Professional Documents

Culture Documents

A. Site Quality Plans

A. Site Quality Plans

Uploaded by

Alleo MarquezCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A. Site Quality Plans

A. Site Quality Plans

Uploaded by

Alleo MarquezCopyright:

Available Formats

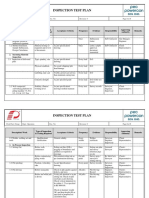

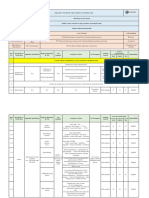

FIELD QUALITY PLAN FOR PUMPS AND MOTORS.

Category Frequency of Agencies Involved

Sl.No Characteristics / items Type of check Instrument Reference documents Acceptance criteria Format or records

of check check P W H

Transportation documents, Completeness and correctness of

1.1 Material Receipt Verification Major Visual Nil 100% Material Dispatch Clearence supply,free fromdamages,verification of JVR E E

Certificate./packing list identification marks.

Storage manual, No Quality detoriaration,

1.2 Material storage and preservation. Major Visual Nil Random JVR E E

Manufacturer’s Instructions Preservation measures are intact

List of documents and

2.1 Availability of the followings Major Verification Nil 100% Master document list Availability,correctness and completeness S E

availability ststus.

2.1.1 1. WPS

2.1.2 2. Field welding schedules

2.1.3 3. Drawings

2.1.4 4. Manuf. Erection guidelines

PQR Test ( only if qualified welding procedure is not To qualify the

2.2 Critical Mechanical Test Lab Test Standard WPS/ASME Sec IX. ASME Sec IX. PQR Test records S EF

available) WPS

Welder Qualification record

2.3 Welder Qualification Test Critical RT/Mechanical test Lab Test 100% Standard WPS/ASME Sec IX. ASME Sec IX. S EF

and welder's ID.

2.4 Erection marking before release for erection. Major Visual Nil 100% Tech specification/Drawings Tech specification/Drawings ITSR S E

Outer and inner surfaces to be free from

2.5 Check for cleanliness of equp/pipe before erection. Major Verification Nil 100% Nil ITSR S E

dust and sticking dirts.

2.6 Readiness of all safety aspects before erection. Major Verification Nil 100% Safety guidelines/manual Safety guidelines/manual Safety check list. S E

2.7 Front release Critical Measurements Water level,tape,dumpy level 100% Tech specification/Drawings Tech specification/Drawings Front release report. S EF

2.8 Check that surface is clean and dressed Major Visual Nil 100% Tech specification/Drawings Tech specification/Drawings Front release report. S E

3.1 Check tht the dimention,oriantation is as per drawing. Major Measurements Water level,tape,dumpy level 100% Tech specification/Drawings Tech specification/Drawings Front release report. S E

3.2 Check centre line marking on foundation Major Measurements Water level,tape,dumpy level 100% Tech specification/Drawings Tech specification/Drawings Front release report. S E

Check bolt holes and pocket straightness and

3.3 Major Visual/Mesurement Water level,tape,dumpy level 100% Tech specification/Drawings Tech specification/Drawings Front release report. S E

cleanliness.

3.4 Check depth of sump Major Visual/Mesurement Water level,tape,dumpy level 100% Tech specification/Drawings Tech specification/Drawings Front release report. S E

check adequate distance between wall and centre of

3.5 Major Visual/Mesurement Water level,tape,dumpy level 100% Tech specification/Drawings Tech specification/Drawings Front release report. S E

pumps.

Intial/rough leveling,orientation and alingment of all Water level,tape,dumpy level,Feeler

3.6 Critical Measurements 100% Tech specification/Drawings Tech specification/Drawings Alingment report S EF

equipment gauge,dial gauge

3.7 Setting of foundation bolts Critical Visual/Mesurement Water level,tape,dumpy level 100% Tech specification/Drawings Tech specification/Drawings Grouting release reports S EF

3.8 Check filling condition of mortar Critical Visual Nil 100% Tech specification/Drawings Tech specification/Drawings Grouting release reports S EF

3.9 Grouting Critical Visual/Mesurement Water level,tape,dumpy level 100% Tech specification/Drawings Tech specification/Drawings Grouting release reports S EF

Water level,tape,dumpy level,Feeler

4.1 Mounting of coupling hubs on all equpment shafts. Major Measurements 100% Tech specification/Drawings Tech specification/Drawings Alingment report S E

gauge,dial gauge

Water level,tape,dumpy level,Feeler

4.2 Coupling of pump and motor Critical Measurements 100% Tech specification/Drawings Tech specification/Drawings Alingment report S EF

gauge,dial gauge

Water level,tape,dumpy level,Feeler

4.3 Coupling gap Major Measurements 100% Tech specification/Drawings Tech specification/Drawings Alingment report S E

gauge,dial gauge

4.4 Final grouting of base frame Critical Visual/Mesurement Water level,tape,dumpy level 100% Tech specification/Drawings Tech specification/Drawings Grouting release reports S EF

Water level,tape,dumpy level,Feeler

4.5 Final coupling alignment without piping. Critical Measurements 100% Tech specification/Drawings Tech specification/Drawings Alingment report S EF

gauge,dial gauge

Tur 02 ALSTOM Confidential Page 1

Water level,tape,dumpy level,Feeler

4.6 Final coupling alignment with piping. Critical Measurements 100% Tech specification/Drawings Tech specification/Drawings Alingment report S EF

gauge,dial gauge

4.7 Fit up inspection Major Measurements Weld gauge/Template Random WPS/Drawing WPS/Drawing Fit Up inspection report S E

4.8 Dimention and alingment of piping Major Measurements Water level,tape,dumpy level 100% Tech specification/Drawings Tech specification/Drawings Pipe alingment report S E

4.9 Final weld inspection Major Measurements Weld gauge/Template Random WPS/Drawing WPS/Drawing/ASME/ANSI/API/AWS/DIN/IBR/IS/BS S E

Check lift of pump rotor Water level,tape,dumpy level,Feeler

5.1 Major Measurements 100% Tech specification/Drawings Tech specification/Drawings Alingment report S E

only for vertiical pumps gauge,dial gauge

Water level,tape,dumpy level,Feeler

5.2 Rotation check for pump coupled with motor Major Measurements 100% Tech specification/Drawings Tech specification/Drawings Alingment report S E

gauge,dial gauge

6.1 Final Inspection Critical Verification NIL 100% Tech specification/Drawings Tech specification/Drawings Check list S EF

Coat meter or

7.1 Painting thikness and shade Major Measurements Random Tech specification/Drawings Tech specification/Drawings Painting report S E

Elcometer

7.1 Verification of quality records for completeness Critical Verification NIL 100% Field quality plan Field quality plan ITSR S EF

Note: Abbreviations: P - Performed by, W - Witnessed by, H-Witness by customer, S – Avlon Supervisor, E – Avlon Engineer, F – Avlon Manager, C – Customer

Tur 02 ALSTOM Confidential Page 2

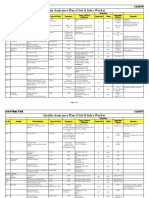

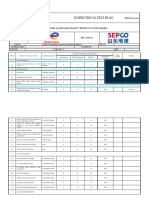

FIELD QUALITY PLAN FOR EOT CRANES.

Category Type of Frequency of Agencies Involved

Sl.No Characteristics / items Instrument Reference documents Acceptance criteria Format or records

of check check check P W H

Transportation documents, Completeness and correctness of

1.1 Material Receipt Verification Major Visual Nil 100% Material Dispatch Clearence supply,free fromdamages,verification of JVR E E

Certificate./packing list identification marks.

Storage manual, No Quality detoriaration,

1.2 Material storage and preservation. Major Visual Nil Random JVR E E

Manufacturer’s Instructions Preservation measures are intact

List of documents and

2.1 Availability of the followings Major Verification Nil 100% Master document list Availability,correctness and completeness S E

availability ststus.

2.1.1 1. WPS

2.1.2 2. Field welding schedules

2.1.3 3. Drawings

2.1.4 4. Manuf. Erection guidelines

PQR Test ( only if qualified welding procedure is Mechanical To qualify the

2.2 Critical Lab Test Standard WPS/ASME Sec IX. ASME Sec IX. PQR Test records S EF

not available) Test WPS

RT/Mechanic Welder Qualification record

2.3 Welder Qualification Test Critical Lab Test 100% Standard WPS/ASME Sec IX. ASME Sec IX. S EF

al test and welder's ID.

2.4 Erection marking before release for erection. Major Visual Nil 100% Tech specification/Drawings Tech specification/Drawings ITSR S E

Check for cleanliness of EOT equpments before Outer and inner surfaces to be free from

2.5 Major Verification Nil 100% Nil ITSR S E

erection. dust and sticking dirts.

Pre assembly level,straightness,diagonal,bolt Measurement Water level,tape,torque

2.6 Major 100% Tech specification/Drawings Tech specification/Drawings SIR S E

tightness. s wrench.

2.7 Readiness of all safety aspects before erection. Major Verification Nil 100% Safety guidelines/manual Safety guidelines/manual Safety check list. S E

Measurement Water level,tape,dumpy

2.8 Front release Critical 100% Tech specification/Drawings Tech specification/Drawings Front release report. S EF

s level

Measurement

3.1 Fit up inspection Major Weld gauge/Template Random WPS/Drawing WPS/Drawing Fit Up inspection report S E

s

Measurement

3.2 Final weld inspection Major Weld gauge/Template Random WPS/Drawing WPS/Drawing/ASME/ANSI/API/AWS/DIN/IBR/IS/BS WISR S E

s

Gantry rails

Visual/Mesur Water level,tape,dumpy

4.1 straightness Major 100% Tech specification/Drawings Tech specification/Drawings EOT inspection report S E

ement level

Visual/Mesur Water level,tape,dumpy

4.2 level of rail top Major 100% Tech specification/Drawings Tech specification/Drawings EOT inspection report S E

ement level

Visual/Mesur Water level,tape,dumpy

4.3 span Major 100% Tech specification/Drawings Tech specification/Drawings EOT inspection report S E

ement level

Visual/Mesur Water level,tape,dumpy

4.4 rail fixing Major 100% Tech specification/Drawings Tech specification/Drawings EOT inspection report S E

ement level

Visual/Mesur Water level,tape,dumpy

4.5 difference in height between rails. Major 100% Tech specification/Drawings Tech specification/Drawings EOT inspection report S E

ement level

Girders and end carriage

5.1 check for LT wheel free movement on gantry rail. Major Visual NIL 100% Tech specification/Drawings Tech specification/Drawings ITSR S E

Crab assembly

check for clearance of trolley track gauge with

6.1 respect to trolly wheel gauge and free movement Major Visual NIL 100% Tech specification/Drawings Tech specification/Drawings ITSR S E

of trolly on girders.

DSL erection

Visual/Mesur Water level,tape,dumpy

7.1 straightness Major 100% Tech specification/Drawings Tech specification/Drawings EOT inspection report S E

ement level

Tur 03 ALSTOM Confidential Page 3

Visual/Mesur Water level,tape,dumpy

7.2 level Major 100% Tech specification/Drawings Tech specification/Drawings EOT inspection report S E

ement level

Visual/Mesur Water level,tape,dumpy

7.3 location with respect to gantry rails. Major 100% Tech specification/Drawings Tech specification/Drawings EOT inspection report S E

ement level

Measurement

7.4 Insulation test Major Megger 100% Tech specification/Drawings Tech specification/Drawings EOT inspection report S E

s

Measurement

7.5 Brake test and deflection load Critical NIL 100% Tech specification/Drawings Tech specification/Drawings EOT inspection report S EF

s

Measurement

7.6 Performance test Critical NIL 100% Tech specification/Drawings Tech specification/Drawings EOT inspection report S EF

s

Up and down creep movement of main hoist ,aux Measurement

7.7 Critical NIL 100% Tech specification/Drawings Tech specification/Drawings EOT inspection report S EF

hoist,traverses. s

Safe travel with full load( long travel and cross Measurement

7.8 Critical NIL 100% Tech specification/Drawings Tech specification/Drawings EOT inspection report S EF

travel ) s

Measurement

7.9 Abnormal sound or vibration Critical NIL 100% Tech specification/Drawings No abnormal sound or vibration during test ITSR S EF

s

8.1 Final Inspection Critical Verification NIL 100% Tech specification/Drawings Tech specification/Drawings Check list S EF

Measurement Coat meter or

9.1 Painting thikness and shade Major Random Tech specification/Drawings Tech specification/Drawings Painting report S E

s Elcometer

10 Verification of quality records for completeness Critical Verification NIL 100% Field quality plan Field quality plan ITSR S EF

Note: Abbreviations: P - Performed by, W - Witnessed by, H-Witness by customer, S – Avlon Supervisor, E – Avlon Engineer, F – Avlon Manager, C – Customer

Tur 03 ALSTOM Confidential Page 4

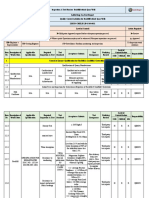

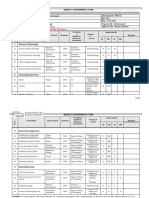

FIELD QUALITY PLAN FOR FEED WATER STORAGE TANK AND DEARATOR.

Category Type of Frequency of Agencies Involved

Sl.No Characteristics / items Instrument Reference documents Acceptance criteria Format or records

of check check check P W H

Transportation documents, Completeness and correctness of

1.1 Material Receipt Verification Major Visual Nil 100% Material Dispatch Clearence supply,free fromdamages,verification of JVR E E

Certificate./packing list identification marks.

Storage manual, No Quality detoriaration,

1.2 Material storage and preservation. Major Visual Nil Random JVR E E

Manufacturer’s Instructions Preservation measures are intact

List of documents and

2.1 Availability of the followings Major Verification Nil 100% Master document list Availability,correctness and completeness S E

availability ststus.

2.1.1 1. WPS

2.1.2 2. Field welding schedules

2.1.3 3. Drawings

2.1.4 4. Manuf. Erection guidelines

PQR Test ( only if qualified welding procedure is Mechanical To qualify the

2.2 Critical Lab Test Standard WPS/ASME Sec IX. ASME Sec IX. PQR Test records S EF

not available) Test WPS

RT/Mechanic

2.3 Welder Qualification Test Critical Lab Test 100% Standard WPS/ASME Sec IX. ASME Sec IX. Welder Qualification record and welder's

S EFID.

al test

2.4 Erection marking before release for erection. Major Visual Nil 100% Tech specification/Drawings Tech specification/Drawings ITSR S E

Outer and inner surfaces to be free from

2.5 Check for cleanliness of equp/pipe before erection. Major Verification Nil 100% Nil ITSR S E

dust and sticking dirts.

Pre assembly level,straightness,diagonal,bolt Measurement Water level,tape,torque

2.6 Major 100% Tech specification/Drawings Tech specification/Drawings SIR S E

tightness. s wrench.

2.7 Readiness of all safety aspects before erection. Major Verification Nil 100% Safety guidelines/manual Safety guidelines/manual Safety check list. S E

Measurement Water level,tape,dumpy

2.8 Front release Critical 100% Tech specification/Drawings Tech specification/Drawings Front release report. S EF

s level

3.1 Check that surface is clean and dressed Major Visual Nil 100% Tech specification/Drawings Tech specification/Drawings Front release report. S E

Check tht the dimention,oriantation is as per Measurement Water level,tape,dumpy

3.2 Major 100% Tech specification/Drawings Tech specification/Drawings Front release report. S E

drawing. s level

Measurement Water level,tape,dumpy

3.3 Check centre line marking on foundation Major 100% Tech specification/Drawings Tech specification/Drawings Front release report. S E

s level

Knock Down Condition:

Measurement

4.1 Dimention and levelling Major Water level,tape 100% Tech specification/Drawings Tech specification/Drawings SIR S E

s

4.2 Develop welding sequence Critical Visual Nil 100% Tech specification/Drawings Tech specification/Drawings WISR S EF

Measurement

4.3 Fit up inspection Major Weld gauge/Template Random WPS/Drawing WPS/Drawing Fit Up inspection report S E

s

Every day

Backing oven with temp

4.4 Check for the baking of electrodes (if applicable) Major Verification before start of WPS/Electrode manufatures recomandations

WPS/Electrode manufatures recomandations Backing registar S E

recorder

welding

Measurement Thermal chalk /thermo

4.5 Pre Heating Major As per WPS WPS WPS Heat treatment chart S E

s couple

4.6 Weld root penetration Minor Visual NIL 100% WPS/Drawing WPS/Drawing WISR S S

4.7 Inter pass cleaning Minor Visual NIL 100% WPS/Drawing WPS/Drawing WISR S S

Measurement Thermal chalk /thermo

4.8 Inter pass temperature Minor As per WPS WPS WPS Heat treatment chart S S

s couple

Measurement

4.9 Final weld inspection Major Weld gauge/Template Random WPS/Drawing WPS/Drawing/ASME/ANSI/API/AWS/DIN/IBR/IS/BS WISR S E

s

5.1 Check installation of all internals Major Visual Nil 100% Tech specification/Drawings Tech specification/Drawings SIR S E

Tur 04 ALSTOM Confidential Page 5

6.1 Cleaneness of dearator heaters Major Visual Nil 100% Tech specification/Drawings Tech specification/Drawings SIR S E

7.1 Check free sliding of base plate. Major Visual NIL 100% Tech specification/Drawings Tech specification/Drawings ITSR S E

Measurement

8.1 Welding dearator with FWST Major Weld gauge/Template Random WPS/Drawing WPS/Drawing/ASME/ANSI/API/AWS/DIN/IBR/IS/BS WISR S E

s

Measurement

8.2 NDT on welding Critical NDT report S EF

s

9.1 Final Inspection Critical Verification NIL 100% Tech specification/Drawings Tech specification/Drawings Check list S EF

Measurement Coat meter or

10.1 Painting thikness and shade Major Random Tech specification/Drawings Tech specification/Drawings Painting report S E

s Elcometer

11 Verification of quality records for completeness Critical Verification NIL 100% Field quality plan Field quality plan ITSR S EF

Note: Abbreviations: P - Performed by, W - Witnessed by, H-Witness by customer, S – Avlon Supervisor, E – Avlon Engineer, F – Avlon Manager, C – Customer

Tur 04 ALSTOM Confidential Page 6

FIELD QUALITY PLAN FOR HP / LP HEATERS.

Category Type of Frequency of Agencies Involved

Sl.No Characteristics / items Instrument Reference documents Acceptance criteria Format or records

of check check check P W H

Transportation documents, Completeness and correctness of

1.1 Material Receipt Verification Major Visual Nil 100% Material Dispatch Clearence supply,free fromdamages,verification of JVR E E

Certificate./packing list identification marks.

Storage manual, No Quality detoriaration,

1.2 Material storage and preservation. Major Visual Nil Random JVR E E

Manufacturer’s Instructions Preservation measures are intact

List of documents and

2.1 Availability of the followings Major Verification Nil 100% Master document list Availability,correctness and completeness S E

availability ststus.

2.1.1 1. WPS

2.1.2 2. Field welding schedules

2.1.3 3. Drawings

2.1.4 4. Manuf. Erection guidelines

PQR Test ( only if qualified welding procedure is Mechanical To qualify the

2.2 Critical Lab Test Standard WPS/ASME Sec IX. ASME Sec IX. PQR Test records S EF

not available) Test WPS

RT/Mechanic

2.3 Welder Qualification Test Critical Lab Test 100% Standard WPS/ASME Sec IX. ASME Sec IX. Welder Qualification record and welder's

S EFID.

al test

2.4 Erection marking before release for erection. Major Visual Nil 100% Tech specification/Drawings Tech specification/Drawings ITSR S E

Outer and inner surfaces to be free from

2.5 Check for cleanliness of Heaters before erection. Major Verification Nil 100% Nil ITSR S E

dust and sticking dirts.

2.6 Readiness of all safety aspects before erection. Major Verification Nil 100% Safety guidelines/manual Safety guidelines/manual Safety check list. S E

Measurement Water level,tape,dumpy

2.7 Front release Critical 100% Tech specification/Drawings Tech specification/Drawings Front release report. S EF

s level

3.1 Check that surface is clean and dressed Major Visual Nil 100% Tech specification/Drawings Tech specification/Drawings Front release report. S E

Check tht the dimention,oriantation is as per Measurement Water level,tape,dumpy

3.2 Major 100% Tech specification/Drawings Tech specification/Drawings Front release report. S E

drawing. s level

Measurement Water level,tape,dumpy

3.3 Check centre line marking on foundation Major 100% Tech specification/Drawings Tech specification/Drawings Front release report. S E

s level

Measurement

3.4 Dimention and levelling Major Water level,tape 100% Tech specification/Drawings Tech specification/Drawings SIR S E

s

3.5 Develop welding sequence Critical Visual Nil 100% Tech specification/Drawings Tech specification/Drawings WISR S EF

3.6 Check free sliding of base plate. Major Visual NIL 100% Tech specification/Drawings Tech specification/Drawings ITSR S E

Measurement

3.7 Fit up inspection Major Weld gauge/Template Random WPS/Drawing WPS/Drawing Fit Up inspection report S E

s

Measurement

3.8 Final weld inspection Major Weld gauge/Template Random WPS/Drawing WPS/Drawing/ASME/ANSI/API/AWS/DIN/IBR/IS/BS WISR S E

s

Measurement

3.9 NDT on welding Critical NDT report S EF

s

4.1 Final Inspection Critical Verification NIL 100% Tech specification/Drawings Tech specification/Drawings Check list S EF

5 Verification of quality records for completeness Critical Verification NIL 100% Field quality plan Field quality plan ITSR S EF

Note: Abbreviations: P - Performed by, W - Witnessed by, H-Witness by customer, S – Avlon Supervisor, E – Avlon Engineer, F – Avlon Manager, C – Customer

Tur 05 ALSTOM Confidential Page 7

FIELD QUALITY PLAN FOR CONDENSER.

Category Type of Frequency of Agencies Involved

Sl.No Characteristics / items Instrument Reference documents Acceptance criteria Format or records

of check check check P W H

Transportation documents, Completeness and correctness of

1.1 Material Receipt Verification Major Visual Nil 100% Material Dispatch Clearence supply,free fromdamages,verification of JVR E E

Certificate./packing list identification marks.

Storage manual, No Quality detoriaration,

1.2 Material storage and preservation. Major Visual Nil Random JVR E E

Manufacturer’s Instructions Preservation measures are intact

List of documents and

2.1 Availability of the followings Major Verification Nil 100% Master document list Availability,correctness and completeness S E

availability ststus.

2.1.1 1. WPS

2.1.2 2. Field welding schedules

2.1.3 3. Drawings

2.1.4 4. Manuf. Erection guidelines

PQR Test ( only if qualified welding procedure is Mechanical To qualify the

2.2 Critical Lab Test Standard WPS/ASME Sec IX. ASME Sec IX. PQR Test records S EF

not available) Test WPS

RT/Mechanic

2.3 Welder Qualification Test Critical Lab Test 100% Standard WPS/ASME Sec IX. ASME Sec IX. Welder Qualification record and welder's

S EFID.

al test

2.4 Erection marking before release for erection. Major Visual Nil 100% Tech specification/Drawings Tech specification/Drawings ITSR S E

Outer and inner surfaces to be free from

2.5 Check for cleanliness of equp/pipe before erection. Major Verification Nil 100% Nil ITSR S E

dust and sticking dirts.

Pre assembly level,straightness,diagonal,bolt Measurement Water level,tape,torque

2.6 Major 100% Tech specification/Drawings Tech specification/Drawings SIR S E

tightness. s wrench.

2.7 Readiness of all safety aspects before erection. Major Verification Nil 100% Safety guidelines/manual Safety guidelines/manual Safety check list. S E

Measurement Water level,tape,dumpy

2.8 Front release Critical 100% Tech specification/Drawings Tech specification/Drawings Front release report. S EF

s level

Check for the beam parts,support plates,air cooler

Measurement

3 for drawing conformaty and dimention prior to Major Water level,tape 100% Tech specification/Drawings Tech specification/Drawings ITSR S E

s

welding.

3.1 Develop welding sequence Critical Visual Nil 100% Tech specification/Drawings Tech specification/Drawings WISR S EF

Measurement

3.2 Fit up inspection Major Weld gauge/Template Random WPS/Drawing WPS/Drawing Fit Up inspection report S E

s

Every day

Backing oven with temp

3.3 Check for the baking of electrodes (if applicable) Major Verification before start of WPS/Electrode manufatures recomandations

WPS/Electrode manufatures recomandations Backing registar S E

recorder

welding

Measurement Thermal chalk /thermo

3.4 Pre Heating Major As per WPS WPS WPS Heat treatment chart S E

s couple

3.5 Weld root penetration Minor Visual NIL 100% WPS/Drawing WPS/Drawing WISR S S

3.6 Inter pass cleaning Minor Visual NIL 100% WPS/Drawing WPS/Drawing WISR S S

Measurement Thermal chalk /thermo

3.7 Inter pass temperature Minor As per WPS WPS WPS Heat treatment chart S S

s couple

Measurement

3.8 Final weld inspection Major Weld gauge/Template Random WPS/Drawing WPS/Drawing/ASME/ANSI/API/AWS/DIN/IBR/IS/BS WISR S E

s

Measurement

3.9 NDT on welding Critical NDT report S EF

s

Check for the condenser neck for drawing Measurement

4 Major Water level,tape 100% Tech specification/Drawings Tech specification/Drawings ITSR S E

conformaty and dimention prior to welding. s

4.1 Develop welding sequence Critical Visual Nil 100% Tech specification/Drawings Tech specification/Drawings WISR S EF

Measurement

4.2 Fit up inspection Major Weld gauge/Template Random WPS/Drawing WPS/Drawing Fit Up inspection report S E

s

Every day

Backing oven with temp

4.3 Check for the baking of electrodes (if applicable) Major Verification before start of WPS/Electrode manufatures recomandations

WPS/Electrode manufatures recomandations Backing registar S E

recorder

welding

Tur 06 ALSTOM Confidential Page 8

Measurement Thermal chalk /thermo

4.4 Pre Heating Major As per WPS WPS WPS Heat treatment chart S E

s couple

4.5 Weld root penetration Minor Visual NIL 100% WPS/Drawing WPS/Drawing WISR S S

4.6 Inter pass cleaning Minor Visual NIL 100% WPS/Drawing WPS/Drawing WISR S S

Measurement Thermal chalk /thermo

4.7 Inter pass temperature Minor As per WPS WPS WPS Heat treatment chart S S

s couple

Measurement

4.8 Final weld inspection Major Weld gauge/Template Random WPS/Drawing WPS/Drawing/ASME/ANSI/API/AWS/DIN/IBR/IS/BS WISR S E

s

Measurement

4.9 NDT on welding Critical NDT report S EF

s

Check for the condenser hotwell for drawing Measurement

5 Major Water level,tape 100% Tech specification/Drawings Tech specification/Drawings ITSR S E

conformaty and dimention prior to welding. s

5.1 Develop welding sequence Critical Visual Nil 100% Tech specification/Drawings Tech specification/Drawings WISR S EF

Measurement

5.2 Fit up inspection Major Weld gauge/Template Random WPS/Drawing WPS/Drawing Fit Up inspection report S E

s

Every day

Backing oven with temp

5.3 Check for the baking of electrodes (if applicable) Major Verification before start of WPS/Electrode manufatures recomandations

WPS/Electrode manufatures recomandations Backing registar S E

recorder

welding

Measurement Thermal chalk /thermo

5.4 Pre Heating Major As per WPS WPS WPS Heat treatment chart S E

s couple

5.5 Weld root penetration Minor Visual NIL 100% WPS/Drawing WPS/Drawing WISR S S

5.6 Inter pass cleaning Minor Visual NIL 100% WPS/Drawing WPS/Drawing WISR S S

Measurement Thermal chalk /thermo

5.7 Inter pass temperature Minor As per WPS WPS WPS Heat treatment chart S S

s couple

Measurement

5.8 Final weld inspection Major Weld gauge/Template Random WPS/Drawing WPS/Drawing/ASME/ANSI/API/AWS/DIN/IBR/IS/BS WISR S E

s

Measurement

5.9 NDT on welding Critical NDT report S EF

s

Check for the for drawing conformaty and

Measurement

6 dimention prior to welding of condenser neck to Major Water level,tape 100% Tech specification/Drawings Tech specification/Drawings ITSR S E

s

the shell.

6.1 Develop welding sequence Critical Visual Nil 100% Tech specification/Drawings Tech specification/Drawings WISR S EF

Measurement

6.2 Fit up inspection Major Weld gauge/Template Random WPS/Drawing WPS/Drawing Fit Up inspection report S E

s

Every day

Backing oven with temp

6.3 Check for the baking of electrodes (if applicable) Major Verification before start of WPS/Electrode manufatures recomandations

WPS/Electrode manufatures recomandations Backing registar S E

recorder

welding

Measurement Thermal chalk /thermo

6.4 Pre Heating Major As per WPS WPS WPS Heat treatment chart S E

s couple

6.5 Weld root penetration Minor Visual NIL 100% WPS/Drawing WPS/Drawing WISR S S

6.6 Inter pass cleaning Minor Visual NIL 100% WPS/Drawing WPS/Drawing WISR S S

Measurement Thermal chalk /thermo

6.7 Inter pass temperature Minor As per WPS WPS WPS Heat treatment chart S S

s couple

Measurement

6.8 Final weld inspection Major Weld gauge/Template Random WPS/Drawing WPS/Drawing/ASME/ANSI/API/AWS/DIN/IBR/IS/BS WISR S E

s

Measurement

6.9 NDT on welding Critical NDT report S EF

s

Inspection of all pipe connections for compliance Measurement

7 Major Water level,tape 100% Tech specification/Drawings Tech specification/Drawings ITSR S E

with drawing,piping plans etc. s

Measurement

7.1 Fit up inspection Major Weld gauge/Template Random WPS/Drawing WPS/Drawing Fit Up inspection report S E

s

Every day

Backing oven with temp

7.2 Check for the baking of electrodes (if applicable) Major Verification before start of WPS/Electrode manufatures recomandations

WPS/Electrode manufatures recomandations Backing registar S E

recorder

welding

Measurement Thermal chalk /thermo

7.3 Pre Heating Major As per WPS WPS WPS Heat treatment chart S E

s couple

7.4 Weld root penetration Minor Visual NIL 100% WPS/Drawing WPS/Drawing WISR S S

7.5 Inter pass cleaning Minor Visual NIL 100% WPS/Drawing WPS/Drawing WISR S S

Tur 06 ALSTOM Confidential Page 9

Measurement Thermal chalk /thermo

7.6 Inter pass temperature Minor As per WPS WPS WPS Heat treatment chart S S

s couple

Measurement

7.7 Final weld inspection Major Weld gauge/Template Random WPS/Drawing WPS/Drawing/ASME/ANSI/API/AWS/DIN/IBR/IS/BS WISR S E

s

Measurement

7.8 NDT on welding Critical NDT report S EF

s

Condenser Tubes

8 Check for suppliers material test certificates. Critical Visual Nil 100% Tech specification/Drawings Availability of MTC ITSR S EF

Check marking of ref. holes for roller Measurement Water level,tape,dumpy

8.1 Critical 100% Tech specification/Drawings Tech specification/Drawings SIR S EF

expanding,recording of reference hole diameter. s level

8.2 Check of cleanliness prior to tubing. Minor Visual NIL 100% Tech specification/Drawings Surfaces to be free from dust and sticking dirts. ITSR S S

check during tubing,recording of the tube Visual/Mesur Water level,tape,dumpy

8.3 Major 100% Tech specification/Drawings Tech specification/Drawings SIR S E

wallthickness at the marked ref. holes ement level

8.4 Check of cleanliness , prior to roller expanding. Major Visual NIL 100% Tech specification/Drawings Surfaces to be free from dust and sticking dirts. ITSR S E

Visual/Mesur Water level,tape,dumpy

8.5 Check during roller expanding of tubes. Major 100% Tech specification/Drawings Tech specification/Drawings SIR S E

ement level

check after roller expanding-milling back of tube Visual/Mesur Water level,tape,dumpy

8.6 Major 100% Tech specification/Drawings Tech specification/Drawings SIR S E

ends,tube projections and tube inlets. ement level

Check for the for drawing conformaty and

Measurement

9 dimention prior to welding of condenser shell to Major Water level,tape 100% Tech specification/Drawings Tech specification/Drawings ITSR S E

s

the water boxes.

9.1 Develop welding sequence Critical Visual Nil 100% Tech specification/Drawings Tech specification/Drawings WISR S EF

Measurement

9.2 Fit up inspection Major Weld gauge/Template Random WPS/Drawing WPS/Drawing Fit Up inspection report S E

s

Every day

Backing oven with temp

9.3 Check for the baking of electrodes (if applicable) Major Verification before start of WPS/Electrode manufatures recomandations

WPS/Electrode manufatures recomandations Backing registar S E

recorder

welding

Measurement Thermal chalk /thermo

9.4 Pre Heating Major As per WPS WPS WPS Heat treatment chart S E

s couple

9.5 Weld root penetration Minor Visual NIL 100% WPS/Drawing WPS/Drawing WISR S S

9.6 Inter pass cleaning Minor Visual NIL 100% WPS/Drawing WPS/Drawing WISR S S

Measurement Thermal chalk /thermo

9.7 Inter pass temperature Minor As per WPS WPS WPS Heat treatment chart S S

s couple

Measurement

9.8 Final weld inspection Major Weld gauge/Template Random WPS/Drawing WPS/Drawing/ASME/ANSI/API/AWS/DIN/IBR/IS/BS WISR S E

s

Measurement

9.9 NDT on welding Critical NDT report S EF

s

10 Pressure test on water side Critical Visual Pressure Gauge 100% Tech specification/Drawings Tech specification/Drawings Pressure test report S EF

10.1 Pressure test on shell side. Critical Visual Pressure Gauge 100% Tech specification/Drawings Tech specification/Drawings Pressure test report S EF

11 Check of water box prior to coating Major Visual NIL 100% Tech specification/Drawings Surfaces to be free from dust and sticking dirts. ITSR S E

11.1 Check of tubesheets prior to coating Major Visual NIL 100% Tech specification/Drawings Surfaces to be free from dust and sticking dirts. ITSR S E

12 Final Inspection Critical Verification NIL 100% Tech specification/Drawings Tech specification/Drawings Check list S EF

Measurement Coat meter or

13 Painting thikness and shade Major Random Tech specification/Drawings Tech specification/Drawings Painting report S E

s Elcometer

14 Verification of quality records for completeness Critical Verification NIL 100% Field quality plan Field quality plan ITSR S EF

Note: Abbreviations: P - Performed by, W - Witnessed by, H-Witness by customer, S – Avlon Supervisor, E – Avlon Engineer, F – Avlon Manager, C – Customer

Tur 06 ALSTOM Confidential Page 10

FIELD QUALITY PLAN FOR HP PIPING,VALVES AND SUPPORTS.

Category Type of Frequency of Agencies Involved

Sl.No Characteristics / items Instrument Reference documents Acceptance criteria Format or records

of check check check P W H

Transportation documents, Completeness and correctness of

1.1 Material Receipt Verification Major Visual Nil 100% Material Dispatch Clearence supply,free fromdamages,verification of JVR E E

Certificate./packing list identification marks.

Storage manual, No Quality detoriaration,

1.2 Material storage and preservation. Major Visual Nil Random JVR E E

Manufacturer’s Instructions Preservation measures are intact

List of documents and

2.1 Availability of the followings Major Verification Nil 100% Master document list Availability,correctness and completeness S E

availability ststus.

2.1.1 1. WPS

2.1.2 2. Field welding schedules

2.1.3 3. Drawings

2.1.4 4. Manuf. Erection guidelines

PQR Test ( only if qualified welding procedure is Mechanical To qualify the

2.2 Critical Lab Test Standard WPS/ASME Sec IX. ASME Sec IX. PQR Test records S EF

not available) Test WPS

RT/Mechanic

2.3 Welder Qualification Test Critical Lab Test 100% Standard WPS/ASME Sec IX. ASME Sec IX. Welder Qualification record and welder's

S EFID.

al test

2.4 Erection marking before release for erection. Major Visual Nil 100% Tech specification/Drawings Tech specification/Drawings ITSR S E

Outer and inner surfaces to be free from

2.5 Check for cleanliness of pipe before erection. Major Verification Nil 100% Nil ITSR S E

dust and sticking dirts.

Measurement Water level,tape,torque

2.6 Pre assembly level,straightness Major 100% Tech specification/Drawings Tech specification/Drawings SIR S E

s wrench.

2.7 Readiness of all safety aspects before erection. Major Verification Nil 100% Safety guidelines/manual Safety guidelines/manual Safety check list. S E

Measurement Water level,tape,dumpy

2.8 Front release Critical 100% Tech specification/Drawings Tech specification/Drawings Front release report. S EF

s level

Check for pitch of threaded Measurement

3 Major Pitch guage Random Tech specification/Drawings Tech specification/Drawings Pipe alingment report S E

fittings s

Alignment of flange connections and bolt Measurement Sprit level and hand

3.1 Major 100% Tech specification/Drawings Tech specification/Drawings Pipe alingment report S E

tightening s tightning

Measurement

4 Fit up inspection Major Weld gauge/Template Random WPS/Drawing WPS/Drawing Fit Up inspection report S E

s

Measurement Water level,tape,dumpy

4.1 Dimention and alingment of piping Major 100% Tech specification/Drawings Tech specification/Drawings Pipe alingment report S E

s level

Every day

Backing oven with temp

4.2 Check for the baking of electrodes (if applicable) Major Verification before start of WPS/Electrode manufatures recomandations

WPS/Electrode manufatures recomandations Backing registar S E

recorder

welding

Measurement Thermal chalk /thermo

4.3 Pre Heating Major As per WPS WPS WPS Heat treatment chart S E

s couple

4.4 Weld root penetration Minor Visual NIL 100% WPS/Drawing WPS/Drawing WISR S S

4.5 Inter pass cleaning Minor Visual NIL 100% WPS/Drawing WPS/Drawing WISR S S

Measurement Thermal chalk /thermo

4.6 Inter pass temperature Minor As per WPS WPS WPS Heat treatment chart S S

s couple

Measurement

4.7 Final weld inspection Major Weld gauge/Template Random WPS/Drawing WPS/Drawing/ASME/ANSI/API/AWS/DIN/IBR/IS/BS WISR S E

s

Measurement

4.8 Post Weld heat treatment Critical Tempreature recorder As per WPS WPS/PQR WPS/PQR Heat treatment chart S EF

s

Measurement Tape,

4.9 Pipe supports Major 100% Tech specification/Drawings Tech specification/Drawings Pipe alingment report S E

s Spirit level,water level

5 Final inspection before pressure test / leak test Critical Verification NIL 100% Tech specification/Drawings Tech specification/Drawings Check list S EF

6 Pressure test/Leak test/ Hydrotest/Pneumatic test Critical Visual Pressure Gauge 100% Tech specification/Drawings Tech specification/Drawings Pressure test report S EF

Tur 07 ALSTOM Confidential Page 11

9 Final Inspection Critical Verification NIL 100% Tech specification/Drawings Tech specification/Drawings Check list S EF

10 Verification of quality records for completeness Critical Verification NIL 100% Field quality plan Field quality plan ITSR S EF

Note: Abbreviations: P - Performed by, W - Witnessed by, H-Witness by customer, S – Avlon Supervisor, E – Avlon Engineer, F – Avlon Manager, C – Customer

Tur 07 ALSTOM Confidential Page 12

FIELD QUALITY PLAN FOR THERMAL INSULATIONS.

Category Type of Frequency of Agencies Involved

Sl.No Characteristics / items Instrument Reference documents Acceptance criteria Format or records

of check check check P W H

Transportation documents, Completeness and correctness of

1.1 Material Receipt Verification Major Visual Nil 100% Material Dispatch Clearence supply,free fromdamages,verification of JVR E E

Certificate./packing list identification marks.

Storage manual, No Quality detoriaration,

1.2 Material storage and preservation. Major Visual Nil Random JVR E E

Manufacturer’s Instructions Preservation measures are intact

List of documents and

2.1 Availability of the followings Major Verification Nil 100% Master document list Availability,correctness and completeness S E

availability ststus.

2.1.3 1. Drawings

2.1.4 2. Manuf. Erection guidelines

2.7 Readiness of all safety aspects before erection. Major Verification Nil 100% Safety guidelines/manual Safety guidelines/manual Safety check list. S E

Measurement Water level,tape,dumpy

2.8 Front release Critical 100% Tech specification/Drawings Tech specification/Drawings Front release report. S EF

s level

Thermal Insulation.

3 Surface cleanliness Minor Visual Nil 100% ------ Free from foreign particles. Insulation test record S S

3.1 Placement of spacers Minor Measurement Measuring tape 100% Specific Drg. as per SpecificDrg. Insulation test record S S

3.2 Support stud welding -completeness Minor Visual Nil 100% Specific Drg. as per Specific Drg. Insulation test record S S

3.3 Placing of correct insulation material Major Verification Nil 100% Specific Drg. or Datas sheet As per specific Drg. or Data sheet Insulation test record S E

3.4 Thickness of each layer Major Measurement Measuring tape Random Specific Drg. as per Specific Drg. Insulation test record S E

Clading

4 Use of correct fastners Major Verification Nil Random Specific Drg. or Datas sheet Data sheet Insulation test record S E

4.1 Void between insulation and cladding Major Verification Nil Random ------------- Free of voids Insulation test record S E

4.2 Overlap of cladding sheets Major Verification Nil 100% Specific Drg. As per specific Drg. Insulation test record S E

4.3 Flushing of vertical cladding Major Verification Nil 100% Specific Drg. As per specific Drg. Insulation test record S E

4.4 Sealing of cut outs Major Verification Nil 100% Specific Drg. As per specific Drg. Insulation test record S E

4.5 Damages to cladding Major Visual Nil 100% ----- Freedom from damages Insulation test record S E

4.6 Color coding/ band/ flow direction Major Verification Nil 100% Specific Drg. or Datas sheet As per specific Drg. or Data sheet Insulation test record S E

5 Verification of quality records for completeness Critical Verification NIL 100% Field quality plan Field quality plan ITSR S EF

Note: Abbreviations: P - Performed by, W - Witnessed by, H-Witness by customer, S – Avlon Supervisor, E – Avlon Engineer, F – Avlon Manager, C – Customer

Tur 08 ALSTOM Confidential Page 13

FIELD QUALITY PLAN FOR TURBINE.

Category Type of Frequency of Agencies Involved

Sl.No Characteristics / items Instrument Reference documents Acceptance criteria Format or records

of check check check P W H

Transportation documents, Completeness and correctness of

1.1 Material Receipt Verification Major Visual Nil 100% Material Dispatch Clearence supply,free fromdamages,verification of JVR E E

Certificate./packing list identification marks.

Storage manual, No Quality detoriaration,

1.2 Material storage and preservation. Major Visual Nil Random JVR E E

Manufacturer’s Instructions Preservation measures are intact

List of documents and

2.1 Availability of the followings Major Verification Nil 100% Master document list Availability,correctness and completeness S E

availability ststus.

2.1.1 1. WPS

2.1.2 2. Field welding schedules

2.1.3 3. Drawings

2.1.4 4. Manuf. Erection guidelines

PQR Test ( only if qualified welding procedure is Mechanical To qualify the

2.2 Critical Lab Test Standard WPS/ASME Sec IX. ASME Sec IX. PQR Test records S EF

not available) Test WPS

RT/Mechanic

2.3 Welder Qualification Test Critical Lab Test 100% Standard WPS/ASME Sec IX. ASME Sec IX. Welder Qualification record and welder's

S EFID.

al test

2.4 Erection marking before release for erection. Major Visual Nil 100% Tech specification/Drawings Tech specification/Drawings ITSR S E

Outer and inner surfaces to be free from

2.5 Check for cleanliness of equp/pipe before erection. Major Verification Nil 100% Nil ITSR S E

dust and sticking dirts.

Pre assembly level,straightness,diagonal,bolt Measurement Water level,tape,torque

2.6 Major 100% Tech specification/Drawings Tech specification/Drawings SIR S E

tightness. s wrench.

2.7 Readiness of all safety aspects before erection. Major Verification Nil 100% Safety guidelines/manual Safety guidelines/manual Safety check list. S E

Measurement Water level,tape,dumpy

2.8 Front release Critical 100% Tech specification/Drawings Tech specification/Drawings Front release report. S EF

s level

Valve Blocks.

Visual/Mesur Water level,tape,dumpy

3 check for correct valve arrangment Major 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

ement level

check for the bolt prestress of the connection

Visual/Mesur Water level,tape,dumpy

3.1 turbine/valve casing.According to torque method Major 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

ement level

or streaching method.

check of alingment of swing arm supports and of Visual/Mesur Water level,tape,dumpy

3.2 Major 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

the welding-on of the support base. ement level

Measurement

3.3 visual check on swing arm support weld. Major Weld gauge/Template Random WPS/Drawing WPS/Drawing/ASME/ANSI/API/AWS/DIN/IBR/IS/BS WISR S E

s

3.4 NDT-DPT check on swing arm support weld. Critical Visual DPT Kit 5% Tech specification/Drawings Tech specification/Drawings/AWS D 1.1 DPT report S EF

Visual/Mesur Water level,tape,dumpy

3.5 Check on adjustment of swing arm supports. Major 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

ement level

check for correct assembly and tighting torqe of Visual/Mesur Water level,tape,dumpy

3.6 Major 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

the seal ring ement level

check for correct assembly and tighting torqe of Visual/Mesur Water level,tape,dumpy

3.7 Major 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

the valve steam packing. ement level

check of the bolt prestress on the stop valve and Visual/Mesur Water level,tape,dumpy

3.8 Major 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

on the control valve (torque and cold tightened) ement level

Visual/Mesur Water level,tape,dumpy

3.9 check of vale stroke of stop valve. Major 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

ement level

Visual/Mesur Water level,tape,dumpy

4 check of vale stroke of control valve. Major 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

ement level

Valve steam packing should not be tightened for Visual/Mesur Water level,tape,dumpy

4.1 Major 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

the stroke check. ement level

Tur 09 ALSTOM Confidential Page 14

check of coupling adjustment of control valve Visual/Mesur Water level,tape,dumpy

4.2 Major 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

actuator and control valve. ement level

check for correct execution of all connections and Visual/Mesur Water level,tape,dumpy

4.3 Major 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

of all locks. ement level

General

Measurement

4.4 general record of turbine and shaft line. Major tape Random Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

s

Measurement

4.5 check of foundation leveling point. Major tape Random Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

s

Measurement

4.6 check of shaft defelection line Major tape Random Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

s

check of disassembly and assembly possibilities of Measurement

4.7 Major tape Random Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

rotors. s

Measurement

4.8 check of pre stress of foundation bolts Major tape Random Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

s

check of prestress of bolts which are not specially Measurement

4.9 Major tape Random Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

recorded. s

LP-Turbine

5 arrangments of slings for the turbine parts Major Visual Nil 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

check for uniform contact of casing on the Visual/Mesur Water level,tape,dumpy

5.1 Major 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

foundation bedplates ement level

Visual/Mesur Water level,tape,dumpy

5.2 check for clearances of the welded in lateral guide. Major 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

ement level

NDT-DPT of the anchoring weld of the lateral

5.3 Critical Visual DPT Kit 5% Tech specification/Drawings Tech specification/Drawings/AWS D 1.1 DPT report S EF

guide

check of alingment of casing lower half,foundation Visual/Mesur Water level,tape,dumpy

5.4 Major 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

bolts provisionaly tightened. ement level

verification of weld connection of LP-Exhaust with Visual/Mesur Water level,tape,dumpy

5.5 Major 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

condenser has been carried out . ement level

Visual/Mesur Water level,tape,dumpy

5.6 positioning check of rotor in the LP-Blade carrier. Major 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

ement level

dimention check of radial cleareances of LP gland Visual/Mesur Water level,tape,dumpy

5.7 Major 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

seal. ement level

check of the supporting guide and fixing element Visual/Mesur Water level,tape,dumpy

5.8 Major 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

of LP-Blade carrier. ement level

Visual/Mesur Water level,tape,dumpy

5.9 check if all loose parts are removed Major 100% Tech specification/Drawings Tech specification/Drawings ITSR S E

ement level

Visual/Mesur Water level,tape,dumpy

6 check of cleanness of the inside of turbine. Major 100% Tech specification/Drawings Tech specification/Drawings ITSR S E

ement level

Visual/Mesur Water level,tape,dumpy

6.1 check of pre stress of bolts of the LP blade carrier. Major 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

ement level

check of pre stress of the flange bolting of the Visual/Mesur Water level,tape,dumpy

6.2 Major 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

outer casing. ement level

check of flange bolting (without specific recording) Visual/Mesur Water level,tape,dumpy

6.3 Major 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

of LP casing parts. ement level

Visual/Mesur Water level,tape,dumpy

6.4 check of LP-Outer casing foundation supports Major 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

ement level

Visual/Mesur Water level,tape,dumpy

6.5 check of pre stress of foundation bolts Major 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

ement level

position check of rotor to LP-Gland seal / coupling Visual/Mesur Water level,tape,dumpy

6.6 Major 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

cover. ement level

dimentional check of clearances of differential Visual/Mesur Water level,tape,dumpy

6.7 Major 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

expantion transmitters ement level

check of connection dimention,coupling cover / Visual/Mesur Water level,tape,dumpy

6.8 Major 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

LP-Casing ement level

check of correction protection of turbine Visual/Mesur Water level,tape,dumpy

6.9 Major 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

component. ement level

HP-Turbine

7 arrangments of slings for the turbine parts Major Visual NIL 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

Tur 09 ALSTOM Confidential Page 15

Visual/Mesur Water level,tape,dumpy

7.1 positioning check of rotor in the outer casing Major 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

ement level

Visual/Mesur Water level,tape,dumpy

7.2 positioning check of steam duct (inlet) Major 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

ement level

Visual/Mesur Water level,tape,dumpy

7.3 positioning check of rotor in the bearing pedestal Major 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

ement level

positioning check of temp. sensor (starting probe.) Visual/Mesur Water level,tape,dumpy

7.4 Major 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

in turbine ement level

check of weight distribution of casing on the Visual/Mesur Water level,tape,dumpy

7.5 Major 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

bearing pedestal. ement level

check of axial sliding possibility of rotor and Visual/Mesur Water level,tape,dumpy

7.6 Major 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

casing. ement level

check of correction protection of turbine Visual/Mesur Water level,tape,dumpy

7.7 Major 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

component. ement level

IP-Turbine

7.8 arrangments of slings for the turbine parts Major Visual Nil 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

Visual/Mesur Water level,tape,dumpy

7.9 check of prestress of bolts of the vertical flange. Major 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

ement level

check of alingment of the screwed IP/LP turbine Visual/Mesur Water level,tape,dumpy

8 Major 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

casing ement level

check of axial position of IP/LP inner parts in outer Visual/Mesur Water level,tape,dumpy

8.1 Major 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

casing ement level

Visual/Mesur Water level,tape,dumpy

8.2 positining check between IP/LP inner parts Major 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

ement level

dimentional check of radial and axial cleareancess Visual/Mesur Water level,tape,dumpy

8.3 Major 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

of IP gland seal. ement level

dimentional check of radial and axial cleareancess Visual/Mesur Water level,tape,dumpy

8.4 Major 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

of position seal in the IP-Inner casing ement level

dimentional check of radial and axial cleareancess Visual/Mesur Water level,tape,dumpy

8.5 Major 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

of IP/LP Blading ement level

check of the supporting guide and fixing element Visual/Mesur Water level,tape,dumpy

8.6 Major 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

of IP-inner casing ement level

Visual/Mesur Water level,tape,dumpy

8.7 positioning check of the rotor in the inner casing Major 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

ement level

Visual/Mesur Water level,tape,dumpy

8.8 positioning check of the rotor in the outer casing Major 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

ement level

Visual/Mesur Water level,tape,dumpy

8.9 check if all loose parts are removed Major 100% Tech specification/Drawings Tech specification/Drawings ITSR S E

ement level

Visual/Mesur Water level,tape,dumpy

9 check for cleanness of the inside of turbine Major 100% Tech specification/Drawings Tech specification/Drawings ITSR S E

ement level

Visual/Mesur Water level,tape,dumpy

9.1 check of prestress of bolts of the IP-Inner casing Major 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

ement level

check of clearance between IP inner casing Visual/Mesur Water level,tape,dumpy

9.2 Major 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

horizontal flange. ement level

check of axial sliding possibility of rotor and Visual/Mesur Water level,tape,dumpy

9.3 Major 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

casing. ement level

Visual/Mesur Water level,tape,dumpy

9.4 check of prestress of bolts of the vertical flange. Major 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

ement level

Visual/Mesur Water level,tape,dumpy

9.5 check of clearance between IP/LP vertical flange. Major 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

ement level

check of prestress of the flange-bolting of the outer Visual/Mesur Water level,tape,dumpy

9.6 Major 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

casing ement level

check of clearance between IP/LP horizontal Visual/Mesur Water level,tape,dumpy

9.7 Major 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

flange. ement level

Visual/Mesur Water level,tape,dumpy

9.8 positioning check of steam duct (inlet) Major 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

ement level

positioning check of temp. sensor (starting probe.) Visual/Mesur Water level,tape,dumpy

9.9 Major 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

in turbine ement level

check of correction protection of turbine Visual/Mesur Water level,tape,dumpy

10 Major 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

component. ement level

Bearing Pedestal

Tur 09 ALSTOM Confidential Page 16

10.1 arrangments of slings for the bearing pedestal Minor Visual Nil 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S S

check of alingment of bearing pedestal lower Visual/Mesur Water level,tape,dumpy

10.2 Major 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

half,foundation bolts provisionally tightened. ement level

check of alingment and tack welding of fixing Visual/Mesur Water level,tape,dumpy

10.3 Major 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

piese. ement level

10.4 Develop welding sequence for fixing plates Critical Visual Nil 100% Tech specification/Drawings Tech specification/Drawings WISR S EF

Measurement

10.5 Welding visual inspection of fixing plates Major Weld gauge/Template Random WPS/Drawing WPS/Drawing/ASME/ANSI/API/AWS/DIN/IBR/IS/BS WISR S E

s

Measurement

10.6 NDT on welding of fixing plates Critical NDT report S EF

s

check of adjustments of fixing piece and axial Visual/Mesur Water level,tape,dumpy

10.7 Major 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

keyway of base plate/bearing pedestal. ement level

dimentional check of clearances between bearing Visual/Mesur Water level,tape,dumpy

10.8 Major 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

pedestal and hold down bar. ement level

Visual/Mesur Water level,tape,dumpy

10.9 check of prestress of foundation bolts Major 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

ement level

Positioning check of rotor in the bearing pedestal

Visual/Mesur Water level,tape,dumpy

11 and dimentionalcheck of clearancess of combined Major 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

ement level

trust/journal bearing.

dimentional check of clearences of combined Visual/Mesur Water level,tape,dumpy

11.1 Major 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

trust / journal bearing. ement level

dimentional check of clearences of axial fixation of Visual/Mesur Water level,tape,dumpy

11.2 Major 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

turbine and bearing pedestal. ement level

dimentional check of clearences of casing support Visual/Mesur Water level,tape,dumpy

11.3 Major 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

and bearing pedestal. ement level

dimentional check of clearences of vertical Visual/Mesur Water level,tape,dumpy

11.4 Major 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

keyway. ement level

check of prestress of the bolts of bearing pedestal Visual/Mesur Water level,tape,dumpy

11.5 Major 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

cover. ement level

Visual/Mesur Water level,tape,dumpy

11.6 dimentional check of clearences of oil wiper. Major 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

ement level

dimentional check of clearences of turbine gear Visual/Mesur Water level,tape,dumpy

11.7 Major 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

and speed sensor. ement level

dimentional check of clearences of turbine Visual/Mesur Water level,tape,dumpy

11.8 Major 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

instruments. ement level

check of correction protection of turbine Visual/Mesur Water level,tape,dumpy

11.9 Major 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

component. ement level

End Bearing Pedestal

check of correct preparation and bonding of Visual/Mesur Water level,tape,dumpy

12 Major 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

foundation bedplates. ement level

check of alingment of bearing pedestal lower Visual/Mesur Water level,tape,dumpy

12.1 Major 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

half,foundation bolts provisionally tightened. ement level

check of alingment and tack welding of foundation Visual/Mesur Water level,tape,dumpy

12.2 Major 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

keys. ement level

12.3 Develop welding sequence for foundation keys. Critical Visual Nil 100% Tech specification/Drawings Tech specification/Drawings WISR S EF

Measurement

12.4 Welding visual inspection of foundation keys. Major Weld gauge/Template Random WPS/Drawing WPS/Drawing/ASME/ANSI/API/AWS/DIN/IBR/IS/BS WISR S E

s

Measurement

12.5 NDT on welding of foundation keys. Critical NDT report S EF

s

Check of finally assembled bearing pedestal lower Visual/Mesur Water level,tape,dumpy

12.6 Major 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

half-alingment and adjustment of foundation key. ement level

Positioning check of rotor in the bearing pedestal

Visual/Mesur Water level,tape,dumpy

12.7 and dimentional check of clearancess of journal Major 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

ement level

bearing.

dimentional check of clearences of journal Visual/Mesur Water level,tape,dumpy

12.8 Major 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

bearing. ement level

check of prestress of the bolts of installed bearing Visual/Mesur Water level,tape,dumpy

12.9 Major 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

pedestal cover. ement level

Visual/Mesur Water level,tape,dumpy

13 dimentional check of clearences of oil shields. Major 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

ement level

Tur 09 ALSTOM Confidential Page 17

Visual/Mesur Water level,tape,dumpy

13.1 measurement of insulation resistance of bearings. Major 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

ement level

dimentional check of clearences of adjustable Visual/Mesur Water level,tape,dumpy

13.2 Major 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

instruments pick ups. ement level

check of correction protection of turbine Visual/Mesur Water level,tape,dumpy

13.3 Major 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

component. ement level

Thermal Insulations

check that the anchor bolts have only been welded Visual/Mesur Water level,tape,dumpy

13.4 Major 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

to the appropriate places(discs,screw heads,etc…) ement level

check that the areas specified in the drawing have Visual/Mesur Water level,tape,dumpy

13.5 Major 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

been insulated by preformed,removable pieces. ement level

check that the insulation has been applied in

layers,that the contact between insulation and the Visual/Mesur Water level,tape,dumpy

13.6 Major 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

casing outer wall is ensured and that sagging of ement level

the insulation at the lower part is avoided.

Check that the insulation thickness (in relation to Visual/Mesur Water level,tape,dumpy

13.7 Major 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

the temp) is accroding to the supplier specification. ement level

Check that the casing lower part has been Visual/Mesur Water level,tape,dumpy

13.8 Major 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

insulated 20% thicker than the upper part. ement level

check if there is a distance of at least 20mm Visual/Mesur Water level,tape,dumpy

13.9 Major 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

between insulation and foundation. ement level

Check that the insulation surface is accroding to Visual/Mesur Water level,tape,dumpy

14 Major 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

specification. ement level

Expan. Sleeve couplings.

Visual/Mesur Water level,tape,dumpy

14.1 Check of shaft line Major 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

ement level

verification that honing has been carried out Visual/Mesur Water level,tape,dumpy

14.2 Major 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

according to instruction. ement level

check of coupling parallelism,radial run-out and Visual/Mesur Water level,tape,dumpy

14.3 Major 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

prestress of coupling bolts. ement level

Visual/Mesur Water level,tape,dumpy

14.4 check of correction protection Major 100% Tech specification/Drawings Tech specification/Drawings Turbine inspection reports S E

ement level

15 Verification of quality records for completeness Critical Verification NIL 100% Field quality plan Field quality plan ITSR S EF

Note: Abbreviations: P - Performed by, W - Witnessed by, H-Witness by customer, S – Avlon Supervisor, E – Avlon Engineer, F – Avlon Manager, C – Customer

Tur 09 ALSTOM Confidential Page 18

FIELD QUALITY PLAN FOR GENERATOR.

Category Type of Frequency of Agencies Involved

Sl.No Characteristics / items Instrument Reference documents Acceptance criteria Format or records

of check check check P W H

Transportation documents, Completeness and correctness of

1.1 Material Receipt Verification Major Visual Nil 100% Material Dispatch Clearence supply,free fromdamages,verification of JVR E E

Certificate./packing list identification marks.

Storage manual, No Quality detoriaration,

1.2 Material storage and preservation. Major Visual Nil Random JVR E E

Manufacturer’s Instructions Preservation measures are intact

List of documents and

2.1 Availability of the followings Major Verification Nil 100% Master document list Availability,correctness and completeness S E

availability ststus.

2.1.1 1. WPS

2.1.2 2. Field welding schedules

2.1.3 3. Drawings

2.1.4 4. Manuf. Erection guidelines

PQR Test ( only if qualified welding procedure is Mechanical To qualify the

2.2 Critical Lab Test Standard WPS/ASME Sec IX. ASME Sec IX. PQR Test records S EF

not available) Test WPS

RT/Mechanic

2.3 Welder Qualification Test Critical Lab Test 100% Standard WPS/ASME Sec IX. ASME Sec IX. Welder Qualification record and welder's

S EFID.

al test

2.4 Erection marking before release for erection. Major Visual Nil 100% Tech specification/Drawings Tech specification/Drawings ITSR S E

Outer and inner surfaces to be free from

2.5 Check for cleanliness of equp/pipe before erection. Major Verification Nil 100% Nil ITSR S E

dust and sticking dirts.

2.6 Readiness of all safety aspects before erection. Major Verification Nil 100% Safety guidelines/manual Safety guidelines/manual Safety check list. S E

Measurement Water level,tape,dumpy

2.7 Front release Critical 100% Tech specification/Drawings Tech specification/Drawings Front release report. S EF

s level

Leak test of flange connection ( stator housing-end Visual/Mesur Water level,tape,dumpy

3 Major 100% Tech specification/Drawings Tech specification/Drawings Generator inspecton report S E

cover,cooler flange,intermediate ring.) ement level

Visual/Mesur Water level,tape,dumpy

3.1 Tighting of end winding wedges Major 100% Tech specification/Drawings Tech specification/Drawings Generator inspecton report S E

ement level

Insulation measurement on the fasterning of the Visual/Mesur Water level,tape,dumpy

3.2 Major 100% Tech specification/Drawings Tech specification/Drawings Generator inspecton report S E

current transformer. ement level

Visual/Mesur Water level,tape,dumpy

3.3 Insulation resistance test of stator winding Major 100% Tech specification/Drawings Tech specification/Drawings Generator inspecton report S E

ement level

Visual/Mesur Water level,tape,dumpy

3.4 High potential test on stator winding Major 100% Tech specification/Drawings Tech specification/Drawings Generator inspecton report S E

ement level

Visual/Mesur Water level,tape,dumpy

3.5 visualcheck of rotor Major 100% Tech specification/Drawings Tech specification/Drawings Generator inspecton report S E

ement level

Visual/Mesur Water level,tape,dumpy

3.6 cleanliness check of rotor Major 100% Tech specification/Drawings Tech specification/Drawings ITSR S E

ement level

Visual/Mesur Water level,tape,dumpy

3.7 Insulation resistance test of rotor. Major 100% Tech specification/Drawings Tech specification/Drawings Generator inspecton report S E

ement level

Visual/Mesur Water level,tape,dumpy

3.8 check that air gap is free of foreign matter Major 100% Tech specification/Drawings Tech specification/Drawings Generator inspecton report S E

ement level

Visual/Mesur Water level,tape,dumpy

3.9 check of radial clearance,air-gap baffles Major 100% Tech specification/Drawings Tech specification/Drawings Generator inspecton report S E

ement level

check radial clearancess between inner end Visual/Mesur Water level,tape,dumpy

4 Major 100% Tech specification/Drawings Tech specification/Drawings Generator inspecton report S E

shielding and fan ement level

insulation resistance test of end shielding(DE and Visual/Mesur Water level,tape,dumpy

4.1 Major 100% Tech specification/Drawings Tech specification/Drawings Generator inspecton report S E

NDE) ement level

insulation resistance test of intermideate ring and Visual/Mesur Water level,tape,dumpy

4.2 Major 100% Tech specification/Drawings Tech specification/Drawings Generator inspecton report S E

pipes ement level

Visual/Mesur Water level,tape,dumpy

4.3 insulation resistance test of gas guide ring Major 100% Tech specification/Drawings Tech specification/Drawings Generator inspecton report S E

ement level

check radial clearancess between gas guide rings Visual/Mesur Water level,tape,dumpy

4.4 Major 100% Tech specification/Drawings Tech specification/Drawings Generator inspecton report S E

and rotor shaft ement level

Tur 10 ALSTOM Confidential Page 19

insulation resistance test of oil baffle housing (H2 Visual/Mesur Water level,tape,dumpy

4.5 Major 100% Tech specification/Drawings Tech specification/Drawings Generator inspecton report S E

side) ement level

check radial clearancess between oil baffle Visual/Mesur Water level,tape,dumpy

4.6 Major 100% Tech specification/Drawings Tech specification/Drawings Generator inspecton report S E

housing and rotor shaft ement level

check radial clearancess between pre baffle ring Visual/Mesur Water level,tape,dumpy

4.7 Major 100% Tech specification/Drawings Tech specification/Drawings Generator inspecton report S E

and rotor shaft ement level

Visual/Mesur Water level,tape,dumpy

4.8 check position of shaft seal housing. Major 100% Tech specification/Drawings Tech specification/Drawings Generator inspecton report S E

ement level

insulation resistance test of shaft seal housing and Visual/Mesur Water level,tape,dumpy

4.9 Major 100% Tech specification/Drawings Tech specification/Drawings Generator inspecton report S E

pipes. ement level

Visual/Mesur Water level,tape,dumpy

5 check size of H2 Seal ring Major 100% Tech specification/Drawings Tech specification/Drawings Generator inspecton report S E

ement level

Visual/Mesur Water level,tape,dumpy

5.1 check clearancess of seal ring. Major 100% Tech specification/Drawings Tech specification/Drawings Generator inspecton report S E

ement level

Visual/Mesur Water level,tape,dumpy

5.2 check radial clearancess of baffle rings Major 100% Tech specification/Drawings Tech specification/Drawings Generator inspecton report S E

ement level

insulation resistance test of oil baffle housing (air Visual/Mesur Water level,tape,dumpy