Professional Documents

Culture Documents

Ijert Ijert: Strength Study On Castellated Beam

Uploaded by

Adnan NajemOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ijert Ijert: Strength Study On Castellated Beam

Uploaded by

Adnan NajemCopyright:

Available Formats

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 2 Issue 12, December - 2013

Strength Study on Castellated Beam

1 2

B. Anupriya Dr. K. Jagadeesan

1

Assistant Professor

Department of Civil Engineering

Arasu Engineering College, Kumbakonam, Tamilnadu, India

2

Professor

Department of Civil Engineering

Mahendra Engineering College, Erode, Tamilnadu, India.

Abstract the section modulus of the original beam section. Thus

This paper is focussed on the investigation behaviour the load carrying capacity of the beam is increased

RT

of shear strength of castellated beam through an considerably. A castellated beam has some limitations

extensive FE study (ANYSIS14).Though castellated also, stress concentration occurs near the perforations

beams are well accepted for industrial buildings, and the shear carrying capacity is reduced. Stress

IJE

power plant and multi-storeyed structures, Due to its concentration may be reduced by making perforations

web opening stress concentration increases at the near the neutral axis where the stress are small making

whole corners and at load application points and also the cut in a zig- zag way. The shear carrying capacity

stiffness of castellated beams decrease as the depth of can be increased by stiffening the web at points of

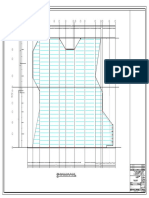

opening increases. concentrated loads and reactions. Fig-1 shows a

Hence to increase the shear strength of the castellated castellated beam.

beam and also to reduce the deflection, shear stiffeners

are introduced along the web opening. From the

results obtained from ANYSIS, It was concluded that h

Deflection without stiffeners is 9.75 mm, when

stiffeners are provided diagonally it is reduced to 7.85

mm, and it is still reduced to 3.99 mm when stiffeners

are provided vertically along with diagonal stiffeners.

H=1.5h.

Key words: Castellated beam, Shear, Deformation, 5h

Stiffeners.

1. Introduction Fig.1. Castellated Beam

Castellated beam is an open web beam but made up of

a single rolled wide flange beam section and is formed 2. Objective of Research work

by flame cutting the beam section in a predetermined The main focus of the research work is to introduce

pattern and rejoining the segments by welding to stiffeners along the web opening so that deflection is

produce a regular pattern of holes in the web. The minimized and shear failure is controlled. In this

beam section obtained in such a way can be even 50% investigation the deflection of castellated beam is

deeper than the original section that is 1.5 times the examined using ANYSIS 14 by providing diagonal and

depth of the original section. By increasing the depth, vertical stiffeners.

the section modulus is increased by about 2.25 times

IJERTV2IS121295 www.ijert.org 3853

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 2 Issue 12, December - 2013

3. Investigation of Castellated Beam 4. Failure Modes of Castellated Beam

1. Select the angle of cut to be 45° for a good There are a number of possible failure modes for

design castellated beams, which are as follows

2. The depth of the stem of the T section at the Vierendeel Mechanism: This occurs due to

minimum cross section should not be less than excessive deformation across one of the

¼ of the original beam section. openings in the web and formation of hinges

3. Calculate the moment of resistance of the in the corners of the castellation.

castellated section which is the product of the Lateral Torsional Buckling of the web: This is

resultant tensile or compressive force and the caused by large shear at the welded joints.

distance between centroids of T sections. Rupture of welded joints in the web: This

a. MR = A σat d arises due to excessive horizontal shear at the

4. The spacing of the castellated beam should welded joint in the web.

not exceed the spacing determined by the Lateral Torsional buckling of the overall

equation beam: Castellated beam undergo lateral

𝑃′ torsional buckling of the whole span.

a. 𝑆 = ′ Where,

𝑊𝐿 Plastic Hinge Formation: This mode of failure

b. S= center to center distance between occurs when lateral torsional buckling is

castellated beams prevented. Areas of plasticity are formed in

c. P’= Net load carrying capacity in N the top and bottom flanges caused by a

d.

W= Design load in N/m2 combination of stresses due to primary flexure

and vierendeel action. The hinges may form

away from point of maximum bending

L= Span of the beam in m moment due to the presence of shear and axial

forces.

1. Stiffeners are designed at the supports and Web buckling: This is caused by heavy

RT

below the concentrated loads. loading and short span of the beam. This may

be avoided at a support by filling the first

2. The beam is checked in shear. the average castellation by welding a plate in the hole.

shear at the end is calculated from

IJE

𝑅

𝜏𝑣𝑎 = ′ 5. Finite Element Analysis

𝑑𝑡

In this paper, a three dimensional (3D) finite element

< 0. 4 fy model is developed using ANYSIS-14 for IC 225 and

IC 300. Various finite element models and von mises

Where stresses are developed. The introduction of an opening

R= end reaction in N in the web of the beam alters the stress distribution

d’= depth of the stem of T – section within the member and also influences its collapse

t= thickness of the stem behavior. The opening decreases the stiffness of the

3. The maximum combined local bending stress beam resulting in larger deformation. The strength

and direct stress in the T Segment is also realized will depend upon the interaction between the

worked out and should be less than the moment and shear. The reduction in moment capacity

permissible bending stress. at the openings is small while the reduction in shear

4. The maximum deflection of the T- section is capacity may be significant. Hence Shear stiffeners are

at the mid span and is due to the net load provided at the opening to improve its shear carrying

carrying capacity and local effects. capacity.

Model 1

IC 225

𝛿 = 𝛿1 + 𝛿2 < L/325 L=3.2 m, tF =7.5 mm, tw =5mm, bw =80mm, HW=150

mm,

Where

Length of stiffeners =190mm, Width of stiffeners = 15

δ1 - Deflection due to net load carrying

mm , Thickness of Stiffener = 5mm

capacity

δ2 - Deflection due to local effects

IJERTV2IS121295 www.ijert.org 3854

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 2 Issue 12, December - 2013

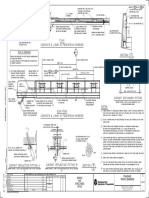

Model 2 Case 2 - With Diagonal Stiffeners

IC 300

L=3.2 m, tF =10 mm, tw =6mm, bw =100mm

HW=200 mm,

Length of stiffners =260mm, Width of

stiffeners = 20 mm , Thickness of Stiffener =

6mm.

6. Analytical Methods

The castellated beams have the disadvantage of

reduced shear capacity due to stress concentrations

near the openings. This can be alleviated to some

extent by providing Stiffeners. Diagonal and vertical

stiffeners are provided along the web opening where

shear force is low. Fig.- 3. CB with Diagonal Stiffeners

Case 1 - Without Stiffeners

Case 2-With Diagonal Stiffeners Case 3 - With Diagonal & Vertical Stiffeners

Case -3-With Diagonal & Vertical Stiffeners

RT

IJE

Fig.-4. CB Diagonal & Vertical Stiffeners

Case -1 Without Stiffeners Case 1. With Out Stiffeners (IC 225)

Table 1. Load Vs Deflection (IC 225)

Load Deflection

(KN) (mm)

10 1.28

20 2.55

30 3.83

40 5.10

50 6.38

60 7.65

70 8.93

80 10.21

90 11.48

100 12.76

Fig.-2. CB without Stiffeners

IJERTV2IS121295 www.ijert.org 3855

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 2 Issue 12, December - 2013

Case 3.With Diagonal and Vertical Stiffeners

Table 3. Load Vs Deflection (IC 225)

WITH OUT STIFFENERS

load Vs Deflection ( IC 225 )

Load Deflection

14.00 (KN) (mm)

12.00

10 0.68

Deflection (mm)

10.00

8.00 20 1.37

6.00 30 2.05

4.00 40 2.74

2.00

50 3.42

0.00

0 50 100 150

60 4.10

load (KN) 70 4.79

80 5.47

Graph 1. With Out Stiffeners (load Vs 90 6.16

Deflection ( IC 225 ) )

100 6.84

Case 2. With Diagonal Stiffeners

WITH DIAGONAL AND VERTICAL STIFFENERS

Table 2. Load Vs Deflection (IC 225)

Load Vs Deflection (IC 225)

Deflection (mm) 8.00

Load(KN) Deflection(mm) 6.00

10 0.96

RT

4.00

20 1.93

2.00

30 2.89

40 3.85 0.00

IJE

50 4.82 0 50

Load ( KN)

100 150

60 5.78

70 6.74 Graph 3. With Diagonal & Vertical Stiffeners (load

80 7.70 Vs Deflection ( IC 225 ) )

90 8.67

100 9.63 Comparison between Load Vs Deflection (IC225)

LOAD

DEFLECTION ( mm)

WITH DIAGONAL STIFFENERS ( KN)

load Vs Deflection ( IC 225 ) With Diagonal

12.00

Without With Diagonal &

10.00 Stiffeners tiffeners Vertical

Deflection (mm)

8.00 Stiffeners

6.00 10 1.28 0.96 0.68

4.00 20 2.55 1.93 1.37

30 3.83 2.89 2.05

2.00

40 5.10 3.85 2.74

0.00

50 6.38 4.82 3.42

0 50 100 150 60 7.65 5.78 4.10

Load (KN)

70 8.93 6.74 4.79

Graph 2. With Diagonal Stiffeners (load Vs 80 10.21 7.70 5.47

Deflection ( IC 225 ) ) 90 11.48 8.67 6.16

100 12.76 9.63 6.84

Table5. Load Vs Deflection (IC 225)

IJERTV2IS121295 www.ijert.org 3856

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 2 Issue 12, December - 2013

COMPARISION BETWEEN WITH OUT STIFFENERS

Load Vs Deflection (IC225) load Vs Deflection ( IC 300)

14.00 12.00

12.00 10.00

Deflection (mm)

10.00 8.00

6.00

Deflection (mm)

8.00

6.00 4.00

4.00 2.00

2.00 0.00

0 50 100 150 200

0.00 load (KN)

0 50 100 150

load ( KN) Graph 6 With Out Stiffeners (load Vs Deflection -

With out Stiffeners IC 300 )

With Diagonal

Stiffeners

With Diagonal & Case2- With Diagonal Stiffeners (IC 300)

Vertical Stiffeners Table 7. Load Vs Deflection (IC 300)

Graph 5 Comparision (load Vs Deflection ( IC Load(KN) Deflection(mm)

225 ) ) 10 0.46

RT

Case1- With Out Stiffeners (IC 300) 20 0.92

Table 6. Load Vs Deflection (IC 300)

30 1.38

40 1.85

IJE

Load(KN) Deflection(mm)

50 2.31

10 0.57

60 2.77

20 1.15

70 3.23

30 1.72

80 3.69

40 2.29

90 4.15

50 2.87

100 4.62

60 3.44 110 5.08

70 4.01 120 5.54

80 4.59 130 6.00

90 5.16 140 6.46

100 5.73 150 6.92

110 6.31 160 7.39

120 6.88 170 7.85

130 7.46

140 8.03

150 8.60

160 9.18

170 9.75

IJERTV2IS121295 www.ijert.org 3857

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 2 Issue 12, December - 2013

WITH DIAGONAL STIFFENERS

load Vs Deflection (IC 300) WITH DIAGONAL AND VERTICAL

9.00 STIFFENERS

8.00 5 load Vs Deflection ( IC 300 )

7.00

Deflection ( mm)

6.00 4

Deflection (mm)

5.00

4.00 3

3.00

2

2.00

1.00 1

0.00

0 50 100 150 200 0

load( KN) 0 50 100 150 200

load (KN)

Graph 7. With Diagonal Stiffeners (load Vs

Graph 8 With Diagonal & vertical Stiffeners (load

Deflection -IC 300 )

Vs Deflection -IC 300 )

Case3- With Diagonal & Vertical Stiffeners (IC 300)

Table 8. Load Vs Deflection (IC 300)

Comparison between Load Vs Deflection

Table 9. Load Vs Deflection (IC 300)

Load(KN) Deflection(mm) LOAD

DEFLECTION ( mm)

10 0.23 ( KN)

RT

With

20 0.47

With Diagonal

30 0.70 Without

Diagonal &

Stiffeners

IJE

40 0.94 Stiffeners Vertical

Stiffeners

50 1.17

60 1.41 10 0.57 0.46 0.23

70 1.64 20 1.15 0.92 0.47

80 1.88 30 1.72 1.38 0.70

90 2.11 40 2.29 1.85 0.94

100 2.35 50 2.87 2.31 1.17

110 2.58 60 3.44 2.77 1.41

120 2.82 70 4.01 3.23 1.64

80 4.59 3.69 1.88

130 3.05

90 5.16 4.15 2.11

140 3.28

100 5.73 4.62 2.35

150 3.52

110 6.31 5.08 2.58

160 3.75

120 6.88 5.54 2.82

170 3.99

130 7.46 6.00 3.05

140 8.03 6.46 3.28

150 8.60 6.92 3.52

160 9.18 7.39 3.75

170 9.75 7.85 3.99

Graph 9 Comparision (load Vs Deflection ( IC 300 ) )

IJERTV2IS121295 www.ijert.org 3858

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 2 Issue 12, December - 2013

References

COMPARISION BETWEEN

Load Vs Deflection (IC 300)

1. M.R.Wakchaure, A.V. Sagade Finite Element

12.00 Analysis of Castellated Steel Beam,

10.00 International Journal of Engineering and

Innovative Technology (IJEIT), Volume 2,

Deflection (mm)

8.00 Issue 1, July 2012

6.00 2. Tadeh Zirakian, Hossein Showkati

“Distortional Buckling of Castellated Beams”

4.00

(Journal of Constructional Steel Research 62,

2.00 pp. 863–871, 2006

0.00

3. O. Kohnehpooshi, H. Showkati, Numerical

Modeling and Structural Behavior of Elastic

0 50 100 150 200

Load (KN) Castellated Section, European Journal of

With out Stiffeners Scientific Research, 2009.

With Diagonal Stiffeners

With Diagonal & Vertical

Stiffeners

Allowable

Deflection = L/325 = 3200/325 = 9.84

Conclusions

From the results obtained from ANYSIS 14, shear

failure is more near the wholes than the web, hence

RT

shear stiffeners are provided on the opening of the web

along the shear zone. Stiffeners are provided

diagonally and deflection is noticed. In another case

stiffeners are provided vertically along with diagonal

IJE

stiffeners and deformation is noted.

Deflection of castellated beam without stiffeners, with

diagonal Stiffeners, and vertical along with diagonal is

given below. For (IC 300) Deflection without stiffeners

is 9.75 mm, when it is arrested diagonally deflection is

reduced to 7.85 mm, and it is still reduced to 3.99 mm

when stiffeners are provided vertically along with

diagonal stiffeners. Hence it is concluded that, shear

strength of castellated beam can be improved by

introducing shear stiffeners along the shear zone.

Load

Deflection (mm)

Specimen With

(KN) With

Detail With Out diagonal

diagonal

Stiffeners & Vertical

Stiffeners

(mm) Stiffeners

(mm)

(mm)

IC 225 100 8.93 6.74 4.79

IC 300 170 9.75 7.85 3.99

IJERTV2IS121295 www.ijert.org 3859

You might also like

- Non-Destructive Testing TechniquesDocument145 pagesNon-Destructive Testing TechniquesAli R.M89% (9)

- Castellated Beam PPT GatDocument33 pagesCastellated Beam PPT GatChittan Mac Maisnam50% (2)

- Insulation Co-ordination in High-voltage Electric Power SystemsFrom EverandInsulation Co-ordination in High-voltage Electric Power SystemsRating: 4.5 out of 5 stars4.5/5 (5)

- About Author: Building Materials & Construction by Saurabh Kumar Soni - DetailsDocument1 pageAbout Author: Building Materials & Construction by Saurabh Kumar Soni - DetailsMADUGULA CHANDRASEKHARNo ratings yet

- Assignment #2Document2 pagesAssignment #2Zakaria MaamarNo ratings yet

- International Journal On Recent TechnoloDocument4 pagesInternational Journal On Recent TechnoloAdnan NajemNo ratings yet

- IJERT Study of Castellated Beam StiffeneDocument5 pagesIJERT Study of Castellated Beam StiffeneAdnan NajemNo ratings yet

- Design comparison of castellated beam between IS:800-1984 and IS:800-2007Document6 pagesDesign comparison of castellated beam between IS:800-1984 and IS:800-2007Samved PatelNo ratings yet

- Chapter II - Tension Members.(0)Document35 pagesChapter II - Tension Members.(0)getachewkassa2123No ratings yet

- Steel Structures-Tension Members-1Document14 pagesSteel Structures-Tension Members-1Ceren ŞirinNo ratings yet

- IJERT Theoretical and Numerical InvestigDocument7 pagesIJERT Theoretical and Numerical InvestigAdnan NajemNo ratings yet

- Design of Castelleated Beam by British CodeDocument8 pagesDesign of Castelleated Beam by British Codemsn sastryNo ratings yet

- Short Proposal Finite ElementDocument9 pagesShort Proposal Finite ElementMuhammad Ilham ZulkipllyNo ratings yet

- Aydin Demir Nacir Caglar Hakan Ozturk - Parameters Affecting Diagonal Cracking Behavior of Reinforced Concrete DeepDocument15 pagesAydin Demir Nacir Caglar Hakan Ozturk - Parameters Affecting Diagonal Cracking Behavior of Reinforced Concrete DeepJoão Paulo MendesNo ratings yet

- RC Jacketing PDFDocument2 pagesRC Jacketing PDFA Mumtaz100% (1)

- Experimental and Analytical Study On Strengthening of Deformed Cold Formed Steel Lipped Channel Section IJERTCONV5IS13172Document6 pagesExperimental and Analytical Study On Strengthening of Deformed Cold Formed Steel Lipped Channel Section IJERTCONV5IS13172sathishNo ratings yet

- In Uence of Clear Edge Distance and Spacing of Piles On Failure of Pile CapDocument18 pagesIn Uence of Clear Edge Distance and Spacing of Piles On Failure of Pile CapajayNo ratings yet

- Kavya.E, Swedha.TDocument7 pagesKavya.E, Swedha.TamokeNo ratings yet

- Chapter 2 - Tension MembersDocument13 pagesChapter 2 - Tension MembersSami IGNo ratings yet

- Theory Q'sDocument5 pagesTheory Q'sChachi CNo ratings yet

- Dog Bone Connection PDFDocument9 pagesDog Bone Connection PDFChinnaraja GandhiNo ratings yet

- 13 33210 1 10 20180123Document16 pages13 33210 1 10 20180123Brice Patrice GollyNo ratings yet

- Design of a High Field Nb3Al Common Coil MagnetDocument4 pagesDesign of a High Field Nb3Al Common Coil MagnetSUBASH mechNo ratings yet

- Comparison of Experimental Strength of R PDFDocument5 pagesComparison of Experimental Strength of R PDFPiyush PrajapatiNo ratings yet

- 11304-Article Text PDF-33210-2-10-20180322Document16 pages11304-Article Text PDF-33210-2-10-20180322Abdollah AlkhatabNo ratings yet

- Effect of Earthquake and Wind on Concrete SilosDocument8 pagesEffect of Earthquake and Wind on Concrete SilosshivsNo ratings yet

- Influence of Clear Edge Distance and Spacing of Piles On Failure of Pile CapDocument17 pagesInfluence of Clear Edge Distance and Spacing of Piles On Failure of Pile CapArshad100% (1)

- Powell (1983) - Ductile Anchor Bolts For Tall ChimneysDocument11 pagesPowell (1983) - Ductile Anchor Bolts For Tall Chimneystimur sibaevNo ratings yet

- 6455 English IranArze PDFDocument6 pages6455 English IranArze PDFrinaldo_apriyan20No ratings yet

- RCC jacketing improves building column strengthDocument3 pagesRCC jacketing improves building column strengthRishika DixitNo ratings yet

- Connection AnalysisDocument13 pagesConnection Analysispavan kumar tNo ratings yet

- Module 2 Tension Members PDFDocument26 pagesModule 2 Tension Members PDFjomarie apolinarioNo ratings yet

- BTECH JournalDocument4 pagesBTECH Journalashith kodavanjiNo ratings yet

- Flexural Behaviour of Trapezoidal Corrugation Beam by Varying Aspect RatioDocument5 pagesFlexural Behaviour of Trapezoidal Corrugation Beam by Varying Aspect RatioijsretNo ratings yet

- PW-5 Ultrasonic Stud WeldingDocument4 pagesPW-5 Ultrasonic Stud WeldingAMB SpainNo ratings yet

- Magnetic Flux Distributions in Transformer Core JointsDocument4 pagesMagnetic Flux Distributions in Transformer Core JointsratheeshkumardNo ratings yet

- Design of Steel Tension Members: Types, Failure Modes, Shear Lag & ConnectionsDocument4 pagesDesign of Steel Tension Members: Types, Failure Modes, Shear Lag & ConnectionsGopal UttupurathNo ratings yet

- Strength of Welded Plate Girder With Corrugated Web PlateDocument6 pagesStrength of Welded Plate Girder With Corrugated Web PlateLệnh BùiNo ratings yet

- Parametric Studies On The Cutouts in Lightly Loaded Aircraft BeamDocument4 pagesParametric Studies On The Cutouts in Lightly Loaded Aircraft Beamanagha.dn7848No ratings yet

- Development of Soft Reduction at Lnexa Profil For The Possibility of Increased Productivity With Maintained or Improved Product QualityDocument8 pagesDevelopment of Soft Reduction at Lnexa Profil For The Possibility of Increased Productivity With Maintained or Improved Product QualityAkash YadavNo ratings yet

- Designing For Flexibility and ReliabilityDocument5 pagesDesigning For Flexibility and Reliabilityluat1983No ratings yet

- Experimental Study of Openings in R.C. Deep Beam: EmailDocument4 pagesExperimental Study of Openings in R.C. Deep Beam: EmailHusen GhoriNo ratings yet

- Cover Plate Welding Details 2008Aug by BlodgettDocument3 pagesCover Plate Welding Details 2008Aug by BlodgettJim StreitmatterNo ratings yet

- Fretting Fatigue On Thread Root of Premium Threaded ConnectionsDocument10 pagesFretting Fatigue On Thread Root of Premium Threaded ConnectionsJesus ZilchNo ratings yet

- Optimization Approach For Common Steel Open Section Under Applying Direct Torque at Warpless End of A Cantilever BeamDocument8 pagesOptimization Approach For Common Steel Open Section Under Applying Direct Torque at Warpless End of A Cantilever BeamInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Beam - Column Joint EC2Document11 pagesBeam - Column Joint EC2undf25No ratings yet

- III Design of Steel Structures Unit 2Document72 pagesIII Design of Steel Structures Unit 2VikrantNo ratings yet

- Shrinkage CrackDocument9 pagesShrinkage CrackRiyaz SiddiqueNo ratings yet

- Castellated BeamDocument15 pagesCastellated BeamFiroz Mandaviya100% (1)

- Mechanical Design of Free Standing Exhaust Stacks For Offshore ApplicationsDocument8 pagesMechanical Design of Free Standing Exhaust Stacks For Offshore ApplicationsgusiNo ratings yet

- 1 s2.0 S2352854019300075 MainDocument7 pages1 s2.0 S2352854019300075 Mainmanjumv27No ratings yet

- Design of tension members and splicesDocument7 pagesDesign of tension members and splicesSourabh SrivastavaNo ratings yet

- Welded ConnectionsDocument9 pagesWelded ConnectionsAnonymous 1sJXK1DKZNo ratings yet

- Study of Castellated Beam Using Stiffeners: A Review: Siddheshwari. A. Patil, Popat. D. KumbharDocument5 pagesStudy of Castellated Beam Using Stiffeners: A Review: Siddheshwari. A. Patil, Popat. D. Kumbhardiksha balwadNo ratings yet

- Finite Element Analysis of Castellated Steel BeamDocument8 pagesFinite Element Analysis of Castellated Steel BeamTomislav ŠimagNo ratings yet

- Theoretical Evaluation of RC Deep Beam With Web Opening by Using Nonlinear Finite Element Software AbaqusDocument10 pagesTheoretical Evaluation of RC Deep Beam With Web Opening by Using Nonlinear Finite Element Software AbaqusOrhan YanyatmazNo ratings yet

- IJERA Paper PDFDocument6 pagesIJERA Paper PDFjaswantNo ratings yet

- Power Transformer Design, Manufacturing and TestingDocument19 pagesPower Transformer Design, Manufacturing and TestingAbd ALRahmanNo ratings yet

- Effect of Stiffeners On Shear Lag in Steel Box GirdersDocument14 pagesEffect of Stiffeners On Shear Lag in Steel Box Girderserky arkvathonejhNo ratings yet

- Parametric Study of Castellated Beam With Circular and Diamond Shaped OpeningsDocument8 pagesParametric Study of Castellated Beam With Circular and Diamond Shaped OpeningsSiva GuruNo ratings yet

- Parametric Study of Castellated Beam With Circular and Diamond Shaped OpeningsDocument8 pagesParametric Study of Castellated Beam With Circular and Diamond Shaped Openingsvenkata369No ratings yet

- Strength of Materials: An Introduction to the Analysis of Stress and StrainFrom EverandStrength of Materials: An Introduction to the Analysis of Stress and StrainRating: 5 out of 5 stars5/5 (1)

- Car Expo 5 Oct 022 REV.08-02Document1 pageCar Expo 5 Oct 022 REV.08-02Adnan NajemNo ratings yet

- Car Expo 5 Oct 022 REV.08-06Document1 pageCar Expo 5 Oct 022 REV.08-06Adnan NajemNo ratings yet

- Car Expo 5 Oct 022 REV.08-01Document1 pageCar Expo 5 Oct 022 REV.08-01Adnan NajemNo ratings yet

- Car Expo 5 Oct 022 REV.08-03Document1 pageCar Expo 5 Oct 022 REV.08-03Adnan NajemNo ratings yet

- 01 Car Expo 29 Sep 022 03-29Document1 page01 Car Expo 29 Sep 022 03-29Adnan NajemNo ratings yet

- Car Expo 5 Oct 022 REV.08-04Document1 pageCar Expo 5 Oct 022 REV.08-04Adnan NajemNo ratings yet

- Slap DesignDocument9 pagesSlap DesignAdnan NajemNo ratings yet

- Foundations of StructuresDocument14 pagesFoundations of StructuresAdnan NajemNo ratings yet

- Car Expo 5 Oct 022 REV.08-05Document1 pageCar Expo 5 Oct 022 REV.08-05Adnan NajemNo ratings yet

- WiringDocument21 pagesWiringSaruNo ratings yet

- Reply To The Discussion by Bakht Et Al. On "Fibre-Reinforced Polymer Composite Bars For The Concrete Deck Slab of Wotton Bridge"Document2 pagesReply To The Discussion by Bakht Et Al. On "Fibre-Reinforced Polymer Composite Bars For The Concrete Deck Slab of Wotton Bridge"Adnan NajemNo ratings yet

- A Review On Major Structure On ElevatedDocument2 pagesA Review On Major Structure On ElevatedAdnan NajemNo ratings yet

- Lecture 17Document31 pagesLecture 17Adnan NajemNo ratings yet

- Technical Report - STEEL - FRAMED BUILDING - Seismic - AnalysisDocument6 pagesTechnical Report - STEEL - FRAMED BUILDING - Seismic - AnalysisAdnan NajemNo ratings yet

- Analysis of RoofDocument8 pagesAnalysis of RoofAdnan NajemNo ratings yet

- AWC WCD1 ConventionalWoodFrame ViewOnly 0107 PDFDocument55 pagesAWC WCD1 ConventionalWoodFrame ViewOnly 0107 PDFjuan pringNo ratings yet

- Precast Reinforced Concrete BarriersDocument30 pagesPrecast Reinforced Concrete BarriersAdnan NajemNo ratings yet

- Norwegian Refugee Council - Itb-Shelter-Upgrades-AnbarDocument50 pagesNorwegian Refugee Council - Itb-Shelter-Upgrades-AnbarAdnan NajemNo ratings yet

- (Barbero, Ever J.) Finite Element Analysis of Comp (B-Ok - Xyz)Document363 pages(Barbero, Ever J.) Finite Element Analysis of Comp (B-Ok - Xyz)Eliezer MendozaNo ratings yet

- Steam Pipe CalculationDocument160 pagesSteam Pipe Calculationherberthhp85% (13)

- Behaviour of Steel-Reinforced Concrete Columns - Cao2019Document10 pagesBehaviour of Steel-Reinforced Concrete Columns - Cao2019Adnan NajemNo ratings yet

- Electrical Installation Design of Residential Buildings Practical GuidelinesDocument42 pagesElectrical Installation Design of Residential Buildings Practical GuidelinesNoel RazaNo ratings yet

- Insulation MaterialsDocument99 pagesInsulation MaterialsRadha100% (2)

- Review Fe Exam Structures SaoumaDocument51 pagesReview Fe Exam Structures Saoumagtslty99100% (1)

- Lecture 04Document39 pagesLecture 04Adnan NajemNo ratings yet

- Vehicle Restraint Systems-Temporary-systems-Hennie-KotzeDocument35 pagesVehicle Restraint Systems-Temporary-systems-Hennie-KotzeAdnan NajemNo ratings yet

- Gmail: Battlefield Successes and Challenges: Recent Efforts To Win The War Against ISISDocument124 pagesGmail: Battlefield Successes and Challenges: Recent Efforts To Win The War Against ISISAdnan NajemNo ratings yet

- Conex Compression Technical BrochureDocument48 pagesConex Compression Technical BrochureAdnan NajemNo ratings yet

- Bridge Engineeing Drawings 10.2 - A4 - 3Document1 pageBridge Engineeing Drawings 10.2 - A4 - 3Adnan NajemNo ratings yet

- Porosity Gizmo LabDocument4 pagesPorosity Gizmo LabJeneenNo ratings yet

- Seismic vulnerability analysis of historic Sultaniya domeDocument12 pagesSeismic vulnerability analysis of historic Sultaniya domemanjunathNo ratings yet

- Rajas Engineering College Question Bank on Aircraft Structures-IIDocument6 pagesRajas Engineering College Question Bank on Aircraft Structures-IIAnonymous 8pCXXsNo ratings yet

- (A) Coefficient of Consolidation by Inflection Point Method - Mesri Et Al., 1999Document3 pages(A) Coefficient of Consolidation by Inflection Point Method - Mesri Et Al., 1999JociellNo ratings yet

- SRM VEC QUESTION BANK ON STRUCTURAL DESIGN AND DRAWINGDocument9 pagesSRM VEC QUESTION BANK ON STRUCTURAL DESIGN AND DRAWINGRiyas Rasheed100% (1)

- RC Rectangular Column DesignDocument12 pagesRC Rectangular Column DesignSachin AgarwalNo ratings yet

- Saes S 010Document28 pagesSaes S 010nadeem shaikhNo ratings yet

- ME331 - Fluid Mechanics: Assignment No.2-Fluid StaticsDocument2 pagesME331 - Fluid Mechanics: Assignment No.2-Fluid StaticsEdrianCliffDelPilarNo ratings yet

- A Critical Review of Construction, Analysis and Behaviour of Stone ColumnsDocument22 pagesA Critical Review of Construction, Analysis and Behaviour of Stone ColumnsEman AhmedNo ratings yet

- Ultra High Rise BuildingsDocument60 pagesUltra High Rise BuildingsPallav Paban Baruah100% (1)

- Performance Data: Curve 14.00 1BB065, 2BB065Document2 pagesPerformance Data: Curve 14.00 1BB065, 2BB065texwan_No ratings yet

- SPE-198397-MS DrillPlan Fatigue Implementation PDFDocument10 pagesSPE-198397-MS DrillPlan Fatigue Implementation PDFДенис ЖангауловNo ratings yet

- Mini Flow Channel ExperimentDocument9 pagesMini Flow Channel Experimentpotato92No ratings yet

- Sardar Sarovar Dam Spillway, Gujarat PDFDocument4 pagesSardar Sarovar Dam Spillway, Gujarat PDFSur RawatNo ratings yet

- Bond-Slip Relationship of Beam Flexural Bars in Interior Beam-Column JointsDocument27 pagesBond-Slip Relationship of Beam Flexural Bars in Interior Beam-Column Jointschaval01No ratings yet

- Ground ImprovementDocument96 pagesGround ImprovementGuilhermeslongo100% (1)

- 17 Earthquake EngineeringDocument70 pages17 Earthquake EngineeringJoselo MontenegroNo ratings yet

- Mall DefenseDocument4 pagesMall DefenseV- irusNo ratings yet

- SpiraxSarco The Steam and Condensate Loop Block 1 14Document498 pagesSpiraxSarco The Steam and Condensate Loop Block 1 14mirceablaga86100% (1)

- Building Services Unit 1Document8 pagesBuilding Services Unit 1Payal Yadav100% (1)

- Fundamental of ExtrusionDocument28 pagesFundamental of Extrusion6014649No ratings yet

- Court filing document number and revision detailsDocument1 pageCourt filing document number and revision detailsMohammed BasheeruddinNo ratings yet

- Manhour Production Rates GuideDocument69 pagesManhour Production Rates GuideUttiyaNo ratings yet

- Electrokinetic Treatment of Desiccated Expansive ClayDocument34 pagesElectrokinetic Treatment of Desiccated Expansive ClayLydia DarmiyantiNo ratings yet

- Module - 5Document9 pagesModule - 5Sipra SamuiNo ratings yet

- Lecture 1 - Introduction & Fluid Properties PDFDocument24 pagesLecture 1 - Introduction & Fluid Properties PDFJohn Kenneth Basas MusicoNo ratings yet

- Orifice discharge experimentDocument2 pagesOrifice discharge experimentDevansh SharmaNo ratings yet

- Free Publications by DevelopmentDocument1 pageFree Publications by DevelopmentaeoiuNo ratings yet