Professional Documents

Culture Documents

Diamond Engineering (Chennai) PVT LTD.,: Welder Qualification Test Record

Uploaded by

mangalraj900Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Diamond Engineering (Chennai) PVT LTD.,: Welder Qualification Test Record

Uploaded by

mangalraj900Copyright:

Available Formats

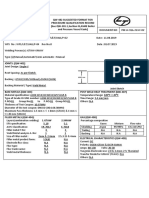

DIAMOND ENGINEERING (CHENNAI) PVT LTD.

,

Chennai - 600119

WELDER QUALIFICATION TEST RECORD

As per ASME SEC IX

Welder's Name : B. Selvakumar Identification No : W421

Test Description

Identification of WPS followed : DE/WPS/CP/10 Rev 0 Dt: 27-01-2011 √ Test Coupon Production weld

Specification of base metal(s) : SA 516 Gr.70 + SA 516 Gr.70 Thickness : 16mm

Testing Condition and Qualification Limits

Welding Variables (QW-350) Actual Values Range Qualified

Welding Process(es) GTAW + FCAW GTAW + FCAW

Type (ie; manual, semi-automatic) used Semi-Automatic Semi-Automatic

Backing (metal, weld metal, double-welded, etc.) Weld Metal Weld Metal

√ Plate Pipe (enter diameter if pipe or tube) Plate Plate

Base metal P- or S- Number to P- or S- Number - -

Filler metal or electrode specification(s) (SFA) (info. only) SFA5.18 + SFA 5.20 SFA5.18 + SFA 5.20

Filler metal or electrode classification(s) (info. only) ER 70S-3 + E71T-1C ER 70S-3 + E71T-1C

Filler metal F-Number(s) 6 6

Consumable insert (GTAW or PAW) NA NA

Filler type (solid/metal or flux cored/powder) (GTAW or PAW) Solid + Tubular Solid + Tubular

Deposited thickness 16mm 5mm to 32mm

Position Qualified (2G, 6G, 3F, etc.) 2G F&H

Vertical progression (Uphill or downhill) NA NA

Type of fuel gas (OFW) NA NA

Inert gas backing (GTAW, PAW, GMAW) CO2 CO2

Transfer mode (spray/globular or pulse to short circuit-GMAW) Globular Globular

GTAW current type/polarity (AC, DCEP, DCEN) DCEP DCEP

RESULTS

Visual examination of completed weld (QW-302.4) : Satisfactory

Bend test : NA

Transverse root and face [QW-462.3(a)] : NA

Longitudinal root and face [QW-432.3(b)] : NA

Side (QW-432.2) : NA

Pipe bend specimen, corrosion-resistant overlay [QW-462.5(C)] : NA

Plate bend specimen, corrosion-resistant overlay [QW-462.5(d)] : NA

Macro test for fusion [QW-462.5(b)] : NA

Macro test for fusion [QW-462.5(e)] : NA

Type Result Type Result

- - - -

- - - -

Alternative radiographic examination results (QW-191) : NA

Fillet weld -fracture test (QW-180) : NA Length and percentage of defects : NA

Macro examination (QW-184) : NA Fillet size : NA Concavity/Convexity : NA

Other test : RT Report No: MIS/2036 Date : 15.01.2011

Film or specimens evaluated by : M/s Diamond Engineering (Chennai) Pvt Ltd.,

Mechanical tests conducted by : NA

Welding supervised by : D. Ramesh, Engineer-Welding (DECPL).

We certify that the statements in this record are correct and that the test coupons were prepared, welded and tested in accordance with the

requirements of Section IX of the ASME BOILER AND PRESSURE VESSEL CODE.

Organization : M/s Diamond Engineering (Chennai) Pvt Ltd.,

Date : By :

You might also like

- SampleDocument5 pagesSample이훈No ratings yet

- Materials Data for Cyclic Loading: Low-Alloy SteelsFrom EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsRating: 5 out of 5 stars5/5 (2)

- WPQ Sunil Yadav W-13 PQR 003 Smaw - PipeDocument1 pageWPQ Sunil Yadav W-13 PQR 003 Smaw - Pipeharshileng3992100% (1)

- Welder Certificate Akilesh YadavDocument1 pageWelder Certificate Akilesh Yadavtripatipankaj023No ratings yet

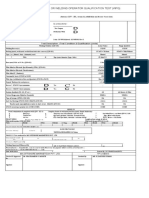

- WPQ Format - SMAWDocument3 pagesWPQ Format - SMAWBalkishan DyavanapellyNo ratings yet

- WPQ ASME IXDocument1 pageWPQ ASME IXEDEN GONZALEZNo ratings yet

- Slamet WPQRDocument1 pageSlamet WPQRChandra Bintang W.PNo ratings yet

- WPQ Formats NEWDocument4 pagesWPQ Formats NEWMANABENDRA MAITRANo ratings yet

- Abdul Muhid WPQRDocument1 pageAbdul Muhid WPQRChandra Bintang W.PNo ratings yet

- Welder Test Certificate - CSDocument1 pageWelder Test Certificate - CSPrathamesh Omtech100% (4)

- WELDER QUALIFICATION REPORTDocument2 pagesWELDER QUALIFICATION REPORTAkash Singh TomarNo ratings yet

- Calificación Termotecnica CoindustrialDocument1 pageCalificación Termotecnica CoindustrialTato VargasNo ratings yet

- Wip Site, Igcar, Kalpakkam: Vacuum Techniques PVT LTD BanagloreDocument3 pagesWip Site, Igcar, Kalpakkam: Vacuum Techniques PVT LTD BanagloreVijayabaraniNo ratings yet

- WPQ 006Document1 pageWPQ 006vinuNo ratings yet

- SEW Welder Performance QualificationsDocument18 pagesSEW Welder Performance QualificationsmahendraNo ratings yet

- 385 2 Internal Gtaw+SmawDocument2 pages385 2 Internal Gtaw+Smawsubash1688No ratings yet

- WPQ 양식 김정균 (DSHI Rev.0)Document5 pagesWPQ 양식 김정균 (DSHI Rev.0)이훈No ratings yet

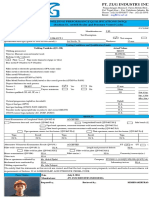

- PT. ZUG INDUSTRY WELDING QUALIFICATION DOCUMENTDocument4 pagesPT. ZUG INDUSTRY WELDING QUALIFICATION DOCUMENTMuhammad Fitransyah Syamsuar PutraNo ratings yet

- WPQ Certificates Klis14Document8 pagesWPQ Certificates Klis14AdhicharanNo ratings yet

- WPQ FormatDocument8 pagesWPQ FormatsanjaykumarmauryaNo ratings yet

- Welder Performance Qualification (WPQ) According To ASME IX Hassan HussienDocument1 pageWelder Performance Qualification (WPQ) According To ASME IX Hassan HussienMahmoud shawkyNo ratings yet

- 171 Gtaw&Smaw Zug Asme (Ade S 5g) WPQDocument4 pages171 Gtaw&Smaw Zug Asme (Ade S 5g) WPQMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Gtaw - Inox - 6g Julio Arriagada Gallegos Constructora Laja Mayo 2023Document1 pageGtaw - Inox - 6g Julio Arriagada Gallegos Constructora Laja Mayo 2023elevacerchileNo ratings yet

- Qw-484A Suggested Format A For Welder Performance Qualifications (WPQ) (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)Document1 pageQw-484A Suggested Format A For Welder Performance Qualifications (WPQ) (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)ventas ventasNo ratings yet

- PT. VISTA BANGUN UTAMA Welder QualificationDocument1 pagePT. VISTA BANGUN UTAMA Welder QualificationHaryanto RNo ratings yet

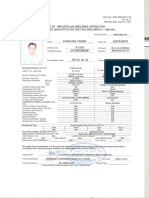

- Welder Qualification Test Certificate for Mohan ReddyDocument2 pagesWelder Qualification Test Certificate for Mohan Reddyvijay100% (1)

- PWPS WPS PQR WPQDocument21 pagesPWPS WPS PQR WPQcsolanki658688% (8)

- QW-301, Section IX, ASME Boiler and Pressure Vessel Code)Document1 pageQW-301, Section IX, ASME Boiler and Pressure Vessel Code)rajuNo ratings yet

- Welder CertificateDocument1 pageWelder CertificatePaul H TampubolonNo ratings yet

- WPQ WeldCanada PDFDocument1 pageWPQ WeldCanada PDFAhmad DanielNo ratings yet

- Gtaw WPQDocument3 pagesGtaw WPQMuhammadShabbirNo ratings yet

- WPQRDocument1 pageWPQRangelito bernalNo ratings yet

- PQR Procedure Qualification RecordsDocument6 pagesPQR Procedure Qualification RecordsDaniel CamposNo ratings yet

- Screenshot 2023-01-31 at 5.18.21 PMDocument9 pagesScreenshot 2023-01-31 at 5.18.21 PMisanNo ratings yet

- AMRITA ENGINEERING WORKS PQRDocument3 pagesAMRITA ENGINEERING WORKS PQRBalkishan DyavanapellyNo ratings yet

- Project: Welder Performace Qualification (WPQ) : Type (Ie Manual, Semi-Automatic) UsedDocument4 pagesProject: Welder Performace Qualification (WPQ) : Type (Ie Manual, Semi-Automatic) Usedalberto jayaNo ratings yet

- 174 Smaw Zug Asme (Asep Wahyudi 3g) WPQDocument4 pages174 Smaw Zug Asme (Asep Wahyudi 3g) WPQMuhammad Fitransyah Syamsuar PutraNo ratings yet

- 175 Smaw Zug Asme (Muhammad Wardi 3g) WPQDocument4 pages175 Smaw Zug Asme (Muhammad Wardi 3g) WPQMuhammad Fitransyah Syamsuar PutraNo ratings yet

- 181-Smaw-Zug-Asme (Rinovianda-3g) - WPQDocument4 pages181-Smaw-Zug-Asme (Rinovianda-3g) - WPQMuhammad Fitransyah Syamsuar Putra100% (2)

- PT. ZUG INDUSTRY WELDING QUALIFICATIONSDocument4 pagesPT. ZUG INDUSTRY WELDING QUALIFICATIONSMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Cert Piping W54.5Document2 pagesCert Piping W54.5SANU0% (1)

- Val Caraig WPQTDocument1 pageVal Caraig WPQTMark Jason M. BrualNo ratings yet

- Sujan Das WQTDocument2 pagesSujan Das WQTMD Shadikul Huq ShezanNo ratings yet

- MD - Akibur Sheikh WQTDocument2 pagesMD - Akibur Sheikh WQTMD Shadikul Huq ShezanNo ratings yet

- WQT Record for Pipeline Welder QualificationDocument99 pagesWQT Record for Pipeline Welder QualificationVivek Jadhav100% (1)

- PT Prakarsalanggeng Welder Qualification TestDocument24 pagesPT Prakarsalanggeng Welder Qualification Testmuhammad rizalNo ratings yet

- WPQ Ix - C - WPW 7.0.4 Form 2007 Rev. 0Document1 pageWPQ Ix - C - WPW 7.0.4 Form 2007 Rev. 0คุณพ่อน้อง บิ๊กบอส100% (1)

- PQR With-PwhtDocument2 pagesPQR With-PwhtKarthikNo ratings yet

- Fillet Inspection SheetDocument2 pagesFillet Inspection SheetShankey JAlanNo ratings yet

- Case Study - Welder WPQ - 2Document6 pagesCase Study - Welder WPQ - 2MOHAMED SALEH ABDALLAH ARAFATNo ratings yet

- WQT Form (ASME) 04-23Document1 pageWQT Form (ASME) 04-23hanz bermejoNo ratings yet

- Welder Performance Qualification (WPQ)Document1 pageWelder Performance Qualification (WPQ)JBStringerNo ratings yet

- Welding Procedure Specification (WPS) : Owner: (As Per QW 482 of ASME Section IX)Document2 pagesWelding Procedure Specification (WPS) : Owner: (As Per QW 482 of ASME Section IX)Saravanan Palanisamy Lakshmi100% (1)

- CALTECH ENGINEERING PQR PROCEDUREDocument8 pagesCALTECH ENGINEERING PQR PROCEDURESrikant GanjiNo ratings yet

- WPQ Flux CoreDocument1 pageWPQ Flux Corealberto jayaNo ratings yet

- WPQ 2Document1 pageWPQ 2FirozNo ratings yet

- Ocrte-9f2ol WelderDocument1 pageOcrte-9f2ol WelderSAHAJ DIGITAL ZONENo ratings yet

- Preliminary WPS for 12.7mm SMAW WeldingDocument3 pagesPreliminary WPS for 12.7mm SMAW WeldingAnonymous 4e7GNjzGW100% (1)

- Toaz - Info Welding Procedure Specification Format PRDocument3 pagesToaz - Info Welding Procedure Specification Format PRKarim ZahranNo ratings yet

- Welding Failure Causes and PreventionDocument5 pagesWelding Failure Causes and Preventionmangalraj900No ratings yet

- Angel SuggestedDocument4 pagesAngel Suggestedmangalraj900No ratings yet

- Procedure For Welder ApprovalDocument1 pageProcedure For Welder Approvalmangalraj900No ratings yet

- TRading StrategyDocument4 pagesTRading Strategymangalraj900No ratings yet

- Diamond Engineering (Chennai) PVT LTD.,: Data Sheet For PQR Parameter DetailsDocument8 pagesDiamond Engineering (Chennai) PVT LTD.,: Data Sheet For PQR Parameter Detailsmangalraj900No ratings yet

- Corrosion ChemistryDocument7 pagesCorrosion ChemistryaamirsaddiqNo ratings yet

- Welding Quality Control Plan (WQCP) Requirements: OrganizationDocument2 pagesWelding Quality Control Plan (WQCP) Requirements: Organizationmangalraj900No ratings yet

- VEEYES FOUNDRY PRIVATE LIMITED WELDING TEMPERATURE CHARTDocument1 pageVEEYES FOUNDRY PRIVATE LIMITED WELDING TEMPERATURE CHARTmangalraj900No ratings yet

- 6a RootDocument1 page6a Rootmangalraj900No ratings yet

- Bharathiyar Kavithai - 1Document64 pagesBharathiyar Kavithai - 1sakinovelsNo ratings yet

- Product Presentation PDFDocument56 pagesProduct Presentation PDFmangalraj900No ratings yet

- Open Vision OVDX Intro JakeDocument18 pagesOpen Vision OVDX Intro Jakemangalraj900No ratings yet

- New Doc 2020-01-06Document5 pagesNew Doc 2020-01-06mangalraj900No ratings yet

- Bgas Question PDFDocument243 pagesBgas Question PDFmangalraj900No ratings yet

- Alternate FuelsDocument28 pagesAlternate Fuelsmangalraj900No ratings yet

- Alternate FuelsDocument28 pagesAlternate Fuelsmangalraj900No ratings yet

- Guide Notes: Inspection PersonnelDocument48 pagesGuide Notes: Inspection Personnelaneeshta100% (10)

- Visual Inspection I y IIDocument68 pagesVisual Inspection I y IISantos Junnior Hipolito SandovalNo ratings yet

- RI CW BDocument5 pagesRI CW Bmangalraj900No ratings yet

- Set 2Document4 pagesSet 2mangalraj900No ratings yet

- Radiographic Reports for WeldsDocument4 pagesRadiographic Reports for Weldsmangalraj900No ratings yet

- RTDocument6 pagesRTmangalraj900No ratings yet

- CSWIP Welding Inspection Notes and QuestionsDocument133 pagesCSWIP Welding Inspection Notes and Questionslram70100% (20)

- Set 1Document5 pagesSet 1mangalraj900No ratings yet

- A New Detection Sensor For Wire Rope Based On Open Magnetization MethodDocument9 pagesA New Detection Sensor For Wire Rope Based On Open Magnetization Methodmangalraj900No ratings yet

- Schedule ChartDocument1 pageSchedule Chartmangalraj900No ratings yet

- Electro Magnetic TestingDocument10 pagesElectro Magnetic Testingmangalraj900No ratings yet

- Slofec™: Fast Corrosion Screening TechniqueDocument10 pagesSlofec™: Fast Corrosion Screening TechniqueshervinyNo ratings yet

- Finite Element Method Characterization of 3D Magnetic Flux Leakage Signal of Crack Discontinuities at Multiple Liftoff ValuesDocument8 pagesFinite Element Method Characterization of 3D Magnetic Flux Leakage Signal of Crack Discontinuities at Multiple Liftoff Valuesmangalraj900No ratings yet

- 32C240 241Document34 pages32C240 241Priya TaylorNo ratings yet

- Cycle of Copper Reactions LabDocument6 pagesCycle of Copper Reactions LabbigfoottedNo ratings yet

- Calculating masonry costs for a residential structureDocument7 pagesCalculating masonry costs for a residential structureSean Franz VilardoNo ratings yet

- Calculatio SheetDocument88 pagesCalculatio SheetLe LeNo ratings yet

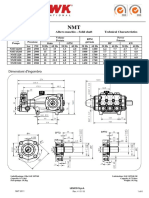

- NMT pump technical specificationsDocument6 pagesNMT pump technical specificationsazkNo ratings yet

- HMK300E Brochure English 4 PDFDocument8 pagesHMK300E Brochure English 4 PDFJo2020MeNo ratings yet

- Linux Interview QuestionsDocument4 pagesLinux Interview QuestionsPaaventhan DharmarajanNo ratings yet

- 2G 3G Interview QuestionsDocument10 pages2G 3G Interview Questionsmohnish1999No ratings yet

- JET 1 Treating EquipmentDocument60 pagesJET 1 Treating Equipmentmasterab100% (3)

- A03 02 05 07Document3 pagesA03 02 05 07Oscar ItzolNo ratings yet

- Yogesh Kumar Garg Resume Mechanical EngineerDocument3 pagesYogesh Kumar Garg Resume Mechanical EngineerYogeshGargNo ratings yet

- Husqvarna R322 Owners ManualDocument40 pagesHusqvarna R322 Owners Manualsheba1023No ratings yet

- GID-253-CV-GTPP-SITE-016, Rev - 1 Ironite IPS FlooringDocument6 pagesGID-253-CV-GTPP-SITE-016, Rev - 1 Ironite IPS FlooringAkash SharmaNo ratings yet

- W101 V2 Ebook 0831Document37 pagesW101 V2 Ebook 0831papagajkoNo ratings yet

- Print: 2Zr-Fe Engine Control Sfi System System DiagramDocument10 pagesPrint: 2Zr-Fe Engine Control Sfi System System DiagramAlfredo MedinaNo ratings yet

- Accomplishment of SB 72-1074Document7 pagesAccomplishment of SB 72-1074aliNo ratings yet

- An Automatic Tool For Generating Test Cases From The System's RequirementsDocument6 pagesAn Automatic Tool For Generating Test Cases From The System's RequirementsSaba Vijay KumarNo ratings yet

- Chemistry PSPM 1 2008/2009Document3 pagesChemistry PSPM 1 2008/2009Viknish Arumugam50% (2)

- GIS Mapping Powers Electricity Planning in BasraDocument25 pagesGIS Mapping Powers Electricity Planning in BasraYaser Al-SolimiNo ratings yet

- Carestation 650 Brochure PDFDocument12 pagesCarestation 650 Brochure PDFzulfiah100% (1)

- 400 Bad Request 400 Bad Request Nginx/1.2.9Document8 pages400 Bad Request 400 Bad Request Nginx/1.2.9bahramhooNo ratings yet

- Directional Drilling Short Answer Questions 2016Document7 pagesDirectional Drilling Short Answer Questions 2016AKSHAY SHEKHAWAT0% (2)

- Goat Milking Stand Plans PDFDocument6 pagesGoat Milking Stand Plans PDFcowboyNo ratings yet

- Pneumatic Can Crusher SystemDocument21 pagesPneumatic Can Crusher Systemkamleshm2No ratings yet

- Intelliheat Manual enDocument21 pagesIntelliheat Manual enĐiềnNo ratings yet

- Fanuc CodeDocument11 pagesFanuc CoderlwersalNo ratings yet

- DL650K9Document187 pagesDL650K9Juan Abraham AjpopNo ratings yet

- 48 Earthquake Safe Construction of Masonry BuildingDocument4 pages48 Earthquake Safe Construction of Masonry Buildingpramod_kNo ratings yet

- Galaxy Y S5360 Android 2.3.6 Gingerbread Official FirmwareDocument23 pagesGalaxy Y S5360 Android 2.3.6 Gingerbread Official Firmwarekharishkhan0% (1)

- HX2-100 2V AGM battery specsDocument2 pagesHX2-100 2V AGM battery specsdarwin gualotoNo ratings yet