Professional Documents

Culture Documents

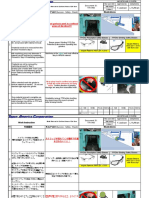

Opstandard: Task # Work Element Description Key Points Notes/ Diagrams

Uploaded by

Arturo Gordillo Abadía0 ratings0% found this document useful (0 votes)

30 views3 pagesThis document provides a standardized process for using a spotting press to inspect dies after repair work. The 10-step process includes preparing the die and press safely, engaging the die slowly to check clearance and movement, and properly removing the die when complete. The purpose is to verify repair quality before putting the die back into production use.

Original Description:

Original Title

Quality check after die repair standard

Copyright

© © All Rights Reserved

Available Formats

XLSX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides a standardized process for using a spotting press to inspect dies after repair work. The 10-step process includes preparing the die and press safely, engaging the die slowly to check clearance and movement, and properly removing the die when complete. The purpose is to verify repair quality before putting the die back into production use.

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

30 views3 pagesOpstandard: Task # Work Element Description Key Points Notes/ Diagrams

Uploaded by

Arturo Gordillo AbadíaThis document provides a standardized process for using a spotting press to inspect dies after repair work. The 10-step process includes preparing the die and press safely, engaging the die slowly to check clearance and movement, and properly removing the die when complete. The purpose is to verify repair quality before putting the die back into production use.

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

You are on page 1of 3

Opstandard

Department: revision

Position: date:

Task # Work Element Description Key Points Notes/ Diagrams

Prepared By: Heather Moore

Checked By: Jeff Thompson

Approved By: Greg Prater # details revision date Name

Opstandard

Department: revision

Position: date:

Task # Work Element Description Key Points Notes/ Diagrams

Prepared By: Heather Moore

Measurement/

Checked By: Jeff Thompson WIP Setting Quality Check Safety

Approved By: Greg Prater # details revision date Name

Standardized Work

Department: Die Maintenance This is to standardize the use of the spotting press to insure a quality repair (clearance ,engagement and proper revision

5-Aug-16

Position: Tool Maker movement of die components) after every repair. date:

Task # Work Element Description Key Points Notes/ Diagrams

Make sure safety blocks are

Spotting Press

1 After repairing cutting edges, replaceing punch's and installed on all 4 corners of die.

buttons, check or repair lifter. Verify work in spotting Follow safety standards noted on

press. spot press.

Make sure pad is out and die is

2 Close and prepare die for die spotting

on safety blocks

Clean press bolster, clean bottom of die, safely

put die on bolster and double check key slots and

Make sure top and bottom of

pin. Check top of die before bringing ram down

3 also look at upper ram for slugs / Damage etc.

die is clean and upper and

lower bolster clean

Before running bolster in check tracks and top of

bolster plate.

Clamp upper die to ram, use 4 T bolts with washers, Check and inspect T bolts, upper /

4 open die slowly until both dies are separated. lower bolsters, and top / bottom

of die for damage and debris.

For trim repair engage slowly ,clay can be used to

match trim lines before engaging, adjust/grind

Install 1mm shims on

clearance if needed. For punch and bushing

bottoming blocks to simulate

repairs, paint the punch and insure centering and

press condition. Use the

5 clearance is ok. Also check the nesting/bearing

spotting press to check trim,

on bushing. Lifters need to be checked for

punch and bushing clearance

movement and interference. The purpose of this

and lifter movement.

standard is to utilize the spotting press to verify

work done.

After spotting is complete secure safety blocks and

6 slowly bring ram down until you touch the blocks. Be careful not to overload blocks.

If to much pressure is applied

blocks could be squeezed out.

After ram is down and upper die is safely on Insure all T clamps have been

7 lower blocks unclamp the upper die. removed from upper die. Install 1mm shims on bottoming blocks to simulate press condition.

Move ram slow to insure no

8 Slowly bring upper ram back to home position. clamps are still holding upper

die.

9 If lower die has been clamped remove T clamps.

Bring bolster back to load / unload position and

10 safely remove die.

Assemble die for production and fill out the (Work order, Follow up, 4M

11 proper paper work that applies to repair. change point, First product tags.)

Prepared By: Mark Rhodes 8/5/2016 MR

Checked By: Chris Jones 8/5/2016 CJ Measurement/

WIP Quality Check Safety

Setting

Approved By: Chris Jones # details revision date Name

You might also like

- Opstandard: Task # Work Element Description Key Points Notes/ DiagramsDocument8 pagesOpstandard: Task # Work Element Description Key Points Notes/ DiagramsArturo Gordillo AbadíaNo ratings yet

- Steinberger R Trem Maintenance Web PDFDocument1 pageSteinberger R Trem Maintenance Web PDFOscar Antonio HumanoNo ratings yet

- Steinberger R Trem MaintenanceDocument1 pageSteinberger R Trem MaintenanceFabio GolfettiNo ratings yet

- Steinberger R Trem Maintenance Web PDFDocument1 pageSteinberger R Trem Maintenance Web PDFOscar Antonio HumanoNo ratings yet

- Steinberger R Trem Maintenance Web PDFDocument1 pageSteinberger R Trem Maintenance Web PDFOscar Antonio HumanoNo ratings yet

- Opstandard: Task # Work Element Description Key Points Notes/ DiagramsDocument5 pagesOpstandard: Task # Work Element Description Key Points Notes/ DiagramsArturo Gordillo AbadíaNo ratings yet

- Job 3395-Emsco FB1600 PumpDocument123 pagesJob 3395-Emsco FB1600 PumpCristian BoselliNo ratings yet

- Standardized Work: Task # Work Element Description Key Points Notes/ DiagramsDocument5 pagesStandardized Work: Task # Work Element Description Key Points Notes/ DiagramsArturo Gordillo AbadíaNo ratings yet

- JSA - Replace Grinding Wheel From Bench GrinderDocument2 pagesJSA - Replace Grinding Wheel From Bench GrinderAshok Suresh100% (1)

- Installing A Mechanical Seal 1Document9 pagesInstalling A Mechanical Seal 1ZakNo ratings yet

- Mark Andy 2200 PM Evaluation Checklist General InformationDocument14 pagesMark Andy 2200 PM Evaluation Checklist General InformationEdwin PerezNo ratings yet

- Opstandard: Task # Work Element Description Key Points Notes/ DiagramsDocument4 pagesOpstandard: Task # Work Element Description Key Points Notes/ DiagramsArturo Gordillo AbadíaNo ratings yet

- Shifting and Loading Unloading of MaterialDocument4 pagesShifting and Loading Unloading of MaterialAdilMunirNo ratings yet

- TROUBLE SHOOTING (Ravindra)Document4 pagesTROUBLE SHOOTING (Ravindra)ravindra kumarNo ratings yet

- Attachment 3 - Bolt Tensioning Task PlanDocument4 pagesAttachment 3 - Bolt Tensioning Task Planchancele nguepdjopNo ratings yet

- TF100-75 - Rynglok R5 Fittings AS-Cross ReferenceDocument4 pagesTF100-75 - Rynglok R5 Fittings AS-Cross ReferenceLorenzoTanNo ratings yet

- Attachment 2 - Bolt Tensioning Task PlanDocument5 pagesAttachment 2 - Bolt Tensioning Task Planchancele nguepdjopNo ratings yet

- Ferris 400S Series Dealer Setup & Adjustment Instructions ManualDocument16 pagesFerris 400S Series Dealer Setup & Adjustment Instructions ManualGustavs KrievkalnsNo ratings yet

- Dayton Arbor Presses Owners ManualDocument8 pagesDayton Arbor Presses Owners ManualBryan AceroNo ratings yet

- CRAFT Installation-Guide For Split Bearings PDFDocument7 pagesCRAFT Installation-Guide For Split Bearings PDFAdrian CantaragiuNo ratings yet

- Excavator Audit Complete PresentationDocument97 pagesExcavator Audit Complete PresentationTechnical Support WarrantyNo ratings yet

- Break Out and Laying Down BhaDocument3 pagesBreak Out and Laying Down BhakhurramNo ratings yet

- As dc08 003 - 1Document5 pagesAs dc08 003 - 1Putra SeptiadyNo ratings yet

- As dc08 003 - 1Document5 pagesAs dc08 003 - 1Putra SeptiadyNo ratings yet

- Standard Operating Procedure / Work Instructions / Visual AidsDocument3 pagesStandard Operating Procedure / Work Instructions / Visual AidsSwapnil BachhavNo ratings yet

- NoteDocument18 pagesNotepikipelukiNo ratings yet

- Dräger Caleo Incubator - User Manual (En) PDFDocument132 pagesDräger Caleo Incubator - User Manual (En) PDFpatrick1009No ratings yet

- Attachment 1 - Bolt Tensioning Task PlanDocument7 pagesAttachment 1 - Bolt Tensioning Task Planchancele nguepdjopNo ratings yet

- Gráfico Diagrama Carta Gantt Calendario de Trabajo Color PastelDocument3 pagesGráfico Diagrama Carta Gantt Calendario de Trabajo Color PastelBrigith Jimena Ccahuana SotoNo ratings yet

- Manual Medicion Tren de RodajeDocument140 pagesManual Medicion Tren de RodajeCarlos Enrique De La Rosa ZambranoNo ratings yet

- FAT Procedure 12m DoorDocument5 pagesFAT Procedure 12m DoorBjørnar HuseNo ratings yet

- Chair Lift Logs!Document11 pagesChair Lift Logs!api-56269050No ratings yet

- ChecklistTyres-invulbaar LEAF EN 09-2020Document2 pagesChecklistTyres-invulbaar LEAF EN 09-2020Melwyn FernandesNo ratings yet

- Troubleshooting in PressDocument1 pageTroubleshooting in PressDavid RodriguezNo ratings yet

- Standardized Work: Heating Steels Before and After WeldingDocument6 pagesStandardized Work: Heating Steels Before and After WeldingArturo Gordillo AbadíaNo ratings yet

- Job Safety Analysis (Jsa) : DQE International Iraq BranchDocument4 pagesJob Safety Analysis (Jsa) : DQE International Iraq Branchhassan100% (1)

- Procedures Manual Volume Four: Written By: Syed M Asim Reviewed By: Faisal DilbaghDocument3 pagesProcedures Manual Volume Four: Written By: Syed M Asim Reviewed By: Faisal DilbaghTalha UsmaniNo ratings yet

- Front Upper Control Arm: Step #1 Step #2Document1 pageFront Upper Control Arm: Step #1 Step #2Damian CrequeNo ratings yet

- Qdoc - Tips Volvo g930 Motor Grader Service Repair ManualpdfDocument16 pagesQdoc - Tips Volvo g930 Motor Grader Service Repair ManualpdfLarzon Rodriguez0% (1)

- IDC SOP # 10 Operation of The Pipe SpinnerDocument2 pagesIDC SOP # 10 Operation of The Pipe SpinnerkareemNo ratings yet

- Equipment Training MaterialDocument20 pagesEquipment Training MaterialHimanshu MishraNo ratings yet

- Style40 42 45 IOMDocument12 pagesStyle40 42 45 IOMVictor Flores ResendizNo ratings yet

- Checklist Piling Work .Pile ConstructionDocument2 pagesChecklist Piling Work .Pile Constructionyash shah88% (34)

- Manual de Reparacion Motor Jac 4da1 Parte 4Document100 pagesManual de Reparacion Motor Jac 4da1 Parte 4Anonymous iBenl3mNNo ratings yet

- API RP 687-2001 (2015) Ut BabbitpdfDocument1 pageAPI RP 687-2001 (2015) Ut BabbitpdfudomNo ratings yet

- Horizon GSG2G1 ImagerDocument5 pagesHorizon GSG2G1 ImagerEsmaDergalNo ratings yet

- Typee IOMDocument9 pagesTypee IOMyusufNo ratings yet

- UniversalDocument11 pagesUniversalAnonymous TYGiADNo ratings yet

- Herman Miller Aeron® Pneumatic Cylinder ReplacementDocument11 pagesHerman Miller Aeron® Pneumatic Cylinder ReplacementCraigNo ratings yet

- Sample: Excavator Safety TrainingDocument61 pagesSample: Excavator Safety Trainingvega f ankaNo ratings yet

- Universal Projector Bracket: Installation InstructionsDocument11 pagesUniversal Projector Bracket: Installation InstructionsSohail KhanNo ratings yet

- 89 Scaffold safety-JOB PROCEDUREDocument2 pages89 Scaffold safety-JOB PROCEDUREkusdiyantaNo ratings yet

- (Grinder Guard) Safety StandardDocument6 pages(Grinder Guard) Safety StandardArturo Gordillo AbadíaNo ratings yet

- Design and Analysis of Press Tool Assembly: Raveendra CH - NagarajuDocument6 pagesDesign and Analysis of Press Tool Assembly: Raveendra CH - Nagarajuvishal agarwal100% (1)

- ArnabGayen 13000720053 PCME-601 CA1Document8 pagesArnabGayen 13000720053 PCME-601 CA1HyperFlickNo ratings yet

- WI - Preavaling Torque TestingDocument3 pagesWI - Preavaling Torque Testingvipulsharma655No ratings yet

- Extract Fan/Exhaust Fan - 3M Task SheetDocument3 pagesExtract Fan/Exhaust Fan - 3M Task Sheetobaidur_rehman_3No ratings yet

- Impulse Poly Bag Sealers: TroubleshootingDocument6 pagesImpulse Poly Bag Sealers: Troubleshootingibss_mcmNo ratings yet

- SKS Scope Mount InstructionsDocument4 pagesSKS Scope Mount Instructions王欢No ratings yet

- Automotive Machining: A Guide to Boring, Decking, Honing & MoreFrom EverandAutomotive Machining: A Guide to Boring, Decking, Honing & MoreRating: 4.5 out of 5 stars4.5/5 (11)

- Standarized Work Ball Lock PunchDocument5 pagesStandarized Work Ball Lock PunchArturo Gordillo AbadíaNo ratings yet

- Unconrolled If Printed: WIP Measurement/ Setting Quality CheckDocument4 pagesUnconrolled If Printed: WIP Measurement/ Setting Quality CheckArturo Gordillo AbadíaNo ratings yet

- Standardized Work: Task # Work Element Description Key Points Notes/ DiagramsDocument6 pagesStandardized Work: Task # Work Element Description Key Points Notes/ DiagramsArturo Gordillo AbadíaNo ratings yet

- Opstandard: Task # Work Element Description Key Points Notes/ DiagramsDocument4 pagesOpstandard: Task # Work Element Description Key Points Notes/ DiagramsArturo Gordillo AbadíaNo ratings yet

- Standardized Work: When To Get CP Control Plan Use For Damaged DiesDocument4 pagesStandardized Work: When To Get CP Control Plan Use For Damaged DiesArturo Gordillo AbadíaNo ratings yet

- Standardized Work: Heating Steels Before and After WeldingDocument6 pagesStandardized Work: Heating Steels Before and After WeldingArturo Gordillo AbadíaNo ratings yet

- Standardized Work: Task # Work Element Description Key Points Notes/ DiagramsDocument6 pagesStandardized Work: Task # Work Element Description Key Points Notes/ DiagramsArturo Gordillo AbadíaNo ratings yet

- Standardized Work: Task # Work Element Description Key Points Notes/ DiagramsDocument5 pagesStandardized Work: Task # Work Element Description Key Points Notes/ DiagramsArturo Gordillo AbadíaNo ratings yet

- Ball Spring: Operating Standard E-3Document3 pagesBall Spring: Operating Standard E-3Arturo Gordillo AbadíaNo ratings yet

- Standardized Work: Task # Work Element Description Key Points Notes/ DiagramsDocument6 pagesStandardized Work: Task # Work Element Description Key Points Notes/ DiagramsArturo Gordillo AbadíaNo ratings yet

- Die Stands (Safety) StandardDocument6 pagesDie Stands (Safety) StandardArturo Gordillo AbadíaNo ratings yet

- Ball Spring: Operating Standard E-3Document2 pagesBall Spring: Operating Standard E-3Arturo Gordillo AbadíaNo ratings yet

- (Grinder Guard) Safety StandardDocument6 pages(Grinder Guard) Safety StandardArturo Gordillo AbadíaNo ratings yet

- Opstandard: Task # Work Element Description Key Points Notes/ DiagramsDocument5 pagesOpstandard: Task # Work Element Description Key Points Notes/ DiagramsArturo Gordillo AbadíaNo ratings yet

- Confined Space Grinding Work Instruction - TranslatedDocument2 pagesConfined Space Grinding Work Instruction - TranslatedArturo Gordillo AbadíaNo ratings yet

- Standardized Work: Heating Steels Before and After WeldingDocument6 pagesStandardized Work: Heating Steels Before and After WeldingArturo Gordillo AbadíaNo ratings yet

- Standardized Work: Task # Work Element Description Key Points Notes/ DiagramsDocument6 pagesStandardized Work: Task # Work Element Description Key Points Notes/ DiagramsArturo Gordillo AbadíaNo ratings yet

- Standarized Work Ball Lock PunchDocument5 pagesStandarized Work Ball Lock PunchArturo Gordillo AbadíaNo ratings yet

- Standardized Work: Task # Work Element Description Key Points Notes/ DiagramsDocument5 pagesStandardized Work: Task # Work Element Description Key Points Notes/ DiagramsArturo Gordillo AbadíaNo ratings yet

- Operating Standard B-2: Work InstructionDocument10 pagesOperating Standard B-2: Work InstructionArturo Gordillo AbadíaNo ratings yet

- Fluids Mechanics HomeworkDocument92 pagesFluids Mechanics Homeworkm3994794% (31)

- BJ SurfactantsDocument2 pagesBJ SurfactantsAquiles Carrera100% (2)

- CO3053 - Lecture 1 - What Is Embedded SystemDocument21 pagesCO3053 - Lecture 1 - What Is Embedded SystemKhánh Tôn Thất PhúcNo ratings yet

- Research Article: International Research Journal of PharmacyDocument5 pagesResearch Article: International Research Journal of PharmacyAlfrets Marade SianiparNo ratings yet

- Handling CFGDocument22 pagesHandling CFGRadit BentoNo ratings yet

- Making Fertilizer Using Ipil Ipil LeavesDocument10 pagesMaking Fertilizer Using Ipil Ipil LeavesRaine TalionNo ratings yet

- The Book of Paradise - Volume IIDocument964 pagesThe Book of Paradise - Volume IItriamazikamno100% (3)

- Routes of Medication AdministrationDocument2 pagesRoutes of Medication AdministrationTracy100% (6)

- Detailed Lesson Plan in Science Grade 10Document9 pagesDetailed Lesson Plan in Science Grade 10christian josh magtarayoNo ratings yet

- Modding For Ysflight - Scenery EditorDocument92 pagesModding For Ysflight - Scenery Editordecaff_42No ratings yet

- CBSE Sample Paper Class 9 Science SA2 Set 7Document13 pagesCBSE Sample Paper Class 9 Science SA2 Set 7PALAK SHARMANo ratings yet

- Dr. Mike Israetel Training Volume Landmarks Hypertrophy RoutineDocument26 pagesDr. Mike Israetel Training Volume Landmarks Hypertrophy RoutineJose Fernando PereiraNo ratings yet

- 2018-Me-184 MMDocument28 pages2018-Me-184 MMKhizer Nauman RanaNo ratings yet

- André Bakker Modeling Flow Fields in Stirred TanksDocument40 pagesAndré Bakker Modeling Flow Fields in Stirred TanksKhalida BekrentchirNo ratings yet

- Food and Beverages Sample Script For NCADocument11 pagesFood and Beverages Sample Script For NCAHONEY ROSE NAKILANo ratings yet

- Lab Assignment-1 1. Create Table Student (Rno, Name, DOB, Gender, Class, College, City, Marks)Document7 pagesLab Assignment-1 1. Create Table Student (Rno, Name, DOB, Gender, Class, College, City, Marks)supreetNo ratings yet

- Rewoquat We 45 TDS 12 02 01Document3 pagesRewoquat We 45 TDS 12 02 01chintanictNo ratings yet

- By Beholding We Are ChangedDocument2 pagesBy Beholding We Are ChangedAdrian EbensNo ratings yet

- Aldehyde Keto. Ncert Book PDFDocument32 pagesAldehyde Keto. Ncert Book PDFAshraf KhanNo ratings yet

- Msi MS 7529 Rev 1.1 PDFDocument33 pagesMsi MS 7529 Rev 1.1 PDFMisael Alves67% (3)

- Shipping Agents in SGDocument3 pagesShipping Agents in SGeason insightsNo ratings yet

- Bombardier Zefiro Technical Description enDocument15 pagesBombardier Zefiro Technical Description ennickerlesstezla100% (1)

- STAT 713 Mathematical Statistics Ii: Lecture NotesDocument152 pagesSTAT 713 Mathematical Statistics Ii: Lecture NotesLiban Ali MohamudNo ratings yet

- Toxic Shock Syndrome - PPTX 1-1Document49 pagesToxic Shock Syndrome - PPTX 1-1Mohammed Khedr100% (1)

- 螳螂拳七長八短 - Tanglangquan Qi Chang Ba Duan - Tanglangquan's Seven Long & Eight Short - Lessons Learned in the World of Martial ArtsDocument2 pages螳螂拳七長八短 - Tanglangquan Qi Chang Ba Duan - Tanglangquan's Seven Long & Eight Short - Lessons Learned in the World of Martial ArtsGianfranco MuntoniNo ratings yet

- Craig - 4353 TX CobraDocument3 pagesCraig - 4353 TX CobraJorge ContrerasNo ratings yet

- Dmbi Assignment 2: Q.1. Explain STAR Schema. Ans-1Document6 pagesDmbi Assignment 2: Q.1. Explain STAR Schema. Ans-1Kanishk TestNo ratings yet

- Naplan Year 9 PracticeDocument23 pagesNaplan Year 9 PracticetonynuganNo ratings yet

- NCERT Class 7 English Part 1 PDFDocument157 pagesNCERT Class 7 English Part 1 PDFVvs SadanNo ratings yet

- GNM SyllabusDocument4 pagesGNM SyllabusVinay SinghNo ratings yet