Professional Documents

Culture Documents

M006-GDB-ARC-RPT-00188 Rev. 2

Uploaded by

Faizuddin SiddiquiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

M006-GDB-ARC-RPT-00188 Rev. 2

Uploaded by

Faizuddin SiddiquiCopyright:

Available Formats

Qatar Rail

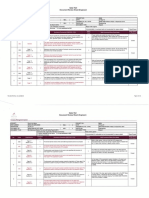

/- Document Review Sheet (Engineer)

Company Management System

roo• t"""' .. , ... ,.. ~ , ,..,.. ,., _,. , ..,..., ...,,_..., uo~ 11 uo- -~.,, , ,.. .,..._,.. , """ , ,.. , .,....,, v o ,.., ,..,"""

BOR General

2017, the review will be done on the next submission

I ii INoted I Closed

I MOOS-GDB-ENG-CER- 1

DVE Design and Verification Cer1ificate (MOOS.GDB-ENG-

__ ..___ ·--REV 1) includes EIGHT cond~ions.

Therefore cannot be considered as Design Verification Certification.

I ' Discussions have been held between ORIPMC, JV, DVE, Areadis and

I

2 I IMC

00125 REV 1

1

1

ii Atkins on 27th March 2017. caveats will be removed as far as possible , Closed

- · · - · ·- certificate with t he submission without conditions CK but some will be rema ining on MSI and until the MEP design is issued..

None of the assumptions are required to be submrtted through the RFI

process as [Tunnel ventilation, Emergency power, Traction power.

same assumptions u the DD1 report (MOOS·GDB·ARC.RPT-

Vehicles, Emergency Management, Public address and CCTV] are all by

vvv913 Rev 1) are listed here. State which assumptions have now been

3 I IMC I

Page 12 of28

Section 1.6 I 1

1

confirmed through RFis or Workshops.

-·· · --, (Deta iled Design) submission and should not include

i

other contractors and largely a repetition of the ERs and NFPA; a single I

fire event is an industry norm and repeated in the ERs; protection against

terrorist acts is outside the ERs. Repeat of DD1 response.

Closed

or rely on future workshops.

The term "assumption" has been relaced by " basis of design''

All design is being be sed on a SIL-2 system and thus compliant w~ th e

_v'" " "' the Fire Detection System within the Switch Box Technical ER.

4 I IMC I

Page 21 of213

Section 5.1.1 I 1

1

Rooms will be designed and installed to SIL-2 as per the Employers

Requirements.

ii

Any discussion for an a ~em ativ e system will be conducted by the JV

I Closed

outside the design.

Include all life safety and cr~ica l systems (e.g. Signalling systems,

'Communication systems, Fare collections gates, Emergency lighting We note that the majority of items listed by the reviewer are already

5 I IMC I

Page 24 of28

Section 6 .4.2 I 1 system, Fire command centre, Em ergency mechanical ventilation

system, Fire fighting pumps, Fire fighting lifts, etc.), shall be connected

ii included. The switchbox does not contain fare collection gates. We do

not sea that the signalling system is relevant to this FLS report..

I Closed

the Emergency Power System. Comply with ER Vo16. 13.3.2 5.b.iv

lEADING EXCEllENCE j1M 203-FQ3 Rev. 50 .11/10/1&

Page 1 of 3

Qatar Rail

Document Review Sheet (Engineer)

"" ~J-J ~I Company Management System

lire extinguishers shall ba provided in such numbers, sizes and

Page 22 of 28 at such locations as determined by the authority having

6 IMC Confirmed in FLS report revision 2 section 5.6.2 Closed

Section 5.6.1 liurisciction in accordance w~h NFPA 130: 5.4.6 . Specify the proposal

the switch box to allow QCDD to approve.

the reference to "anomoly" and clearly state the design loading

trucks on the access road end on the herd standing to allow carrying capacity figures quoted in the report come st raight from

Page 23 of28

7 I IMC I Section 5.9.4

to approve. QCDD standards so must be assummed to be to their sat isfaction. The Closed

a DD2 (Detailed Design) submission and should not include reference to an anomoly has been removed.

!assumptions or rely on future workshops.

th at "Concrete is proposed for the sw~chbox walking

Page 15 of 28 Section has been updated. Refer to updated report and drawings now

8 I IMC I Section 3.1.2

1 M006-GDB-STR-DWG-YWSB010.1L- 53100 details

showing Steel.

Closed

t t LWUKI\ W ALKWAY PLAN for the Sw ~chbox.

9 SPO Section 1.5.3 and 1.54 2015 and QCS 2014 edition shall be mentioned here

reference standards mentioned hera shall be the latest e~ions

10 SPO Sect1on 1.5.5

k and update

letter reference "MOOB-GDB-ENG-LTR-00516" is not found 1n

11 SPO Sect1on 6 4.3

par OR Low Voltage (LV) Power Distribution System Gu1dehnes, the

>le-4 shall be modified:

12 SPO Sect1on 6 4.3 Emergency light1ng facilities shall be supplied from the Central

System

BACS shall be fed from UPS.

LEADING EXCELLENCE 11M 20H03 Rev 50. 11/10/16

Page2 of 3

~

Qatar Rail

Document Review Sheet (Engineer)

Company Management System

Report has been given a condit1onnal NOWC status with regards

Building (architecture and structure) only

13 BOR General

of MEP design are to be dealt wrth dunng MEP 002 and

DC2 submiSsions.

14 BOR General

C. SONO E. FaiVNot approved

SA 1·1 Manager N81lle:

FLS Engineer Position:

c Chevallller I MEP Manager

ft;l~

Eric

Saleek Poovakundll I E&M Elec. Engr

-

Signature: f;l'{m/) Signature: Signature:

Mourad Zouyene I SA 1·1 Manager

lain McLean I E&M Eng. Elec Date: Z4 AUG 2017 loate: I loate: I Z4 AUG 2017

LEADING EXCELLENCE l l M·W3·HJ.l Rev '> O. 31/10/!C. Page3 of3

ALYSJ

j o i n t vent u re

QATAR INTEGRATED RAIL PROJECT

Doha Metro: Gold Line

Bin Mahmoud Switchbox

Fire And Life Safety Report {002)

M006-GDB-ARC-RPT-00188

PREPARATION BY CONTRACTOR:

Action Name Signature Role Company Date

Originator Paul Curran $£,.. Discipline

Engineer

ATKINS 24-Apr-2017

Technical

Checker lan Johnson

-·- ~L-· Director

ATKINS 24-Apr-2017

~ 6Z./;7~ v

Reviewer Dionysios PP ( Engineering

ALYSJ-JV

Panagiotopoulos · - · Man"!g_er

Approval Carlo Germani Ji;~/ Project Director ALYSJ-JV ax-b-~ ~

/I"' f

ENGINEER'S ASSISTANT /

l\

,. \~~

Engineer's

Samuel Adair McChesney ~ Qatar Rail 4 AUG Z017

Assistant

STATUS ~

A B c \ D) E F

Approved "'---/

Fail/Not No Review

Approved w ith SONO NOWC

Approved Required

Comments

I Document Number: MOOG-GDB-ARC-RPT-00188 Rev 2 Page 1 of 29 24-Apr-2017

Uncontrolled if printed, refer to EDMS for current version

Right First Time, Every Time – Zero Defect

Revision History:

Rev. Date Description Originator Checked Reviewed Approved

1 13-Dec-2016 Issued for approval PCU IJO DPN CGE

2 24-Apr-2017 Issued for approval PCU IJO DPN CGE

Controlled Copy Issue Log: (Applicable only for hard copy as may be required outside of EDMS)

This hard copy document has been assigned as below and will be reissued automatically upon any future

revision.

Copy Company Name Representative

Document Number: M006-GDB-ARC-RPT-00188 Rev 2 Page 2 of 29 24-Apr-2017

Uncontrolled if printed, refer to EDMS for current version

Right First Time, Every Time – Zero Defect

CONTENTS

EXECUTIVE SUMMARY ...............................................................................................................................8

1 INTRODUCTION ...................................................................................................................................9

1.1 General Description 9

1.2 Scope 10

1.3 Authority Having Jurisdiction 11

1.4 Status of the JV contract documents 11

1.5 Applicable Codes and References 11

1.6 Basis for this fire and life safety report 12

2 OCCUPANCY CLASSIFICATION AND HAZARD OF CONTENTS ..................................................14

2.1 Occupancy classification 14

2.2 Hazard evaluation 14

3 FEATURES OF FIRE PROTECTION..................................................................................................15

3.1 Construction Materials 15

3.2 Compartmentation 16

3.3 External fire spread 17

3.4 Roof finish classification 17

3.5 Interior finish for floors, walls and ceilings 17

3.6 Fire Doors 17

4 MEANS OF EGRESS ..........................................................................................................................18

4.1 Evacuation scenarios: 18

4.2 Level of Exit Discharge (LED) 18

4.3 Means of escape underground 18

4.4 Means of escape components 19

4.5 Illumination of means of egress and emergency lighting 20

5 FIRE PROTECTION SYSTEMS ..........................................................................................................21

5.1 Fire detection and alarm system 21

5.2 Fire sprinkler system 21

5.3 Clean agent fire extinguishing systems 21

5.4 Standpipes 21

5.5 External hydrants (by others) 22

5.6 Portable fire extinguishers 22

5.7 Emergency ventilation system 22

5.8 Pressurization 22

5.9 Fire service access 22

6 BUILDING SERVICES ........................................................................................................................24

6.1 General: 24

6.2 Heating, ventilation and air-conditioning equipment 24

6.3 Wiring requirements 24

6.4 Emergency power 24

6.5 Fire command centre 25

6.6 Lifts 25

7 APPENDIX A - DRAWINGS ................................................................................................................27

CONCLUSION .............................................................................................................................................28

Document Number: M006-GDB-ARC-RPT-00188 Rev 2 Page 3 of 29 24-Apr-2017

Uncontrolled if printed, refer to EDMS for current version

Right First Time, Every Time – Zero Defect

TABLES

Table 1: Components Fire Rating ............................................................................................................. 15

Table 2: Fire ratings for specific rooms/areas .......................................................................................... 16

Table 3: Minimum NFPA dimensional criteria for exit stairwell ................................................................ 20

Table 4: Power supply .............................................................................................................................. 25

Table 5: Relevant drawings ...................................................................................................................... 27

FIGURES:

Figure 1: Location Plan ............................................................................................................................... 9

Figure 2: 3D massing................................................................................................................................ 10

Figure 3: Switchbox walkways .................................................................................................................. 18

Figure 4: Fire appliance highway turning radii [QCDFSS 4.1 Annex D] ................................................... 23

Document Number: M006-GDB-ARC-RPT-00188 Rev 2 Page 4 of 29 24-Apr-2017

Uncontrolled if printed, refer to EDMS for current version

Right First Time, Every Time – Zero Defect

ABBREVIATIONS

AHJ Authority Having Jurisdiction

CFD Computational Fluid Dynamics

ER Employer’s Requirements

ER 5-3.5 Qatar Integrated Railways Project, Volume 5 Employer’s Requirements –

Particular – Section 3.5 “Station Sizing” - (Stamped documents)

ER 6-10 Requirements, namely Qatar Integrated Railways Project, Volume 6

Employer’s Requirements – Design and Specifications - Section 10 “Fire

Protection and Life Safety Requirements” (Stamped documents)

ER 6-11 Requirements, namely Qatar Integrated Railways Project, Volume 6

Employer’s Requirements – Design and Specifications - Section 11

“Architectural design of stations and buildings” (Stamped documents)

ER 6-13 Requirements, namely Qatar Integrated Railways Project, Volume 6

Employer’s Requirements – Design and Specifications - Section 13

“Mechanical, Electrical, Plumbing (MEP) Specifications” (Stamped

documents)

FLS Fire and Life Safety

GL Gold Line

ICC Integrated Control Centre (Referred to as the Operational Control Centre by

NFPA 130)

JV Joint venture comprising Aktor S.A.-Larsen & Tourbo Limited-Yapi Merkezi

Insaat V.E.-Sezai Turkes Feyzi Akkaya Marine Construction-Al Jaber

Engineering LLC

LED Level of exit discharge

NFPA National Fire Protection Association

OCC Operational Control Centre

OTE Over Track Exhaust

TSEVS Tunnel and station emergency ventilation systems

TVS Tunnel ventilation system

TPS Traction Power Sub-Station (when within stations)

QCD Qatar Civil Defence

QCDFSS Qatar Civil Defence Fire Safety Standard

Document Number: M006-GDB-ARC-RPT-00188 Rev 2 Page 5 of 29 24-Apr-2017

Uncontrolled if printed, refer to EDMS for current version

Right First Time, Every Time – Zero Defect

DEFINITIONS

Term Definition

Point of safety A point of safety is one of the following: (1) an enclosed exit that leads to a

public way or safe location outside the station, trainway, or vehicle; (2) an at-

grade point beyond the vehicle, enclosing station, or trainway; (3) any other

approved location. [NFPA 130:3.3.35]

Point of safety A location that (a) is exterior to and away from a building; or (b) is within a

building of any construction type protected throughout by an approved

automatic sprinkler system and that is either (1) within an exit enclosure

meeting the requirements of this Code, or (2) within another portion of the

building that is separated by smoke barriers in accordance with Section 8.5

having a minimum 1 / 2 -hour fire resistance rating, and that portion of the

building has access to a means of escape or exit that conforms to the

requirements of this Code and does not necessitate return to the area of fire

involvement; or (c) is within a building of Type I, Type II(222), Type II(111),

Type III(211), Type IV, or Type V(111) construction (see 8.2.1.2) and is either

(1) within an exit enclosure meeting the requirements of this Code, or (2) within

another portion of the building that is separated by smoke barriers in

accordance with Section 8.5 having a minimum 1/ 2 -hour fire resistance rating,

and that portion of the building has access to a means of escape or exit that

conforms to the requirements of this Code and does not necessitate return to

the area of fire involvement. [NFPA 101:3.3.213 & Glossary of terms]

Place of A place where people are protected from the effects of fire and smoke [CIBSE

relative safety Guide E “Fire Safety Engineering”]

Exit That portion of a means of egress that is separated from all other spaces of a

building or structure by construction or equipment as required to provide a

protected way of travel to the exit discharge.

[NFPA 101:3.3.83 & Glossary of terms]

Exits include exterior exit doors, exit passageways, horizontal exits, exit stairs,

and exit ramps. In the case of a stairway, the exit includes the following:

(1) Stair enclosure

(2) Door to the stair enclosure

(3) Stairs and landings inside the enclosure

(4) Door from the stair enclosure to the outside or to the level of exit discharge

(5) Any exit passageway and its associated doors, if such are provided, so as to

discharge the stair directly to the outside. In the case of a door leading directly

from the street floor to the street or open air, the exit comprises only the door.

Exit Hallways, corridors, passages, or tunnels used as exit components and

passageway separated from other parts of the building in accordance with NFPA 101, Life

Safety Code. [NFPA 101:7.2.6 & Glossary of terms].

Exit access That portion of a means of egress that leads to an exit

[NFPA 101:3.3.84 & Glossary of terms]

Exit discharge That portion of a means of egress between the termination of an exit and a

public way. [NFPA 101:3.3.85 & Glossary of terms]

Document Number: M006-GDB-ARC-RPT-00188 Rev 2 Page 6 of 29 24-Apr-2017

Uncontrolled if printed, refer to EDMS for current version

Right First Time, Every Time – Zero Defect

Term Definition

Smoke barrier A continuous membrane, or a membrane with discontinuities created by

protected openings, where such membrane is designed and constructed to

restrict the movement of smoke. [NFPA 101:3.3.31.2 & Glossary of terms]

Smoke A continuous membrane that is designed to form a barrier to limit the transfer

partition of smoke [NFPA 101:3.3.256 & Glossary of terms]

Draft Stop A continuous membrane used to subdivide a concealed space to resist the

passage of smoke and heat [NFPA 5000:3.3.173 & Glossary of terms]

(Draft stopping materials shall be not less than 13 mm gypsum board, or other

approved materials adequately supported)

NOTE:

Images within this document are indicative for the purposes of fire safety and may not be an

accurate representation of the final layout.

Document Number: M006-GDB-ARC-RPT-00188 Rev 2 Page 7 of 29 24-Apr-2017

Uncontrolled if printed, refer to EDMS for current version

Right First Time, Every Time – Zero Defect

EXECUTIVE SUMMARY

The purpose of this report is to provide description of the Fire Protection and Life Safety

features to be adopted for the Gold Line Bin Mahmoud Switchbox.

The Gold Line comprises 13 stations, three switchboxes and a stabling yard. Fire and Life

Safety reports have been produced for each individual station, switchbox and the stabling

yard to support the architectural, structural, mechanical, electrical and public health

submissions; which this report should be read in conjunction with.

This submission addresses Fire Protection provisions and Means of Escape, together with

measures such as fire compartmentation, mode of protection (extinguishment),

standpipes, risers, call points etc.

All the Fire Safety protection provisions are designed to comply with NFPA 130:2014 and

the QCDD regulations prevailing at the date of this report, as well as all the latest editions

of the standards, codes and regulations in relation to the fire regulations in Qatar. No

waivers to the above requirements are needed for this switchbox and the design is

compliant with these fire and life safety standards.

This report is the DD2 stage continuation of the DD1 stage FLS report M006-GDB-ARC-

RPT-00098.

Document Number: M006-GDB-ARC-RPT-00188 Rev 2 Page 8 of 29 24-Apr-2017

Uncontrolled if printed, refer to EDMS for current version

Right First Time, Every Time – Zero Defect

1 INTRODUCTION

1.1 General Description

1.1.1 This report outlines the principles of the Fire and Life Safety design for the Bin

Mahmoud switchbox as part of the larger Gold Line Doha Metro contract.

1.1.2 The Bin Mahmoud switchbox shall be constructed using a cut and cover technique,

overall measures circa 197m long x 18-31m wide with the track circa 22m below

ground.

Bin Mahmoud Switchbox

Figure 1: Location Plan

1.1.3 The switchbox is located immediately to the east end of the Bin Mahmoud station box

and is a section of tunnel where a portion of the wall separating two trainways is omitted

so that trains can move from one track to the other. The switchbox is not normally

occupied except for planned maintenance. There is an emergency evacuation shaft

located centrally at the east end of the switchbox and access to the station platform

emergency egress system at the west end.

1.1.4 The grade level buildings have been addressed in the production of this report.

1.1.5 This report addresses the Bin Mahmoud switchbox only. Fire and life safety provisions

for separate switchboxes, tunnels, stations or other facilities are addressed by other

individual line or system wide reports.

1.1.6 Separate documents and reports have been prepared by the JV, or are the

responsibility of other parties, to address specific elements, such as:

i. Fire and life safety strategy (M006-GDB-ARC-RPT-00020)

ii. MEP Basis of design report: Electrical Services (M006-GDB-ELE-RPT-00001)

Document Number: M006-GDB-ARC-RPT-00188 Rev 2 Page 9 of 29 24-Apr-2017

Uncontrolled if printed, refer to EDMS for current version

Right First Time, Every Time – Zero Defect

iii. MEP Basis of design report: Mechanical Services (M006-GDB-MEP-RPT-

00002)

iv. Tunnel ventilation and smoke control systems (by Systems Contractor)

v. Public address and mass notification (by Systems Contractor)

vi. Communications and monitoring (by Systems Contractor)

vii. External road network and fire hydrant system (by others)

Figure 2: 3D massing

1.2 Scope

1.2.1 Included in this report

i. construction classification;

Document Number: M006-GDB-ARC-RPT-00188 Rev 2 Page 10 of 29 24-Apr-2017

Uncontrolled if printed, refer to EDMS for current version

Right First Time, Every Time – Zero Defect

ii. accessibility to fire apparatus;

iii. means of egress;

iv. compartmentalization;

v. exterior walls;

vi. roof covering;

vii. fire zoning;

viii. fire rating of building material and building structural elements;

ix. evacuation strategy;

x. occupancy types and density, and

xi. travel distances.

1.3 Authority Having Jurisdiction

1.3.1 The Authority Having Jurisdiction (AHJ) for this project is Qatar Civil Defence.

1.4 Status of the JV contract documents

1.4.1 Drawings listed in Volume 8 of the Employer’s Requirements are provided for

information only.

1.5 Applicable Codes and References

1.5.1 The principal codes and documents upon which the tunnels, switchboxes and stations

have been designed are listed below. Where the Employer’s Requirements do not

specify a particular edition of a code or standard then the most current is adopted.

1.5.2 The ER subsume the standards on which they are based, in the following order of

priority:

i. NFPA 130

ii. Qatar Civil Defence Fire Safety Standards (QCDFSS)

iii. Qatar Construction Standards (QCS)

1.5.3 Project specific documents:

i. Qatar Integrated Railways Project, Volume 5 Employer’s Requirements –

Particular – Section 3.5 “Station Sizing” - (Stamped document);

ii. Blue Line patronage figures as issued via M006-GDB-ARC-RFI-00008

iii. Qatar Integrated Railways Project, Volume 6 Employer’s Requirements –

Design and Specifications - Section 10 “Fire Protection and Life Safety

Requirements” – (Stamped document);

iv. NFPA 130 Standard for fixed Guideway Transit and Passenger Rail Systems,

2014 edition;

v. NFPA 101 Life Safety Code, 2015 edition;

vi. QCDFSH Qatar Civil Defence Fire Safety Handbook;

vii. QCDFSS Qatar Civil Defence Fire Safety Standards, 2008 edition; and

viii. Qatar Construction Specifications 2010 edition.

1.5.4 Qatar Civil Defence fire safety reference standards include:

i. QCDFSS 1.1 Basic Requirements, 23 September 2007 edition;

Document Number: M006-GDB-ARC-RPT-00188 Rev 2 Page 11 of 29 24-Apr-2017

Uncontrolled if printed, refer to EDMS for current version

Right First Time, Every Time – Zero Defect

ii. QCDFSS 2.10: Fire protection water supplies, 27 March 2008 edition;

iii. QCDFSS 6.2: Rising main for fire-fighting, 18 February 2008 edition;

iv. QCDFSS 4.1: External access to site and building, 18 February 2008; and

v. QCDFSS 8.2.3: Fire command centre, 17 September 2007.

1.5.5 NFPA reference standards include:

i. NFPA 10 Standards for Portable Fire Extinguishers 2013 edition;

ii. NFPA 13 Standard for the Installation of Sprinkler Systems 2013 edition;

iii. NFPA 14 Standard for the Installation of Standpipe and Hose Systems 2013

edition;

iv. NFPA 24 Standard for the Installation of Private Fire Service Mains and Their

Appurtenances 2013 edition;

v. NFPA 70 National Electrical Code 2014 edition;

vi. NFPA 72 National Fire Alarm Code 2013 edition;

vii. NFPA 80 Standard for Fire Doors and Other Opening Protectives 2013 edition;

viii. NFPA 90A Standard for the Installation of Air Conditioning and Ventilating

Systems 2015 edition;

ix. NFPA 105 Standard for the Installation of Smoke Door Assemblies and Other

Opening Protectives 2013 edition;

x. NFPA 110 Standard for Emergency and Standby Power Systems, 2013

edition;

xi. NFPA 170 Standard for Fire Safety and Emergency Symbols 2015 edition;

xii. NFPA 220 Standard on Types of Building Construction 2015 edition;

xiii. NFPA 251, Standard Methods of Tests of Fire Resistance of Building

Construction and Materials 2006 edition; and

xiv. NFPA 5000 Building Construction and Safety Code 2015 edition.

1.5.6 The lists above are not exhaustive. Standards such as the British Standards (BS),

European Standards (EN) and other internationally approved standards may be used

in specifying, detailing of structure, fire safety systems, materials and devices subject

to the approval of QCD.

1.6 Basis for this fire and life safety report

The following items form the basis for this fire and life safety report and they are based

upon the Employers Requirements:

1.6.1 The fire protection methods of ER 6:10.3.2.9, NFPA 130, NFPA 101, QCDFSS and the

design approach outlined in this report are based on the premise that there will be a

single fire event from a single fire source and that multiple simultaneous fire incidents

will not occur.

1.6.2 The fire safety strategy for the Bin Mahmoud switchbox, Bin Mahmoud station and

associated ancillary facilities is based on the prescriptive-based methods of the code

and includes client specific requirements noted within the documents listed in Section

1.5 above.

1.6.3 The rolling stock and traction units are not part of the JV’s contract, but the fire strategy

has been based on the premise that they will be constructed to meet the requirements

of EN 45545.

Document Number: M006-GDB-ARC-RPT-00188 Rev 2 Page 12 of 29 24-Apr-2017

Uncontrolled if printed, refer to EDMS for current version

Right First Time, Every Time – Zero Defect

1.6.4 Protection against certain terrorist acts will generally require protection methods

beyond those required by NFPA 130, NFPA 101 and are outside the scope of this fire

and life safety report.

1.6.5 Emergency management and operation procedures:

The authority that is responsible for the safe and efficient operation of the passenger

rail system shall anticipate and plan for emergencies that could involve the system.

This shall comply with NFPA 130 Chapter 9 and involve, as a minimum –

i. Developing operational procedures for the management of emergency

situations

ii. Actively involving participating agencies such as Civil Defence, Police,

Medical, and Utility Companies.

iii. Maintaining a operations control centre for the operation and supervision of

the system

iv. Maintaining a list of all participating agencies and personnel

v. Establishing a command post to supervise and co-ordinate during an

emergency

vi. Insuring that personnel from the authority and participating agencies have the

necessary training to function during an emergency.

vii. Maintaining written records and recordings.

viii. Insuring that traction power is removed and restored in a controlled and safe

manner.

The authority shall operate an Integrated Control Centre (ICC) for the operation and

supervision of the system in accordance with the requirements of NFPA 130: 9.6. It is

noted that the provision of the ICC falls outside the scope of the Gold Line JV.

1.6.6 Emergency communications [by others]

Blue light stations are required at locations dictated by NFPA 130: 6.4.2 to allow

emergency service and authorised personnel to communicate with the ICC and

disconnect traction power.

1.6.7 Closed circuit television (CCTV) [by others]

A closed circuit television system shall be installed to permit remote operators to

monitor activity during both normal and emergency events. The system shall be

controllable from both the ICC and the adjacent station control room. The system

circuits shall be protected from fire damage for a period of not less than 1 hour in

accordance with NFPA 130: chapter 12. It is noted that ER 6-10.4.7.5b-iii stipulates that

fire resistive halogen free cables be used rather than the alternative arrangements

permitted by NFPA such as encasement or diversity in routing. The CCTV coverage

shall include as a minimum:

i. Platform and concourse public areas,

ii. Escape routes including exits,

iii. In corridors adjoining technical rooms.

iv. In tunnel sections

Document Number: M006-GDB-ARC-RPT-00188 Rev 2 Page 13 of 29 24-Apr-2017

Uncontrolled if printed, refer to EDMS for current version

Right First Time, Every Time – Zero Defect

2 OCCUPANCY CLASSIFICATION AND HAZARD OF CONTENTS

2.1 Occupancy classification

2.1.1 Per the definition given by NFPA 130: 3.3.52.1 the switchbox is part of a “Automated

Fixed Guideway Transit System”. Namely an electrified transportation system, utilizing

a fixed guideway, operating on right-of-way for the mass movement of passengers

within a metropolitan area, and consisting of its fixed guideways, fully automated

driverless transit vehicles, and other rolling stock; power system; buildings;

maintenance facilities; stations; transit vehicle yard; and other stationary and movable

apparatus, equipment, appurtenances, and structures

2.2 Hazard evaluation

2.2.1 The switchbox presents the conditions found in most buildings and will be classified as

Ordinary Hazard with regard to life safety hazard evaluation, per NFPA 101: 6.2 and

ER 6-10.4.1.2. i.e. contents likely to burn with moderate rapidity or to give off a

considerable volume of smoke. This classification does not apply to the sprinkler

protection classification, NFPA 13, Standard for the installation of sprinkler systems.

Document Number: M006-GDB-ARC-RPT-00188 Rev 2 Page 14 of 29 24-Apr-2017

Uncontrolled if printed, refer to EDMS for current version

Right First Time, Every Time – Zero Defect

3 FEATURES OF FIRE PROTECTION

3.1 Construction Materials

3.1.1 The switchbox has been designed to be constructed in reinforced concrete using a cut

and cover method. The minimum type of construction stipulated by NFPA 130 for

perimeter walls and related construction is Type II non-combustible construction. The

Employer’s Requirements further stipulates this as Type II (222). The switchbox vertical

exit shaft and ventilation structure are required to achieve at least Type I (332) non-

combustible construction [NFPA 130: 6.2.2.5]. Reinforced concrete is proposed and

meets the Type I criteria.

3.1.2 Steelwork is proposed for the switchbox walking surfaces intended for evacuation of

passengers and meets the non-combustible criteria.

3.1.3 Within the switchbox, ancillary areas are separated from the trainway sections by a

minimum of 2 hour fire resistive construction.

3.1.4 Type I and Type II construction are those types in which the fire walls, structural

elements, walls, floors and roofs are of approved non-combustible or limited

combustible materials. The switchbox structural elements have been designed to be

constructed in reinforced concrete and this meets the Type I and Type II criteria. Table

2 below is extracted from NFPA 220 Table 4.1.1 and indicates the fire resistance rating

that components of Type I (332) and Type II (222) construction must achieve.

Table 1: Components Fire Rating

Fire resistance rating (hours)

Type of Construction Type I Type II

(332)1 (222)1

Components

Exterior bearing walls

Supporting more than one floor, columns or other bearing walls 3 2

Supporting one floor only 3 2

Supporting a roof only 3 1

Interior bearing walls

Supporting more than one floor, columns or other bearing walls 3 2

Supporting one floor only 2 2

Supporting a roof only 2 1

Columns

Supporting more than one floor, columns or other bearing walls 3 2

Supporting one floor only 2 2

Supporting a roof only 2 1

Beams, girders, trusses and arches

Supporting more than one floor, columns or other bearing walls 3 2

Document Number: M006-GDB-ARC-RPT-00188 Rev 2 Page 15 of 29 24-Apr-2017

Uncontrolled if printed, refer to EDMS for current version

Right First Time, Every Time – Zero Defect

Fire resistance rating (hours)

Type of Construction Type I Type II

(332)1 (222)1

Supporting one floor only 2 2

Supporting a roof only 2 1

Other

Floor – Ceiling assemblies 2 2

Roof – Ceiling assemblies 1.5 1

Note 1: First Arabic numeral Exterior bearing walls

Second Arabic numeral Columns, beams, girders, trusses and

arches, supporting bearing walls,

columns, or loads from more than one

floor

Third Arabic numeral Floor construction

3.1.5 Fire windows in fire resistance-rated assemblies are restricted to those locations

permitted by NFPA 101: Table 8.3.4.2.

3.2 Compartmentation

3.2.1 Refer to the Fire and Life Safety Strategy [Fire Policy] drawings listed in Appendix A for

the location of fire resistance rated barriers and fire doors.

3.2.2 Compartmentation for the switchbox is summarized in Table 3 below and based upon

the Employer’s Requirements ER 6-10.5.2., NFPA 130 and NFPA 101.

3.2.3 Where one element supports another, the more onerous fire rating requirement has

been applied to the supporting structure.

Table 2: Fire ratings for specific rooms/areas

Element Fire resistance Fire door

rating (hours) assembly (hours)

Ventilation or exit shaft structure 3 N/A

Exit enclosure 2 1.5

Fireman’s lift enclosures 2 1.5

Fire-fighting lobbies 2 1.5

3.2.4 Underground structures (stations, egress shafts, vent shafts, etc,) are protected from

the accidental ingress of flammable and combustible liquids. This includes the

prohibition on any vent or fan shaft used for the ventilation of the underground station

Document Number: M006-GDB-ARC-RPT-00188 Rev 2 Page 16 of 29 24-Apr-2017

Uncontrolled if printed, refer to EDMS for current version

Right First Time, Every Time – Zero Defect

terminating at grade on any vehicle roadway and if terminating on a median or sidewalk

then complying with NFPA 130:5.2.3.

3.3 External fire spread

3.3.1 The grade level emergency shafts, ventilation shafts and other structures are presently

more than 6m from other buildings such that there is no requirement for non-load

bearing external walls to be fire rated.

3.3.2 The requirement that external finishes comply with QCD FSS 3.2 and NFPA 5000

Chapter 37 “Exterior Wall Construction” has been communicated to and co-ordinated

with the Branding Architect.

3.4 Roof finish classification

3.4.1 For construction Type I (332) & Type II (222) the required minimum roof-covering

classification is Class B [NFPA 5000: Table 38.2.2]. This has been communicated to

and co-ordinated with the Branding Architect for incorporation. The roof covering shall

be tested and is required to comply with one of the following:

i. NFPA 256, or other approved test methods;

ii. FM 4470, Approval for Class 1 Roof Covers;

iii. UL 790, Standard Test Methods for Fire Tests of Roof Covering; or

iv. ASTM E 108, Standard Test Methods for Fire Tests of Roof Coverings.

3.5 Interior finish for floors, walls and ceilings

3.5.1 Interior finish for walls, floor and ceilings comply with NFPA 101 Chapter 10 “Interior

Finish, contents and furnishings” and are non-combustible.

3.6 Fire Doors

3.6.1 Fire doors serving as opening protectives have a minimum fire protection rating as

specified in NFPA 101: Table 8.3.4.2 and part repeated in Table 3 herein.

3.6.2 Fire door assemblies shall be installed in accordance with NFPA 80 and shall be self

closing or automatic closing in accordance with NFPA 101: 7.2.1.8.

3.6.3 Fire windows in fire resistance-rated assemblies are restricted to those locations

permitted by NFPA 101: Table 8.3.4.2 and shall be required to comply with NFPA 251.

Document Number: M006-GDB-ARC-RPT-00188 Rev 2 Page 17 of 29 24-Apr-2017

Uncontrolled if printed, refer to EDMS for current version

Right First Time, Every Time – Zero Defect

4 MEANS OF EGRESS

4.1 Evacuation scenarios:

4.1.1 In the event of a fire within the tunnel or switchbox the intent is for the train to continue

to the next station where passengers may evacuate via the exit system within the

station.

4.1.2 If a train is halted within the switchbox or tunnel due to a fire it is understood that the

emergency smoke control system shall operate so that occupants may evacuate in the

direction of the fresh air along the walkway and then evacuate via either the exit system

within the station or the exit system in the switchbox or tunnel.

4.2 Level of Exit Discharge (LED)

4.2.1 The level of exit discharge for the switchbox is external ground level.

4.3 Means of escape underground

4.3.1 The switchbox incorporates a walkway on one side of each trainway so that occupants

may evacuate to the nearest exit system. The walkway provides an unobstructed clear

space of at least 800mm width at the walking surface and corresponds with the NFPA

130: 6.3.2.1 requirements above that plane per ER 6-10.5.1.1 i), i.e. 610mm at the

walking surface, graduating to 760mm wide at 1575mm above the walking surface to

430mm wide at 2025mm above the walking surface.

Figure 3: Switchbox walkways

4.3.2 If a train is halted within the Bin Mahmoud station, switchbox or adjacent tunnel due to

a fire it is understood that the emergency smoke control system shall operate so that

occupants may evacuate in the direction of the fresh air along the walkway and then

evacuate using an emergency exit shaft.

4.3.3 The location of the train when it stops, the nature of the incident (e.g. whether it is a

derailment or fire and where it originates) will in part influence the ICC directed tunnel

ventilation response and hence whether passengers evacuate to the switchbox escape

shaft, Bin Mahmoud station escape shaft or cross passages east of the switchbox and

hence Al Sadd Station

Document Number: M006-GDB-ARC-RPT-00188 Rev 2 Page 18 of 29 24-Apr-2017

Uncontrolled if printed, refer to EDMS for current version

Right First Time, Every Time – Zero Defect

4.3.4 Evacuation of a train is based on the premise that occupants of a 60m long 3 car section

may move up or down within it and access to the walkway is controlled by the ICC to a

single door. Qatar Rail have confirmed that occupants cannot move between two 60m

long trains.

4.3.5 Raised walkways are provided with a continuous handrail on the side opposite the

trainway. The handrail does not project more than 114mm into the clear zone stipulated

by the Employer’s Requirement ER 6-10:5.1.1 i).

4.3.6 While the trainway is more than 760mm below the walkway a guarding is not required

along the open edge as the bottom of the trainway is closed with a deck (NFPA 130:

6.3.3.6).

4.3.7 In the switchbox the raised walkways connect with the track level crosswalk with steps.

The crosswalks are provided at track level to ensure walkway continuity and provide a

uniform walking surface at the top of the rail.

4.3.8 The switchbox fire-fighting stair and fire-fighting lift shaft are separated from the

trainway by a fire-fighting lobby.

4.3.9 The fire-fighting stairwell, fire-fighting lift and lift lobby are all pressurized.

4.3.10 The fire-fighting lobby at track level measures 9m2 in area with a minimum dimension

of 2.7m and so is compliant with the minimum dimensions set out by QCDFSS 2.2.13

of not less than 6m2 in area and 2m in either dimension. Thus the lobby is large enough

to accommodate a wheelchair refuge, fire-fighting equipment and passengers escaping

4.3.11 The exit stair shaft from track level to transfer level, linking exit passage way at transfer

level and exit stair shaft from transfer level to grade is protected as required for exits.

This includes but is not limited to –

i. minimum 2 hour fire rated enclosure with 90 minute self-closing fire doors;

ii. only contain equipment necessary for life safety within the exit; and

iii. do not open directly into any normally unoccupied space, i.e. are lobbied from

lift shafts, technical shafts and technical rooms.

4.3.12 Employer’s Requirements stipulate that the fire-fighting stairwell be provided with air

conditioning during evacuation. This requirement is achieved without compromising

NFPA requirements for the protection of exit enclosures [NFPA 101: 7.1.3.2.1].

4.3.13 The utility chase (Level -5) below the transfer corridor (level -4) is normally unoccupied,

secured from unauthorized access and used exclusively for the routing of electrical,

mechanical, or plumbing equipment. Hence the space is not subject to the provisions

of chapter 7 (Means of Egress) of NFPA 101.

4.4 Means of escape components

4.4.1 A exit door clear width of 820mm is provided between the tunnel walkway and fire-

fighting lobby, fire-fighting lobby and exit stairwell, and this exceeds both NFPA 130

and ER requirements of 810mm The doors open in the direction of escape, i.e. into the

lobby and into the stairwell at tunnel level and in the opposite direction at street level

Document Number: M006-GDB-ARC-RPT-00188 Rev 2 Page 19 of 29 24-Apr-2017

Uncontrolled if printed, refer to EDMS for current version

Right First Time, Every Time – Zero Defect

4.4.2 While noting that NFPA 130 does not require the fire-fighting stair to be any wider than

1120mm, a width of circa 1175mm is proposed, excluding a 114mm allowance for

handrails on each side.

4.4.3 Minimum dimensional criteria for the switchbox exit stairs are as follows:

Table 3: Minimum NFPA dimensional criteria for exit stairwell

Stair Component Dimensional Criteria

Stair width 1120mm (1175mm egress width proposed)

Maximum height of risers 180mm maximum

Minimum tread depth 280mm

Minimum headroom 2285mm minimum

Maximum height between landings 3660 mm

4.5 Illumination of means of egress and emergency lighting

4.5.1 As a minimum the lighting and emergency lighting systems comply with the

requirements of NFPA 101 sections 7.8 and 7.9, except as modified by NFPA 130 and

the Employer’s Requirements -

i. Exit lights, essential signs and emergency lights are included in the emergency

lighting system in accordance with NFPA 70;

ii. emergency fixtures, exit lights, and signs are wired separately from emergency

distribution panel;

iii. lighting system is designed so that, during a period of evacuation, illumination

levels of trainway walkways and walking surfaces shall not be less than 2.7 lx

measured along the path of egress at the walking surface;

iv. the emergency lighting system in the trainway produce illumination on the

walkway that does not exceed a uniformity ratio of 10:1 for the maximum

maintained horizontal illuminance to the minimum maintained horizontal

illuminance;

v. point illumination of means of egress elements are permitted to exceed the

10:1 uniformity ratio; and

vi. dynamic signs indicating the direction and distance to the nearest safe

emergency exit are provided at 25m centres along the walkway.

Document Number: M006-GDB-ARC-RPT-00188 Rev 2 Page 20 of 29 24-Apr-2017

Uncontrolled if printed, refer to EDMS for current version

Right First Time, Every Time – Zero Defect

5 FIRE PROTECTION SYSTEMS

5.1 Fire detection and alarm system

5.1.1 Whilst not required by NFPA 130 the tunnel trainway and technical rooms located within

the switchbox are provided with automatic fire detection as mandated by the

Employer’s Requirements.

The tunnel trainway and the switchbox fire detection system is provided and designed

by others (Railway Systems Contractor) except in the switchbox technical rooms where

the fire detection system is provided and designed by the JV contractor.

The fire detection and alarm system will interface with ICC/Rail SCADA via BACS

5.2 Fire sprinkler system

5.2.1 As per NFPA 130 and the Employer’s requirements an automatic sprinkler protection

system is not provided in the tunnel trainway.

5.3 Clean agent fire extinguishing systems

5.3.1 Electrical rooms within the switchbox and at grade, where the presence of water is not

desirable, are protected with clean agent fire extinguishing systems designed, installed

and maintained in compliance with NFPA 2001 [per ER 6-10:4.7.3-bi]. The fire

suppression system is operated automatically by a QCD approved fire detection

system. It is noted that QCDFSS 6.8 does not permit the use of Carbon Dioxide for fire

suppression or the storage of the clean agent within the protected enclosure.

5.3.2 The TPS room between Bin Mahmoud station and switchbox and the electrical rooms

at grade are protected with a clean agent fire extinguishing system.

5.4 Standpipes

5.4.1 A Class I standpipe system, wet pipe, is provided within the switchbox as required by

NFPA 130 and ER 6-10.5.5.2.c. The system shall be installed in accordance with NFPA

14 [per ER 6-10.5.5.2.c.ii] and ER 6-13.2.14.6.

5.4.2 Water breaching inlets to the system to permit QCD to supply additional water are

provided at fire service access points at grade per QCD standards including QCDFSS

6.2:5.0 and within 18m of the adjacent fire appliance access road.

5.4.3 The initial supply of water for the sprinkler and standpipe system is from storage tanks

located in the adjoining stations and be of adequate supply for at least one hour,

including supply to the adjacent tunnel system. The tanks comply with QCDFSS 2.10.

5.4.4 Within the tunnel the standpipe system is not enclosed in fire-rated construction as the

system is fed from two locations and isolation valves are installed not more than 244m

apart.

5.4.5 The fire standpipe system complies with and be approved by QCD (QCDFSS 1.1, 6.1,

6.2).

Document Number: M006-GDB-ARC-RPT-00188 Rev 2 Page 21 of 29 24-Apr-2017

Uncontrolled if printed, refer to EDMS for current version

Right First Time, Every Time – Zero Defect

5.5 External hydrants (by others)

5.5.1 NFPA 14 requires that a hydrant be provided within 30.5m (100ft) of the fire department

breeching inlet such that it is readily accessible by emergency services and can be

used to supply water to the underground standpipe systems. The provision of fire

hydrants falls under the landscaping and roadside improvements being undertaken by

Ashghal. The provision of fire hydrants will be raised as part of the interface with the

Ashghal works. It is noted that NFPA 14 permits the distance between breeching inlet

and hydrant to exceed 30.5m with the approval of the AHJ.

5.6 Portable fire extinguishers

5.6.1 Portable fire extinguishers shall be provided in such numbers, sizes and types and at

such locations as determined by the authority having jurisdiction in accordance with

NFPA 130: 6.4.5. At this time it is not proposed to provide portable fire extinguishers

within the operational trainways.

5.6.2 Both CO2 and ABC type portable fire extinguishers shall be provided for the sub-surface

and at grade technical areas such that they are within 15m of all areas, or as otherwise

required by the authority having jurisdiction in accordance with NFPA 130: 6.4.5.

5.7 Emergency ventilation system

5.7.1 The tunnel emergency ventilation system [by others] does not form part of this report

and shall be developed and submitted in due course by the Systems Contractor. This

submission should include fire scenarios involving a train on fire stopping in the tunnel

and a train stopping in the tunnel due to another emergency in the tunnel.

5.8 Pressurization

5.8.1 The switchbox stairwell, lift shaft and lobbies and are protected from the ingress of

smoke as follows [ER 6-10.4.6.3d-v & ER 6-13.2.6.6 b)]:

Stair case & lift shaft are pressurized with relief @ 50 Pa pressure difference.

Fire lobbies and pressurized corridors are pressurized with relief @ 25 Pa

pressure difference.

5.9 Fire service access

5.9.1 Access to the switchbox for the fire and rescue service is available via both the station

and switchbox escape shafts. Each escape shaft incorporates a fire-fighting lift and

pressurized stairwell. Access at street level incorporates a separate entrance for fire

service personnel to access the fire-fighting lift without being hindered by exiting

patrons. Vehicular access routes for Civil Defence appliances is by either public road

or service road and extends to within 10m of the access points to the emergency shaft

entrances.

5.9.2 Fire service vehicle access routes are a minimum of 6m wide, have an unobstructed

vertical clearance of 4.5m, accommodate two way traffic and be capable of

accommodating the stationary load from a 24 tonne fire appliance.

Document Number: M006-GDB-ARC-RPT-00188 Rev 2 Page 22 of 29 24-Apr-2017

Uncontrolled if printed, refer to EDMS for current version

Right First Time, Every Time – Zero Defect

5.9.3 Access routes for the emergency services are such that dead end roads occur; hence

turning areas are provided.

5.9.4 The fire appliance hard standing are within 10m of the building entry points, measure

at least 6m x 15m and are capable of accommodating the stationary load from a 45

tonne fire appliance. In addition, the hard standing is within 45m of every point on the

projected plan area of each building at ground level and within 50m of a fire hydrant.

5.9.5 Vehicle access route turning radii, internal and external, comply with QCDFSS 4.1,

refer to extract from Annex D below.

Figure 4: Fire appliance highway turning radii [QCDFSS 4.1 Annex D]

(Figure relates to turning radii not road widths)

5.9.6 At the time of writing the structures above grade are predominantly single storey. As

the design evolves these structures shall be evaluated in terms of compliance with

QCDFSS in terms of providing access panels along the perimeter.

5.9.7 The area between the switchbox emergency exit at grade and the public road has been

designed as a open and unrestrained space. A 400m2 area has been safeguarded for

the emergency services to use and may be used as a muster area to facilitate

passengers being bussed away but it is not intended that passengers be restricted or

prevented from dispersing themselves.

5.9.8 Interface meetings shall be held with Ashghal to discuss and agree responsibility for

roads and lay-bys.

Document Number: M006-GDB-ARC-RPT-00188 Rev 2 Page 23 of 29 24-Apr-2017

Uncontrolled if printed, refer to EDMS for current version

Right First Time, Every Time – Zero Defect

6 BUILDING SERVICES

6.1 General:

6.1.1 Specifications for general building services and utilities are included in other

documents. Specific and/or additional requirements for building services and utilities

resulting from fire and life safety provisions are included in the sections below.

6.2 Heating, ventilation and air-conditioning equipment

6.2.1 Heating ventilation ductwork and related equipment is in accordance with NFPA 90A.

6.3 Wiring requirements

6.3.1 All wiring materials and installations within the station other than those for traction

power conform to the requirements of NFPA 70 and in addition satisfy the requirements

of NFPA 130: chapter 12.

6.3.2 Fire resistive cables are listed and have a minimum 1 hour fire resistive rating in

accordance with ANSI/UL 2196 and be installed per the listing requirements. It is

understood that the ER 6- 10.3.2.14 statement that cables be non-combustible is a

typing mistake and that ER 6-10.4.4.4. takes precedence.

6.4 Emergency power

6.4.1 Emergency power is provided in accordance with Article 700 of NFPA 70 and Chapter

4 of NFPA 110. The supply system for emergency purposes, in addition to the normal

services to the station building, is one or more of the types of systems described in

subsections 700.12(A) through 700.12(E) of NFPA 70. All cabling is fire resistive per

6.3.2 above.

6.4.2 The following emergency systems are connected to the emergency power supply:

i. fire detection and alarm system (BY ALYSA JV and others);

ii. emergency lighting and signage systems;

iii. emergency communication system; (by others)

iv. public address system (by others);

v. Incident command centre (by others);

vi. the stairwell, lobby and lift pressurization system within the escape shaft;

vii. fire-fighting lift

viii. escalators (in stations);

ix. the Building Automation Control System (BACS) (also called the Building

Management System (BMS));

x. tunnel ventilation system (by others);

xi. fire protection systems

xii. UPS and relevant sub-circuits

6.4.3 Per Qatar Rail letter M006-GDB-ENG-LTR-00516 (Low voltage power distribution

system guidelines) the power supply for various systems shall be as follows:

Document Number: M006-GDB-ARC-RPT-00188 Rev 2 Page 24 of 29 24-Apr-2017

Uncontrolled if printed, refer to EDMS for current version

Right First Time, Every Time – Zero Defect

Table 4: Power supply

Item Normal Life Central UPS By

power Safety Battery others

supply System (MSI)

Emergency lighting facilities for Yes

means of escape (escape route

luminaires) and signage

Fire pump (i.e. in stations) Yes

Fire-fighting lift within Al Sharq EE Yes

shaft

Smoke management systems Yes

(stairwell, lift lobby and lift shaft

pressurization fan) within Al Sharq

EE shaft

Fire detection and alarm system Yes

Clean Agent Yes

Building Automation Control Yes

System

Smoke management systems in the Yes

tunnels

Emergency communication system Yes

6.5 Fire command centre

6.5.1 The station control room in Bin Mahmoud Station fulfils the role of a fire command

centre and is designed in accordance with NFPA 72 and the relevant Qatar standards

QCDFSS 8.2.3. The room is enclosed in 2 hour rated construction, approached via a 2

hour protected corridor from the fire-fighting staircase and is protected from the ingress

of smoke (ER 6-10.4.7.5a i-iii, ER 6-10.8.5.8 and ER6-11.4.6.4).

6.6 Lifts

6.6.1 The switchbox box evacuation shaft contains a staggered lift arrangement for

emergency services access and the evacuation of injured or disabled persons.

Consequently the design of each lift complies with the requirements of QCDFSS 6.6.3

per ER 6-10.5.1.3.b.j and section 54 of NFPA 5000 as this is now directed by Civil

Defence.

Fire fighter lift requirements include:

enclosure within a fire rated protected shaft;

provision of a fire-fighting lobby within a fire rated enclosure at each level;

pressurization of the fire-fighting lobby to prevent smoke ingress;

equipment for the fire services to take control of the Lift;

protection of the power supply;

they shall not be used primarily as goods Lifts (QCDFSS 6.6.3 – 5); and

be large enough to accommodate a 610mm x 2030mm ambulance stretcher with

minimum 125mm radius corners (NFPA 5000, Chapter 54) in the horizontal open

position.

Document Number: M006-GDB-ARC-RPT-00188 Rev 2 Page 25 of 29 24-Apr-2017

Uncontrolled if printed, refer to EDMS for current version

Right First Time, Every Time – Zero Defect

The lift lobbies and transfer corridor (exit passageway) can accommodate the turning

movements required by a 610mm x 2030mm ambulance stretcher.

Document Number: M006-GDB-ARC-RPT-00188 Rev 2 Page 26 of 29 24-Apr-2017

Uncontrolled if printed, refer to EDMS for current version

Right First Time, Every Time – Zero Defect

7 APPENDIX A - DRAWINGS

The following drawings have been produced to accompany this report:

Discipline: Architecture

Location: Bin Mahmoud switchbox

Title: Fire Policy Drawings

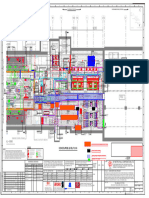

Table 5: Relevant drawings

Level

code Number Model or drawing title Scale

M006-GDB-ARC-DWG-YCAGAAA

AA 25251 ARCHITECTURAL SYMBOLS

M006-GDB-ARC-DWG-YWSB010

AG 32340 Ground level Fire policy 1-100

IL 32341 Intermediate level Fire policy 1-100

ZZ 32342 Intermediate, Track & Undertrack Fire policy 1-100

ZZ 32343 Longitudinal section Fire policy 1-100

Document Number: M006-GDB-ARC-RPT-00188 Rev 2 Page 27 of 29 24-Apr-2017

Uncontrolled if printed, refer to EDMS for current version

Right First Time, Every Time – Zero Defect

CONCLUSION

This Fire Life Safety Report addresses the FLS requirements for Bin Mahmoud switchbox.

The station design complies with the requirements of NFPA 130:2014 and QCDD and no

waivers are required for fire and life safety compliance.

Document Number: M006-GDB-ARC-RPT-00188 Rev 2 Page 28 of 29 24-Apr-2017

Uncontrolled if printed, refer to EDMS for current version

Right First Time, Every Time – Zero Defect

END OF REPORT

Document Number: M006-GDB-ARC-RPT-00188 Rev 2 Page 29 of 29 24-Apr-2017

Uncontrolled if printed, refer to EDMS for current version

Qatar Rail

......... Document Review Sheet (Engineer)

RA I L ...J---,J _,J I Company M anagement System

~

BOR I General I 3 r.;-_,-_:_ ;:.:..: :: ~:.--·: ---- ·- -~:·.- - ...... ---- ----------· :-.. :.. -.__.. -· I ii

Interim DVE Design and Verification Certificate (M006-GDB-

~ .. -.;-CER-00125 REV 1) includes EIGHT conditions.

I Discussions have been held between QRIPMC, JV, DVE, Arcadis

and Atkins on 27th March 2017. caveats will be removed as far as

possible, but some will be remaining on MSI and until the MEP

2 I IMC

I M006-GDB-ENG-CER-~ 1 'Therefore cannot be considered as Design Verification Certification.

00125 REV 1 ii design is issued ..

Provide DVE c ertificate w it h the submission without

conditions or assumptions.

None of the assumptions are required to be submitted through the

RFI process as [Tunnel ventilation, Emergency power, Traction

The same assumptions as the DD1 report (M006-GDB-ARC-RPT- power, Vehicles, Emergency Management, Public address and

ooog8 Rev 1) are listed here. State which assumptions have now CCTV] are all by other contractors and largely a repetition of the ERs

Page 12 of 28

3 I IMC I Section 1.6 I 1

1

been confinned through RFis or Workshops.

This is a DD2 (Detailed Design) submission and should not include

i and NFPA; a single fire event is an industry nonn and repeated in th

ERs; protection against terrorist acts is outside the ERs. Repeat of

assumptions or rely on future workshops. 001 response.

The term "assumption" has been relaced by "basis of design"

All design is being based on a SIL-2 system and thus compliant with

'Confirm the Fire Detection System within the Switch Box Technical I l theER

Page 21 of 28

4 I IMC I Section 5.1 .1 I 1 Rooms will be designed and installed to SIL-2 as per the Employers

Requirements. Any discussion for an alternative system will be conducted by the JV

outside the design.

Include all life safety and critical systems (e.g. Signalling systems,

Communication systems, Fare collections gates, Emergency I I

We note that the majority of items listed by the reviewer are already

5 I IMC I

Page 24 of 28

Section 6.4.2 I 1

I

lighting system, Fire command centre, Emergency mechanical

ventilation system, Fire fighting pumps, Fire fighting lifts, etc.), shall

nnected to the Emergency Power System. Comply with ER

ii included. The switch box does not contain fare collection gates. We

do not see that the signalling system is relevant to this FLS report.

13.3.2.5.b.iv

fire extinguishers shall be provided in such numbers, sizes

Page 22 of 28 and types and at such locations as detennined by the authority

6 IMC Confinned in FLS report revision 2 section 5.6.2

Section 5.6. 1 having jurisdiction in accordance with NFPA 130: 5.4.6. Specify the

proposalforthesv·"·• • - .. •- ·"- ~~~~·- -- -- ---

-· ~·

LEADING EXCELLENCE I TM-203 -F03 Rev. >.0, 31/10/16 Page 1 of 2

Qatar Rail

\

'1 Document Review Sheet (Engineer)

RAILJ...-l.rJI Company Management System

..

A

Remove the reference to "anomoly" and clearly state the design

loading for fire trucks on the access road and on the hard standing carrying capacity figures quoted in the report come straight from

Page 23 of 28

7 IMC to allow QCDD to approve. standards so must be assummed to be to their satisfaction.

Section 5.9.4

is is a DD2 (Detailed Design) submission and should not include reference to an anamoly has been removed.

assumptions or rely on future workshops.

Clause states that "Concrete is proposed for the switchbox walking

Page 15 of 28 has been updated. Refer to updated report and drawings

8 IMC surfaces". Drawing M006-GDB-STR-DWG-YWSB010-IL-53100

Section 3.1. 2 now showing Steel.

details the STEELWORK WALKWAY PLAN for the Switch box.

c. SONO E. FaiVNot approved

Document Review Status Code: D

ourad Zouyene SA 1-1 Mngr Samuel Adair McChesney

Benjamin O'Regan FLS Engineer Engineer's Assistant

James Quinlan Arch Fin Mngr

Kerry Jothy Architect

Mousa D Abulhawa HVAC/MEP Manager

lain Mclean E&M Elec. Engr I Date: I I Date : Date: Date:

LEADING EXCEllENCE 11M 203-FO~ Ro>v ~ 0. ll/10/16 Page 2 of 2

You might also like

- History of Psychological TestingDocument20 pagesHistory of Psychological TestingLen Len84% (19)

- Method Statement of Survey Work PDFDocument49 pagesMethod Statement of Survey Work PDFUdayan Chakraborty100% (1)

- Ldip 2020-2022Document70 pagesLdip 2020-2022Mark Joseph BurlaNo ratings yet

- My Career Episode 2Document7 pagesMy Career Episode 2Ekundayo John100% (1)

- Semi Annual Report July Dec 2010Document6 pagesSemi Annual Report July Dec 2010Robert Ulatan100% (3)

- Risk assessment of crane workshopDocument13 pagesRisk assessment of crane workshopNauman Qureshi89% (9)

- 1 Colostomy and IleostomyDocument4 pages1 Colostomy and IleostomyAnna Sofia ReyesNo ratings yet

- Navitas (Contractor)Document1 pageNavitas (Contractor)roy wilsonNo ratings yet

- Circular Road SafetyDocument8 pagesCircular Road SafetyramprakashpNo ratings yet

- Oqry.: Guidelines and Procedures For The Calibration, Operation and Maintenance of The Inertial ProfilerDocument2 pagesOqry.: Guidelines and Procedures For The Calibration, Operation and Maintenance of The Inertial ProfilerMt. Apo TravelsNo ratings yet

- 2021-017 - SPD Guidelines For PunchlistingDocument12 pages2021-017 - SPD Guidelines For PunchlistingLuis Enrico PamintuanNo ratings yet

- Db02 - PPT - PRM 13 Oct 2023Document10 pagesDb02 - PPT - PRM 13 Oct 2023amjad31may74No ratings yet

- Arabic Reference For Primavera - Part 1 (Time Schedule) - by Eng. Said El NaggarDocument779 pagesArabic Reference For Primavera - Part 1 (Time Schedule) - by Eng. Said El Naggarsaidnaggar100% (2)

- Integrity Dev't. Review of NIA by OmbDocument13 pagesIntegrity Dev't. Review of NIA by OmbPastidjaNo ratings yet

- Providing Road Connectivity to ICTT VallarpadamDocument23 pagesProviding Road Connectivity to ICTT VallarpadamshijinkuttanNo ratings yet

- ANOH Midstream Gas Plant Development ITT Major BuildingsDocument1 pageANOH Midstream Gas Plant Development ITT Major BuildingsAyodele Oluwaseyi DinaNo ratings yet

- 3 Year Development PlanDocument199 pages3 Year Development PlanJorge DanielleNo ratings yet

- Third Report of Criteria Committee Rev-I Background Third CriteriaDocument2 pagesThird Report of Criteria Committee Rev-I Background Third CriteriaED Track 1 RdsoNo ratings yet

- QAP (ITP) FOR STRUCTURAL FAB & ERECTION CommentsDocument4 pagesQAP (ITP) FOR STRUCTURAL FAB & ERECTION CommentsEr Mangesh MohiteNo ratings yet

- Mst-Kmc-El-00022 - Wiring Accessories (Code B)Document17 pagesMst-Kmc-El-00022 - Wiring Accessories (Code B)apsarNo ratings yet

- Petro Supply-Mobile Crane 80 TonDocument12 pagesPetro Supply-Mobile Crane 80 TonbasdNo ratings yet

- INSULATION TEST PLAN FOR MRT PROJECTDocument8 pagesINSULATION TEST PLAN FOR MRT PROJECTBangkit SamosirNo ratings yet

- IREC-KPI-F01 - KPI - Civil Eng. & Construction ++Document1 pageIREC-KPI-F01 - KPI - Civil Eng. & Construction ++Zainarul Aswad RazaliNo ratings yet

- Seeds-I: Revision No. 00Document22 pagesSeeds-I: Revision No. 00ArnieNo ratings yet

- Scope of ActivityDocument9 pagesScope of ActivityBangkit SamosirNo ratings yet

- 01 Design Sec Parking Building IfcDocument182 pages01 Design Sec Parking Building Ifcmoe9ka100% (1)

- مصفوفة مقاولي شركة النقلDocument2 pagesمصفوفة مقاولي شركة النقلyasirNo ratings yet

- R R R R: Em's SubmittalsDocument4 pagesR R R R: Em's SubmittalsNaresh KumarNo ratings yet

- ch2-GeneralDocument30 pagesch2-GeneralJuan ManuelNo ratings yet

- S-990-5132-301 - B Work Breakdown System ProcedureDocument16 pagesS-990-5132-301 - B Work Breakdown System ProcedureMahadevan MahalingamNo ratings yet

- Agenda Items Resolved Action Taken by Action Done / PendedDocument6 pagesAgenda Items Resolved Action Taken by Action Done / PendednooneparticularNo ratings yet

- CMR July December 2018Document5 pagesCMR July December 2018Rico MangubatNo ratings yet

- Saudi Aramco Typical Inspection Plan: Radiographic Testing (RT) On IK Projects Satip-Nde-Rt-01 15-Nov-17 Mechanical - NdeDocument11 pagesSaudi Aramco Typical Inspection Plan: Radiographic Testing (RT) On IK Projects Satip-Nde-Rt-01 15-Nov-17 Mechanical - NdeSyed Mohammed Abdul Aleem SoofiyaniNo ratings yet

- Agra-REP-JVTI-QAS-00157-E01 - Method Statement For TBM Tunnelling & Associated Works - (R0) 220808Document5 pagesAgra-REP-JVTI-QAS-00157-E01 - Method Statement For TBM Tunnelling & Associated Works - (R0) 220808shaikh iftekhar aliNo ratings yet

- Haneef-Sheraz2021 Article DevelopmentOfWellComplexityCalDocument31 pagesHaneef-Sheraz2021 Article DevelopmentOfWellComplexityCalWasayRazaNo ratings yet

- Screenshot 2023-07-20 at 11.06.59Document32 pagesScreenshot 2023-07-20 at 11.06.59Andreas Nur HadiNo ratings yet

- Highway Rating CircularDocument18 pagesHighway Rating CircularSasanka SekharNo ratings yet

- Slope StabilityDocument11 pagesSlope Stabilityrohit ThakurNo ratings yet

- Ipc 9121中文 印制板制造工艺疑难解答pcb制程中的故障排除Document32 pagesIpc 9121中文 印制板制造工艺疑难解答pcb制程中的故障排除cdmingNo ratings yet

- Painting WorksDocument9 pagesPainting WorksBangkit SamosirNo ratings yet

- Construction of 220kV Gas Insulated Sub Station at Punjab UniversityDocument32 pagesConstruction of 220kV Gas Insulated Sub Station at Punjab Universityishfi02shahNo ratings yet

- Mos - Method Statement For Welding Works For CalorifierDocument6 pagesMos - Method Statement For Welding Works For Calorifiernasir habibNo ratings yet

- Saudi Aramco Typical Inspection PlanDocument10 pagesSaudi Aramco Typical Inspection PlanSyed Mohammed Abdul Aleem SoofiyaniNo ratings yet

- HEELOODocument29 pagesHEELOOIdris AdeniranNo ratings yet

- ECDIS Considerations: David EdmondsDocument22 pagesECDIS Considerations: David EdmondsTatarasanuRazvanNo ratings yet

- Checklists For Road ConstructionDocument23 pagesChecklists For Road ConstructionAnimesh Narayan SinghNo ratings yet

- Construction Documentation Flow Chart - DIFC CP05 Office BuildingDocument5 pagesConstruction Documentation Flow Chart - DIFC CP05 Office BuildingQazi ShahzadNo ratings yet

- q11017 0100d Lps Sta Pk2 Ele MST 00003 c2 MV LV, MCC, SMDB & VFD Panel NewDocument47 pagesq11017 0100d Lps Sta Pk2 Ele MST 00003 c2 MV LV, MCC, SMDB & VFD Panel NewKarthick NatrajanNo ratings yet

- (1st Workshop) Introduction Schedule-R1Document22 pages(1st Workshop) Introduction Schedule-R1Aqsha QNo ratings yet

- SUBJECT: Amended Levels of Authorities of DPWH Officials For Procurement of Civil Works, ConsultingDocument14 pagesSUBJECT: Amended Levels of Authorities of DPWH Officials For Procurement of Civil Works, ConsultingJoshua BrentNo ratings yet

- Operations & Maintenance Engineering RCM Handbook: Eni S.p.A. Exploration & Production DivisionDocument124 pagesOperations & Maintenance Engineering RCM Handbook: Eni S.p.A. Exploration & Production DivisionGlad BlazNo ratings yet

- Aip of KayapaDocument81 pagesAip of Kayapaapi-437456788100% (1)

- Central Office: ManilaDocument106 pagesCentral Office: ManilaJhon Jezar CalumagNo ratings yet

- Maintenance of Screw Conveyor Continous Ship Unloader With Reliability Centered Maintenance (RCM) MethodDocument14 pagesMaintenance of Screw Conveyor Continous Ship Unloader With Reliability Centered Maintenance (RCM) Methodilham rakaNo ratings yet

- Eofficenoticeboard DownloadDocument1 pageEofficenoticeboard DownloadJames Vanlalfakawma ChhangteNo ratings yet

- Malaysia's Engineering DNA: Corporate Presentation on Project ControlsDocument132 pagesMalaysia's Engineering DNA: Corporate Presentation on Project ControlsazwanbaharNo ratings yet

- Week01 Project ScopeDocument49 pagesWeek01 Project ScopeLucas WangNo ratings yet

- BOQ For FACDocument1 pageBOQ For FACZaki AnwerNo ratings yet

- Financial Appraisal Framework 20 - 03 - 2023Document31 pagesFinancial Appraisal Framework 20 - 03 - 2023SakareSreenivasNo ratings yet

- 106 20170705 Method Statement For ExcavationDocument17 pages106 20170705 Method Statement For ExcavationEmad RakatNo ratings yet

- Distributed Process Control ReportFrom EverandDistributed Process Control ReportNo ratings yet

- Managing Software Deliverables: A Software Development Management MethodologyFrom EverandManaging Software Deliverables: A Software Development Management MethodologyNo ratings yet

- TJS ECS Plant RoomDocument1 pageTJS ECS Plant RoomFaizuddin SiddiquiNo ratings yet

- Revised External Layout Recieved by GC Dated 07.12.2023Document1 pageRevised External Layout Recieved by GC Dated 07.12.2023Faizuddin SiddiquiNo ratings yet

- Agcc02 11718a CRD RKM Co Wod 90533Document1 pageAgcc02 11718a CRD RKM Co Wod 90533Faizuddin SiddiquiNo ratings yet

- Emergency Exit Interface DocumentDocument11 pagesEmergency Exit Interface DocumentFaizuddin SiddiquiNo ratings yet

- Cable Routing For MEP and SystemsDocument1 pageCable Routing For MEP and SystemsFaizuddin SiddiquiNo ratings yet

- Annexure 9Document26 pagesAnnexure 9Faizuddin SiddiquiNo ratings yet

- Final Guideline of DILRMP 02-01-2019Document245 pagesFinal Guideline of DILRMP 02-01-2019Joe JohnsonNo ratings yet

- M006-GDB-ARC-RPT-00020 Rev 3Document53 pagesM006-GDB-ARC-RPT-00020 Rev 3Faizuddin SiddiquiNo ratings yet

- M006-GDB-ARC-RPT-00084 Rev 3Document67 pagesM006-GDB-ARC-RPT-00084 Rev 3Faizuddin SiddiquiNo ratings yet

- Automation Boosts Lab ProductivityDocument4 pagesAutomation Boosts Lab ProductivityMuhammad Hanzalah AtifNo ratings yet

- Status of Women in PakistanDocument9 pagesStatus of Women in PakistanMajeed UllahNo ratings yet

- Msds Kalium DikromatDocument6 pagesMsds Kalium DikromatKeynan HaqieNo ratings yet

- Pharmacokinetics AtfDocument31 pagesPharmacokinetics AtfOAbdullahCh ChNo ratings yet

- SurePath Collecction Vial 500017013 Rev4!08!2020Document6 pagesSurePath Collecction Vial 500017013 Rev4!08!2020Pankaj WaghNo ratings yet

- Order 704189 - PSC Requisition - Ulta Lab TestsDocument2 pagesOrder 704189 - PSC Requisition - Ulta Lab TestsAmerica PerfectoNo ratings yet

- 5 6269504843056939800Document141 pages5 6269504843056939800SwapardeshiNo ratings yet

- Washington HospitalsDocument9 pagesWashington HospitalsJoe FrascaNo ratings yet

- Nursing Care for Cholera DiarrheaDocument2 pagesNursing Care for Cholera DiarrheaMichael Angelo Garcia RafananNo ratings yet

- Catarina Miotto TortozaDocument2 pagesCatarina Miotto TortozacatNo ratings yet

- Physical Education: Quarter 1 - Module 2: Physical Fitness ActivitiesDocument27 pagesPhysical Education: Quarter 1 - Module 2: Physical Fitness ActivitiesKeith Tristan RodrigoNo ratings yet

- Stressful Family or Friend SituationsDocument2 pagesStressful Family or Friend SituationsCinthia Hoyos jiménezNo ratings yet

- ORGS 1136 - Week 4 Notes ORGS 1136 - Week 4 NotesDocument3 pagesORGS 1136 - Week 4 Notes ORGS 1136 - Week 4 NotesTara FGNo ratings yet

- I STATDocument24 pagesI STATPraveen RamasamyNo ratings yet

- Trauma - Revisited - Ferenczi and Modern Psy - Andre HaynalDocument23 pagesTrauma - Revisited - Ferenczi and Modern Psy - Andre HaynalJessica MézquitaNo ratings yet

- Application Form For Permit To Operate (PTO) Air Pollution Source InstallationsDocument3 pagesApplication Form For Permit To Operate (PTO) Air Pollution Source InstallationsMiguel Antonio Uy EscolarNo ratings yet

- QUIZ 3 Disaster Readiness and Risk ReductionDocument5 pagesQUIZ 3 Disaster Readiness and Risk ReductionRain Gamboa100% (1)

- IFOBT For CRC ScreeningDocument91 pagesIFOBT For CRC Screeningkillua0707No ratings yet

- Clostridioides Difficile Infection in Patients WitDocument10 pagesClostridioides Difficile Infection in Patients WitElena Cuiban100% (1)

- Class 11 English Notes BirthDocument5 pagesClass 11 English Notes BirthFarhan Al ZayedNo ratings yet

- Ateneo de Zamboanga University: Level IiDocument7 pagesAteneo de Zamboanga University: Level IiNur SetsuNo ratings yet

- Myotonic Dystrophy PresentationDocument8 pagesMyotonic Dystrophy Presentationapi-318918663No ratings yet

- S.B.D.S. College of Nursing Aherwan (Ratia) Advance Nursing Practice Lesson Plan Topic: - CommunicationDocument72 pagesS.B.D.S. College of Nursing Aherwan (Ratia) Advance Nursing Practice Lesson Plan Topic: - CommunicationAnand BhawnaNo ratings yet

- 2020年07月六级真题(全1套)Document12 pages2020年07月六级真题(全1套)六级真题及解析(1990-2022)No ratings yet

- Jung and The OtherDocument113 pagesJung and The OtherEtel AdlerNo ratings yet

- Yield of Thoracoscopic Biopsy Truenat in The Diagnosis of Tubercular Pleural EffusionDocument7 pagesYield of Thoracoscopic Biopsy Truenat in The Diagnosis of Tubercular Pleural EffusionThomas KurianNo ratings yet

- FisabaroxefuragegobaDocument2 pagesFisabaroxefuragegobaOswaldo Jurado0% (1)