Professional Documents

Culture Documents

Engine Plan Maintenance System Weekly

Uploaded by

Kacang Goreng0 ratings0% found this document useful (0 votes)

18 views6 pagesThe document provides a checklist for monthly maintenance of engine equipment on a tug boat. It lists 17 key components that should be checked and maintained each month, including the main engine, fuel system, lubricating oil system, starting system, alternator, turbocharger, gearbox, and other parts. Specific maintenance tasks are outlined for each component, such as cleaning, inspections, filter changes, and replacing parts according to recommended hours of use. The goal is to ensure all engine equipment is in good working condition through regularly scheduled preventative maintenance.

Original Description:

Original Title

Engine Monthly

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document provides a checklist for monthly maintenance of engine equipment on a tug boat. It lists 17 key components that should be checked and maintained each month, including the main engine, fuel system, lubricating oil system, starting system, alternator, turbocharger, gearbox, and other parts. Specific maintenance tasks are outlined for each component, such as cleaning, inspections, filter changes, and replacing parts according to recommended hours of use. The goal is to ensure all engine equipment is in good working condition through regularly scheduled preventative maintenance.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

18 views6 pagesEngine Plan Maintenance System Weekly

Uploaded by

Kacang GorengThe document provides a checklist for monthly maintenance of engine equipment on a tug boat. It lists 17 key components that should be checked and maintained each month, including the main engine, fuel system, lubricating oil system, starting system, alternator, turbocharger, gearbox, and other parts. Specific maintenance tasks are outlined for each component, such as cleaning, inspections, filter changes, and replacing parts according to recommended hours of use. The goal is to ensure all engine equipment is in good working condition through regularly scheduled preventative maintenance.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 6

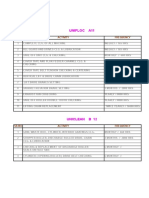

ENGINE PLAN MAINTENANCE SYSTEM WEEKLY

CHECKLIST PEMELIHARAAN ENGINE MINGGUAN

Name Of Tug Boat/ Nama TB : Day/Hari : Date/ Tanggal :

Rating Assessment

No Equipment Monthly Police Date of Done Remark

G F P

1. MAIN ENGINE NO. 1

1 Bed Plate, Coloum and Every month to be clean from water, dust & oil

Engine Every month to be check for mounting, loose

Body bolts and deterioration of isolator

2 Crank Case Every month to be clean from dust & oil

Before instalation make sure the breather on

dry condition

3 Fuel System According RH 300 to be change Fuel Oil Filter

with same specificatin

According RH 300 to be change Racor Filter

with same specificatin

Every month to be check general condition of

Fuel Injection Pump

Every month to be check general condition of

Nozzle Injector

4 Lub Oil System According RH 700 to be change Lubricating Oil

with same specificatin

According RH 300 to be cleaning LO Filter

According RH 700 to be change LO Filter

5 Starting System Every month to be check Battery Liquid with phisical

condition, cable connection & level of liquid as

maintainance

Every month (according RH 500) to be check

general condition of Motor Starter

6 Alternator Every month (according RH 500) to be check

general condition of Alternator

Every month (according RH 500) to be check

general condition of Alternator battery

7 Turbocharger Every month (according RH 300) to be check

condition of Air Cleaner

Every month (according RH 300) to be check

condition of Air Filter

8 Gearbox Every month to be check general condition

of Gearbox with hose/pipes & joint

Every month to be check manometer

Every month to be check LO & LO Filter

phisical condition

According RH 1500 to be change LO & LO Filter

with same specification

According RH 750 to be cleaning gearbox cooler

9 Governoor Every month to be check general condition

10 Hoses - Clamps Every month to be check general condition

11 Damper System Every month to be check general condition of

damper with dents, cracks & leaks of the fluid

12 V belt for Alternator Every month (according RH 1000) to be check

13 V - Belt for Sea Water Every month (according RH 1000) to be check

Pump

14 Impeller for Sea Water Every month (according RH 1000) to be check

Pump

15 Zinc Anode for Inter Every month (according RH 500) to be check

Cooler

16 Zinc Anode for LO Cooler Every month (according RH 500) to be check

17 Zinc Anode for FW Cooler Every month (according RH 500) to be check

Rating Assessment

No Equipment Monthly Police Date of Done Remark

G F P

2. MAIN ENGINE NO. 2

1 Bed Plate, Coloum and Every month to be clean from water, dust & oil

Engine Every month to be check for mounting, loose bolts

Body and deterioration of isolator

2 Crank Case Every month to be clean from dust & oil

Before instalation make sure the breather on dry

condition

3 Fuel System According RH 300 to be change Fuel Oil Filter with

same specificatin

According RH 300 to be change Racor Filter with

same specificatin

Every month to be check general condition of

Fuel Injection Pump

Every month to be check general condition of

Nozzle Injector

4 Lub Oil System According RH 700 to be change Lubricating Oil with

same specificatin

According RH 300 to be cleaning LO Filter

According RH 700 to be change LO Filter

5 Starting System Every month to be check Battery Liquid with phisical

condition, cable connection & level of liquid as

maintainance

Every month (according RH 500) to be check

general condition of Motor Starter

6 Alternator Every month (according RH 500) to be check

general condition of Alternator

Every month (according RH 500) to be check

general condition of Alternator battery

7 Turbocharger Every month (according RH 300) to be check

condition of Air Cleaner

Every month (according RH 300) to be check

condition of Air Filter

8 Gearbox Every month to be check general condition of

Gearbox with hose/pipes & joint

Every month to be check manometer

Every month to be check LO & LO Filter phisical

condition

According RH 1500 to be change LO & LO Filter

with same specification

According RH 750 to be cleaning gearbox cooler

9 Governoor Every month to be check general condition

10 Hoses - Clamps Every month to be check general condition

11 Damper System Every month to be check general condition of

damper with dents, cracks & leaks of the fluid

12 V belt for Alternator Every month (according RH 1000) to be check

13 V - Belt for Sea Water Every month (according RH 1000) to be check

Pump

14 Impeller for Sea Water Every month (according RH 1000) to be check

Pump

15 Zinc Anode for Inter Every month (according RH 500) to be check

Cooler

16 Zinc Anode for LO Cooler Every month (according RH 500) to be check

17 Zinc Anode for FW Cooler Every month (according RH 500) to be check

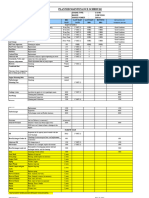

Rating Assessment

No Equipment Monthly Police Date of Done Remark

G F P

3. AUXILIARY / GENERATOR ENGINE NO. 1

1 Bed Plate, Coloum and Every month to be clean from water, dust & oil

Engine Every month to be check for mounting, loose bolts

Body and deterioration of isolator

2 Crank Case Every month to be clean from dust & oil

Before instalation make sure the breather on dry

condition

3 Fuel System According RH 300 to be change Fuel Oil Filter with

same specificatin

According RH 300 to be change Racor Filter with

same specificatin

Every month to be check general condition of

Fuel Injection Pump

Every month to be check general condition of

Nozzle Injector

4 Lub Oil System According RH 700 to be change Lubricating Oil with

same specificatin

According RH 300 to be cleaning LO Filter

According RH 700 to be change LO Filter

5 Starting System Every month to be check Battery Liquid with phisical

condition, cable connection & level of liquid as

maintainance

Every month (according RH 500) to be check

general condition of Motor Starter

6 Alternator Every month (according RH 500) to be check

general condition of Alternator

Every month (according RH 500) to be check

general condition of Alternator battery

7 Turbocharger Every month (according RH 300) to be check

condition of Air Cleaner

Every month (according RH 300) to be check

8 V - Belt for Alternator RH 1000 to be check

9 V - Belt for Sea Water RH 1000 to be check

Pump

10 Air Filter RH 500 to be check

RH 1500 to be change

4. AUXILIARY / GENERATOR ENGINE NO. 2

1 Bed Plate, Coloum and Every month to be clean from water, dust & oil

Engine Every month to be check for mounting, loose bolts

Body and deterioration of isolator

2 Crank Case Every month to be clean from dust & oil

Before instalation make sure the breather on dry

condition

3 Fuel System According RH 300 to be change Fuel Oil Filter with

same specificatin

According RH 300 to be change Racor Filter with

same specificatin

Every month to be check general condition of

Fuel Injection Pump

Every month to be check general condition of

Nozzle Injector

4 Lub Oil System According RH 700 to be change Lubricating Oil with

same specificatin

According RH 300 to be cleaning LO Filter

According RH 700 to be change LO Filter

5 Starting System Every month to be check Battery Liquid with phisical

condition, cable connection & level of liquid as

maintainance

Every month (according RH 500) to be check

general condition of Motor Starter

Rating Assessment

No Equipment Monthly Police Date of Done Remark

G F P

6 Alternator Every month (according RH 500) to be check

general condition of Alternator

Every month (according RH 500) to be check

general condition of Alternator battery

7 Turbocharger Every month (according RH 300) to be check

condition of Air Cleaner

Every month (according RH 300) to be check

8 V - Belt for Alternator RH 1000 to be check

9 V - Belt for Sea Water RH 1000 to be check

Pump

10 Air Filter RH 1000 to be check

RH 1500 to be change

5. OTHER MACHINERY

1 Air Compressor Every month to be check & inspection

To be check suction, delivery & seat valve

2 FO Purifier FO Purifier must be function

Every month to be check & inspection

To be check noise, vibration & leakage

3 LO Purifier LO Purifier must be function

Every month to be check & inspection

To be check noise, vibration & leakage

4 Oily Water Separator Every month to be check general condition

To be check cable & gonnection

To be check bilge pipe & alarm 15 ppm

5 Bow Thruster Every month to be check general condition

Every month to be add grease with instalation

6. PUMP'S AND STEERING GEAR

1 LO Pump for Main Engine Every month to be check general condition

* To be check leakage & waste oil below pump

Every month to be running test

2 LO Pump for Auxiliary Every month to be check general condition

Engine * To be check leakage & waste oil below pump

Every month to be running test

3 FO Pump for Main Engine Every month to be check general condition

* To be check leakage & waste oil below pump

Every month to be running test

4 FO Pump for Auxiliary Every month to be check general condition

Engine * To be check leakage & waste oil below pump

Every month to be running test

5 SW Pump for Main Engine Every month to be check general condition

** To be check impeller & V Belt at RH 1000

Every month to be running test

6 SW Pump for Auxiliary Every month to be check general condition

Engine ** To be check impeller & V Belt at RH 1000

Every month to be running test

7 FW Pump for Main Engine Every month to be check general condition

To be check leakage & inspect impeller

Every month to be running test

8 General / Ballast Pump ** Every month to be check general condition

To be check leakage & inspect impeller

Every month to be running test

9 Hydarulic Pump Steering Every month to be check general condition including

Gear engine Steering Gear

Every month to be check LO condition

Every month running test

Rating Assessment

No Equipment Monthly Police Date of Done Remark

G F P

7. PIPING AND FITTING SYSTEM

1 Bilge Piping System Every month to be check general condition

To be check for leakage, flange, packing, tighten all

bolts & add grease when necessarry

2 FO Piping System Every month to be check general condition

To be check for leakage, flange, packing, tighten all

bolts & add grease when necessarry

3 LO Piping System Every month to be check general condition

To be check for leakage, flange, packing, tighten all

bolts & add grease when necessarry

4 FW Piping System Every month to be check general condition

To be check for leakage, flange, packing, tighten all

bolts & add grease when necessarry

5 SW Piping System Every month to be check general condition

To be check for leakage, flange, packing, tighten all

bolts, add grease & replace anode when necessarry

6 Sea Chest System Every month to be check general condition

To be check for leakage, flange, packing, tighten all

bolts, add grease & replace anode when necessarry

7 All Pipes on deck with Every month to be check general condition

valve To be check for leakage, flange, packing, tighten all

bolts & add grease when necessarry

8. HEAT EXCHANGER & COOLERS

1 FO Heater Every month to be check general condition

Every month running test

2 LO Cooler for Main Engine Every months to be check general condition

Every month to be open & cleaning

Zinc Anode to be check at RH 500

3 FW Cooler for Main Every month to be check general condition

Engine Every month to be open & cleaning

Zinc Anode to be check at RH 500

Every month running test

4 FW Cooler for Auxiliary Every month to be check general condition

Engine Every month to be open & cleaning

Zinc Anode to be check at RH 500

9. ELECTRICAL COMPONENT AND EQUIPMENT

1 Main Switch Board / Panel Every month to be check general condition

Board To be check cable & connection including light at

panel board

Keep be cleaning when necessary

2 Circuit Breaker Every month to be check general condition

To be check cable & connection

Keep be cleaning when necessary

3 Air Conditioner Every month to be check general condition

To be check & inspection

for leak in pipes &connection

Keep be cleaning when necessary

4 DC Wiring System Every month to be check general condition

To be check cable & connection

Keep be cleaning when necessary

Rating Assessment

No Equipment Monthly Police Date of Done Remark

G F P

10. EMERGENCY ENGINE / GENERATOR

1 Diesel Generator To be check general condition & running test every Saturday

11. ENGINE ROOM AND TANKS

11.1 Engine Room

1 Engine Room Every month to be check general condition

To be clean from leakage & waste oil

Every month to be swap & cleaning the wall

2 Engine Room Store Every month to be up date inventory

11.2 Tanks

2 Bilge Tank Every month to be check general condition

To be check cover, nut & packing of manhole

3 Fuel Oil Tank Every month to be check general condition

Fuel Oil Tank To be check cover, nut & packing of manhole

4 Lubricating Oil Tank Every month to be check general condition

4 Lubricating Oil Tank To be check cover, nut & packing of manhole

5 Hydarulic Oil Tank Every month to be check general condition

5 Hydarulic Oil Tank To be check cover, nut & packing of manhole

6 Ballast Tank Every month to be check general condition

6 Ballast Tank To be check cover, nut & packing of manhole

7 Fresh Water Tank Every month to be check general condition

Fresh Water Tank To be check cover, nut & packing of manhole

DAMAGE OF VESSEL

Date & Place of Damage

Location

Corective Action &

Recommendation

Note : G Good

F Fair P Poor

Prepared by : Acknowledge by : Superintendent / Port

Engineer

You might also like

- Jeep 1995 YJ XJ Lubrication and MaintenanceDocument34 pagesJeep 1995 YJ XJ Lubrication and MaintenancesharpxmenNo ratings yet

- CFM Doc Leap 1B Cid Eng Ab 3 V1Document41 pagesCFM Doc Leap 1B Cid Eng Ab 3 V1Paulo SanzNo ratings yet

- HINO FM 1000 HR Service SheetDocument7 pagesHINO FM 1000 HR Service SheetYudi AriantoNo ratings yet

- TR 350M 3 - C1 1eDocument14 pagesTR 350M 3 - C1 1eFayez Alnamarneh86% (7)

- PML 087a - PMS - EngineDocument70 pagesPML 087a - PMS - EngineFidriNo ratings yet

- Maintenance of Sub Station EquipmentDocument57 pagesMaintenance of Sub Station Equipmentsofyan_shah100% (2)

- MFM Consolidated Preventive Maintenance Ver 2 - 3132017Document201 pagesMFM Consolidated Preventive Maintenance Ver 2 - 3132017Paul CansinoNo ratings yet

- Cat C18 Maintenance.Document1 pageCat C18 Maintenance.ChiefNo ratings yet

- 99 Ta 516151Document7 pages99 Ta 516151Onofre100% (1)

- Preventive Sheet 13-02-2023Document15 pagesPreventive Sheet 13-02-2023Vishal MehtreNo ratings yet

- PM Check Sheet (PC1250-8,8R)Document2 pagesPM Check Sheet (PC1250-8,8R)Naughty VongNo ratings yet

- Preventive Maintenance Manual - DRFDocument115 pagesPreventive Maintenance Manual - DRFmliugong100% (8)

- 1a. PS1000 PC200-8MO Adi WDocument28 pages1a. PS1000 PC200-8MO Adi WDeni SetiawanNo ratings yet

- Om F106 6 F106 6A GBDocument257 pagesOm F106 6 F106 6A GBKrunoslav Kasunić86% (7)

- Lubrication Systems - Application & Installation Guide - Lebw4957Document50 pagesLubrication Systems - Application & Installation Guide - Lebw4957aledolz100% (2)

- TIS0003768.002 en-US Boomer 282 - MaintenanceDocument240 pagesTIS0003768.002 en-US Boomer 282 - MaintenanceJuan Yanayaco RamosNo ratings yet

- Washing Spares Book - Layout 1Document54 pagesWashing Spares Book - Layout 1eaglego00No ratings yet

- Manual Mantenimiento Yanmar 4TNV98TDocument29 pagesManual Mantenimiento Yanmar 4TNV98Tdavid ignacioNo ratings yet

- PSA Oxymat Servicio de MantenimientoDocument28 pagesPSA Oxymat Servicio de Mantenimientovictor hugo valqui lopezNo ratings yet

- Routine & Preventive MaintenanceDocument8 pagesRoutine & Preventive Maintenancevinay956No ratings yet

- XAS 88 KDDocument4 pagesXAS 88 KDNuno PaivaNo ratings yet

- Reverse Osmosis (RO) Preventive MaintenanceDocument5 pagesReverse Osmosis (RO) Preventive MaintenanceAmy FitzpatrickNo ratings yet

- Prevention of Actuator Emissions in the Oil and Gas IndustryFrom EverandPrevention of Actuator Emissions in the Oil and Gas IndustryNo ratings yet

- ACMV Maintenance Check ListDocument7 pagesACMV Maintenance Check ListHtet Linn Aung100% (2)

- Deck Plan Maintenance System Weekly: 1. Hull & Load LineDocument3 pagesDeck Plan Maintenance System Weekly: 1. Hull & Load LineKacang GorengNo ratings yet

- Manual For Jackup Refrigeration SystemDocument134 pagesManual For Jackup Refrigeration Systemcastropedro2002No ratings yet

- VMC Maintenance ScheduleDocument5 pagesVMC Maintenance ScheduleHải TạNo ratings yet

- 50 200 Cylinder Diesel EngineDocument30 pages50 200 Cylinder Diesel EngineFranklin FernandezNo ratings yet

- VMC Maintenance ScheduleDocument5 pagesVMC Maintenance Scheduleadel allamNo ratings yet

- 2e Handing Over Note Satinder Pal SinghDocument14 pages2e Handing Over Note Satinder Pal SinghSriram SridharNo ratings yet

- Engine Power Train Case Final Drive Oil & Coolant Type and Capacity NO. Unit Komatsu D85Ess-2Document5 pagesEngine Power Train Case Final Drive Oil & Coolant Type and Capacity NO. Unit Komatsu D85Ess-2luthelapu4100% (2)

- SD 45TFDocument132 pagesSD 45TFJUAN MANUEL RUIZ BERMEJONo ratings yet

- Of-MF 08B - Preventive Maintenance ChecklistDocument3 pagesOf-MF 08B - Preventive Maintenance ChecklistJBMMPL - QUALITYNo ratings yet

- Maintenance and Inspection ItemsDocument5 pagesMaintenance and Inspection ItemsMarko DjurisicNo ratings yet

- Service Protocol: Technical Data Page 99Document2 pagesService Protocol: Technical Data Page 99SuperhypoNo ratings yet

- RASYIDDocument25 pagesRASYIDAbdur RasyidNo ratings yet

- Preventive Checklist For Process EquipmentDocument9 pagesPreventive Checklist For Process EquipmentVishal MehtreNo ratings yet

- Maintenance List - AK Stage V - 2020Document4 pagesMaintenance List - AK Stage V - 2020André SilvaNo ratings yet

- PM PlanDocument56 pagesPM PlanAdrian Christopher Moldez100% (1)

- Check Sheet PS Pc78uu-6 EditDocument3 pagesCheck Sheet PS Pc78uu-6 EditToko SerbaNo ratings yet

- Generator PM SOWsbsDocument1 pageGenerator PM SOWsbsVinay ThakurNo ratings yet

- Maintenance ProgramDocument3 pagesMaintenance ProgramEdgar Jr SuyatNo ratings yet

- Pump PPM ChecklistDocument4 pagesPump PPM ChecklistAjay VarmaNo ratings yet

- 3.3.9 Air Compressor Maintenance LogDocument1 page3.3.9 Air Compressor Maintenance LogSubzone Three100% (1)

- Honda Maintenance ScheduleDocument1 pageHonda Maintenance ScheduletaylorNo ratings yet

- 2 Maintenance Schdule Blow Room, Carding DecDocument15 pages2 Maintenance Schdule Blow Room, Carding DecBHASKAR MITRANo ratings yet

- Som 10.1 H - Ae PMSDocument1 pageSom 10.1 H - Ae PMSAmit BhadauriaNo ratings yet

- Som 10.1 C Me Machinery PmsDocument2 pagesSom 10.1 C Me Machinery PmsAmit BhadauriaNo ratings yet

- Maintenance R1Document45 pagesMaintenance R1Juan LaitonNo ratings yet

- NO Date Personel Maintenance Task Remarks Required Spare PartsDocument6 pagesNO Date Personel Maintenance Task Remarks Required Spare PartsharisNo ratings yet

- TOPIC 10 LubricationDocument29 pagesTOPIC 10 LubricationVLADIMIR VERA VELARDE100% (1)

- Compressed Air Preventative Maintenance: Checklist & LogsDocument3 pagesCompressed Air Preventative Maintenance: Checklist & Logsvibin globalNo ratings yet

- PC 1250 1000 HR Service SheetDocument5 pagesPC 1250 1000 HR Service SheetJamyansuren TseveendorjNo ratings yet

- PC 1250 500 HR Service SheetDocument5 pagesPC 1250 500 HR Service SheetJamyansuren TseveendorjNo ratings yet

- SSR Instruction ManualDocument12 pagesSSR Instruction Manualgrandmas developerNo ratings yet

- Tip On Power Transformer Preventive MaintenanceDocument2 pagesTip On Power Transformer Preventive MaintenanceSamrong Chek BENo ratings yet

- Maintenance Schedule For Water Distribution Systems: Description Comments Maintenance FrequencyDocument1 pageMaintenance Schedule For Water Distribution Systems: Description Comments Maintenance FrequencyGaurav JhaNo ratings yet

- Service Manual: Tennant A80Document33 pagesService Manual: Tennant A80Павел КорчагинNo ratings yet

- File Pms Engine Tug Boat Maju Daya 53Document14 pagesFile Pms Engine Tug Boat Maju Daya 53k684ryjm8vNo ratings yet

- PMS PER WAKTUDocument57 pagesPMS PER WAKTUAbdul BasitNo ratings yet

- Diesel Generator ChecksDocument1 pageDiesel Generator ChecksRevanthNo ratings yet

- Maintenance InstructionsDocument3 pagesMaintenance InstructionsNavnath GawasNo ratings yet

- Sample Check ListDocument2 pagesSample Check ListHarsun HarNo ratings yet

- 420 Maintenance ScheduleDocument4 pages420 Maintenance Scheduleicyan.ahmad.tiNo ratings yet

- Positive Displacement PumpsDocument1 pagePositive Displacement Pumpsshoaib lodhiNo ratings yet

- Standard Operating Procedure: Department: Engineering Services Item: GeneratorDocument2 pagesStandard Operating Procedure: Department: Engineering Services Item: GeneratorGhure Berai -ঘুরে বেড়াইNo ratings yet

- J23313-Maintenance LogDocument2 pagesJ23313-Maintenance LogLab BiosNo ratings yet

- PM FormDocument19 pagesPM Formwong warasNo ratings yet

- Baghouse Collectors (Non-Compressed Air) Examples: Rugged Pleat (RP) & RF SeriesDocument2 pagesBaghouse Collectors (Non-Compressed Air) Examples: Rugged Pleat (RP) & RF SeriesALI TAVAKOLINIANo ratings yet

- Linde ChecklistDocument47 pagesLinde ChecklistVicente TanNo ratings yet

- Inspection Sheet UNTUK DozerDocument12 pagesInspection Sheet UNTUK DozerkkmechNo ratings yet

- MAINTENANCEDocument26 pagesMAINTENANCENicholas Isola0% (1)

- Komatsu Wa470 6 Operation Maintenance ManualDocument20 pagesKomatsu Wa470 6 Operation Maintenance Manualtanna100% (22)

- Oil Injected Screw Compressors TrainingDocument16 pagesOil Injected Screw Compressors TrainingHitesh sharmaNo ratings yet

- Avon UTC 1535c5Document32 pagesAvon UTC 1535c5juana100% (1)

- Honda GX670Document58 pagesHonda GX670JFrink333100% (2)

- Aircraft System Prelim Module 4 Oil System RevisedDocument30 pagesAircraft System Prelim Module 4 Oil System RevisedGertrudeshane IletoNo ratings yet

- Trouble ShootingDocument22 pagesTrouble ShootingAhmad MubarokNo ratings yet

- 35m GB PDFDocument38 pages35m GB PDFTin Aung KyiNo ratings yet

- Work Shop RepairDocument14 pagesWork Shop RepairSuhendraNo ratings yet

- CC ToolsDocument12 pagesCC ToolsLuis HuirseNo ratings yet

- Maintenance Interval Schedule 420FDocument4 pagesMaintenance Interval Schedule 420FSeguir AdelanteNo ratings yet

- Hitachi Ex270 Engine Parts ManualDocument90 pagesHitachi Ex270 Engine Parts ManualJay Mechanic0% (1)

- New Ecm Excavator 3975-06Document15 pagesNew Ecm Excavator 3975-06khaled kamelNo ratings yet

- F240a 22Document93 pagesF240a 22ניקולאי איןNo ratings yet

- PM 3 (1000 HOUR Interval) : ChecklistDocument3 pagesPM 3 (1000 HOUR Interval) : ChecklistPutera Bumi NusantaraNo ratings yet

- FORM 10125 VHP 16S5 GSI Enginator ManualsDocument1,144 pagesFORM 10125 VHP 16S5 GSI Enginator Manualschris pinkneyNo ratings yet

- En Us t2 2005Document462 pagesEn Us t2 2005Rafael Canizares ChiarandiNo ratings yet

- VACC Automotive Environmental GuideDocument40 pagesVACC Automotive Environmental Guidesgvfnbfhg100% (1)

- Caterpillar Wheel Loader TroubleshootingDocument26 pagesCaterpillar Wheel Loader TroubleshootingNezar Amin100% (3)