Professional Documents

Culture Documents

GENIUS-SERIES - Operation Manual 3B - Scan1

Uploaded by

Centrifugal SeparatorCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

GENIUS-SERIES - Operation Manual 3B - Scan1

Uploaded by

Centrifugal SeparatorCopyright:

Available Formats

MITSUBISHI

SELFJECTOR

GENIUS -SERIES

Instruction Manual

Operation Manual 3B

(GSH-1)

for English

MITSUBISHI KAKOKI KAISHA Ltd.

IMPORTANT

This manual has been edited primarily to give instructions for processing mineral oils

such as fuel oils and lubricating oils.

SELFJECTOR Instruction Manual Operation Manual 3B

WARNING

This instruction manual is a guide for using an automatic discharge type oil purifier, the "Mitsubishi

SELFJECTOR Genius Series" (hereinafter referred to as the SELFJECTOR).

The SELFJECTOR is a centrifugal separator rotating at high speeds. Please read through this manual

and obtain a complete understanding of the contents of the manual before using the SELFJECTOR.

Handle the SELFJECTOR safely and operate it in the right way to get the best service.

The Instruction Manual for the SELFJECTOR is configured as shown on the

following page. This volume is one of the manuals composing Part 4,

Operation Manual 3B.

Be sure to use the appropriate manuals and have a complete

understanding of the contents of the manual before starting your work.

SELFJECTOR Instruction Manual Operation Manual 3B

①: Design Engineer ②: Installer ③: Engine Engineer ④: Operator

Intended

Part

Manual Description Reader

①②③④

1 Outline of fitting-out aboard Information for transportation, handling and storage of the

machine

O O

Instructions for installation and dimensions

System diagram and connection diagram

2 Operation Manual 1 Precautions for safety

Configuration and structure of SELFJECTOR

O O

Motor, starter, automatic control panel

Multi-Monitor

3 Operation Manual 2 Precautions for safety

Functions of components

O O

Operation setting items and adjustment procedures

How to start and stop

4 Operation Manual 3A Precautions for safety

Function, operation and maintenance information on O O

automatic control panel GBC-1 & GBC-2

Operation Manual 3B Precautions for safety

Function, operation and maintenance information on O O

automatic control panel GSH-1

5 Maintenance Manual Precautions for safety

How to disassemble and reassemble

O O

Maintenance and checkup procedure

Trouble shooting

NOTE

The Part 4 manuals (Operation Manuals 3A & 3B) deal with the following types of the automatic

control systems. When you purchase the SELFJECTOR controlled by one of these control

systems, the associated operation manual of Part 4 will be supplied.

Automatic control systems: GBC-1, GBC-2, GSH-1

SELFJECTOR Instruction Manual Operation Manual 3B

CONTENTS (1 / 2)

1. PRECAUTIONS FOR SAFETY .................................................................................................. 1-1

1.1. SYMBOLS ASSOCIATED WITH SAFETY ................................................................................ 1-1

1.2. PRECAUTIONS FOR SAFETY ................................................................................................. 1-2

2. OVERVIEW OF AUTOMATIC CONTROL PANEL..................................................................... 2-1

3. FRONT PANEL FUNCTIONS OF AUTOMATIC CONTROL PANEL......................................... 3-1

4. PROGRAMMABLE CONTROLLER........................................................................................... 4-1

4.1. PROGRAMMABLE CONTROLLER........................................................................................... 4-1

4.2. PROGRAMMABLE CONTROLLER CONFIGURATION............................................................ 4-1

4.3. FUNCTIONS OF INDIVIDUAL PARTS OF PROGRAMMABLE CONTROLLER ....................... 4-2

4.4. OPERATION DISPLAY PANEL................................................................................................. 4-5

5. RELAY BOARD.......................................................................................................................... 5-1

6. TIMER TIME SETTING PROCEDURES..................................................................................... 6-1

6.1. TIMER SETTING TIMES ........................................................................................................... 6-1

6.2. COUNTER SETTING VALUES ................................................................................................. 6-4

6.3. TIMER/ COUNTER TIME SETTING PROCEDURES................................................................ 6-6

7. PREPARATIONS FOR OPERATION......................................................................................... 7-1

7.1. AUTOMATIC CONTROL PANEL .............................................................................................. 7-1

7.2. PURIFIER .................................................................................................................................. 7-1

8. AUTOMATIC OPERATION ........................................................................................................ 8-1

8.1. HIDENS SYSTEM OPERATION ............................................................................................... 8-1

8.2. PURIFIER OPERATION ............................................................................................................ 8-6

8.3. SLUDGE DISCHARGE TEST.................................................................................................. 8-10

8.4. AUTOMATIC STOP .................................................................................................................8-10

8.5. EMERGENCY STOP ............................................................................................................... 8-10

9. ALARMS..................................................................................................................................... 9-1

9.1. TYPES OF ALARMS ................................................................................................................. 9-1

9.2. ALARM RESET ......................................................................................................................... 9-1

SELFJECTOR Instruction Manual Operation Manual 3B

CONTENTS (2 / 2)

10. ALARM AND CORRECTIVE ACTION ..................................................................................... 10-1

10.1. "01": OIL LEAKAGE................................................................................................................. 10-1

10.2. "02": NO OPENING OF BOWL ................................................................................................ 10-2

10.3. "03": ABNORMAL WATER CONTENT ALARM....................................................................... 10-2

11. MONITORING INPUT AND OUTPUT SIGNALS......................................................................11-1

12. MAINTENANCE........................................................................................................................ 12-1

12.1. "AUTO. RUNNING" LAMP NOT ILLUMINATED...................................................................... 12-1

12.2. INDICATION OF OPERATION DISPLAY PANEL ERROR ..................................................... 12-3

13. AUTOMATIC OPERATION FLOW DIAGRAM......................................................................... 13-1

14. TIMING CHART ........................................................................................................................ 14-1

14.1. HIDENS OPERATION ............................................................................................................. 14-1

14.2. PURIFIER OPERATION .......................................................................................................... 14-4

SELFJECTOR Instruction Manual Operation Manual 3B

1.PRECAUTIONS FOR SAFETY

Prior to use, carefully read through the "Precautions for Safety", and operate the SELFJECTOR in the

right way.

The precautions for safety in this instruction manual are intended for enabling the user to use the

SELFJECTOR safely and properly, and protecting the user from personal injury and damage. Carefully

read through the precautions until you have a complete understanding before performing any job or

procedure for operation or maintenance of the SELFJECTOR.

1.1.SYMBOLS ASSOCIATED WITH SAFETY

In this instruction manual, the precautions are headed by the following symbols. Since all of them

are important precautions associated with safety, be sure to strictly observe them.

DANGER: Indicates an imminently hazardous situation which, if not heeded, will result

in death or serious injury.

WARNING: Indicates a potentially hazardous situation which, if not heeded, could result

in death or serious injury.

CAUTION: Indicates a hazardous situation which, if not heeded, may result in minor or

moderate injury or damage to the machine or facilities.

NOTE: Indicates the items which should be done or which will be of help if kept in mind for

operating the machine or performing work.

SELFJECTOR Instruction Manual 1-1 Operation Manual 3B

1.2.PRECAUTIONS FOR SAFETY

CAUTION

The automatic control panel is a part of the equipment designed for automatic operation of the

SELFJECTOR. Improper handling of the panel could cause malfunctions and jeopardize your

safety. Before operation, maintenance and inspection of the panel, thoroughly read through this

manual and pay special heed to your safety when using the panel.

• Do not attempt disassembly and reworking of the control panel without permission of

Mitsubishi Kakoki.

• Never place the equipment in a position close to flammable materials.

If it is placed in a position close to flammable materials, an explosion or fire could result.

• Before proceeding with wiring, check to ensure that the input power supply to the system is

OFF.

There is danger of an electrical shock.

• Make sure that wiring is done by qualified electrical engineers.

• Connect the equipment to the hull in an electrically effective way by use of the ground

terminal of the panel.

(Make sure that the equipment is grounded.)

• Check to ensure that the rated voltage and frequency of the panel coincide with those of the

power supply.

Should questions arise concerning the contents of the manual,

please contact Mitsubishi Kakoki or your nearest Mitsubishi

Kakoki service agent.

SELFJECTOR Instruction Manual 1-2 Operation Manual 3B

SELFJECTOR Instruction Manual 1-3 Operation Manual 3B

2.OVERVIEW OF AUTOMATIC CONTROL PANEL

The control panel is used for automatic purification of the feed oil by the Mitsubishi SELFJECTOR. It is so

designed that, if a trouble like an abnormal oil leakage or sludge discharge failure (failure to open the bowl)

occurs during operation, the supply of the feed oil and then the SELFJECTOR may be stopped

automatically.

<Automatic Operation Process>

Closes the main cylinder of the bowl → Supplies sealing water → Supplies feed oil (purifier operation) →

Supplies replacement water → Opens the main cylinder of the bowl (discharges sludge).

The control panel outputs “Feeding” signal to the Multi-Monitor (MM), and has separated water discharged

in response to “alarm (water detection)” signal from the Multi-Monitor. If the number of times water

discharge is detected is abnormally large, the control panel automatically shuts down the SELFJECTOR

after completion of the discharge process. For detailed information on the Water Detector Function (WD)

of the Multi-Monitor, refer to “OPERATION MANUAL 2”.

The control panel has a built-in programmable controller to control the automatic operation processes.

The control panel consists of the following devices.

Programmable controller

(1) CPU board: PZ3M

(2) Operation display panel: S-10D-M

(3) Expansion board: PZ3ME (Option)

Control switches, pilot lamps, fuses, relay board and terminal board

SELFJECTOR Instruction Manual 2-1 Operation Manual 3B

3.FRONT PANEL FUNCTIONS OF AUTOMATIC CONTROL PANEL

The front panel configuration and functions of the automatic control panel are shown below.

5 3

8

1

OFF ON

2

MM機能 警報リセット 自動運転 制御電源

MM FUNCTION ALARM RESET AUTO. CONT.

RUNNING SOURCE

OFF ON

非常停止 排出テスト

自動停止 制御電源

EMERG. DISCHG.

7 STOP TEST

AUTO. CONT.

STOP SOURCE

6 4

(1) "CONT. SOURCE"

Lights when power is supplied to the automatic control panel.

(2) "CONT. SOURCE ON-OFF"

Turns on/off the power for the automatic control panel.

SELFJECTOR Instruction Manual 3-1 Operation Manual 3B

(3) "AUTO. RUNNING"

The pushbutton is a switch for starting automatic operation. The built-in pilot lamp will stay ON

during automatic operation.

(4) "AUTO. STOP"

When this pushbutton is pressed during automatic operation, the SELFJECTOR will stop

automatically after discharging sludge.

(5) "ALARM RESET"

When any alarm occurs during operation, the built-in pilot lamp will come on. The type of alarm that

has occurred can be known from the data display on the front panel.

When the pushbutton is pressed, the sustained alarm will be reset.

(6) "DISCHG. TEST"

When this pushbutton is pressed during automatic operation, the SELFJECTOR is forced to

discharge sludge.

(7) "EMERG. STOP"

When this pushbutton is pressed, all the valves will immediately close, and the SELFJECTOR will

stop.

(8) "MM FUNCTION SWITCH"

This selector switch is used for ON/OFF control of feed signal output from the control panel to the

Multi-Monitor.

When the "MM FUNCTION SWITCH" is off position, feeding signal is not outputted from the control

panel to the Multi-Monitor even if the SELFJECTOR is on feeding.

(9) "OPERATION DISPLAY PANEL"

The operation display panel displays input and output data, ON/OFF status of input and output

signals and kinds of alarm signals. Also, it is possible to enter and alter various set values on the

graphic panel.

SELFJECTOR Instruction Manual 3-2 Operation Manual 3B

4.PROGRAMMABLE CONTROLLER

4.1.PROGRAMMABLE CONTROLLER

The programmable controller contains the logic for automatic operation of the purifier.

It is a flexible controller whose programs can be rewritten from an external tool.

The programmable controller contains the functions for inputting and outputting signals from/to the

external devices, and the timer functions.

4.2.PROGRAMMABLE CONTROLLER CONFIGURATION

The programmable controller consists of the following devices. (For details, refer to Section 4.3.)

The CPU board and expansion board are mounted in the automatic control panel, whereas the

operation display panel is mounted on the front of the automatic control panel.

4.2.1.CPU Board

The CPU board is a device which outputs and inputs signals to and from external devices. The

following signals are connected to the CPU board.

[Input Signals]

From Multi-Monitor

o Oil leakage signal (LM)

o No-discharge signal (DD)

o Water detection signal (WD)

From automatic control panel

o ON signal of each pushbutton on front of the control panel

[Output Signals]

o Discharge signal, feeding signal, etc. to the Multi-Monitor

o OPEN/CLOSE signals to solenoid valves

o ON signal to front panel pilot lamps

o STOP signal to motor starter, alarm signal to console, etc.

SELFJECTOR Instruction Manual 4-1 Operation Manual 3B

4.2.2.Operation Display Panel

The operation display panel is a device for changing the timer and counter settings of the

programmable controller and indicating SELFJECTOR alarms. It is connected to the CPU board

by a communications cable.

The timers and counters must be set to different values, depending on:

o Model number of SELFJECTOR,

o Type of feed oil,

o Operating water pressure and sealing water pressure.

It is therefore necessary that the settings are changed to match the operating condition.

4.2.3.Expansion Board (Option)

This is a device for expansion of input/output. Normally, it is not provided.

4.3.FUNCTIONS OF INDIVIDUAL PARTS OF PROGRAMMABLE CONTROLLER

4.3.1.CPU Board

Screw x 4 Connector terminal

ビス×4 コネクタ端子

入力表示LED

Tool port

ツールポート Input display LED

CN1

CN2

I1

I4

I5

I6

I7

I0

I2

I3

I10

I11

I12

I13

I14

I15

I16

I17

RUN

TERM

CN3 動作状態LED

Operating status LED

PWR

RUN

CPU

Communications

通信ポート Output display LED

port 出力表示LED

Connector

コネクタ端子 terminal

Q10

Q11

Q12

Q13

Q14

Q15

Q16

Q17

Q0

Q1

Q2

Q3

Q4

Q5

Q6

Q7

Mode selector switch

モード切替え CN4

(Normal position: RUN)

スイッチ CPU基板

CPU board

(通常:TERM側)

拡張基板

Expansion board (Option)

(オプション)

Fig. 4-1 Outside View of CPU Board

SELFJECTOR Instruction Manual 4-2 Operation Manual 3B

4.3.2.Functions of Individual Parts of CPU Board

Name Symbol Description

Operating Status LED PWR Comes on when the power supply is turned on.

RUN Stays ON during operation.

When it is OFF, temporarily set the mode switch (SW1) to RUN, and

then to TERM again to light the LED.

CPU Comes on when an error occurs in the CPU.

Input Display LED I0-I17 The LEDs indicate the input status of signals.

When a pushbutton on the front panel is set to ON or a detector is

caused to be ON, the associated LED lights.

Output Display LED Q0-Q17 The LEDs indicate the output status of signals.

When a pilot lamp on the front panel is lit, or a solenoid valve is

opened or closed, or a detector signal is output, the associated LED

lights.

Mode Switch SW1 Normally set to RUN.

TERM side is used at the time of a exclusive communication

apparatus use.

Tool Port CN3 The operation display panel is connected to the port.

To rewrite the program, connect a dedicated tool to the port.

Communications Port CN2 Not used

Connector Terminal CN1 The flat cable for input signals is connected to the terminal.

CN4 The flat cable for output signals is connected to the terminal.

o To replace the CPU board, disconnect the connector and loosen the four screws to remove

the board.

SELFJECTOR Instruction Manual 4-3 Operation Manual 3B

4.3.3.Functions of Input and Output Display LEDs

For the input and output display LED Nos. and functions, refer to the following table.

Table 4-1 Detailed Functions of Input and Output Display LEDs

Name LED No. Description

Input Display LED I0 Lights when Leakage signal is inputted from the Multi-Monitor.

I1 Lights when No-discharge signal is inputted from the Multi-Monitor.

I2 Lights when Water Detection signal is inputted from the Multi-Monitor.

I3

I4

I5

I6

I7 Stays ON during operation of motor of SELFJECTOR.

I10 Lights when Push-button switch “AUTO. START” is pushed.

I11 Lights when Push-button switch “AUTO. STOP” is pushed.

I12 Lights when Push-button switch “DISCHG TEST” is pushed.

I13 Lights when Push-button switch “ALARM RESET” is pushed.

I14 Lights when Change-over switch “MM FUNCTION” is set to “ON”.

I15

I16

I17

Output Display LED Q0 Lights when bowl opening water solenoid valve (SV1) is energized.

(Total Discharge)

Q1 Lights when bowl closing water solenoid valve (SV2) is energized.

Q2 Lights when sealing water/replacement water solenoid valve (SV3) is

energized.

Q3 Lights when feed valve solenoid valve (SV4) is energized.

Q4 Lights when bowl opening water solenoid valve (SV9) is energized.

(Partial Discharge)

Q5

Q6

Q7 Stays ON during automatic operation.

Q10 Q10 / Lights when alarm occurs.

Q11

Q12 Lights when stop signal is output to starter. *1

Q13 Lights when alarm cancel signal is output to starter. *1

Q14 Lights when collective alarm signal is output to console. *2

Q15 Stays ON during feeding process (for Leakage Monitor Function (LM) of

the Multi-Monitor interlocking).

Q16 Stays ON during discharge process (for Discharge Detector Function

(DD) of the Multi-Monitor interlocking).

Q17

NOTE

*1....The starter refers to the separately installed motor starter of the SELFJECTOR.

*2....The console refers to the remote control console.

SELFJECTOR Instruction Manual 4-4 Operation Manual 3B

4.4.OPERATION DISPLAY PANEL

Data Display Section

Address Display Section (Upper/Lower Stage)

アドレス表示部 データ表示部(上段/下段)

SET MAIN

ADDRESS DATA

MAIN

MON OPT

TIM

CNT

REG IN (REG) TIM CNT

MON OUT

- +

ALM M

MITUBISHI KAKOKI KAISHA,LTD.

CLR ENT

モード表示部

Mode Display Section 操作キー

Control Keys

Fig. 4-2 Outside View of Operation Display Panel

SELFJECTOR Instruction Manual 4-5 Operation Manual 3B

4.4.1.Functions of Individual Sections of Operation Display Panel

Name Symbol Description

Address Display Section ADDRESS Displays the number of the timers/counters or input/output

signals whose data is displayed in the data display section.

Data Display Section DATA Displays the data (timer setting time/time elapsed, etc.) for the

item indicated on the address display section or mode display

section.

Mode Display Section MAIN Lights when an ordinary operation data (main screen) is

displayed. When the MAIN is ON, the upper stage of the data

display section indicates the elapsed time of the discharge

interval timer (CO15). (Unit: Minutes)

The lower stage indicates a water content value. (Option)

TIM Lights when the set time/elapsed time of the timer are

displayed or the setting is changed. When the TIM is ON, the

set time is displayed in the upper stage of the data display

section, and the elapsed time displayed in the lower stage.

CNT Lights when the set time/elapsed time of the timer (counter) is

displayed or the setting is changed. When the CNT is ON, the

set time is displayed in the upper stage of the data display

section.

The lower stage displays the elapsed time.

REG Lights when the internal memory data of the programmable

controller is displayed. (Normally not used)

MON Lights when input/output signals are monitored. When the

MON is ON, the ON/OFF status of the input/output signal is

displayed in the data display section.

IN Lights when an input signal is monitored.

OUT Lights when an output signal is monitored.

Lights when an internal signal is monitored. (Normally not

M

used)

ALM Lights when an alarm is displayed.

When the ALM is ON, the alarm number is displayed in the

data display section.

SELFJECTOR Instruction Manual 4-6 Operation Manual 3B

Name Symbol Description

Input Key SET Use this key when there is a need for changing a setting.

MAIN Use this key to have ordinary operation data displayed on the

screen (to display the “main screen”).

MON Use this key when input/output signals are to be monitored on

the screen.

OPT Press OPT then ENT to display the number of the alarm that

occurred last.

← (REG) In the timer/counter setting change mode, use this key to

move the cursor to the left digit.

→ TIM CNT Use this key to display the set time/elapsed time of the timer

and counter.

In the timer/counter setting change mode, use the key to move

the cursor to the right digit.

- Use this key to decrement a setting or an address (number) by

1.

+ Use this key to increment a setting or an address (number) by

1.

CLR Use this key to clear a changed setting.

ENT Use this key to enter a changed setting.

SELFJECTOR Instruction Manual 4-7 Operation Manual 3B

4.4.2.Expansion Board (Option)

Input display LED

入力表示LED

I20

I21

I22

I23

I24

I25

I26

I27

Q20

Q21

Q22

Q23

Q24

Q25

出力表示LED Q26

Output display LED Q27

Expansion

拡張基板 board

(Option)

(オプション)

Terminals

端子台

Fig. 4-3 Skiagram of Expansion Board

The expansion board is used for analog inputting of the Electrostatic Capacity Type Water

Detector (WD) reading. It is provided only for a control panel with an optional water display.

The board has signal input and output functions, but the functions are not normally used.

SELFJECTOR Instruction Manual 4-8 Operation Manual 3B

5.RELAY BOARD

The relay board is mounted on the rear side of the CPU board.

It accommodates auxiliary relays and fuses. The relay contacts are opened and closed by the output

signals from the programmable controller.

When a fuse blows or an auxiliary relay goes out of order, remove the four screws, remove the cover and

the connector connected to the CPU board, and replace the fuse or auxiliary relay with a spare one.

Screw x 4 Fuse Internal terminal Fuse

Cover

External terminal Auxiliary relay Connector terminal

Fig. 5-1 Relay board

SELFJECTOR Instruction Manual 5-1 Operation Manual 3B

6.TIMER TIME SETTING PROCEDURES

6.1.TIMER SETTING TIMES

The times to be set for the timers vary with the following factors.

o Model number of SELFJECTOR

o Type of feed oil

o Operating water pressure and sealing water pressure

It is therefore necessary to set the timers to match the field conditions. When a test run and

adjustments are performed by Mitsubishi Kakoki service personnel, the timers are set to the proper

values suitable for the field conditions before handover. If changes occur in the properties of feed oil

thereafter, refer to the following explanations and change the set times properly.

Table 6-1 Timer Nos. and Uses (Standard)

Timer No. Use Time that can be set

T000 Operation intervals of each solenoid valve 0.0-999.9 s

T001 Bowl opening time (Total discharge) 0.0-999.9 s

T002 Replacement water supply time (Total discharge) 0.0-999.9 s

T003 Sealing water (regulating water) supply time (Total discharge) 0.0-999.9 s

T004 Bowl washing water supply time 0.0-999.9 s

T011 Bowl opening time (Partial discharge) 0.0-999.9 s

T012 Replacement water supply time (Partial discharge) 0.0-999.9 s

T013 Sealing water (regulating water) supply time (Partial discharge) 0.0-999.9 s

C014 Intermittent bowl closing water supply intervals 1-9999 min

C015 Sludge discharge intervals 1-9999 min

T016 Operating water supply for closing bowl. 0.0-999.9 s

C022 Monitoring time 1-9999 min

C026 Water detection count reset time 1-9999 min

Table 6-2 Counter Nos. and Uses (Standard)

Timer No. Use Time that can be set

C023 Bowl washing counter 1-100

C027 Water detection count 1-9999 times

SELFJECTOR Instruction Manual 6-1 Operation Manual 3B

Standard Times to Be Set for Timers/Counters

(HIDENS Operation)

Table 6-3

Timer

Item Unit SJ10GH SJ20GH SJ30GH SJ50GH SJ60GH SJ70GH SJ100GH SJ120GH SJ150GH

N o .

Interval T000 sec 15 15 15 15 15 15 20 20 20

Opening bowl T001 sec 3

Replacement water T002 sec 10 11 14 21 21 26 38 38 37

Regulating Fuel oil 0

T003 sec

water Lubricating oil 1 1 2 3 3 3 5 5 5

Bowl washing Fuel oil 0

T004 sec

water Lubricating oil 12 13 19 26 26 31 48 48 47

Opening bowl(partial) T011 sec 0.6

Replacement water(partial) T012 sec 2 2 2 3 3 6 6 6 6

Regulating Fuel oil 0

T013 sec

Water(partial) Lubricating oil 1 1 2 3 3 3 5 5 5

Intermittent water supply C014 min 15

Operating water supply for

T016 sec 5

closing bowl

Discharge interval C015 min NOTE1

Detection count reset C026 min 30

Water detection setting

C027 times 6

counter

Monitoring time C022 min 20

Bowl washing Fuel oil 0

C023 times

counter Lubricating oil 6

NOTE1: For discharge intervals, refer to Table 6-5 “standard discharge intervals for general

guidance”.

NOTE2: Please use C021 by fixing to 1.

NOTE

Timer settings for sealing water and replacement water in the above list are based on the feed

rate at 8 L/min. for SJ10GH to 30GH, at 12 L/min. for SJ50GH to 70GH, at 16 L/min. for

SJ100GH and 120GH and at 18 L/min. for SJ150GH. For practical setting, always measure the

flow rate actually and select proper values accordingly.

Fuel oil purifiers have no regulating water feeding process and bowl washing processes.

SELFJECTOR Instruction Manual 6-2 Operation Manual 3B

Standard Times to Be Set for Timers/Counters

(Purifier Operation: Total discharge)

Table 6-4

Timer

Item U n i t SJ10GH SJ20GH SJ30GH SJ50GH SJ60GH SJ70GH SJ100GH SJ120GH SJ150GH

N o .

Interval T000 sec 15 15 15 15 15 15 20 20 20

Opening bowl T001 sec 3

Replacement water T002 sec 5 8 12 14 14 19 29 29 32

Sealing water T003 sec 9 10 12 18 18 20 32 32 27

Bowl washing Fuel oil 0

T004 sec

water Lubricating oil 12 13 19 26 26 31 48 48 47

Opening bowl(partial) T011 sec 0.6

Replacement water(partial) T012 sec 2 2 2 3 3 6 6 6 6

Regulating Fuel oil 0

T013 sec

Water(partial) Lubricating oil 1 1 2 3 3 3 5 5 5

Intermittent water supply C014 min 15

Operating water supply for

T016 sec 5

closing bowl

Discharge interval C015 min NOTE1

Detection count reset C026 min 30

Water detection setting

C027 times 6

counter

Monitoring time C022 min 20

Bowl washing Fuel oil 0

C023 times

counter Lubricating oil 6

NOTE1: For discharge intervals, refer to Table 6-5 “standard discharge intervals for general

guidance”.

NOTE2: Please use C021 by fixing to 1.

NOTE3: In case of purifier operation by automatic type GSH-1, the timers T011, T012, T013, C022,

C026 and C027 are nonfunctional and need no change in set value.

NOTE

Timer settings for sealing water and replacement water in the above list are based on the feed

rate at 8 L/min. for SJ10GH to 30GH, at 12 L/min. for SJ50GH to 70GH, at 16 L/min. for

SJ100GH and 120GH and at 18 L/min. for SJ150GH. For practical setting, always measure the

flow rate actually and select proper values accordingly.

Prior to purifier operation, do the following settings.

o Select the gravity disc to match the type of oil to be treated. (Refer to Operation Manual 2.)

o Fully close the circulation line backpressure valve attached to the purifier and fully open

the shut off valve.

o Set the Water Detector selector dial to “No Water / heavy liquid detector function” position

and the Water Detection output switch to OFF. (Refer to Operation Manual 2.)

SELFJECTOR Instruction Manual 6-3 Operation Manual 3B

Table 6-5 shows the standard discharge intervals for general guidance in processing fuel and lubricating

oils.

Table 6-5

Fuel oils Lubricating oils

C Fuel Oil

A Fuel Oil Cross-head engine Trunk piston engine

(380mm2/S at 50°C)

Standard Standard Standard Standard

HIDENS

120 min 60 min 120 min 60 min

Operation

Purifier

120 min 60 min 120 min 60 min

Operation

6.2.COUNTER SETTING VALUES

The inside of the bowl can be cleaned after every few total discharge operations in order to remove

unevenly accumulated sludge and dirt.

Table 6-6 shows the standard bowl washing counters for general guidance in processing fuel and

lubricating oils.

Table 6-6

Fuel oils Lubricating oils

C Fuel Oil

A Fuel Oil Cross-head engine Trunk piston engine

(380mm2/S at 50°C)

Standard Standard Standard Standard

Bowl

washing 0 times 0 times 6 times 6 times

counter

NOTE

The Bowl washing count shown above is set so that the washing interval will be 24 hours.

The Bowl washing interval is given by: (Except when the Bowl washing count is 0.)

The Bowl washing interval (min)

= Discharge interval (C015) x Total discharge count (C021) x Bowl washing count (C023)

SELFJECTOR Instruction Manual 6-4 Operation Manual 3B

6.2.1.FUNCTUION OF BOWL WASHING COUNTER

The washing in the bowl is at every total discharge

The bowl washing is made each time the Bowl Washing counter C023 reaches its set total sludge

discharge count.

The bowl washing is performed in such a way that washing water is supplied into the bowl after a routine

total sludge discharge for the period of time set on the bowl washing timer T004 totally drained.

When the set count is "1"

Bowl washing is made after each total sludge discharge.

When the set count is "0" or "100"

No bowl washing is made.

When the set count is "2 to 99"

Bowl washing is made once in the number of times of total sludge discharge that corresponds the

setting.

SELFJECTOR Instruction Manual 6-5 Operation Manual 3B

6.3.TIMER/ COUNTER TIME SETTING PROCEDURES

To set the time of a timer, proceed as described below.

① Set the power switch of the control panel to "ON" and check to see that the "CONT. SOURCE"

pilot lamp, the "RUN" LED of the CPU board, and the LED of the "mode display section" on the

operation display panel are ON.

② Press the control keys of the operation display panel in the following sequence. Confirm the

displays of the display section before proceeding ahead.

Set Time/Elapsed Time Call Procedures

設定時間/経過時間の呼び出し操作手順

MAIN - or +

TIM CNT TIM CNT

T001~T025は、1回押す

For T001-T025, press TIM CNT once. タイマ番号を選択

Select a timer number.

C014~C027は、2回押す

For C014-C027, press TIM CNT twice.

Set Time Change Procedures

設定時間の変更操作手順

SET

(REG)

or - or + ENT

TIM CNT

桁選択

To select a digit To設定時間増減

increase or decrease the set time

NOTE

o The time cannot be set in hours (HR). For 3HR for example, set 180 MIN.

o For information on the timer numbers and uses, refer to Section 6.1.

o The units of time displayed in the data display section are shown below.

o 0.1 second for timer Nos. T001-T025

o 1 minute for timer Nos. C014-C015 and C022, C026

o 1 time for counter No. C021 and C023, C027

SELFJECTOR Instruction Manual 6-6 Operation Manual 3B

6.3.1.Calling Set Time and Elapsed Time

Here is an example of procedure. Suppose that timer No. C015--Discharge Interval was already

set to 60 minutes. In this case, proceed as described below to call the set time or elapsed time

before entering automatic operation or during automatic operation.

MAIN - or +

TIM CNT TIM CNT

タイマ番号を選択

Select a timer No.

If the keys are operated in the above sequence, the upper stage of the data display section

shows the set time of the timer, whereas the lower stage shows the elapsed time of the timer.

Control Key Display Address Data

Upper stage

Lower stage

ADDRESS DATA Elapsed time of C015

MAIN MAIN

0048

TIM

CNT

Water content value or

REG

MON

IN

OUT

0.0 blank

ALM M

ADDRESS DATA Timer No. Set time of timer

MAIN

TIM

001 10.0 T000-T025 0.0-999.9 s

TIM CNT

CNT

Elapsed time of timer

REG

MON

IN

OUT

0.0 0.0-999.9 s

ALM M

ADDRESS DATA Timer No. Set time of timer

MAIN

TIM

014 0010 C014-C027 0000-9999 min

TIM CNT

CNT

Elapsed time of timer

*1

REG

MON

IN

OUT

0000

ALM M

0000-9999 min

ADDRESS DATA Timer No. Set time of C015

- +

MAIN

TIM

015 0060 C015

or CNT Elapsed time of C015

REG

MON

IN

OUT

0032

ALM M

Fig. 6-1

*1. Each time the TIM CNT key is pressed, the "TIM" LED and "CNT" LED alternately light.

SELFJECTOR Instruction Manual 6-7 Operation Manual 3B

6.3.2.Changing Set Time

Here is an example of procedure to change a set time.

To change the set time of 60 minutes in the preceding section to 180 minutes, for example,

proceed as described below.

Whenever a set time is changed, make sure that the set time is called beforehand by the

procedure described in Section 6.3.1 Calling Set Time.

SET

(REG)

or + ENT

TIM CNT

設定時間増加

To increase the set time

When the control keys are operated in the sequence shown above, the data will be displayed as

shown in Fig. 6-2.

Control Key Display Address Data

Upper stage

Lower stage

ADDRESS DATA Timer No. C015 Set time of C015

SET MAIN

015 0060 Set digit flashes.

TIM

CNT

Elapsed time of C015

REG

MON

IN

OUT

0033

ALM M

ADDRESS DATA Timer No. C015 Set time of C015

MAIN

TIM

015 0060 Set digit flashes.

(REG)

or TIM CNT CNT

Elapsed time of C015

Select digit to

REG

MON

IN

OUT

0033

be set ALM M

ADDRESS DATA Timer No. C015 Set time of C015

+ MAIN

015 0180 Set digit flashes.

TIM

CNT Elapsed time of C015

Keep REG IN

0033

depressed MON OUT

ALM M

ADDRESS DATA Timer No. C015 Set time of C015

MAIN

TIM

015 0180

ENT CNT Elapsed time of C015

REG

MON

IN

OUT

0033

*1 ALM M

Fig. 6-2

*1. Before entering a set time by the ENT key, press the CLR key to restore the original set time.

SELFJECTOR Instruction Manual 6-8 Operation Manual 3B

6.3.3.Monitoring Elapsed Time of Discharge Interval

The elapsed time of discharge interval (C015) can be monitored by pressing the MAIN key of

the operation display panel. If the optional water value display function is provided, the water

content value can also be displayed.

When the power switch of the automatic control panel is set to ON, the "main screen indicating

ordinary operation data" will open.

When it is 23 minutes for example since the start of feeding, if the water content value is 0.1%,

the upper stage will indicate 0023, whereas the lower stage will indicate 0.1.

Control Key Display Address Data

Upper stage

Lower stage

ADDRESS DATA Elapsed time of C015

MAIN MAIN

0023

TIM

CNT

Water content value or

REG

MON

IN

OUT

0.1 blank

ALM M

Fig. 6-3

SELFJECTOR Instruction Manual 6-9 Operation Manual 3B

7.PREPARATIONS FOR OPERATION

7.1.AUTOMATIC CONTROL PANEL

CAUTION

o Refer to Section 6.1 and check to ensure that each of the timers has been set to the proper

value suitable for the actual conditions (type of feed oil, model number of SELFJECTOR,

working water pressure, etc.).

o Pay special heed to the discharge interval timer "C015", as it affects the quantity of sludge to

be accumulated in the bowl of the SELFJECTOR. Make sure that the timer is set to the

proper value suitable for the type of feed oil. (To change the set time, refer to Section 6.)

o For information on the Water Detector Function (WD) of the Multi-Monitor, refer to Section 4

in "Operation Manual 2".

7.2.PURIFIER

CAUTION

o Make sure that the gravity disc for HIDENS is installed in the SELFJECTOR.

o Make sure that the circulation line backpressure valve is fully opened and the shut off valve is

fully closed attached to the SELFJECTOR. (Refer to the figure as following.)

o Make sure position of the switches in the Multi-Monitor (MM) is right. (Water detector selector

dial, Water detection output switch, etc.)

o Make sure the set pressure value of the operating water reducing valve is right.

o About details of the above, refer to Section 3.3, 3.6 and 3.7, 4, 5.5 and so on in "Operation

Manual 2".

Analogue type pressure gauge

Pressure sensor Shut off valve

Circulation line

Circulation line back pressure valve

Heavy liquid connecting piping

SELFJECTOR Instruction Manual 7-1 Operation Manual 3B

8.AUTOMATIC OPERATION

8.1.HIDENS SYSTEM OPERATION

Step 1. Start the SELFJECTOR by using the separately mounted starter.

Step 2. Set the power switch provided on the control panel to "ON".

Step 3. Set the timer and counter in the control panel.

Step 4. The "CONT. SOURCE" pilot lamp will come on.

Check the ammeter of the starter to confirm that the SELFJECTOR has reached the rated

speed. Thereafter, press pushbutton "AUTO. START" provided on the control panel. Pilot

lamp "AUTO. RUNNING" will come on.

Step 5. The timers in the programmable controller provided in the control panel will operate in the

following sequence to perform continuous purifier operation.

(Refer to the attached Section 16 Automatic Operation Flow and Section 17 Timing Chart

as well.)

Interval timer T000 starts operation.

o Solenoid valve SV2 will open to supply the bowl closing water and close the bowl.

T000...When the timer expires,

o Solenoid valve SV2 will close to stop supplying the bowl closing water.

o Solenoid valve SV3 will open to supply replacement water.

o Replacement water timer T002 will start operation.

SELFJECTOR Instruction Manual 8-1 Operation Manual 3B

T002...When the timer expires,

o Solenoid valve SV3 will close to stop supplying replacement water.

o Solenoid valve SV1 will open to supply the bowl opening water and open the bowl.

o Bowl opening water timer T001 will start operation.

T001...When the timer expires,

o Solenoid valve SV1 will close to stop supplying the bowl opening water.

o Solenoid valve SV2 will open to supply the bowl closing water and close the bowl.

o At the same time, interval timer T000 will start operation.

T000...When the timer expires,

o Solenoid valve SV3 will open to supply regulating water.

o Regulating water timer T003 will start operation.

NOTE

In case of the fuel oil purifier, the regulating water does not be supplied.

o At the same time, interval timer T000 will restart operation.

T003...When the timer expires,

o Solenoid valve SV3 will close to stop supplying regulating water.

T000...When the timer expires,

o Solenoid valve SV2 will close to stop supplying the bowl closing water.

o Interval timer T000 will restart operation.

T000...When the timer expires,

(1) Solenoid valve SV4 will open to supply operating air and open the feed valve to

supply the feed oil into the bowl and start purifier operation. At the same time,

discharge interval timer C015 will start operation.

(2) During operation of the discharge interval timer C015, the bowl closing water will be

intermittently supplied.

In other words, the following processes will be repeated: Operation of C014 →

Expiry of C014 → Operation of T016 (opens SV2 to supply bowl closing water) →

Expiry of T016 (closes SV2 to stop supplying bowl closing water) → Operation of

C014.

(3) The "Feeding" signal will be output to the Multi-Monitor.

② ①

SELFJECTOR Instruction Manual 8-2 Operation Manual 3B

② ①

When a water detection signal is received from the Multi-Monitor (when the Monitoring timer

C022 have expired.), or when C015...timer expires,

o Discharge interval timer C015 will be reset.

o Monitoring timer C022 will be reset.

o Solenoid valve SV4 will close to close the feed valve.

o At the same time, interval timer T000 will start operation.

o The "Feeding" signal output to the Multi-Monitor will be stopped.

o The "Discharging" signal will be output to the Multi-Monitor.

T000...when the timer expires,

o Solenoid valve SV3 will open to supply replacement water.

o Replacement water timer T002 will start operation.

o The bowl washing counter C023 is counted one time and is added one time to the

current count.

T002...when the timer expires,

o Solenoid valve SV3 will close to stop supplying replacement water.

o At the same time, solenoid valve SV1 will open to supply the bowl opening water and

open the bowl to discharge sludge.

o Bowl opening water timer T001 will start operation.

T001...when the timer expires,

o Solenoid valve SV1 will close to stop supplying the bowl opening water.

o Solenoid valve SV2 will open to supply the bowl closing water and close the bowl.

o At the same time, interval timer T000 will start operation.

④ ③ ② ①

SELFJECTOR Instruction Manual 8-3 Operation Manual 3B

④ ③ ② ①

T000...when the timer expires, (When the Bowl washing counter C023 have expired.)

o Interval timer T000 will restart operation.

o The "Discharging" signal output to the Multi-Monitor will be stopped.

T000...when the timer expires,

o Solenoid valve SV3 will open to supply the bowl washing water.

o Bowl washing water timer T004 will start operation.

T004...when the timer expires,

o Solenoid valve SV3 will close to stop supplying the bowl washing water.

o At the same time, solenoid valve SV1 will open to supply the bowl opening water

and open the bowl to discharge washing water.

o Solenoid valve SV2 will close to stop supplying the bowl closing water.

o Bowl opening water timer T001 will start operation.

T001...when the timer expires,

o Solenoid valve SV1 will close to stop supplying the bowl opening water.

o Solenoid valve SV2 will open to supply the bowl closing water and close the bowl.

o At the same time, interval timer T000 will start operation.

T000...when the timer expires,

o Solenoid valve SV3 will open to supply regulating water.

o Regulating water timer T003 will start operation.

NOTE

In case of the fuel oil purifier, the regulating water does not be supplied.

o Interval timer T000 will restart operation.

T003...when the timer expires,

o Solenoid valve SV3 will close to stop supplying regulating water.

T000...when the timer expires,

o Solenoid valve SV2 will close to stop supplying the bowl closing water.

o Interval timer T000 will restart operation.

T000...When the timer expires, (When the Bowl washing counter C023 have not

expired.)

o Solenoid valve SV3 will open to supply regulating water.

o Regulating water timer T003 will start operation.

o The "Discharging" signal output to the Multi-Monitor will be stopped.

NOTE

In case of the fuel oil purifier, the regulating water does not be supplied.

o Interval timer T000 will restart operation.

④ ③

SELFJECTOR Instruction Manual 8-4 Operation Manual 3B

④ ③

When a water detection signal is received from the Multi-Monitor, (When the Monitoring

timer C022 have not expired.)

o Operation of discharge interval timer C015 will be stopped temporarily.

(Lapsed time is held.)

o Monitoring timer C022 will be reset.

o Solenoid valve SV4 will close to close the feed valve.

o Interval timer T000 will restart operation.

o The "Feeding" signal output to the Multi-Monitor will be stopped.

o The "Discharging" signal will be output to the Multi-Monitor.

T000...when the timer expires,

o Solenoid valve SV3 will open to supply replacement water.

o Replacement water timer T012 (for partial) will start operation.

T012...when the timer expires,

o Solenoid valve SV3 will close to stop supplying replacement water.

o Solenoid valve SV2 will open to supply bowl closing water.

o Interval timer T000 will restart operation.

T000...when the timer expires,

o Solenoid valve SV9 will open to supply bowl opening water (for partial) to the

bowl and discharge sludge and separated water.

o Opening bowl timer T011 (for partial) will start operation.

T011...when the timer expires,

o Solenoid valve SV9 will close to stop supplying the bowl closing water.

o Solenoid valve SV2 will stay open to supply bowl closing water and close the

bowl.

o Interval timer T000 will start operation.

T000...when the timer expires,

o Solenoid valve SV2 will close to stop supplying bowl opening water.

o The "Discharging" signal will be output to the Multi-Monitor.

o Solenoid valve SV3 will open to supply regulating water.

o Regulating water (for partial discharge) timer T013 will start operation.

T013...when the timer expires,

o Solenoid valve SV3 will close to stop supplying the regulating water.

o Interval timer T000 will start operation.

T000...When the timer expires,

(1) Operation of discharge interval timer C015 will re-started

(2) Monitoring timer C022 will start operation.

(3) During operation of the discharge interval timer C015, the bowl opening water will

be intermittently supplied.

In other words, the following processes will be repeated: Operation of C014 →

Expiry of C014 → Operation of T016 (opens SV2 to supply bowl closing water) →

Expiry of T016 (closes SV2 to stop supplying bowl closing water) → Operation of

C014.

(4) The "Feeding" signal will be output to the Multi-Monitor.

SELFJECTOR Instruction Manual 8-5 Operation Manual 3B

8.2.PURIFIER OPERATION

CAUTION

When SJ10GH to 150GH types are used in the total discharge mode (purifier operation), select

an appropriate gravity disc that fits the specific gravity of feed liquid and install it in position.

Then, fully open the shut off valve and fully close the circulation line backpressure valve. After

that, set the Water Detector selector dial to No working position and the water detection output

switch to OFF position. Operate the SELFJECTOR on that condition. (Refer to Section 6.4.2.4 in

"Operation Manual 1".)

Step 1. Start the SELFJECTOR by the separately mounted starter.

Step 2. Set the power switch provided on the control panel to "ON".

Step 3. Pilot lamp "CONT. SOURCE" will come on.

Step 4. Check the ammeter of the starter to confirm that the SELFJECTOR has reached the rated

speed. Thereafter, press pushbutton "AUTO. START" provided on the control panel. Pilot

lamp "AUTO. RUNNING" will come on.

Step 5. The timers in the programmable controller provided in the control panel will operate in the

following sequence to perform continuous purifier operation.

(Refer to the attached time chart as well.)

Interval timer T000 will start operation.

o Solenoid valve SV2 will open to supply the bowl closing water and close the bowl.

T000...when the timer expires,

o Solenoid valve SV2 will close to stop supplying the bowl closing water.

o Solenoid valve SV3 will open to supply replacement water.

o At the same time, replacement water timer T002 will start operation.

T002...when the timer expires,

o Solenoid valve SV3 will close to stop supplying replacement water.

o At the same time, solenoid valve SV1 will open to supply the bowl opening water and

open the bowl to discharge the replacement water.

o Bowl opening water timer T001 will start operation.

SELFJECTOR Instruction Manual 8-6 Operation Manual 3B

T001...when the timer expires,

o Solenoid valve SV1 will close to stop supplying the bowl opening water.

o Solenoid valve SV2 will open to supply the bowl closing water and close the bowl.

o At the same time, interval timer T000 will start operation.

T000...when the timer expires,

o Solenoid valve SV3 will open to supply sealing water.

o Sealing water time timer T003 will start operation.

o At the same time, interval timer T000 will restart operation.

T000...when the timer expires,

o Solenoid valve SV2 will close to stop supplying the bowl closing water.

T003...when the timer expires,

o Solenoid valve SV3 will close to stop supplying sealing water.

o Interval timer T000 will start operation.

T000...when the timer expires,

(1) Solenoid valve SV4 will open to send the operating air to open the feed valve and

feed the feed oil into the bowl to perform purifier operation. At the same time,

discharge interval timer C015 will start operation.

(2) During operation of the discharge interval timer C015, the bowl opening water will be

intermittently supplied.

In other words, the following processes will be repeated: Operation of C014 →

Expiry of C014 → Operation of T016 (opens SV2 to supply bowl closing water) →

Expiry of T016 (closes SV2 to stop supplying bowl closing water) → Operation of

C014.

(3) The "Feeding" signal will be output to the Multi-Monitor.

② ①

SELFJECTOR Instruction Manual 8-7 Operation Manual 3B

② ①

C015...when the timer expires,

o Discharge interval timer C015 will be reset.

o Solenoid valve SV4 will close to close the feed valve.

o At the same time, interval timer T000 will start operation.

o The "Feeding" signal output to the Multi-Monitor will be stopped.

o The "Discharging" signal will be output to the Multi-Monitor.

T000...when the timer expires,

o Solenoid valve SV3 will open to supply replacement water.

o Replacement water timer T002 will start operation.

o The bowl washing counter C023 is counted one time and is added one time to the

current count.

T002...when the timer expires,

o Solenoid valve SV3 will close to stop supplying the replacement water.

o At the same time, solenoid valve SV1 will open to supply the bowl opening water and

open the bowl to discharge sludge.

o Bowl opening water timer T001 will operate.

T001...when the timer expires,

o Solenoid valve SV1 will close to stop supplying the bowl opening water.

o Solenoid valve SV2 will open to supply the bowl closing water and close the bowl.

o At the same time, interval timer T000 will start operation.

② ③

SELFJECTOR Instruction Manual 8-8 Operation Manual 3B

② ③

T000...when the timer expires, (When the Bowl washing counter C023 have expired.)

o Interval timer T000 will restart operation.

o The "Discharging" signal output to the Multi-Monitor will be stopped.

T000...when the timer expires,

o Solenoid valve SV3 will open to supply the bowl washing water.

o Bowl washing timer T004 will start operation.

T004...when the timer expires,

o Solenoid valve SV3 will close to stop supplying the bowl washing water.

o At the same time, solenoid valve SV1 will open to supply the bowl opening water

and open the bowl to discharge washing water.

o Solenoid valve SV2 will close to stop supplying the bowl closing water.

o Bowl opening water timer T001 will start operation.

T001...when the timer expires,

o Solenoid valve SV1 will close to stop supplying the bowl opening water.

o Solenoid valve SV2 will open to supply the bowl closing water and close the bowl.

o Interval timer T000 will start operation.

T000...when the timer expires,

o Solenoid valve SV3 will open to supply sealing water.

o Sealing water timer T003 will start operation.

o Interval timer T000 will restart operation.

T000...when the timer expires,

o Solenoid valve SV2 will close to stop supplying the bowl closing water.

T003...when the timer expires,

o Solenoid valve SV3 will close to stop supplying sealing water.

o Interval timer T000 will start operation.

T000...When the timer expires, (When the Bowl washing counter C023 have not

expired.)

o Solenoid valve SV3 will open to supply sealing water.

o Sealing water timer T003 will start operation.

o Interval timer T000 will restart operation.

o The "Discharging" signal output to the Multi-Monitor will be stopped.

T000...when the timer expires,

o Solenoid valve SV2 will close to stop supplying the bowl closing water.

SELFJECTOR Instruction Manual 8-9 Operation Manual 3B

8.3.SLUDGE DISCHARGE TEST

8.3.1.SLUDGE DISCHARGE TEST DURING FEEDING OPERATION

During feeding operation, a test can be performed to discharge the sludge from inside the bowl freely at

any time regardless of the elapse of the feed time. Press pushbutton "DISCHG TEST" provided on the

control panel by the following procedures. Then the SELFJECTOR will enter the "Partial Discharge" or

"Total Discharge" process to discharge sludge. After sludge has been discharged, the SELFJECTOR will

continue automatic operation in the original mode.

(1) PARTIAL DISCHARGE

Press the "DISCHG. TEST" pushbutton once.

(2) TOTAL DISCHARGE

Press the "DISCHG. TEST" pushbutton twice in five seconds.

8.3.2.SLUDGE DISCHARGE TEST EXCEPTING SELFJECTOR IS IN AUTOMATIC OPERATION

When the SELFJECTOR is not in automatic operation, pressing the "DISCHG. TEST" pushbutton

provided on the control panel will open the bowl closing water solenoid valve SV2 to supply the working

water to close the bowl. The partial bowl opening water solenoid valve SV9 will then continue to

open for the set time of the partial bowl opening timer T011.

This function is not used to normal operation.

8.4.AUTOMATIC STOP

When pushbutton "AUTO. STOP" provided on the control panel is pressed, the SELFJECTOR will

automatically stop after going through the replacement water process and then discharging sludge.

(During feed operation, the feed oil supply is first stopped.)

8.5.EMERGENCY STOP

CAUTION

When the SELFJECTOR is shut down because of an emergency, discharge failure (no

opening of bowl) or overload, it will stop operation without discharging the sludge

accumulated in the bowl. If the SELFJECTOR is directly restarted, the bowl might lose

balance and cause a hazardous situation. For this reason, be sure to disassemble the

bowl and remove the sludge according to the instruction manual for the SELFJECTOR

proper before restarting operation.

In cases of emergency, press pushbutton "EMERG. STOP" provided on the control panel. In any of

the processes, the power supply to the SELFJECTOR will be interrupted, and all the valves will

close, and the SELFJECTOR will stop operation.

SELFJECTOR Instruction Manual 8-10 Operation Manual 3B

9.ALARMS

9.1.TYPES OF ALARMS

When any of the following alarms occurs, the control panel will cause pilot lamp "ALARM" to light

and will transmit an alarm signal to the remote console.

o "Oil Leakage" alarm,

o "No Opening of Bowl" alarm,

o "Abnormal Water Content" alarm which occurs when the water detection setting counter C027

expires,

When the "ALARM" pilot lamp comes on, the operation display panel on the front of the control

panel will display any of the alarm numbers (ALM. No.) of Table 9-1 as shown in Fig. 9-1.

When the MAIN key is pressed while an alarm number is on display, the "Main Screen" will

reappear.

When pushbutton "ALARM RESET" provided on the control panel is pressed, the screen displayed

before occurrence of an alarm will be restored.

Display Address Data

Upper stage

Lower stage

ADDRESS DATA ALM No.

MAIN

TIM

01

CNT

REG IN Blank

MON OUT

ALM M

Fig. 9-1

Table 9-1

ALM No. Alarm Name

01 OIL LEAKAGE

02 NO OPENING OF BOWL

03 ABNORMAL WATER CONTENT

9.2.ALARM RESET

CAUTION

Remove the cause of an alarm before pressing the "ALARM RESET" pushbutton.

Press pushbutton "ALARM RESET" provided on the control panel to reset the alarm circuit.

SELFJECTOR Instruction Manual 9-1 Operation Manual 3B

10.ALARM AND CORRECTIVE ACTION

10.1."01": OIL LEAKAGE

This alarm will be generated by the Leakage Monitor Function (LM) of the Multi-Monitor when the

light liquid side pressure falls due to outflow of the feed oil or processed oil toward the heavy liquid

side or sludge chute side of the SELFJECTOR during feeding operation. When this alarm occurs,

the SELFJECTOR will automatically stop operation after discharging sludge.

Table 10-1

Alarm Cause of Alarm Corrective Action

OIL 1. The bowl failed to close because of a fault in the 1. Refer to the separate

LEAKAGE SELFJECTOR proper. "Maintenance Manual".

Alarm No. 01

2. The bowl closing water was not supplied because 2. Repair or replace the valve

solenoid valve SV2 failed to open. with a non-defective one.

3. The required sealing water was not supplied 3. Same as above

because solenoid valve SV3 failed to open.

4. The required sealing water was not supplied 4. Adjust the set time of the

because the set time of sealing water timer "T003" timer.

or "T013" was too short.

5. Solenoid valve SV2 or SV3 failed to open because 5. Replace the auxiliary relay

of a defective auxiliary relay in the control panel. with a spare one.

6. Defective Multi-Monitor (MM) 6. Refer to the separate

"Maintenance Manual".

7. Defective water or air system 7. Refer to the separate

"Maintenance Manual".

SELFJECTOR Instruction Manual 10-1 Operation Manual 3B

10.2."02": NO OPENING OF BOWL

This alarm occurs when the Discharge Detector Function (DD) of the Multi-Monitor fails to detect

discharge despite the fact that a DISCHARGE SLUDGE signal was sent to the bowl opening

solenoid valves (SV1, SV9).

When this alarm occurs, the SELFJECTOR will stop operation immediately.

Table 10-2

Alarm Cause of Alarm Corrective Action

NO 1. The bowl failed to open because of a fault in the 1. Refer to the separate

OPENING SELFJECTOR proper. "Maintenance Manual".

OF BOWL

Alarm No. 02 2. The bowl opening water was not supplied because 2. Repair or replace the valve

solenoid valve SV1 or SV9 failed to open. with a non-defective one.

3. Solenoid valve SV1 or SV9 failed to open because 3. Replace the auxiliary relay

of a defective auxiliary relay in the control panel. with a spare one.

4. Defective Multi-Monitor (MM) 4. Refer to the separate

"Maintenance Manual".

5. Defective water or air system 5. Refer to the separate

"Maintenance Manual".

6. The set pressure of the reducing valve was low, so 6. Refer to the separate

that amount of sludge discharge was too less. "Operation Manual2", and

adjust the reducing valve as

required.

10.3."03": ABNORMAL WATER CONTENT ALARM

This alarm occurs when the water detection count is abnormally high.

When the Multi-Monitor detects the water content in the bowl, its water detection signal is input to

the CPU board and a water discharge operation is effected, when the water detection setting

counter (C027) adds one time to the current count. C027 is reset every time the water detection

count reset timer (C026), which is repetitively actuated during automatic operation, expires. If the

water content of the feed oil is abnormally high, water detection is repeated within a short period of

time, C027 counts up to give an abnormal water content alarm signal. When this signal is issued,

the SELFJECTOR is automatically stopped after discharging sludge.

SELFJECTOR Instruction Manual 10-2 Operation Manual 3B

11.MONITORING INPUT AND OUTPUT SIGNALS

Pressing the MON key on the operation display panel will enable you to monitor the input and output

signals such as the ON/OFF status of the solenoid valves.

To monitor the input and output signals, press the control keys of the operation display panel in the

following sequence, and check the displays of the display section before proceeding ahead. For the

details of the displays, refer to Fig. 11-1. For the details of signals, refer to Section 4.3.3 "Functions of

Input/Output Indicating LEDs".

Operating Procedures for Monitoring Input and Output Signals

入出力信号モニタの操作手順

MAIN MON MON MON - or +

1~3回押す

Press MON one to three times. 入出力番号を選択

入力信号のモニタは(I)は、IN

To を選択

monitor input signal, select IN for (I).

出力信号のモニタは(Q)は、OUTを選択

To monitor output signal, select OUT for (Q).

内部信号のモニタは(M)は、M

To を選択

monitor internal signal, select M for (M).

③ 33210

2 1 0 No. (I/Q/M)

ADDRESS DATA

MAIN

TIM

000 8___

CNT ④

REG IN

MON OUT

ALM M

No. (I/Q/M)

① ② 77654

6 5 4

No. Details of Display

① Stays ON during monitoring of I/O signal.

② Indicates the type of signal being monitored.

IN: Input signal (I)

OUT: Output signal (Q)

M: Internal signal (M)

Each time the MON key of the operation display panel is pressed, the signal

types change as shown below.

IN → OUT → M → IN → OUT →・・・・

③ Indicates the number of the signal being monitored.

Example of display

o Indicates "000" when any of the signal Nos. 0-7 is being monitored.

o Indicates "010" when any of the signal Nos. 10-17 is being monitored.

④ Indicates the ON/OFF status of signal.

ON :"8" indicated

OFF:" " (blank) indicated

Fig. 11-1

SELFJECTOR Instruction Manual 11-1 Operation Manual 3B

12.MAINTENANCE

12.1."AUTO. RUNNING" LAMP NOT ILLUMINATED

Pilot lamp "AUTO. RUNNING" on the front of the control panel will normally stay ON during

automatic operation.

If the "AUTO. RUNNING" pilot lamp is OFF, the following three causes are suspected.

(1) Defective pilot lamp bulb

(2) Defective relay

(3) Blown fuse

(4) Defective programmable controller itself

In the case of cause (1) or (2), replace with a spare one.

In the case of cause (3) or (4), all of the solenoid valves and pneumatically operated valves will

close, and the automatic operation functions will stop.

(The SELFJECTOR, however, will continue to rotate.)

Check to locate the cause and take corrective action in the sequence shown on the following page.

If there is nothing wrong with the control functions of the programmable controller, pilot lamp "RUN"

provided on the CPU board will always be ON during operation.

SELFJECTOR Instruction Manual 12-1 Operation Manual 3B

Set the power switch of the

Note 1) In the case of mark *, contact

control panel to "ON".

Mitsubishi Kakoki, or your nearest

Mitsubishi Kakoki service agent.

The "CONT. SOURCE" OFF

pilot lamp on the front of

the control panel is Set the power switch on the front of the

control panel to "OFF" and then replace

ON the power fuse in the panel with a spare

one.

Check the operation

indicating LED on the CPU

board.

ON

Pilot lamp "RUN" is

*

In this case, temporarily set the power

OFF Input signal LED "I7" ON switch on the front of the control panel to

is "OFF" and then to "ON" again. If the

same situation persists, automatic

operation can no longer be performed.

ON

Pilot lamp "CPU" is

OFF

OFF

Temporarily set the mode Check whether the

selector switch of the CPU motor operation in

board to "RUN" and then to progress signal output

"TERM" again to check from the starter is

whether pilot lamp "RUN" available.

lights.

Lights Available

Motor operation in

progress signal is

Pilot lamp "RUN"

Temporarily bridge the

Unavailable

Does not light. external terminals "M11"

* and "M12" to check whether

A defective CPU board is Check the starter. LED "I7" on the CPU board

suspected. lights.

Does not light.

LED "I7"

Light

*

Check the external wiring A defective CPU

between the starter and board is suspected.

automatic control panel.

SELFJECTOR Instruction Manual 12-2 Operation Manual 3B

12.2.INDICATION OF OPERATION DISPLAY PANEL ERROR

If a trouble occurs in the operation display panel, an error number will appear in the address

indicating section.

If an error number is on display, perform checks according to the following table.

Error No. Cause Check Point

E10 The power supply to the CPU board Check whether the "PWR" LED on the CPU board is

is unavailable. ON.

The communications cable is Check the connections of the communications cable.

open-circuited or improperly Replace the communications cable.

connected.

E11, E90 The CPU board is incorrectly set or Contact Mitsubishi Kakoki or your nearest Mitsubishi

defective. Kakoki service agent.

E20-E26 The communications cable is Check the connections of the communications cable.

E31, E80 open-circuited or improperly Replace the communications cable.

connected.

E30 The mode selector switch on the Set the mode selector switch to "TERM".

CPU board is placed at "RUN"

position.

NOTE

Error No. "E10" will appear for a while after the power supply to the automatic control

panel has been turned on. This is not an error.

CAUTION

When you check or replace the CPU board and/or communications cables, use care to

prevent electrical shock.

SELFJECTOR Instruction Manual 12-3 Operation Manual 3B

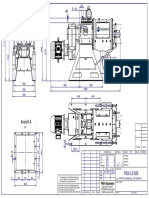

13.AUTOMATIC OPERATION FLOW DIAGRAM

Automatic Electric

Starter Power source

(GSH-1) Control panel

SV4 5

S

3 P SV3 SV2 SV1 SV9

R4 S S S S

9

CV1 4

WD

1

C

OIL HEATER

7 10

LM

6 12

E MM

13

B 2

M

A DD 8

11

P

C

MKK SUPPLY

F D

Fig. 17-1

1 SELFJECTOR A Dirty oil inlet

2 Gear pump B Purified oil outlet

3 Solenoid valves unit for operating water C Compressed air inlet

SV1: Solenoid valve (for Bowl opening water)

SV2: Solenoid valve (for Bowl closing water)

SV3: Solenoid valve (for Sealing water)

SV9: Solenoid valve (for Partial bowl opening water)

4 3-way cylinder valve (Feed valve) D Sludge & Water outlet

5 3-way solenoid valve (SV4: for Feed valve air supply) E Water inlet

6 Multi-Monitor F Drain

7 Leakage Monitor function (LM) G Circulation

8 Discharge detector function (DD) P Pressure gauge

9 Water detector function (WD) C Compound gauge

10 Oil heater M Motor

11 Oil strainer

12 Flow control valve

13 Pressure control valve (Needle valve)

SELFJECTOR Instruction Manual 13-1 Operation Manual 3B

14.TIMING CHART

14.1.HIDENS OPERATION

14.1.1.HIDENS Operation (Automatic Operation, Automatic Stopping)

SELFJECTOR Instruction Manual Operation Manual 3B

14.1.2.HIDENS Operation (Bowl Washing)

SELFJECTOR Instruction Manual Operation Manual 3B

14.1.3.HIDENS Operation (Alarm)

SELFJECTOR Instruction Manual Operation Manual 3B

14.2.PURIFIER OPERATION

14.2.1.Purifier Operation (Automatic Operation, Automatic Stopping)

SELFJECTOR Instruction Manual Operation Manual 3B

SELFJECTOR Instruction Manual Operation Manual 3B

APPENDIX (SJ-G Series)

The appended drawing to this manual contains all of the optional detectors and circuits, some of which

may not be provided or used, depending on the specification for the SELFJECTOR you have purchased.

Refer to the drawing in the finished drawing as well.

SELFJECTOR Instruction Manual Operation Manual 3B

SELFJECTOR Instruction Manual

You might also like

- Operation Manual 3A E-0309Document71 pagesOperation Manual 3A E-0309jjgonzalezquinaNo ratings yet

- Genius-Series - Operation Manual 3a - Gie-0309-Om3a - Scan1Document71 pagesGenius-Series - Operation Manual 3a - Gie-0309-Om3a - Scan1Centrifugal Separator0% (1)

- MH - 3 Instruction Manual (Operation Manual 1)Document71 pagesMH - 3 Instruction Manual (Operation Manual 1)alin_popovici_12No ratings yet

- SJ-GENUIE-SERIES Compressed 2 PDFDocument444 pagesSJ-GENUIE-SERIES Compressed 2 PDFZawYeLinNo ratings yet

- Operation Manual 1 SamgongDocument60 pagesOperation Manual 1 SamgongMustafa GözütokNo ratings yet

- MF-114 Operation Manual 2 PDFDocument134 pagesMF-114 Operation Manual 2 PDFThanh Nghị BùiNo ratings yet

- 8M-003 Operation Manual For Purifier (SJ80F, SJ40F)Document291 pages8M-003 Operation Manual For Purifier (SJ80F, SJ40F)Leonid KolesnikovNo ratings yet

- SJ-H Series OM3 (In English) - PLCDocument58 pagesSJ-H Series OM3 (In English) - PLCTapajyoti Giri100% (1)

- m10-3 Oil Purifier Operation Manual 3aDocument76 pagesm10-3 Oil Purifier Operation Manual 3aDavid BogdanNo ratings yet

- Operation Manual 2-SamgongDocument121 pagesOperation Manual 2-SamgongДима КулаваNo ratings yet

- Operation & Maintenance ManualDocument222 pagesOperation & Maintenance ManualTammy Jim Tanjutco100% (2)

- Alfa Laval Manual 2Document58 pagesAlfa Laval Manual 2Rajiv RanjanNo ratings yet

- Mopx Parameter ListDocument30 pagesMopx Parameter ListAL KUSCUNo ratings yet

- AD-0376-C C20 - Alarm and Montoring System - OperationDocument243 pagesAD-0376-C C20 - Alarm and Montoring System - OperationGaurav Kumar100% (1)

- Epc 41 Control UnitDocument26 pagesEpc 41 Control UnitEser67% (3)

- ALFA LAVAL EPC41 Component DescriptionDocument26 pagesALFA LAVAL EPC41 Component DescriptionMery A. Dominguez100% (10)

- Alfa Laval Separartor s937 Operating InstructionsDocument56 pagesAlfa Laval Separartor s937 Operating InstructionsIgors VrublevskisNo ratings yet

- SA 836 - Separation System - Installation - 2005Document51 pagesSA 836 - Separation System - Installation - 2005Centrifugal SeparatorNo ratings yet

- 蒸汽调节阀Document26 pages蒸汽调节阀陈浩祥100% (1)

- Sauter Valve 1763170steam Reg. ValveDocument24 pagesSauter Valve 1763170steam Reg. ValveSergei GovorkoNo ratings yet

- Alfa Laval PA 605 Installation ReferenceDocument50 pagesAlfa Laval PA 605 Installation ReferenceS.Reza Maleki0% (1)

- 03Document47 pages03LekembauerNo ratings yet

- FWG - JWSP-26-C100 - N-012053Document32 pagesFWG - JWSP-26-C100 - N-012053sridharNo ratings yet

- Parameter ListDocument22 pagesParameter ListRoger Andres Ordoñez100% (2)

- Pleiger Control Loop: User's Manual V1.30Document26 pagesPleiger Control Loop: User's Manual V1.30Pamella100% (1)

- GEA Westfalia OSD 6 91 067 Parts ListDocument2 pagesGEA Westfalia OSD 6 91 067 Parts ListVaggelis MexisNo ratings yet

- Instruction X338771enDocument904 pagesInstruction X338771endionpanag100% (3)

- 01810821Document92 pages01810821Prihanto Edy HermawanNo ratings yet

- User's Manual For REMIND EPC 50Document50 pagesUser's Manual For REMIND EPC 50Power Flower100% (4)

- Technical Manual OPTOIO - 16/32: Integrated Management System IMS I/O Module OPTOIO-32Document16 pagesTechnical Manual OPTOIO - 16/32: Integrated Management System IMS I/O Module OPTOIO-32徐玉坤No ratings yet

- 3 Operation InstructionDocument22 pages3 Operation Instructioncengiz kutukcuNo ratings yet

- MH - 6 Maintenance Manual For SelfejectorDocument98 pagesMH - 6 Maintenance Manual For Selfejectoralin_popovici_12No ratings yet

- Service Manual Pu100Document146 pagesService Manual Pu100Dito Aprian100% (3)

- Service Manual: Separation Unit 841Document160 pagesService Manual: Separation Unit 841alex_alexutzuu100% (1)

- Mopx Parameter ListDocument28 pagesMopx Parameter ListEser100% (2)

- 2.5-4 Remote Control System Geamot 40m For Diesel EnginesDocument1,124 pages2.5-4 Remote Control System Geamot 40m For Diesel EnginesJorge Arimana100% (1)

- Spare Parts Catalogue: Separation Unit 841Document90 pagesSpare Parts Catalogue: Separation Unit 841alex_alexutzuuNo ratings yet

- PU 150 - Separation System - Parts - 2006Document60 pagesPU 150 - Separation System - Parts - 2006Centrifugal Separator100% (2)