Professional Documents

Culture Documents

Welding Procedure Specification (WPS) : Accordance To ISO 15609-1 (Arc Welding)

Uploaded by

Ramzi BEN AHMEDOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Welding Procedure Specification (WPS) : Accordance To ISO 15609-1 (Arc Welding)

Uploaded by

Ramzi BEN AHMEDCopyright:

Available Formats

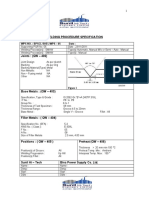

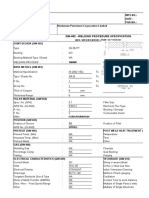

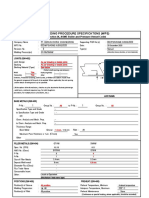

Welding Procedure Specification Page…..from…..

(WPS) pWPS:

Accordance to ISO 15609-1 (Arc Welding) WPQR(15614):

Name of Component Manufacturer: WPS No : Supporting PQR No :

Identity of the object tested : Weld CJP or PJP : Manual Machine Semi-Automatic Automatic

Material Group (ISO 15608): Type of Joint (ISO 17659):

Workpiece 1- Std Code: Workpiece 2 -Std Code: Welding Position (ISO 6947) :

Material thickness (mm) : Joint Preparation method (cleaning ,degreasing ,including to be used; Jigging ,

Pipes size accordance ANSI B36.10 : Grinding ,fixtures & tack welding) acc. to ISO9692

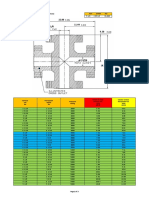

Joint Design (Sketch) Illustration & Welding Sequences Technique

1.Gap (Root opening): Symbolic representation on Design 1. Stringer : drag

2.Root Face: acc. to ISO 2553 2. Whipping

3.Bevel Angel: 3. -Weave :circles

4.Theoretical Throat a1: Crescent

4.

5.Theoretical Throat a2: Zig- zag

6.S1: 5. Box weave

7.S2: 6. Double J

Sequence of Inspection 7. Type of Tack weld

Prior to Welding 8. process(ISO4063):

During Welding Grinding of Root Seam: yes no Wire brushing of Will be delete

After Welding Grinding of inter-pass: yes no interpass:yesno Will not be delete

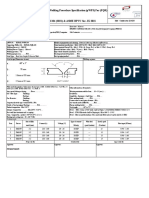

Welding Details

Pass Identity Size of Current & Arc current & Preheat & WFS Travel Speed Mode of metal Stick Out

Process

No of Filler Filler Voltage force Polarity Inter-pass (m/min) (Cm/min) transfer (mm)

Details & Setting process(ISO4063): 114,121,131,135,136,137 Adjust Details & Setting process(ISO4063): 141 Adjust

Brand & model of welding machine : Brand & model of welding machine:

Brand & model of Torch: Brand & model of Torch:

Brand & Code of Filler: Brand & Code of Filler:

Type of Arc Welding: MIG/MAG Standard , PULSE MIG, Dual pulse. Pre-gas flow time(s) :

Pre-gas flow time(s) : Post-gas flow time(s) :

Post-gas flow time(s) : Start current (%):

Type & percent composition (acc. to ISO 14175) & Gas flow rate: Upslope time(s):

Shielding: Downslope time(s) :

Backing: Final current (%):

Torch angle: Ac Balance (unit=1 or unit= %) :

Backhand/Forehand: Ac Frequency(Hz) :

Inductance setting: Ac Waveform :

Type of Liner/size: Type of Gas nozzle/ Size:

Type of Gas nozzle/size: Cap diameter of tungsten tip(Ac current):

Type of Drive roll kits: Tip angle of tungsten electrode(DC current):

Type of contact Tip/size: Pulse welding details:

Standard & Brand of Flux : Pulse frequency(Hz) :

Burn back & Soft-start: Pulse Current: Background current pulse (%):

Other information: Pulse Time (pulse Balance or width) (%) :

Details & Setting process(ISO4063): 111 [Background time pulse]

Brand & model of welding machine : HF arc start duration(s):

Brand & Code of Electrode : HF arc start frequency(Hz):

Hot-start current (%): HF arc start current DC(A):

Hot start Time (S): HF arc start current AC(A):

Arc Force (%): LIFT start current DC(A):

Characteristic Cell Electrode Setting (A/V): LIFT start current AC(A):

Re-drying of Electrod temperature & time: Type & percent composition & Gas flow rate:

Other information: Shielding:

Details of Gouging: Backing:

Process: Trailing gas:

Width: Tungsten Electrode code/size(ISO 6848 or AWS A5.12):

Depth: Type of ceramic gas nozzle:

Other information: Collet body or Gas lens body:

Details of Backing system Torch angle:

Type of Backing: Material of Backing: Backhand/Forehand:

Other information: Tig Feeder : Wire feed speed(cm/min):

Wire start delay time(s):

Test Required

Wire retract time (s):

VT PT MT UT RT

Turn on & turn off time in pulse mode(s):

Other Test :

Other information:

Details of Heat treatment

Pre-heat maintenance temperature(ISO 13916): Post-weld heat treatment:

Method: Temperature: Time: Method: Temperature: Time:

Heating rate: Heating rate: Cooling rate:

Location: Other information: Location: Other information:

Name Signature: Date

This WPS is suitable for repair. This WPS is not suitable for repair.

Design by: Eng. Zanjani

You might also like

- QW 482 WPSDocument2 pagesQW 482 WPSsmit patelNo ratings yet

- ISO 4063 - The Chronological Overview of Nomenclature System ISO 4063 For Welding and Allied ProcessesDocument10 pagesISO 4063 - The Chronological Overview of Nomenclature System ISO 4063 For Welding and Allied ProcessesBorn ToSin90% (10)

- Welding Procedure Specification: ST NDDocument1 pageWelding Procedure Specification: ST NDMaung SleeperNo ratings yet

- Cape BmedDocument381 pagesCape BmedJamal's UploadsNo ratings yet

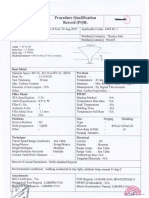

- WPS, PQR, WPQ PoojaDocument10 pagesWPS, PQR, WPQ PoojaRajmahesh Dakhore100% (1)

- Welding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test CertificateDocument3 pagesWelding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test Certificateramesh rajaNo ratings yet

- Operating FactorDocument9 pagesOperating Factormekhman mekhtyNo ratings yet

- WDI-WPS-072 Rev.00 SMAW 2Document4 pagesWDI-WPS-072 Rev.00 SMAW 2MohamedNo ratings yet

- Afcons Infrastructure Limited: Procedure Qualification Record (PQR)Document21 pagesAfcons Infrastructure Limited: Procedure Qualification Record (PQR)GaapchuNo ratings yet

- Auto Continuum PDFDocument164 pagesAuto Continuum PDFJosé Carlos de Alencar Dias100% (1)

- A194A194M-15 Standard Specification For Carbon and Alloy Steel Nuts For Bolts For High Pressure or High Temperature Service, or BothDocument13 pagesA194A194M-15 Standard Specification For Carbon and Alloy Steel Nuts For Bolts For High Pressure or High Temperature Service, or BothChuthaNo ratings yet

- 5 NDT Method For ConcreteDocument1 page5 NDT Method For ConcreteRamzi BEN AHMEDNo ratings yet

- Draft WPSDocument32 pagesDraft WPSAnilkumar G NairNo ratings yet

- Welding Questions PDFDocument42 pagesWelding Questions PDFA. ΒρατσισταNo ratings yet

- Radiographic Film Interpretation for WeldsDocument193 pagesRadiographic Film Interpretation for WeldsHussain AL-AqilNo ratings yet

- PQR DT Macro 60mm Smaw Astm A 516 Gr60Document4 pagesPQR DT Macro 60mm Smaw Astm A 516 Gr60Boran YelkenciogluNo ratings yet

- WPQR - Form As Per EN PDFDocument3 pagesWPQR - Form As Per EN PDFAnilNo ratings yet

- Welding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateDocument2 pagesWelding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateAmjad PathanNo ratings yet

- PQR Procedure Qualification Record Krishna SteelDocument2 pagesPQR Procedure Qualification Record Krishna SteelHarshit Adwani100% (2)

- P WPSDocument3 pagesP WPSAnilkumar G NairNo ratings yet

- CH 31Document11 pagesCH 31juanNo ratings yet

- Nisoc: Preliminary Welding Procedure Specification (PWPS) For (PQR)Document3 pagesNisoc: Preliminary Welding Procedure Specification (PWPS) For (PQR)pejman.imaniNo ratings yet

- WPS PQRDocument126 pagesWPS PQRBuditama ChandranegaraNo ratings yet

- Wps - Asme Ix - Gtaw - PipaDocument5 pagesWps - Asme Ix - Gtaw - PipaMuhammad Fitransyah Syamsuar PutraNo ratings yet

- PQR / WPQ Witness Report: Weld Layer (S) Welding Process Electrode Current Voltag e Travel Speed Dia. Class Polarity AmpDocument1 pagePQR / WPQ Witness Report: Weld Layer (S) Welding Process Electrode Current Voltag e Travel Speed Dia. Class Polarity AmpSatish KeskarNo ratings yet

- WPS PQR As Per IsDocument3 pagesWPS PQR As Per Istarun kaushalNo ratings yet

- BS 00644 2009 (En) PDFDocument28 pagesBS 00644 2009 (En) PDFMahendran MNo ratings yet

- API 579-2 - 13.1 Rev1Document50 pagesAPI 579-2 - 13.1 Rev1osbertodiaz100% (2)

- P&IDDocument18 pagesP&IDhectornicolauNo ratings yet

- Destructive TestDocument17 pagesDestructive TestRamzi BEN AHMEDNo ratings yet

- Ambient Crude Oil StorageDocument13 pagesAmbient Crude Oil StorageSrihari KodimelaNo ratings yet

- WPSDocument5 pagesWPSParshottam Brahmxatriya100% (1)

- Welding Module #2 PDFDocument112 pagesWelding Module #2 PDFHARSH SHARMANo ratings yet

- WPS For A333 ADocument1 pageWPS For A333 ARamzi BEN AHMED100% (1)

- WPS For A333 ADocument1 pageWPS For A333 ARamzi BEN AHMED100% (1)

- Welding Process: Mma/Smaw TYPES: Manual: Preliminary Welding Procedure Specification (PWPS) Nama: Shah Nadzri Bin JasmirDocument3 pagesWelding Process: Mma/Smaw TYPES: Manual: Preliminary Welding Procedure Specification (PWPS) Nama: Shah Nadzri Bin Jasmirshahaljawaie87100% (2)

- Welding Procedure Specification (WPS) : JointsDocument2 pagesWelding Procedure Specification (WPS) : JointsNielNo ratings yet

- DraftDocument32 pagesDraftAnilkumarNo ratings yet

- Aluminum Weld Procedure Qualification Record: (AWS D1.2-2008)Document1 pageAluminum Weld Procedure Qualification Record: (AWS D1.2-2008)Amin ThabetNo ratings yet

- Procedure Qualification SpecificationDocument4 pagesProcedure Qualification Specificationriyas.hvacworkNo ratings yet

- PROCEDURE QUALIFICATION RECORD (PQRDocument2 pagesPROCEDURE QUALIFICATION RECORD (PQRBalkishan DyavanapellyNo ratings yet

- (P22) Nsc-1020-Tr-0102-5a.5a-Wps-04-NewDocument4 pages(P22) Nsc-1020-Tr-0102-5a.5a-Wps-04-NewBIIS QAQC Babu SivaNo ratings yet

- PQR - Gmaw BCCDocument2 pagesPQR - Gmaw BCCBasel MohammadNo ratings yet

- Welding Procedure Specification (WPS) : Standard Applicable: BS EN ISO 15609 1:2019 & BS EN ISO 15614 1: 2017 Level 2Document2 pagesWelding Procedure Specification (WPS) : Standard Applicable: BS EN ISO 15609 1:2019 & BS EN ISO 15614 1: 2017 Level 2phong NguyenduyNo ratings yet

- Welding Procedure Specification (WPS) : Joint Design PositionDocument9 pagesWelding Procedure Specification (WPS) : Joint Design PositionpetermanroelibraryNo ratings yet

- F5-Welding Procedure SpecificationDocument2 pagesF5-Welding Procedure Specificationveera Satya saiNo ratings yet

- WPS For SSDocument1 pageWPS For SSdeepakNo ratings yet

- Procedure Qualification Record (PQR) : 1-2mm 2-5mmDocument26 pagesProcedure Qualification Record (PQR) : 1-2mm 2-5mmDHANEESH VELLILAPULLINo ratings yet

- Welding Procedure Specification (WPS)Document2 pagesWelding Procedure Specification (WPS)Ramadhan AdityaNo ratings yet

- Procedure Qualification Record (PQR) FormDocument1 pageProcedure Qualification Record (PQR) FormEarl HarbertNo ratings yet

- Method Statement - STOP-LOGSDocument7 pagesMethod Statement - STOP-LOGSMohammad Bader Al-DeinNo ratings yet

- Tofd & Pe ReportDocument1 pageTofd & Pe ReportLuong Ho VuNo ratings yet

- Wps Blank Form 2sheetDocument4 pagesWps Blank Form 2sheetdidi sudiNo ratings yet

- PIPING WPS and PQRDocument5 pagesPIPING WPS and PQRshibaprasad0115No ratings yet

- LARSEN & TOUBRO LTD. WELDING PROCEDURE SPECIFICATIONDocument2 pagesLARSEN & TOUBRO LTD. WELDING PROCEDURE SPECIFICATIONRohiNo ratings yet

- WPS-SW-DSA Welding Process Spec. Sub-Arc Qualification Report Rev 2Document2 pagesWPS-SW-DSA Welding Process Spec. Sub-Arc Qualification Report Rev 2Makamu Max Las MokgaoganyiNo ratings yet

- d1 6 PQR 675 070 13 Digital FormDocument2 pagesd1 6 PQR 675 070 13 Digital FormJimmy MyNo ratings yet

- (P22) Nsc-1020-Tr-0102-5a.5a-Wps-04Document9 pages(P22) Nsc-1020-Tr-0102-5a.5a-Wps-04BIIS QAQC Babu SivaNo ratings yet

- QW - 482 Welding Procedure Specifications (WPS) : BASE METAL (S) (QW-403) : JOINTS (QW-402) : or ToDocument2 pagesQW - 482 Welding Procedure Specifications (WPS) : BASE METAL (S) (QW-403) : JOINTS (QW-402) : or ToattaullaNo ratings yet

- WPS SMAW Fillet Welding ProcedureDocument2 pagesWPS SMAW Fillet Welding ProcedurecrysNo ratings yet

- 螢幕截圖 2022-12-30 上午9.17.25Document1 page螢幕截圖 2022-12-30 上午9.17.25Dave CheungNo ratings yet

- Negemco For Engineering & Contracting Processing Equipment Welding Procedure Spcifications (Qw-482)Document3 pagesNegemco For Engineering & Contracting Processing Equipment Welding Procedure Spcifications (Qw-482)Khaled GamalNo ratings yet

- WPS for Manual SMAW Welding of 316L Stainless Steel Butt JointsDocument3 pagesWPS for Manual SMAW Welding of 316L Stainless Steel Butt JointsAmjad PathanNo ratings yet

- HRP Ii WPS STR 209aDocument4 pagesHRP Ii WPS STR 209aRohiNo ratings yet

- Reliance Engineering Associates (P) Limited Welding Procedure SpecificationDocument1 pageReliance Engineering Associates (P) Limited Welding Procedure SpecificationdeepakNo ratings yet

- WPS FormatDocument1 pageWPS FormatbalamuruganNo ratings yet

- Wps 2-8Document1 pageWps 2-8Anonymous XYt4Y9qNo ratings yet

- Negemco For Engineering & Contracting Processing Equipment Welding Procedure Spcifications (Qw-482)Document3 pagesNegemco For Engineering & Contracting Processing Equipment Welding Procedure Spcifications (Qw-482)Khaled GamalNo ratings yet

- Balajee Tanks & Vessels: QW 482 Welding Procedure Specifications (WPS)Document2 pagesBalajee Tanks & Vessels: QW 482 Welding Procedure Specifications (WPS)Eswara Rao BodduNo ratings yet

- PQR FormatDocument2 pagesPQR FormatBE GNo ratings yet

- WC9Document5 pagesWC9Suresh KrishnanNo ratings yet

- PWPS 102 - CopyDocument2 pagesPWPS 102 - CopyCyril J PadiyathNo ratings yet

- 0160e-Welding Procedures Data Sheet PDFDocument1 page0160e-Welding Procedures Data Sheet PDFShane SNo ratings yet

- Kaushik Shah Date: 2011 Form 001 - Format CDocument6 pagesKaushik Shah Date: 2011 Form 001 - Format CsriramNo ratings yet

- Centrifugal Pump Installation ProcedureDocument1 pageCentrifugal Pump Installation ProcedureRamzi BEN AHMEDNo ratings yet

- Butterfly Valves - CatalogDocument30 pagesButterfly Valves - CatalogRamzi BEN AHMEDNo ratings yet

- Guidelines On Qualification For Personnel DealingDocument1 pageGuidelines On Qualification For Personnel DealingRamzi BEN AHMEDNo ratings yet

- ASME B16.5 Flange Temperature and Pressure Ratings ChartDocument4 pagesASME B16.5 Flange Temperature and Pressure Ratings ChartRamzi BEN AHMEDNo ratings yet

- Catalogue Béné InoxDocument30 pagesCatalogue Béné InoxRamzi BEN AHMEDNo ratings yet

- Max Allowable Pressure of Pipes and PipellinesDocument73 pagesMax Allowable Pressure of Pipes and PipellinesRamzi BEN AHMEDNo ratings yet

- Welding Guidelines: Welding Guidelines For Non-Alloy Construction Materials Submerged Arc Welding of Non-Alloy SteelsDocument2 pagesWelding Guidelines: Welding Guidelines For Non-Alloy Construction Materials Submerged Arc Welding of Non-Alloy SteelsRamzi BEN AHMEDNo ratings yet

- API RP 14E - Design and Installation of Offshore Proeuction Platform Piping SystemsDocument1 pageAPI RP 14E - Design and Installation of Offshore Proeuction Platform Piping Systemsสิทธิไชย อรุณวํฒนชัยNo ratings yet

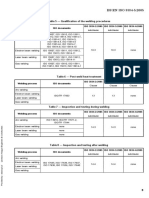

- BS EN ISO 3834-5:2005: Table 1 - Welders and Welding OperatorsDocument1 pageBS EN ISO 3834-5:2005: Table 1 - Welders and Welding OperatorsRamzi BEN AHMEDNo ratings yet

- Grain Refinement of Aluminum Casting Alloys : G.K. Sigworth and T.A. Kuhn, Alcoa Primary MetalsDocument8 pagesGrain Refinement of Aluminum Casting Alloys : G.K. Sigworth and T.A. Kuhn, Alcoa Primary MetalsRamzi BEN AHMEDNo ratings yet

- Table 5 - Qualification of The Welding Procedures: BS EN ISO 3834-5:2005Document1 pageTable 5 - Qualification of The Welding Procedures: BS EN ISO 3834-5:2005Ramzi BEN AHMEDNo ratings yet

- ISO 3834-1 quality requirements for fusion welding of metallic materialsDocument1 pageISO 3834-1 quality requirements for fusion welding of metallic materialsRamzi BEN AHMEDNo ratings yet

- Api 6a FLG Slide Rule SizeDocument9 pagesApi 6a FLG Slide Rule SizeRamzi BEN AHMEDNo ratings yet

- Process and Instrument Diagram SymbolsDocument24 pagesProcess and Instrument Diagram SymbolsBabak Hosseini100% (1)

- GTAW & TIG Welding Question BankDocument19 pagesGTAW & TIG Welding Question BankRamzi BEN AHMEDNo ratings yet

- API Flanged - Studded Crosses and Tees Slide RuleDocument3 pagesAPI Flanged - Studded Crosses and Tees Slide RuleRamzi BEN AHMEDNo ratings yet

- Steel Castings, Surface Acceptance Standards, Visual ExaminationDocument3 pagesSteel Castings, Surface Acceptance Standards, Visual ExaminationRamzi BEN AHMEDNo ratings yet

- Influence of Heat Inputs On Weld Profiles and Mechanical Properties of Carbon and Stainless SteelDocument9 pagesInfluence of Heat Inputs On Weld Profiles and Mechanical Properties of Carbon and Stainless SteelRamzi BEN AHMEDNo ratings yet

- Fusion Bonded Epoxy-Coated Pipe Piles: Standard Specification ForDocument4 pagesFusion Bonded Epoxy-Coated Pipe Piles: Standard Specification ForRamzi BEN AHMEDNo ratings yet

- Chemical Pretreatment for RO and NF SystemsDocument16 pagesChemical Pretreatment for RO and NF SystemsBerliana Cahya NingtiasNo ratings yet

- BS en 30-2-2 - 1999Document10 pagesBS en 30-2-2 - 1999Khaled Moustafa KamelNo ratings yet

- 653 Exam 1-05 PDFDocument29 pages653 Exam 1-05 PDFSaid Alauddeen FaiszNo ratings yet

- Welding, Cutting & Grinding-1Document131 pagesWelding, Cutting & Grinding-1like saddamNo ratings yet

- Material and Equipment Standard: IPS-M-ME-206Document30 pagesMaterial and Equipment Standard: IPS-M-ME-206RezaNo ratings yet

- Welding of Aerospace AlloysDocument46 pagesWelding of Aerospace Alloyscreativechand100% (1)

- Transsteel 2200: / Perfect Charging / / Solar EnergyDocument132 pagesTranssteel 2200: / Perfect Charging / / Solar EnergyAlejandro LujambioNo ratings yet

- Subsea Structural Materials, Welding, and Inspection: ScopeDocument16 pagesSubsea Structural Materials, Welding, and Inspection: ScopeМонсеф АйчаNo ratings yet

- Im642 PDFDocument58 pagesIm642 PDFCarlos PadillaNo ratings yet

- The Evolution of Shielding GasDocument3 pagesThe Evolution of Shielding GasSharad ShahNo ratings yet

- Product Data Sheet for OK AristoRod 12.50Document2 pagesProduct Data Sheet for OK AristoRod 12.50João GuilhermeNo ratings yet

- K to 12 Guide for Gas Metal Arc Welding NC IIDocument17 pagesK to 12 Guide for Gas Metal Arc Welding NC IIlawrenceNo ratings yet

- Filcord C: MIG/MAG Solid wires-TIG Rods C-MN and Low-Alloy SteelsDocument2 pagesFilcord C: MIG/MAG Solid wires-TIG Rods C-MN and Low-Alloy SteelsPavelNo ratings yet

- XMT 350 Mpa Auto-LineDocument64 pagesXMT 350 Mpa Auto-LineVicente ZambranoNo ratings yet

- BananaDocument31 pagesBananaPuja BadheNo ratings yet

- Training Program - SudanDocument4 pagesTraining Program - SudanKhalid HafezNo ratings yet

- Maintain Training Facilities-TemplatesDocument19 pagesMaintain Training Facilities-TemplatesCris VillapanaNo ratings yet

- E Panasonic Tawers en 0Document20 pagesE Panasonic Tawers en 0Jason JiangNo ratings yet

- School of Mechanical Engineering: Lab Manual of Semester - V U5AEA20 - Aircraft Structures Repair LabDocument31 pagesSchool of Mechanical Engineering: Lab Manual of Semester - V U5AEA20 - Aircraft Structures Repair LabAasto Ashrita AastikaeNo ratings yet

- Mesin Las LinconDocument3 pagesMesin Las LinconIrwansyahNo ratings yet

- WPS Sa 517Document2 pagesWPS Sa 517DHANANNJAI SINGH -No ratings yet

- Welding MCQDocument116 pagesWelding MCQRohan YaduvanshiNo ratings yet

- Manufacturing of A Car Body: A Project Report For The Award of The Degree Bachelor of TechnologyDocument23 pagesManufacturing of A Car Body: A Project Report For The Award of The Degree Bachelor of TechnologyDHRUV SINGHALNo ratings yet

- CH 5 WeldingDocument71 pagesCH 5 WeldingnunuNo ratings yet

- Welding Parameters For Inconel 625 Overlay On Carbon Steel Using GMAWDocument6 pagesWelding Parameters For Inconel 625 Overlay On Carbon Steel Using GMAWSyarief Nahdi100% (1)