAL OR HORIZONTAL REINFORCEMENT

SHALL BE PROVIDED. ATTAINED THEIR WORKING CONDITION AND STRENGTH.

D. PROVIDE BEAM BLOCKS AT EVERY FOURTH

H. ALL EXPOSED STRUCTURAL MEMBERS SHALL RECEIVE AT LEAST TWO (2) COATS OF RED LEAD OR ZINC CHROMATE PRIMER PAINT. 200 MM 12MMØ AT 400MM O.C. 12MMØ AT 600MM O.C.

COARSE AND POST AT 3000MM O.C. (SEE DET.) I. ACI REFERS TO AMERICAN CONCRETE INSTITUTE, AISC TO AMERICAN INSTITUTE OF STEEL CONSTRUCTION, AND ASTM TO

AMERICAN SOCIETY FOR TESTING MATERIALS.

CERTIFIED BY: NAME OF PROJECT: APPROVED BY: SHEET CONTENT:

NOTE

THIS DRAWING IS AN INSTRUMENT OF PROFESSIONAL SERVICE IS THE

INTELLECTUAL PROPERTY AND DOCUMENT OF THE ENGINEER. ITS SHALL

BE UNLAWFUL FOR ANY PERSON TO DUPLICATE OR TO MAKE COPIES OF SPS. MITCHELLE & FRANCIS GREGG FUNCLARA

ALFREDO T. INFANTE III

CIVIL ENGINEER

THE SAID DOCUMENT FOR USE IN THE REPITITION OF AND FOR OTHER S-1

PROJECTS OR BUILDINGS WITHOUT THE CONSENT OF THE ENGINEER, LOCATION: ADDRESS: BLK. 6 LOT 12, ST. PAUL VILLAGE AS SHOWN

BLK. 6 LOT 12, ST. PAUL VILLAGE MANDURRIAO, ILOILO CITY

PRC NO.: 116475 VALIDITY: 5-10-2024 WHETHER EXECUTED PARTLY OR IN WHOLE. MANDURRIAO, ILOILO CITY

PTR NO.: 7729246 DATE: 1-19-2022 RA 9266, ART 3, SEC 20 (4) LOT OWNER: DATE: PLACE:

SPS. MITCHELLE & FRANCIS GREGG FUNCLARA 7 / 14

TIN: PLACE: ILOILO CITY

You might also like

- DUPA, Roads & Bridges - ExcelDocument436 pagesDUPA, Roads & Bridges - ExcelRoger DinopolNo ratings yet

- Plumbing Permit Drawings PDFDocument3 pagesPlumbing Permit Drawings PDFJeremy BoyceNo ratings yet

- Structual Plan 2-Storey ResidentialDocument9 pagesStructual Plan 2-Storey ResidentialMark Christian EsguerraNo ratings yet

- QAHD Office Building 30 M Structural Plans-S100.0Document1 pageQAHD Office Building 30 M Structural Plans-S100.0Adrian PachecoNo ratings yet

- Facility Inspection ChecklistDocument50 pagesFacility Inspection ChecklistMurali Dharma Raja Praphu50% (2)

- Structural Plan 3 Storey Building Balamban Cebu (2) Model - PDF 1Document1 pageStructural Plan 3 Storey Building Balamban Cebu (2) Model - PDF 1roger100% (2)

- Zoleta Residence - Structural PlansDocument5 pagesZoleta Residence - Structural PlansJc SulitNo ratings yet

- Structural - AOBDocument21 pagesStructural - AOBMr. Mark B.No ratings yet

- Concrete Cottages, Small Garages and Farm Buildings (1918)Document250 pagesConcrete Cottages, Small Garages and Farm Buildings (1918)Chuck AchbergerNo ratings yet

- Details - WF Wall Footing Masonry Details: CHB To Slab-On-Grade End DetailsDocument1 pageDetails - WF Wall Footing Masonry Details: CHB To Slab-On-Grade End Detailsacurvz20050% (1)

- Typical Beam Details Typical Footing Details: Schedule of Footings Schedule of BeamsDocument1 pageTypical Beam Details Typical Footing Details: Schedule of Footings Schedule of BeamsRenel GarciaNo ratings yet

- General Notes Foundations: Two - Storey Residential Building With Roof DeckDocument1 pageGeneral Notes Foundations: Two - Storey Residential Building With Roof DeckKarlo CabanginNo ratings yet

- Structural 2storeyDocument11 pagesStructural 2storeyMark James Mateo100% (1)

- PlanDocument8 pagesPlanMark Christian EsguerraNo ratings yet

- General Notes BridgeDocument6 pagesGeneral Notes BridgeEnglish for KidsNo ratings yet

- Building Standards and RulesDocument8 pagesBuilding Standards and Rulesthanuja sharonNo ratings yet

- Anchor BoltDocument2 pagesAnchor BoltWidya Prasetya100% (1)

- StructuralDocument15 pagesStructuralMark James MateoNo ratings yet

- General Construction Notes:: Notes On Beams and GirdersDocument1 pageGeneral Construction Notes:: Notes On Beams and GirdersJaycee RollanNo ratings yet

- Carpet Floorring-Method StatementDocument6 pagesCarpet Floorring-Method StatementMuhib sadeddeinNo ratings yet

- Masonry Tools Lesson Plan FinalDocument9 pagesMasonry Tools Lesson Plan FinalCharles Vincent Paniamogan100% (2)

- 160007-SWP-QS-CostPlanB-140318 Rev02 BNDocument163 pages160007-SWP-QS-CostPlanB-140318 Rev02 BNMinh TanNo ratings yet

- General Construction Notes: Bureau of DesignDocument15 pagesGeneral Construction Notes: Bureau of DesignRicoyan YanNo ratings yet

- 107 Spanish Architecture TermsDocument7 pages107 Spanish Architecture TermsHugh Fox IIINo ratings yet

- Design: Construction NotesDocument1 pageDesign: Construction NotesLhea May Paz SarguetNo ratings yet

- General Construction NotesDocument1 pageGeneral Construction NotesLon OdiNo ratings yet

- Residential bldg-CS0Document1 pageResidential bldg-CS0ar.arvinarceNo ratings yet

- Gen Notes StrucDocument1 pageGen Notes StrucorderNo ratings yet

- 1 Mps Building Dingras StructuralDocument6 pages1 Mps Building Dingras StructuralMekaela DiataNo ratings yet

- Roof Framing Plan: Construction NotesDocument1 pageRoof Framing Plan: Construction NotesNefritiri BlanceNo ratings yet

- EBC E2 3P Final PDFDocument1 pageEBC E2 3P Final PDFengrNo ratings yet

- Construction Notes: 30 BAR. DIA. 30 BAR. DIA. 40Document1 pageConstruction Notes: 30 BAR. DIA. 30 BAR. DIA. 40MARKCHRISTMASNo ratings yet

- S-1 RevisedDocument1 pageS-1 Revisedbernard1agoncillioNo ratings yet

- GennotesDocument1 pageGennotesNeil ArmstrongNo ratings yet

- A. General Notes: B. Notes and Concrete Mixes and PlacingDocument1 pageA. General Notes: B. Notes and Concrete Mixes and Placingdomin domNo ratings yet

- General Construction Notes: Schedule of Minimum Slab ReinforcementDocument2 pagesGeneral Construction Notes: Schedule of Minimum Slab ReinforcementDominic Robiso DatuinNo ratings yet

- General Construction Notes: Schedule of Minimum Slab ReinforcementDocument1 pageGeneral Construction Notes: Schedule of Minimum Slab ReinforcementDominic Robiso DatuinNo ratings yet

- E:/1. Hai Phat/Nh19/1. Detail Design/99. Xuat Ho So/General Notes/General Notes - DWG - Date: Thu, 22 Oct 2020 - 1:58Pm Pc:LamntDocument2 pagesE:/1. Hai Phat/Nh19/1. Detail Design/99. Xuat Ho So/General Notes/General Notes - DWG - Date: Thu, 22 Oct 2020 - 1:58Pm Pc:LamntHoang Nguyen HuyNo ratings yet

- 23kk0043 Set BDocument30 pages23kk0043 Set BcemirasmpcNo ratings yet

- General NotesDocument1 pageGeneral NotesMark Christian EsguerraNo ratings yet

- Ns2-Vk02-P0ucb-171652 - CHS Electrical & Control Building - Beam & Girder Re-Bar Schedule - Fi-2Document3 pagesNs2-Vk02-P0ucb-171652 - CHS Electrical & Control Building - Beam & Girder Re-Bar Schedule - Fi-2Doan Ngoc DucNo ratings yet

- Plan 20ld0130 - Part 3Document11 pagesPlan 20ld0130 - Part 3MarjanNo ratings yet

- SCHEDULESDocument1 pageSCHEDULESpankaj kushwahNo ratings yet

- General Construction Notes: Bureau of DesignDocument1 pageGeneral Construction Notes: Bureau of DesignGarry WaveNo ratings yet

- s100 - Ground Floor - Column Layout PlanDocument1 pages100 - Ground Floor - Column Layout PlanOsama FouadNo ratings yet

- PDW-TZ-1133 Tubular Lighting Pole DesignDocument1 pagePDW-TZ-1133 Tubular Lighting Pole Designihsan ul haqNo ratings yet

- Wall Footing Details: Typical Connection Detail of Masonry WallDocument1 pageWall Footing Details: Typical Connection Detail of Masonry WallCarlo M. FloresNo ratings yet

- General Construction Notes:: Rehabilitation and Expansion of Puntales Feeder PortDocument1 pageGeneral Construction Notes:: Rehabilitation and Expansion of Puntales Feeder Portalezandro del rossiNo ratings yet

- General Construction Notes:: Rehabilitation and Expansion of Puntales Feeder Port S-01 24-59Document1 pageGeneral Construction Notes:: Rehabilitation and Expansion of Puntales Feeder Port S-01 24-59alezandro del rossiNo ratings yet

- Plumbing DWGDocument3 pagesPlumbing DWGJamillette NovesterasNo ratings yet

- General: Schedule of CHB & Ceramic Block ReinforcementDocument1 pageGeneral: Schedule of CHB & Ceramic Block Reinforcementbobmarley20161934No ratings yet

- Construction Notes:: General MasonryDocument1 pageConstruction Notes:: General MasonryJohn And ThenaNo ratings yet

- 23lg0043 - Plans Set 2 of 5Document9 pages23lg0043 - Plans Set 2 of 5Sherwin NatinoNo ratings yet

- Structural Notes: General: Reinforcing SteelDocument1 pageStructural Notes: General: Reinforcing SteelJohn Eric D. WongNo ratings yet

- PDW-TV-495 6.0 Meters Wide Bituminous Carpet Road-Iso A3Document1 pagePDW-TV-495 6.0 Meters Wide Bituminous Carpet Road-Iso A3ihsan ul haqNo ratings yet

- Plot - 1 - TERRACE ROOF BEAM LAYOUTDocument1 pagePlot - 1 - TERRACE ROOF BEAM LAYOUTMõhâmméd WassimNo ratings yet

- PS04-Wall-1-Reniforcment Detalis-Concerte DimensionDocument1 pagePS04-Wall-1-Reniforcment Detalis-Concerte Dimensionmahmoudfathyahmed28No ratings yet

- PS04-Wall-2-RFT-28-8-2022-Concerte DimensionDocument1 pagePS04-Wall-2-RFT-28-8-2022-Concerte Dimensionmahmoudfathyahmed28No ratings yet

- Civil / Structural Construction Notes: Nearest Faultline Site Location FromDocument1 pageCivil / Structural Construction Notes: Nearest Faultline Site Location FromVince Bagsit PolicarpioNo ratings yet

- C-1 Mark C-2: Stair Detail 2 Stair Detail 3Document1 pageC-1 Mark C-2: Stair Detail 2 Stair Detail 3Ysabelle TagarumaNo ratings yet

- Reejoy S. Andrin, Ce Mr. Jessie Jay Ano-Os: A. General Notes Table of Lap Splices H. MasonryDocument1 pageReejoy S. Andrin, Ce Mr. Jessie Jay Ano-Os: A. General Notes Table of Lap Splices H. Masonryreejoy1994No ratings yet

- 1 - FIRST FLOOR LVL - To SEVENTH FLOOR LVLDocument1 page1 - FIRST FLOOR LVL - To SEVENTH FLOOR LVLMANOJTRIVEDI100% (1)

- Podium NTCB-005-CB-4018-OF02-00202 - 08Z PDFDocument8 pagesPodium NTCB-005-CB-4018-OF02-00202 - 08Z PDFSean HarshaNo ratings yet

- Jayamangal Dining BlockDocument4 pagesJayamangal Dining BlockShiwani SahNo ratings yet

- Plumbing 01Document1 pagePlumbing 01schneidereit realtyNo ratings yet

- S1 Structural NotesDocument1 pageS1 Structural NotesRaynz PatronNo ratings yet

- QAHD Office Building 30 M Structural Plans-S102.0Document1 pageQAHD Office Building 30 M Structural Plans-S102.0Adrian PachecoNo ratings yet

- British Commercial Computer Digest: Pergamon Computer Data SeriesFrom EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesNo ratings yet

- Americanback New PlanDocument1 pageAmericanback New PlanAlfred T. Infante IIINo ratings yet

- CS1 6Document1 pageCS1 6Alfred T. Infante IIINo ratings yet

- A1 PermitsDocument1 pageA1 PermitsAlfred T. Infante IIINo ratings yet

- SUMMARYDocument2 pagesSUMMARYAlfred T. Infante IIINo ratings yet

- Criteria For Design AnalysisDocument1 pageCriteria For Design AnalysisAlfred T. Infante IIINo ratings yet

- FoundationDocument1 pageFoundationAlfred T. Infante IIINo ratings yet

- TrussDocument1 pageTrussAlfred T. Infante IIINo ratings yet

- Heat Load Calculations As-Built Ventillation Layout: D P W HDocument1 pageHeat Load Calculations As-Built Ventillation Layout: D P W HAlfred T. Infante IIINo ratings yet

- Bernwood, Some Structural Members Are Modified To Reduce CostDocument2 pagesBernwood, Some Structural Members Are Modified To Reduce CostAlfred T. Infante IIINo ratings yet

- LPL Series: Low Profile Linear LED and FluorescentDocument1 pageLPL Series: Low Profile Linear LED and FluorescentJamil AhmadNo ratings yet

- DIWAN DEODI, Hyderabad PDFDocument18 pagesDIWAN DEODI, Hyderabad PDFTANYA SRIVASTAVANo ratings yet

- Arch 201 NotesDocument8 pagesArch 201 NotesStephen JordanNo ratings yet

- Lecture Two: Shell Structures Dome StructuresDocument14 pagesLecture Two: Shell Structures Dome StructuresIssack MattewNo ratings yet

- TECH - Wyntk - Truss Facts For Eng and ArcDocument24 pagesTECH - Wyntk - Truss Facts For Eng and Arcshaikh85No ratings yet

- Islamic Architecture: TH THDocument5 pagesIslamic Architecture: TH THQwin San AndresNo ratings yet

- PHILIPS TMS022 2xTL-D36W HFS - 827 /: Luminaire Data SheetDocument7 pagesPHILIPS TMS022 2xTL-D36W HFS - 827 /: Luminaire Data Sheethau nguyenNo ratings yet

- Quotation For Expandable Container HouseDocument8 pagesQuotation For Expandable Container HousePatricia TungpalanNo ratings yet

- New Warehouse Indostar Report - Week 23Document19 pagesNew Warehouse Indostar Report - Week 23Herdiana LindratwantoNo ratings yet

- Rancon - BOQ For BepzaDocument13 pagesRancon - BOQ For Bepzakazi Shahanewaz HossainNo ratings yet

- Stone Masonry and Precast Block Masonry Work: NotesDocument9 pagesStone Masonry and Precast Block Masonry Work: NotesVarma ChintamaneniNo ratings yet

- Shed Material List Part (1 of 9)Document2 pagesShed Material List Part (1 of 9)nwright_besterNo ratings yet

- Project Brief Sales KitDocument72 pagesProject Brief Sales KitmartinNo ratings yet

- Paving Flooring and DadoDocument17 pagesPaving Flooring and DadozfrlNo ratings yet

- Chapter Fifteen Grant and Graham InvestigateDocument6 pagesChapter Fifteen Grant and Graham InvestigateJulio PerezNo ratings yet

- 16G101 2 TranslationDocument124 pages16G101 2 TranslationTianyi MuseNo ratings yet

- SL - No. Unit Rate. QuantityDocument6 pagesSL - No. Unit Rate. QuantityNaveen RevannaNo ratings yet

- 1 Excavation: SR - No. Iteam Unit Labour RateDocument18 pages1 Excavation: SR - No. Iteam Unit Labour RateSarinNo ratings yet

- Skylight Detail ManualDocument16 pagesSkylight Detail ManualChristine Joy TumangNo ratings yet

- A7.70 - MOCK UP Rev.2 MarkupDocument1 pageA7.70 - MOCK UP Rev.2 MarkupjhamiralexNo ratings yet

- 1 Building Const 3Document99 pages1 Building Const 3ashleyane garlanNo ratings yet

- PLAINCRETE Blocks Matibay Pa!: Load Bearing Reinforced Concrete Blocks Money ConstructontheDocument7 pagesPLAINCRETE Blocks Matibay Pa!: Load Bearing Reinforced Concrete Blocks Money ConstructontheJim Bryan RazNo ratings yet